Brand VSt3ps – purpose

Structural carbon steel of ordinary quality VSt3ps is used for the manufacture of parts, non-load-bearing/load-bearing components of welded/prefabricated structures operating at positive temperatures.

Additional information:

1. Sheet/shaped rolled products of category 5 with a cross-section up to 10mm – load-bearing components of welded structures operating under variable loads at temperatures of -40 +4250C.

2. Rolled products with a cross-section of 10–25 mm – load-bearing components of welded structures with guaranteed weldability, operating in the temperature range -40 +4250С.

Standards

| Name | Code | Standards |

| Ribbons | B34 | GOST 19851-74 |

| Steel pipes and connecting parts for them | B62 | GOST 3262-75, GOST 8696-74, GOST 10704-91, GOST 10705-80, GOST 10706-76, GOST 10707-80, GOST 12132-66, GOST 20295-85, GOST 24950-81, TU 14-3- 1160-83, TU 14-3-1428-86, TU 1380-001-08620133-05, TU 14-3Р-56-2001, TU 14-3-377-99, TU 1373-013-02949352-2003 |

| Ribbons | B24 | GOST 3560-73, GOST 6009-74, STP M309-74 |

| Classification, nomenclature and general norms | IN 20 | GOST 380-2005 |

| Long and shaped rolled products | B22 | GOST 4781-85, GOST 5267.0-90, GOST 5422-73, GOST 5781-82, GOST 8239-89, GOST 8240-97, GOST 8278-83, GOST 8281-80, GOST 8282-83, GOST 8283-93, GOST 8509-93, GOST 8510-86, GOST 9234-74, GOST 10551-75, GOST 10884-94, GOST 11474-76, GOST 12492.1-90, GOST 12492.2-90, GOST 12492.4-90, GOST 12492.5-90 , GOST 12492.14-90, GOST 19240-73, GOST 19425-74, GOST 19771-93, GOST 19772-93, GOST 25577-83, GOST 26020-83, GOST 30565-98, GOST 535-2005, GOST 30136-95, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006, OST 5.9086-85, OST 5.9087-84, TU 14-1-3094-80, TU 14-2-341-78, TU 14-2-853- 89, TU 14-2-949-91, TU 14-1-5282-94, STO ASChM 20-93, TU 14-1-5283-94, TU 14-105-568-93, TU 14-1-5254 -94 |

| Rails. Overlays. Linings. Crutches | B42 | GOST 5812-82, GOST 8142-89, GOST 16277-93 |

| Sheets and strips | B23 | GOST 82-70, GOST 8568-77, GOST 14637-89, GOST 14918-80, GOST 16523-97, GOST 19903-74, GOST 16523-89, GOST 16523-70, GOST 103-2006, GOST 19903-90, TU 36.26.11-5-89, TU 14-1-3023-80 |

| Metal forming. Forgings | B03 | GOST 8479-70, ST TsKBA 010-2004 |

| Welding and cutting of metals. Soldering, riveting | B05 | OST 26-260.453-92 |

| Blanks. Blanks. Slabs | B31 | OST 3-1686-90, TU 14-1-4944-90 |

| Thermal and thermochemical processing of metals | B04 | ST TsKBA 026-2005 |

| Sheets and strips | B33 | TU 14-1-3579-83, TU 14-1-4431-88 |

| Long and shaped rolled products | B32 | TU 14-105-454-86, TU 14-2-849-89, TU 14-11-245-88, TU 14-1-1271-75, TU 14-136-367-2008 |

| Test methods. Package. Marking | B29 | TU 14-106-485-99 |

| Low carbon steel wire | B71 | TU 14-4-1813-97 |

Hand over the alloy x12m (GOST 5950 - 73, the latest version does not contain the material) in St. Petersburg

cutting

| Initial data | Machinability Ku | |||

| State | HB, MPa | sB, MPa | hard alloy | high speed steel |

| hot rolled | 124 | 400 | 1,8 | 1,6 |

Description

Hand over alloy 18хгт (GOST 4543 - 71) in St. Petersburg

St3kp steel is used: for the production of expanded metal sheets, light-loaded elements of welded and non-welded structures and parts operating at temperatures from -40 °C to +400 °C; shaped profiles used in carriage building; forgings with a diameter of up to 300 mm. strength classes KP 175, KP 195; hot-rolled trough and C-shaped profiles for agricultural machines; corrugated diamond and point steel for shipbuilding; profile for the tractor final drive housing; electric welded pipes for the manufacture of parts and structures in the motorcycle and bicycle industry; hot-rolled steel sheets with one-sided rhombic and lenticular corrugation; double-headed, T-bar and P5 type rails intended for ground and overhead tracks; steel bent closed welded square and rectangular sections intended for use in agricultural engineering, tractor manufacturing and other sectors of the national economy; spikes of accuracy class C, designed for fastening railway rails to wooden sleepers and beams.

