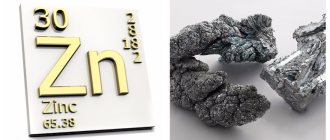

Zinc as a simple substance

What is zinc in its usual form?

This is a silver-blue metal that quickly becomes covered with a protective oxide film in air. This makes it seem like it's not very shiny. However, once the film is removed, zinc exhibits the properties of all metals - a beautiful characteristic shine and radiance. It is found in nature in many minerals and ores. So, the most common of them are:

- zinc blende, or sphalerite;

- cleiophanes;

- marmatite;

- wurtzite;

- Smithsonite;

- calamine;

- zincite;

- willemite;

- Franklenite and others.

In mixed ores, Zinc is usually found together with its constant companions, such as:

- Thallium;

- Germanium;

- Indium;

- Gallium;

- Cadmium.

In total, this metal accounts for 0.076% of the earth's crust. This is slightly more than copper. Also 0.07 mg/l of this substance is found in sea water.

The formula of zinc as a simple substance is Zn. The crystal lattice is hexagonal, dense. The type of chemical bond is metallic.

Element Zinc: characteristics

This element is located in the periodic table in the second group, a secondary subgroup. Serial number 30, mass of Zinc – 65.37. The only and constant oxidation state is +2. Electronic configuration of the outer layer of the atom 4s2.

In the table, Zinc, Copper, Cadmium, Chromium, Manganese and many others are transition metals. These include all those whose electrons fill the outer and pre-external d and f energy sublevels.

Transition metals include the platinum group (Gold, Iridium, Palladium, Platinum, Osmium and others). All of them are characterized by the formation of complex compounds in which they act as a complexing agent with different coordination numbers. All this is typical for the element we are considering.

There are 5 naturally stable isotopes with mass numbers from 64 to 70. 65Zn is radioactive, with a half-life of 244 days.

A Brief History of the Element's Discovery

People knew what zinc was even before our era. After all, it was then that they learned to use alloys containing this metal. The Egyptians used ores containing copper and zinc, smelted them and obtained a very strong, oxidation-resistant material. Household items and dishes made from this material were found.

The name zinc appears in the writings of the physician Paracelsus in the 16th century AD. During the same period, the Chinese began to actively use the metal, casting coins from it. Gradually, knowledge about this substance and its good technical properties is spreading to Europe. Then in Germany and England they also learned what zinc is and where it can be used.

Brass was one of the first and most famous alloys, used since ancient times in Cyprus and later in Germany and other countries.

The name comes from the Latin zincum, but the etymology is not entirely clear. There are several versions.

- From the German zinke, which translates as “edge.”

- From the Latin zincum, meaning “white coating.”

- Persian “cheng”, that is, stone.

- Old German zinco, which translates as “plaque”, “eyesore”.

The element received its current name only at the beginning of the 20th century. The importance of zinc ions in the human body also became known only relatively recently (20th century). Before this, no ailments were associated with this element.

However, it is known that already in ancient times, many peoples used soups made from young lamb meat as a means of recovery from illness and for a speedy recovery. Today we can say that the effect was achieved due to zinc ions, which this dish contains quite a lot. It helped restore blood circulation, relieve fatigue and activated brain activity.

Chemical properties

Under normal conditions, the surface of a piece of metal is instantly covered with a dull gray-white coating - zinc oxide. This occurs because oxygen in the air instantly oxidizes the pure substance.

If pure metal is stored in open, humid air for a long time, it will be destroyed by carbon dioxide. How does the simple substance zinc react with:

- halogens;

- chalcogens;

- oxygen;

- acids;

- alkalis;

- ammonia and ammonium (its salts);

- weaker metals.

Does not react with nitrogen. If we take chemically absolutely pure zinc, then it does not react with any of the listed substances.

It is obvious that zinc is an amphoteric metal. When reacting with alkalis, it forms complex compounds - hydroxinates.

Physical properties

Several characteristics can be identified.

- Color – silver blue.

- Density – 7.13 g/cm3.

- Melting point – 420 °C (belongs to the group of low-melting metals).

- Under normal conditions it is a fragile substance.

- Boiling point – 906 oC.

- When heated to 100-150 °C, malleability and ductility increase, making wire and rolling into foil is possible.

- Above 200 °C it is easily ground into gray powder, losing its plasticity.

- He is an excellent guide.

- Thermal conductivity is good, as is the heat capacity.

Such physical parameters allow the metal to be used in connections with other elements. For example, a widely known zinc alloy is brass.

