Forging is often used in modern manufacturing. Forging has been relevant for many years. It was also used for the manufacture of weapons, vehicles, household items and much more.

Today, forging is used somewhat less frequently, but in metal processing it is still a very important operation that cannot be avoided.

Forging is used to produce blanks for shafts and gears. It is widely used in everyday life, to obtain decorative elements of buildings and structures, fences, etc.

It should be noted that in addition to hot forging, cold forging has also become widespread. In the first method, the workpiece is constantly subjected to heating and impact processing, and in the second, a set of equipment is used that allows the production of almost the same parts as in hot forging.

Types of forging machines

The advantages of cold metal forging include the absence of the need to create a forge and install equipment and devices, without which it is simply impossible to work.

Cold forging of metal can be done automatically, and without any particular difficulties. This ensures increased efficiency in the production of products. Even manual production makes it possible to increase labor productivity, that is, to produce entire batches of parts according to the selected sample. There is always the possibility of organizing small-scale and mass production. This is beneficial when placing large orders, for example, in the manufacture of fences, window bars, etc.

To set up a cold forging workshop, you do not need to have large areas.

During cold forging, there is no change in the internal structure of the metal. The product retains high strength and characteristics. When cold forging metal, there is the possibility of artificial aging, which makes it possible to produce antique parts.

We can say that the use of cold forging technology allows us to produce inexpensive products with maximum quality.

With your own hands

It is possible to make manual forging machines with your own hands. Craftsmen most often produce a snail and a torsion bar. Producing the snail yourself will allow you to assemble a device with a conductor of the desired configuration and size.

To improve the performance of devices, it is advisable to supplement them with an electric drive. You can also make similar models of equipment yourself. Homemade electric mechanisms with manual and automatic modes have increased productivity.

Working surface of the snail before attaching the template

Universal equipment designed for bending workpieces of different sections: profile pipes (here about a machine for corrugated pipes), strips, round timber and squares, has a complex structure. Therefore, it is practically very difficult to assemble this equipment yourself.

Tools and devices are hand-held items, almost always made by hand.

Hot Forging Equipment

If we compare the cold and hot forging methods, we can say that the first method requires the worker to have greater skill, artistic skills and the ability to work with a set of necessary tools.

Forging of the material occurs after preheating in a forge furnace called a forge. The forge is equipped with equipment for forced air supply. Heating is carried out to a predetermined temperature, after which the product is transferred to the anvil. This is a metal plate where impact processing of a heated workpiece is carried out. It is performed using hammers and sledgehammers of different weights. One worker hits the desired place with a light hammer, and the second, with a heavy hammer or sledgehammer, delivers a strong blow to the designated place. After the workpiece has cooled, it is again loaded into the oven for heating. All movements of the part during its processing are performed using pliers with long handles.

In addition to the above-mentioned basic tools, hot forging uses many special tools that allow cutting hot metal and forming complex surfaces during hot forging.

Forge

Furnaces called forges are used to heat the workpieces. Its design includes several components:

- barrel made of fire-resistant material;

- hearth, with built-in grate;

- air supply and exhaust systems;

- working window where long workpieces are fed;

- a chimney through which combustion products are removed.

In addition, the forge also includes a quenching bath. The operation of a classic forge is based on the unique reducing ability of carbon. This ability successfully resists the oxidation of the workpiece, that is, its combustion. The calorific value of carbon is also important. When supplying air, you need to regulate its quantity. There should be enough of it to burn the carbon, and the heat generated will raise the temperature in the forge.

The air supply to the forge should be adjusted so that the supplied oxygen is not enough to oxidize the metal. But if the heated workpiece is kept in this state for more than the required time, then supersaturation with carbon will occur. There is such a term - overdrying. The metal becomes very brittle. Cast iron can be used as an overdried metal.

Muffle furnace

Equipment used to heat parts made of different materials to a given temperature is called a muffle furnace.

The difference between this equipment is the presence of a muffle. This is the name of the part that protects the workpiece from contact with fuel and combustion products and at the same time serves as a chamber where the part is heated.

In practice, two types of such furnaces are used, with a permanent and replaceable muffle. In one furnace, the loaded parts undergo all operations - from heating to complete readiness, in the other only until cooling. As the required temperature and a certain holding time of the workpiece are reached, one muffle is removed and another is put in its place.

It should be noted that both the forge and muffle furnaces can use different types of fuel - gas, coal, firewood, light and dark oil products, etc.

Anvil

One of the main tools used in both cold and hot forging is the anvil. It is on its surface that blacksmiths deform the workpiece and bring it to its finished form. The anvils are heavy and therefore rigidly fixed to a wooden block.