Steel VSt3ps – chemical composition

Mass fraction of elements no more than, %:

| Silicon | Manganese | Copper | Arsenic | Nickel | Sulfur | Carbon | Phosphorus | Chromium |

| 0,05–0,17 | 0,4–0,65 | 0,3 | 0,08 | 0,3 | 0,05 | 0,14–0,22 | 0,04 | 0,3 |

The closest equivalents (analogues) of steel 03Х17Н14М3

| USA (ASTM/AISI) | 316, 316, S31600, S31603, S31673, S31683 |

| Germany (DIN, WNr) | 1.4404, 1.4435, 1.4436, X2CrNiMo17-12-2, X2CrNiMo17-12-3, X2CrNiMo18-12, X2CrNiMo14-3, X2CrNiMo17-13-3 |

| Japan (JIS) | SUS316L, SCS16 |

| France (AFNOR) | X2CrNiMo18-14-3, X2CrNiMo18-15-4, Z2CND17-12, Z3CND17-11-02, Z3CND17-12-03, Z3CND18-14-03, Z3CND18-14-08, Z3CND19-15-04, Z6CND18-12- 03 |

| England (BS) | 316L, 316S11, 316S13, 316S14, 316S31, 316S33, LW22, LWCF22, X2CrNiMo18-14-3 |

| Euronorms (EN) | 1.4432, 1.4435, X2CrNiMo17-12-3, X2CrNiMo18-14-3 |

| Italy (UNI) | 316LM1, X2CrNiMo17-13, X2CrNiMo17-13KG, X2CrNiMo18-14-3 |

| Spain (UNE) | F.3533, X2CrNiMo17132 |

| China (GB) | 00Cr17Ni14Mo2, 00Cr17Ni14Mo3 |

| Sweden (SS) | 2343, 2353 |

| Hungary (MSZ) | X2CrNiMo18-14-3, KO38LC |

| Romania (STAS) | 2MoNiCr175 |

| Finland (SFS) | X2CrNiMo17-13-3 |

| Czech Republic (CSN) | 17350 |

| Austria (ONORM) | X2CrNiMo18-14-3KW |

| Australia (AS) | 316L |

| South Korea (KS) | STS316L, STSF316L |

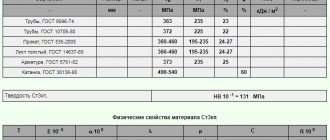

Material VSt3ps – mechanical properties

| Assortment | GOST | Dimensions – thickness, diameter | Heat treatment mode | t | KCU | y | d5 | st | sв |

| mm | 0C | kJ/m2 | % | % | MPa | MPa | |||

| .Rental hot rolled steel. | up to 20 | Delivery status | 26 | 245 | 370–480 | ||||

| 20–40 | 25 | 235 |

Application of material

The main characteristics of one of the most popular materials, such as maintaining the strength of the material despite high loads and a wide range of withstandable temperatures, allow the use of 3ps steel in load-bearing structures. Another advantage is the absence of the need to heat the metal before welding and heat treatment after welding.

Thanks to this, St3ps is used in production:

- Rolled sheet metal with a thickness of material within 10 mm, used for the construction of load-bearing structures connected by welding and used under varying influence of weight on elements from 11 to 25 mm in thickness.

- In the manufacture of reinforcement with a smooth profile used in the reinforced concrete industry.

- Production of profile parts for agricultural engineering.

- Production of expanded metal sheets.

- Manufacturing of pipeline parts.

- Production of connecting profiles for pipeline structures designed to operate under temperature conditions from -20 to +200°.

- Production of electric welding pipes.

- Production of the main layer of cladding for products requiring resistance to wear and corrosion.

Brand VSt3ps – physical properties

| t | r | R 109 | E 10-5 | l | a 106 | C |

| 0C | kg/m3 | Ohm m | MPa | W/(m deg) | 1/Grad | J/ (kg deg) |

| 20 | 2.13 | |||||

| 100 | 2.08 | |||||

| 200 | 2.02 | |||||

| 300 | 1.95 | |||||

| 400 | 1.87 | |||||

| 500 | 1.76 | |||||

| 600 | 1.67 | |||||

| 700 | 1.53 |

Standards

| Name | Code | Standards |

| Ribbons | B34 | GOST 19851-74 |

| Steel pipes and connecting parts for them | B62 | GOST 3262-75, GOST 8696-74, GOST 10704-91, GOST 10705-80, GOST 10706-76, GOST 10707-80, GOST 12132-66, TU 14-3-1160-83, TU 14-3-1428 -86, TU 14-3Р-56-2001, TU 1373-013-02949352-2003 |