Biological role

What is zinc from a medical and biological point of view? Does it matter for the life of organisms and how great is it? It turns out that zinc ions simply must be present in living beings. Otherwise, the deficit will lead to the following consequences:

- anemia;

- decreased insulin;

- allergies;

- weight loss and memory;

- fatigue;

- depression;

- blurred vision;

- irritability and others.

The main places of concentration of zinc ions in the human body are the pancreas, liver and muscles. It is also this metal that is part of most enzymes (for example, carbonic anhydrase). Therefore, most catalytic reactions occur with the participation of zinc.

What exactly do ions do?

- Participate in the synthesis of male hormones and seminal fluid.

- Promotes the absorption of vitamin E.

- Participate in the breakdown of alcohol molecules in the body.

- They are direct participants in the synthesis of many hormones (insulin, growth hormone, testosterone and others).

- Takes part in hematopoiesis and healing of damaged tissues.

- Regulates the secretion of the sebaceous glands, maintains normal hair and nail growth, and promotes regeneration processes in the skin.

- It has the ability to eliminate toxins from the body and strengthen the immune system.

- Affects the formation of taste sensations, as well as the sense of smell.

- Takes part in transcription processes, vitamin A metabolism, nucleic synthesis and decay.

- It is a participant in all stages of cell growth and development, and also accompanies the process of gene expression.

All this once again proves how important this metal is. Its role in biological systems was clarified only in the 20th century. Many troubles and illnesses in the past could have been avoided if people had known about treatment with zinc-based drugs.

How can you maintain the required amount of this element in the body? The answer is obvious. It is necessary to consume foods containing zinc. The list can be long, so we will indicate only those with the maximum number of the element in question:

- nuts and seeds;

- legumes;

- meat;

- seafood, especially oysters;

- cereals and bread;

- milk products;

- greens, vegetables and fruits.

Historical reference

Zinc is as old as the earth's crust and has been used by humans since ancient times. The Romans were probably the first to use the raw material for copper coins from a mixture of copper and zinc ore under Emperor Augustus (20 BC to 14 AD). In 1374, the Indians recognized zinc as a “new” metal. Ancient Hindu scriptures from this period first describe processes for producing zinc metal from ore.

In the late 13th century, Marco Polo described the production of zinc oxide in Persia, where it was used to treat inflammation of the eyes. In the early 17th century, European scientists such as Albertus Magnus, George Agricola and Paracelsus confirmed the importance of the new metal for humans. In 1743 William Champion built the first zinc works in Bristol with an annual capacity of about 200 tons. The first zinc rolling mill was built in Belgium in 1805.

Despite its long history, zinc today finds application in new areas: in high-tech products, in the telecommunications field and in the aerospace industry. Since zinc ore is widely distributed geographically throughout the world, zinc can rightfully be considered the “raw material of the future.”

Zinc hydroxide, characteristics, properties and preparation, chemical reactions.

Zinc hydroxide is an inorganic substance with the chemical formula Zn(OH)2.

Description

Under standard conditions, zinc hydroxide appears as colorless crystals and is an amorphous substance. Currently, 5 polymorphic modifications are known, of which only the modification with orthorhombic system is stable. Zinc hydroxide is practically insoluble in water and exhibits amphoteric properties (with a predominance of basic ones).

Receipt

- Interaction of soluble zinc salts with alkalis:

Physical properties of zinc hydroxide

| Parameter name: | Meaning: |

| Chemical formula | Zn(OH)2 |

| Synonyms and names in a foreign language | zinc hydroxide |

| Type of substance | inorganic |

| Appearance | colorless trigonal crystals |

| Color | white, colorless |

| Taste | —* |

| Smell | — |

| Physical state (at 20 °C and atmospheric pressure 1 atm.) | solid |

| Density (state of matter – solid, at 20 °C), kg/m3 | 3053 |

| Density (state of matter – solid, at 20 °C), g/cm3 | 3,053 |

| Decomposition temperature, °C | 125 |

| Molar mass, g/mol | 99,38474 |

| Solubility in water, g/100 ml | 0,000199 |

*Note:

- no data.

Physical properties

| Molar mass | 99.424 g/mol |

| Melting point, melting point | decomposes |

| Density, ρ | 3.05 g/cm3 |

| Solubility in water, Ks | 0.000042 g/100 g [20°C] |

Chemical properties of zinc hydroxide. Chemical reactions of zinc hydroxide

Zinc hydroxide is an amphoteric base, i.e. it has both basic and acidic properties.