Structurally, the anvil consists of:

- horns;

- platband with holes;

- bases with paws for installing an anvil.

For the manufacture of such a tool, 45L steel is used. Anvils are products manufactured in accordance with GOST 11396-75 (standardizes hornless products weighing from 92 to 200 kg), GOST 11398-75 (defines requirements for products with two horns and weighing from 100 to 270 kg).

The hardness of the material from which anvils are made is 340 - 477 HB.

Cold forging machines

To carry out cold forging work, various tools and technological equipment are in great demand. Most of the tools can be purchased at any tool store, but individual devices will have to be ordered. You can also purchase a ready-made set for production and devices for cold forging.

The required tools also include a welding machine. There are many offers on the market for the supply of welding equipment, but for the needs of the forge, it makes sense to purchase a device that can work with both direct and alternating current. Such a device makes it possible to work with thin sheets without the risk of ruining them.

An angle grinder is needed for mechanical processing of workpieces. With its help you can trim something, sand something. Such a machine must have a certain reserve of power and high speeds. A stripping machine wouldn't hurt either. It will be needed to align the weld in hard-to-reach places, for example, at the junction of two planes.

The power tools you will need are a drill, a hammer drill.

In addition to the listed tools, you will also need a set of technological devices. To obtain individual parts, a template is used; it is used to obtain metal arcs or rings. Without such a device as a volumetric device, it will not be possible to obtain patterns.

Forging equipment for cold forging can be purchased as part of ready-made kits, or you can make it yourself.

Snail machine

Equipment called “Snail” allows you to make various curls. For greater convenience in work, snails with a collar are used.

Torsion bar machine

Torsion bar forging equipment is designed to twist the rod along its axis.

To make this machine with your own hands you will need the following materials and tools:

- steel sheet;

- I-beam;

- metalworking yews;

- fasteners;

- angle grinder;

- welding machine;

- drive station consisting of a gearbox and an electric motor.

Gnitik machine

This type of equipment is used for bending rod material or pipes to a certain radius and angle. Working with this equipment does not require much effort, and after processing the metal does not change its structure.

This is how gnuts work. To obtain the finished product, the workpiece is placed between the bending shaft and the stop. The flexible shaft puts pressure on the workpiece, and the stop prevents it from being completely deformed.

Wave machine

Equipment of this type makes it possible to produce wave-shaped products from circles, squares and other types of rolled products. It is used to make details such as waves and zigzags.

The universal machine for cold and hot forging NK-1 is an installation that contains several blocks. It allows you to perform many operations and produce various parts - curls, rings, etc. Equipment of this brand allows you to apply a design to metal strips, pipes and other types of profiles. In this case, the cold deformation method is used.

Factory-produced equipment for cold bending of volutes, commas, curls, spirals, photo

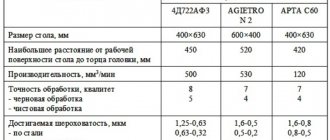

There are several types of equipment for making curls. They differ in structure, control method and, accordingly, cost . The instrument should be selected based on the skills possessed by the performer, the metal processing technology chosen by the master, and financial capabilities.

Universal mechanisms

Universal bending machines with electric drive or manual control allow you to produce elements of various shapes: curls, rings, monograms and others. Such mechanisms most often have several mandrels (conductors), which are attached to the working surface and provide a variety of manufactured parts.

MV21-30

Universal machine for forging and bending BlackSmith MB21-30. Photo ForgingPRO

In addition, patterns of different shapes allow you to bend round and square rods, strips, and corrugated pipes of different sections . Such machines have a wide range of applications. They are suitable for use by production workers who implement a small number of projects: for themselves, acquaintances and friends.

Performers are provided with a wide range of universal machines, which have minor differences. The most popular model is the MV21-30; the machines are assembled by manufacturers from Russia and China.

Manual machine “Snail”

Machines with manual (lever) “snail” control are intended exclusively for the production of curls, volutes, and commas. Such a mechanism has several components : a work table located on a leg or a massive base, to which the lower (support) part of the lever is attached, as well as the upper part of the lever, which is the main “force” for bending workpieces from rods and squares.

Cold forging machine Snail type Stalex SBG-30. Photo ForgingPRO

In addition, the kit includes one or more mandrels (other names: patterns, templates, jigs), which are located on the table. In the second case, they are alternately placed in holes on the table.

Templates for hand forging

Conductors are part of the machine, but they also often act as a simple device for manual processing of workpieces. Similar tools are used in hot and cold forging, actually bending metal. The patterns are fixed in a vice, placed on an anvil or welded to the work surface.

Creating a curl for a baluster on a jig.