What are mechanical properties?

The mechanical properties of aluminum, like other materials, are properties that are associated with the elastic and inelastic response of the material to the application of a load to it, including the relationship between stress and strain. Examples of mechanical properties are:

- modulus of elasticity (tensile, compressive, shear)

- tensile strength (tensile, compressive, shear)

- yield strength

- fatigue limit

- elongation (relative) at break

- hardness.

Mechanical properties are often mistakenly referred to as physical properties.

The mechanical properties of materials, including aluminum and its alloys, that are obtained by tensile testing of the material, such as tensile modulus, tensile strength, tensile yield strength and elongation, are called tensile mechanical properties.

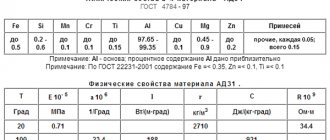

Question 7. Aluminum alloys, and their composition, properties and operating features

For building structures, aluminum alloys containing alloying components and impurities of 5-7% are used (technical aluminum with impurities up to 1% is used very rarely due to its low strength and only for decorative and enclosing elements). Aluminum alloys are divided into deformable

(processed

by pressure

: pressing, drawing, rolling, stamping, etc.), used in building structures, and in

foundries

, used mainly in mechanical engineering.

Aluminum alloys are alloyed

manganese, magnesium, silicon, zinc, copper, chromium, titanium, or several of these components at the same time, depending on which the alloy system receives a name and brand with a symbol.

Aluminum alloys are supplied in various thermal

processing and hardening (hardening, drawing).

Technical aluminum

has very high corrosion resistance, but is low-strength and ductile.

Aluminum-manganese and aluminum-magnesium

the alloys have high corrosion resistance, relatively high strength and are easy to weld.

Multicomponent alloys

have medium and high corrosion resistance, medium and high strength indicators and can be used in welded and riveted load-bearing and enclosing structures.

To improve corrosion resistance, aluminum alloys can be clad

(coated with a thin film of pure aluminum during the manufacture of the semi-finished product).

The structure of aluminum alloys consists of aluminum crystals strengthened by alloying elements (alloying elements enter into solid solution with aluminum and strengthen it).

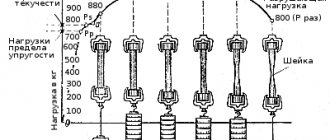

In Fig. Figure 1 shows diagrams of the tensile performance of some aluminum alloys (for comparison, a curve for steel 3 is also given).

Picture 1

1-technical aluminum AD1M;

2- alloy 1915T; 3- steel 3 The mechanical properties

of aluminum alloys depend not only on the chemical composition, but also on the conditions of their processing. Aluminum alloys have a tensile elasticity modulus E = 0.7∙104 kN/cm2, and a shear elasticity modulus G = 0.27∙104 kN/cm2, which is almost 3 times less than that of steel; therefore, at equal stresses, the deflections of aluminum structures are 3 times greater. Poisson's ratio =0.3. There is no yield plateau on the stress-strain diagram of aluminum alloys. The yield strength is conventionally taken to be the stress at which the relative residual deformation reaches =0.2%. At temperatures above 100 °C there is a slight decrease in strength characteristics, and starting from about 200 °C creep appears. The coefficient of thermal expansion of aluminum = 0.000023, which is 2 times greater than that of steel. At lower temperatures, all mechanical properties of aluminum alloys improve. The impact strength of alloys at normal temperatures is lower than that of steel (about 3.0 kg∙m/cm2), and almost does not decrease at subzero temperatures.

The change in the mechanical properties of aluminum alloys during aging occurs more intensely than that of steel, and the increase in yield strength and strength is much higher. The increase in the strength of aluminum alloys during aging is taken into account when assigning their design resistances. Calculation formulas for aluminum structures under various force influences have the same form as for steel structures. The values of various coefficients are taken depending on the grades of alloys according to the design standards for aluminum structures SNiP II-24-74.