Zinc hydroxide is a weak insoluble base.

The chemical properties of zinc hydroxide are similar to those of hydroxides of other amphoteric metals. Therefore, it is characterized by the following chemical reactions:

1. reaction of zinc hydroxide and sodium hydroxide:

Zn(OH)2 + 2NaOH → Na2[Zn(OH)4].

As a result of the reaction, sodium tetrahydroxozincate is formed. The reaction uses a concentrated solution of sodium hydroxide.

2. reaction of zinc hydroxide and potassium hydroxide:

Zn(OH)2 + 2KOH → K2[Zn(OH)4].

As a result of the reaction, sodium tetrahydroxozincate is formed.

3. reaction of zinc hydroxide and phosphoric acid:

3Zn(OH)2 + 2H3PO4 → Zn3(PO4)2 + 6H2O.

As a result of the reaction, zinc orthophosphate and water are formed.

4. reaction of zinc hydroxide and nitric acid:

Zn(OH)2 + 2HNO3 → Zn(NO3)2 + 2H2O.

As a result of the reaction, zinc nitrate and water are formed.

The reactions of zinc hydroxide with other acids proceed similarly.

5. reaction of zinc hydroxide and hydrogen iodide:

Zn(OH)2 + 2HI → ZnI2 + 2H2O.

As a result of the reaction, zinc iodide and water are formed.

6. reaction of zinc hydroxide and carbon monoxide:

2Zn(OH)2 + CO2 → Zn2(OH)2CO3 + H2O.

As a result of the reaction, zinc dihydroxide carbonate and water are formed. During the reaction, zinc hydroxide is used in the form of a suspension.

7. thermal decomposition reaction of zinc hydroxide:

Zn(OH)2 → ZnO + H2O (t = 100-250 °C).

As a result of the reaction, zinc oxide and water are formed.

Health Hazard

When heated or burned, it decomposes to form toxic gases: nitrogen oxides and zinc oxides. The substance is irritating to the eyes, skin and respiratory tract.

Inhaling dust can cause irritation to the nose and throat. Ingestion may cause irritation and corrosion of the digestive tract. In case of contact with eyes, it causes irritation to the cornea. Contact with skin causes irritation.

Respiratory system

Quantitative information on the systemic toxicity of zinc compounds is not available at this time. Elevated concentrations of zinc in the blood and urine of people exposed to smoke containing zinc oxide may indicate pulmonary absorption of hazardous substances, but more detailed studies are not available. In most of the reported cases, elevated serum zinc concentrations were not detected, even though significant toxic effects occurred.

Animal experiments show that inhaled zinc compounds can be absorbed anywhere in the respiratory tract. The degree of absorption probably depends on the clearance mechanisms in the relevant sections (nasopharynx, tracheobronchial region: trachea, bronchi or alveolar region). One study suggests that about 5-18% of soluble zinc compounds (including zinc nitrate ) are absorbed in the nasopharynx, and about 13-50% in the tracheobronchial and alveolar regions.

It can be assumed that zinc is not absorbed in the respiratory tract due to its good solubility in water and the high degree of binding of zinc ions to proteins.

Leather

In vitro studies on human skin showed that zinc sulfate , which is readily soluble in water, absorbed less than 3% of the administered dose within 24 hours. The maximum superficial flow rate was 0.6 μg/sq.cm. Increased absorption was observed for damaged skin (blistering due to burns). Nitrate dust can dissolve in sweat and thus promote increased dermal absorption.

Gastrointestinal tract

In humans, depending on individual characteristics, the absorption of zinc ions from the digestive tract ranges from 8 to 80%. In people with high zinc stores, absorption is 20-30%. Absorption of zinc occurs throughout the small intestine through both passive diffusion and active transport mechanisms.

Reactions in which Zinc Hydroxide is involved

- Zn(OH)2 + 2NaOH -> Na2[Zn(OH)4]

- Na2[Zn(OH)4] -> Zn(OH)2″|v” + 2NaOH

- Na2[Zn(OH)4] + 2HCl -> 2NaCl + Zn(OH)2″|v” + 2H2O

- Na2[Zn(OH)4] + CO2 -> Na2CO3 + Zn(OH)2″|v” + H2O

- {M}(OH)2 + H2{X} = {M}{X} + 2H2O, where M =

Mg Ca Ba Sr Cu Zn>;>X = SO4 SO3 CO3

Sources

- https://FB.ru/article/181833/chto-takoe-tsink-formula-soedineniya-tsinka-primenenie-tsinka