| Ribbons | B24 | GOST 3560-73, GOST 6009-74, STP M309-74 |

| Classification, nomenclature and general norms | IN 20 | GOST 380-2005 |

| Long and shaped rolled products | B22 | GOST 5267.0-90, GOST 5422-73, GOST 5781-82, GOST 7511-73, GOST 8239-89, GOST 8240-97, GOST 8278-83, GOST 8281-80, GOST 8282-83, GOST 8283-93, GOST 8509-93, GOST 8510-86, GOST 9234-74, GOST 10551-75, GOST 11474-76, GOST 12492.1-90, GOST 12492.13-90, GOST 12492.14-90, GOST 19240-73, GOST 19425-74 , GOST 19771-93, GOST 19772-93, GOST 25577-83, GOST 30565-98, GOST 535-2005, GOST 30136-95, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006, OST 5.9086-85, GOST OST 5.9087-84, TU 14-2-341-78, TU 14-2-949-91, TU 14-1-5283-94, TU 14-1-5254-94 |

| Rails. Overlays. Linings. Crutches | B42 | GOST 5812-82, GOST 8142-89, GOST 16277-93 |

| Sheets and strips | B23 | GOST 82-70, GOST 8568-77, GOST 14637-89, GOST 14918-80, GOST 16523-97, GOST 19903-74, GOST 16523-89, GOST 16523-70, GOST 103-2006, GOST 19903-90, OST 5.9094-85, TU 36.26.11-5-89, TU 14-1-3023-80, STP M324-90 |

| Metal forming. Forgings | B03 | GOST 8479-70, OST 5R.9125-84, ST TsKBA 010-2004 |

| Blanks. Blanks. Slabs | B31 | OST 3-1686-90, TU 14-1-4944-90 |

| Welding and cutting of metals. Soldering, riveting | B05 | OST 36-58-81 |

| Sheets and strips | B33 | TU 14-1-3579-83, TU 14-1-4431-88 |

| Long and shaped rolled products | B32 | TU 14-11-245-88, TU 14-1-1271-75, TU 14-136-367-2008 |

Legend

Mechanical properties

| HRСе | HB | KCU | y | d5 | sT | sв |

| MPa | kJ/m2 | % | % | MPa | MPa | |

| Rockwell hardness | Brinell hardness | Impact strength | Relative narrowing | Elongation at break | Yield strength | Short-term strength limit |

| Ku | s0.2 | t-1 | s-1 |

| Relative machinability factor | Proof of yield strength with 0.2% tolerance when loaded to plastic strain value | Torsional endurance limit (symmetrical cycle) | Endurance limit under compression-tension (symmetrical cycle) |

| N | number of deformation/stress cycles sustained by an object under load before fatigue failure/crack appears |

Electric welded pipes ST3PS GOST

Straight-seam electric-welded steel pipes (GOST 10704-91, 10705-80) Ø 10 – 426 mm:

Electric-welded steel pipes ST3SP are pipes made by forming and electric welding of rolled sheets or strips.

Electric-welded longitudinal steel pipes ST3PS are manufactured by welding a straight joint parallel to the pipe axis. Electric-welded straight-seam carbon steel pipes are used for laying gas pipelines and pipelines with a working pressure of no more than 16 MPa.

You can find more complete information about the product in the catalog.

ST3PS steel is a semi-quiet structural material of ordinary quality. It is used for the manufacture of load-bearing and secondary structures that are operated at temperatures above 0 degrees. This type is one of the most popular metals; it is produced by the converter and open-hearth methods.

Decoding of St3 stamps

Any brand can be decrypted in accordance with established standards and regulatory documentation. The designation of steel according to GOST allows you to determine the main qualities when deciphering grades. GOST 380 determines the presence of the following types of metal:

It is worth considering that indices must be used for any marking.

Properties of various brands of St3

The brand of material can be deciphered as follows:

- ST is a designation that indicates the ordinary quality of carbon steel. Let's use St3sp5 as an example.

- 3 – a number that is the conventional number of the alloy grade. Depending on the carbon concentration, numbers ranging from 0 to 6 can be used.

- G - in some cases, a similar symbol may be used to designate manganese. A certain type of steel, for example, St3gps, contains 0.8% manganese.

- Sp is the degree of deoxidation of the material. When considering St3ps5, we can say that the structure is semi-quiet, but at the same time the degree of deoxidation is quite high. The designation “ps” is used for semi-quiet alloys, “kp” - boiling alloys.

St3kp2 is deciphered in a similar way relatively recently. Previously, other standards were used for labeling. In addition, previously the metal was divided into several different groups.

Other brands in this category:

- Brand VSt2kp

- Brand VSt2ps

- Brand VSt2sp

- Brand VSt3Gps

- Brand VSt3kp

- Brand VSt3sp

- Brand VSt4kp

- Brand VSt4ps

- Brand VSt5ps

- Brand VSt5sp

- Brand VSt6ps

- Brand VSt6sp

- Brand St0

- Brand St1

- Brand St1kp

- Brand St1ps

- Brand St1sp

- Brand St2kp

- Brand St2ps

- Brand St2sp

- Brand St3Gps

- Brand St3Gsp

- Brand St3kp

- Brand St3ps

- Brand St3sp

- Brand St4kp

- Brand St4ps

- Brand St4sp

- Brand St5Gps

- Brand St5ps

- Brand St5sp

- Brand St6ps

- Brand St6sp