The advantages of aluminum alloys

include: relatively high strength with low density of the material itself; high manufacturability when processed by pressing, rolling or forging, allowing the production of products of complex shapes; high resistance to corrosion, high mechanical characteristics at low temperatures; no sparking during impacts.

Disadvantages of aluminum alloys:

relatively small elastic modulus; high coefficient of thermal expansion; relative complexity of making connections; scarcity and still high cost; low fire resistance.

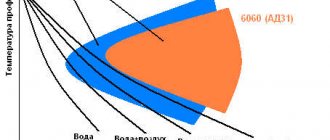

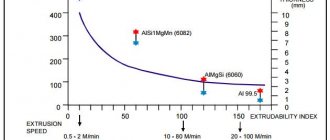

Aluminum alloy profiles for aluminum structures are produced by rolling, pressing or bending

. Only flat profiles are rolled: sheets, strips, tapes. Pressed profiles can be of very different shapes; their cross-section must fit into a circle with a matrix diameter of 320 mm (there are separate presses with a matrix diameter of 530 mm). These profiles are made on special presses. A cylindrical billet of aluminum alloy heated to approximately 400°C is pressed through a steel matrix with a hole in the shape of the profile section. The matrix is held by a holder. Both solid and hollow (tubular) profiles can be pressed.

Bent profiles are made by bending thin sheets or strips on roller bending machines or press brakes.

QUESTION 8.

Basics of calculation of metal structures.

Design diagram, supporting fastening of elements. Limit states. Groups of limit states. Calculation of structures based on permissible stresses and comparison with calculations based on limit states Basics of calculation of metal structures

The purpose and purpose of structural calculations is

checking the strength, stability and rigidity of the pre-planned structural design of the structure, which makes it possible to clarify the dimensions and ensure the reliability of the structure at the lowest possible cost of metal. Calculation of structures and their structural elements is carried out on the basis of methods of strength of materials and structural mechanics. The main goal of these methods is to determine the internal forces that arise in structures under the influence of applied loads.

The calculation begins with drawing up a design diagram of the structure, temporarily distracting from the actual cross-sectional shape of the elements. The supporting fastenings of the elements are endowed with some theoretical properties (hinged supports, supports with elastic and rigid pinches, etc.). Having determined the forces in the elements according to the accepted design scheme, they select sections, check the load-bearing capacity and design the fastenings in such a way as to satisfy the assigned tasks. Sometimes more accurate methods for determining stresses are necessary, taking into account the development of plastic deformations. However, the mathematical complexity of these methods forces us to often use a number of coefficients in the formulas, the values of which are given in the tables. According to SNiP II-23-81*, building structures are designed to withstand other force impacts based on limit states.

Beyond the limit state

a state of the structure is accepted in which it ceases to satisfy the operational requirements imposed on it, i.e. either loses its ability to resist external influences, or suffers unacceptable deformation or local damage.

studfiles.net

Elastic modulus

The modulus of elasticity, often called Young's modulus, is the ratio of the stress that is applied to a material to the corresponding strain in the range where they are directly proportional to each other.

There are three types of stresses and, accordingly, three types of elastic moduli for any material, including aluminum:

- tensile modulus of elasticity

- compressive modulus of elasticity

- shear modulus of elasticity (shear modulus of elasticity).

Table - Tensile elastic moduli of aluminum and other metals [1]

Yield strength

The stress required to achieve a specified small plastic deformation in aluminum or other material under uniaxial tensile or compressive load.

If the plastic deformation under tensile load is specified as 0.2%, then the term “yield strength 0.2%” (Rp0.2) is used.

Figure 4 – Typical stress-strain diagram for aluminum alloys

Density

The theoretical density of aluminum at room temperature (20 ºС), which is based on the dimensions of the crystal lattice, is 2698.72 kg/m3 [1]. Experimental data are in the range from 2996.6 to 2698.8 kg/m3.

The dependence of the density of aluminum on the degree of its purity in both solid and liquid states is shown in Figure 2.