- https://xn--80aaafltebbc3auk2aepkhr3ewjpa.xn--p1ai/gidroksid-tsinka-harakteristika-svoystva-i-poluchenie-himicheskie-reaktsii/

- https://dic.academic.ru/dic.nsf/ruwiki/869017

- https://ru.wikipedia.org/wiki/%D0%93%D0%B8%D0%B4%D1%80%D0%BE%D0%BA%D1%81%D0%B8%D0%B4_%D1 %86%D0%B8%D0%BD%D0%BA%D0%B0

- https://allbreakingnews.ru/gidroksid-cinka-xarakteristika-svojstva-i-poluchenie-ximicheskie-reakcii/

- https://chemiday.com/ru/encyclopedia/znoh2

- https://charchem.org/ru/subst-ref/?id=2564

Properties of zinc alloys

Of course, all compositions with this metal differ from each other in its percentage content. In general, zinc alloys have good casting and mechanical properties. The first and most important thing is corrosion resistance. It manifests itself most of all in an atmosphere of dry, clean air. Possible manifestations of corrosion can be seen in industrial cities. This is due to the presence of vapors of hydrochloric acid, chlorine and sulfur oxides in the air, which, condensing with moisture, make it difficult to form a protective film. Copper-tin-zinc is an alloy characterized by high protective properties. It is this composition that is least susceptible to corrosion, especially in an industrial atmosphere. If we talk about the casting properties of zinc, then, of course, they depend on the alloying elements in its alloys.

For example, aluminum makes their structure homogeneous, fine-grained, refines it, and reduces the negative influence of iron. Another important alloying element is copper. It increases strength characteristics and reduces intercrystalline corrosion. The copper-zinc alloy has high impact strength, but at the same time partially loses its casting properties.

Which oxides react with water?

Of all the oxides, only the following react with water:

1) all active basic oxides (oxides of alkali metal and alkali metal);

2) all acid oxides, except silicon dioxide (SiO2);

those. From the above it follows that they definitely do not react with water:

1) all low-active basic oxides;

2) all amphoteric oxides;

3) non-salt-forming oxides (NO, N2O, CO, SiO).

Note:

Magnesium oxide reacts slowly with water when boiled. Without strong heating, the reaction of MgO with H2O does not occur.

The ability to determine which oxides can react with water even without the ability to write the corresponding reaction equations already allows you to get points for some questions in the test part of the Unified State Exam.

Now let's figure out how certain oxides react with water, i.e. Let's learn to write the corresponding reaction equations.

Active basic oxides react with water to form their corresponding hydroxides. Recall that the corresponding metal oxide is a hydroxide that contains the metal in the same oxidation state as the oxide. For example, when the active basic oxides K+12O and Ba+2O react with water, their corresponding hydroxides K+1OH and Ba+2(OH)2 are formed:

K2O + H2O = 2KOH – potassium hydroxide

BaO + H2O = Ba(OH)2 – barium hydroxide

All hydroxides corresponding to active basic oxides (alkaline metal and alkali metal oxides) belong to alkalis. Alkalis are all metal hydroxides that are highly soluble in water, as well as the slightly soluble calcium hydroxide Ca(OH)2 (as an exception).

The interaction of acidic oxides with water, as well as the reaction of active basic oxides with water, leads to the formation of the corresponding hydroxides. Only in the case of acidic oxides do they correspond not to basic ones, but to acidic hydroxides, more often called oxygen-containing acids. Let us recall that the corresponding acidic oxide is an oxygen-containing acid that contains an acid-forming element in the same oxidation state as in the oxide.

Thus, if we, for example, want to write down the equation for the interaction of the acidic oxide SO3 with water, first of all we must remember the basic sulfur-containing acids studied in the school curriculum. These are hydrogen sulfide H2S, sulfurous H2SO3 and sulfuric H2SO4 acids. Hydrogen sulfide acid H2S, as can be easily seen, does not contain oxygen, so its formation during the interaction of SO3 with water can be immediately excluded. Of the acids H2SO3 and H2SO4, only sulfuric acid H2SO4 contains sulfur in the oxidation state +6, as in SO3 oxide. Therefore, it is precisely this that will be formed in the reaction of SO3 with water:

H2O + SO3 = H2SO4

Similarly, the oxide N2O5, containing nitrogen in the oxidation state +5, reacting with water, forms nitric acid HNO3, but in no case nitrous HNO2, since in nitric acid the oxidation state of nitrogen, as in N2O5, is +5, and in nitrous — +3:

N+52O5 + H2O = 2HN+5O3

Exception:

Nitrogen (IV) oxide (NO2) is a non-metal oxide in the +4 oxidation state, i.e. in accordance with the algorithm described in the table at the very beginning of this chapter, it should be classified as acidic oxides. However, there is no acid that contains nitrogen in the +4 oxidation state.

In the case of NO2 oxide, it is generally accepted that two acids correspond to it at once, since its interaction with water leads to the simultaneous formation of two acids:

2NO2 + H2O = HNO2 + HNO3

Biocomplexes

Carbonic anhydrase: showing hydroxide group (red) attached to zinc (gray) Zinc fingers.

The zinc ion (green) is coordinated by two histidine residues and two cysteine residues. A very large number of metalloenzymes contain zinc (II). Also, many proteins contain zinc for structural reasons. The zinc ion is always four-coordinate with at least three ligands, which are amino acid side chains. In imidazole nitrogen, the histidine side chain is a common ligand. Below are typical examples of two types of zinc-protein complexes.

At the active resting site of carbonic anhydrase, the zinc ion is coordinated by three histidine residues. The fourth position is occupied by a water molecule, which, as in hydrolysis, is highly polarized (see above). When carbon dioxide enters the active site, a nucleophilic attack occurs on the oxygen atom, which carries a partial negative charge or a full negative charge if the water molecule is dissociated. Cooperation2 quickly converts to bicarbonate ion.[23]

[(-hys)3Zn (H2O)]2+ + CO2 → [(-hys)3Zn]2+ + HCO3− + H+

Some peptidases, such as glutamate carboxypeptidase II, are thought to act in a similar way: the zinc ion promotes the formation of a nucleophilic reagent.[23]

The zinc finger motif is a rigid substructure in a protein that facilitates the binding of the protein to another molecule, such as DNA.[24] In this case, all four coordination positions are occupied by histidine and cysteine residues. The tetrahedral geometry around the zinc ion constrains the α helix fragment and the antiparallel β sheet fragment into specific orientations relative to each other.

Magnesium ion, which has a higher concentration in biological fluids, cannot perform these functions because its complexes are much weaker than those of zinc.

Galvanizing methods

Metallurgical plants are distinguished not only by their equipment, but also by the production methods used. It depends on the pricing policy, and location (natural resources used for the metallurgical industry). There are several galvanizing methods, which are discussed below.

Hot galvanizing method

This method involves dipping a metal part in a liquid solution. It happens like this:

- The part or product is degreased, cleaned, washed and dried.

- Next, the zinc is melted to a liquid state at temperatures up to 480 °C.

- The prepared product is lowered into the liquid solution. At the same time, it is well wetted in the solution and a coating up to 450 microns thick is formed. This is 100% protection against the effects of external factors on the product (moisture, direct sunlight, water with chemical impurities).

Hot galvanizing of metal structures

But this method has a number of disadvantages:

- The zinc film on the product results in an uneven layer.

- This method cannot be used for parts that meet exact standards according to GOST. Where every millimeter is considered a defect.

- After hot-dip galvanizing, not every part will remain strong and wear-resistant, since brittleness appears after passing through high temperatures.

This method is also not suitable for products coated with paints and varnishes.

Cold galvanizing

This method has 2 names: galvanic and electrolytic. The method of coating a product with corrosion protection is as follows:

- The metal part, the product is prepared (degreased, cleaned).

- After this, the “staining method” is carried out - a special composition is used, which has the main component - zinc.

- The part is coated with this composition by spraying.

Cold galvanizing

Thanks to this method, parts with precise tolerances and products coated with paints and varnishes are protected. Increases resistance to external factors leading to corrosion.

Disadvantages of this method: thin protective layer - up to 35 microns. This results in less protection and shorter protection periods.

Thermal diffusion method

This method makes a coating that is an electrode with positive polarity, while the metal of the product (steel) becomes negative polarity. An electrochemical protective layer appears.

The method is applicable only if the parts are made of carbon steel, cast iron, or steel with impurities. Zinc is used in the following ways:

- At temperatures from 290 °C to 450 °C in a powder medium, the surface of the part is saturated with Zn. Here, the marking of the steel, as well as the type of product, matter - the appropriate temperature is selected.

- The thickness of the protective layer reaches 110 microns.

- A product made of steel or cast iron is placed in a closed tank.

- A special mixture is added there.

- The last step is special treatment of the product to prevent the appearance of white efflorescence from salt water.