Figure 2 - Density of aluminum depending on the degree of its purity in the solid state (20 degrees Celsius) and liquid state (1000 degrees Celsius)

The density of liquid aluminum with a purity of 99.996% is presented in Table 3.

Table 3 - Density of liquid aluminum with a purity of 99.996%

Elongation (at break)

Often called "relative elongation". An increase in the distance between two marks on a test specimen that occurs as a result of the specimen deforming under tension until it breaks between the marks.

The amount of elongation depends on the cross-sectional dimensions of the sample. For example, the amount of elongation that is obtained when testing an aluminum sheet specimen will be lower for a thin sheet than for a thick sheet. The same applies to extruded aluminum profiles.

Figure 5 – Influence of alloying elements on strength properties and relative elongation [4]

Extension A

Percentage elongation after specimen rupture at an initial mark spacing of 5.65 √ S0, where S0 is the initial cross-sectional area of the test specimen. The outdated designation of this quantity A5 is currently not used. A similar value in Russian-language documents is designated δ5.

It is easy to check that for round samples this distance between the original marks is calculated as 5·d.

Extension A50mm

The percentage elongation after specimen rupture, relative to the original length between the 50 mm marks and the constant original width of the test specimen (typically 12.5 mm). In the USA, a distance between marks of 2 inches is used, that is, 50.8 mm.

Electrical resistivity

The accepted value of electrical resistivity of ultrapure aluminum (99.990%) at 20 ºC is 2.2548×10-8 Ohm m or 64.94% of the International Annealed Copper Standard (IACS). The electrical resistance of 99.9% pure aluminum at various temperatures is shown in Table 5.

Table 5 - Electrical resistivity of pure aluminum (99.90%)

The electrical conductivity of pure aluminum is isotropic unless it contains oriented dislocations.

The effect of grain size on electrical resistivity in industrial aluminum is negligible. However, cold-worked aluminum has, in the direction of the resulting cold plastic deformation, a slightly higher – 0.5-1.0% – electrical conductivity.

Shear strength

The maximum specific stress, that is, the maximum load divided by the original cross-sectional area that a material can withstand when tested in shear. Shear strength is usually about 60% of tensile strength.

Shear strength is an important quality characteristic of rivets, including aluminum ones.

Figure 6 – Compressive strength, shear strength, load-bearing strength and hardness of various aluminum alloys [4]

Hardness

The resistance of a metal to plastic deformation, usually measured by making an impression.

Brinell Hardness (HB)

Penetration resistance of a spherical indenter under standardized conditions.

For aluminum and aluminum alloys, the hardness of NV is approximately equal to 0.3 Rm, where Rm is the tensile strength expressed in MPa [2].

If a tungsten carbide indenter is used, the designation HBW is used.

Vickers Hardness (HV)

Penetration resistance of a square pyramid diamond indenter under standardized conditions. Hardness HV is approximately equal to 1.10·HB [2].

Minerals, deposits...and native aluminum?

Aluminum reserves in nature are enormous. Among metals, it holds first place in prevalence. But the “sociability” and activity of the element have led to the fact that the metal is practically absent in its pure form.

Aluminum production in millions of tons

There are many minerals containing aluminum:

- bauxite;

- aluminas;

- feldspars;

- nephelines;

- corundum.

So extracting aluminum raw materials is not difficult.

If all reserves on Earth are depleted (which is doubtful), then aluminum can be extracted from seawater. There its content is 0.01 mg/l.

Anyone who wants to see native aluminum will have to descend into the craters of volcanoes.

The origin of such a metal is from the very depths of our planet.

Fatigue

The tendency of a metal to fail under prolonged cyclic stress that is well below its tensile strength.

Figure 7 – Difference in fatigue behavior of low-carbon steel and aluminum alloys [3]

Fatigue strength

The maximum stress amplitude that a product can withstand for a given number of loading cycles. Typically expressed as the stress amplitude that gives a 50% probability of failure after a given number of loading cycles [2].

Fatigue endurance

The limiting stress below which a material will withstand a specified number of stress cycles [2].