Thermal diffusion galvanizing

This method is mainly used when it is necessary to coat parts that have a complex shape: threads, small strokes. The formation of a uniform protective layer is important, since these parts undergo multiple exposures to external aggressive environments (constant moisture).

This method provides the highest percentage of product protection against corrosion.

Galvanized coating is wear-resistant and practically indelible, which is very important for parts that are rotated and disassembled from time to time

Production and use of pure metal

Many types of everyday household items are galvanized. For example:

- metal roofs of buildings,

- building gutters,

- water tanks, etc.

A fairly large proportion of zinc is used in the designs of disposable zinc-carbon non-rechargeable batteries. The brass manufacturing process also requires significant amounts of this substance.

A characteristic feature of zinc is the formation of a number of useful compounds:

- Sulfide (phosphor of old TV screens, oscilloscopes, fluorescent lamps and luminous paints);

- Sulfate (weed protectants, use in textile production);

- Oxide (used to make rubber, helps improve the properties of plastics, paints, inks, concrete, cosmetics).

Many well-known alloys are formed on the zinc component. For example, brass, dental amalgam, bronze and some types of solders. Galvanizing not only prevents water tanks from rusting. Almost all types of cough and cold medicines, vitamin tablets and supplements cannot do without this substance.

Common dietary supplement tablets (capsules) include calcium supplements for strong teeth and bones, vitamin C, omega-3 for the eyes, and zinc for a stronger immune system.

Zinc deficiency in the body is accompanied by various problems in relation to the health of the body and leads to the development of diseases. True, this problem is mainly typical for developing countries, where there are factors of malnutrition in the population and a lack of balanced healthy nutrition.

Galvanizing methods

Today, there are different technologies for applying zinc to the surface of products. It is necessary to consider each of them in detail.

Hot galvanizing method

The metal product is degreased, washed and etched in advance. Zinc is melted at a temperature of 450–480 °C. The part is lowered into the liquid metal. The operating principle of this method is based on the fact that iron and its alloys are well wetted. As a result, a coating of significant thickness from 40 to 450 microns is formed, due to which the product is reliably protected from corrosion. However, the hot method also has disadvantages. These include:

- uneven layer thickness;

- it is impossible to use the method for parts with precise tolerances, and in cases where the characteristics of the fastener change under the influence of high temperature.

There is also a possibility that after hot-dip galvanizing, the strength of the fastening will decrease, the so-called embrittlement. To avoid such a situation, the product must be thermally treated after applying zinc, but even this does not provide a complete guarantee. The method under consideration is not suitable for parts coated with paints or powder paints. The reason is the low adhesion between them and hot zinc.

Hot zinc surface treatment

Cold galvanizing method

This method has 2 more names: galvanic and electrolytic. In this case, the technology resembles the process of dyeing a product, but instead of paints, a special composition containing zinc is used. As a result, the part is coated with an anti-corrosion layer. Unlike the previous method, fasteners of any size and painted products can be cold galvanized. Using this method, increased chemical resistance is achieved. The weak points of the method include the small thickness of the layer - 5–35 microns, which leads to a decrease in anti-corrosion properties. The method under consideration, like the previous one, does not exclude the occurrence of embrittlement.

Thermal diffusion galvanizing method

The coating obtained using this method is a positive electrode, while the steel is negative. This is how electrochemical protection occurs. Thermal diffusion galvanizing can only be used for products whose materials are carbon steel, cast iron and low-impurity steel. The galvanizing process occurs as follows. The surface of the product is saturated with zinc, and the medium should be powder and the temperature should be 290–450 °C. The steel grade and product type affect the choice of temperature. In this way, you can achieve any thickness of the protective layer from 6 to 110 microns. With this method, a part is placed in a closed container and a special saturated mixture is added. Final treatment is required to ensure that white corrosion products do not form on the products when they come into contact with salt water and condensate.

The described technology is applicable to workpieces with threads and complex geometric shapes. As a result, a uniform layer is formed over the entire surface; zinc does not accumulate in recesses or joints. Thanks to this advantage, there is no need to remove the coating on the internal threaded part, as is necessary after hot-dip galvanizing. There is also no embrittlement, meaning this technology is suitable for high-strength fasteners. The level of anti-corrosion resistance is 1.5–2 times higher than with galvanic galvanizing, and 3–5 times higher than with the hot method. Also, this technology is characterized by high adhesion of the zinc layer to paints and high accuracy, so the scope of application also extends to structures with precise tolerances. The applied anti-corrosion layer is very wear-resistant and therefore suitable for parts that are frequently assembled and disassembled.