1.Carbon steel bolts, screws, socket head screws and studs.

For bolts, screws and studs made of carbon unalloyed or alloyed steels , in accordance with GOST ISO 898-1-2014, the following strength classes are established - 3.6; 4.6; 4.8; 5.6; 5.8; 6.8; 8.8; 9.8; 10.9 and 12.9.

The strength class designation consists of two numbers:

the first corresponds to 1/100 of the nominal value of tensile strength ( tensile strength ) in N/mm2;

the second corresponds to 1/10 of the ratio of the nominal value of the yield strength to the nominal value of the ultimate strength in percent.

The product of these two numbers corresponds to 1/10 of the nominal value of the yield strength in N/mm2.

For example, let's take the designation of the strength class on screws DIN 7991 - 10.9.

Tensile strength = 10*100 = 1000 N/mm2 = 1000 MPa.

Yield strength value = 1000*0.9 = 900 N/mm2 = 900 MPa.

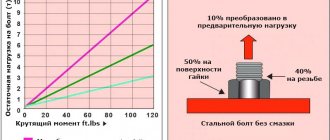

In other words, the yield strength means the maximum working load on the product. If this load is exceeded, the product will change its geometry and mechanical properties, and destruction of the fastener is also possible. Values of ultimate strength Rm and test load stress Sp. depending on the strength class of the products, are given below:

| Set of products | Strength class | Tensile strength, N/mm2 | Test load voltage, N/mm2 | |

| Nominal | No less | Nominal | ||

| Bolt, screw, hexagon socket screw, hairpin. | 3.6 | 300 | 330 | 200 |

| 4.6 | 400 | 400 | 225 | |

| 4.8 | 400 | 420 | 310 | |

| 5.6 | 500 | 500 | 280 | |

| 5.8 | 500 | 520 | 380 | |

| 6.6 | 600 | 600 | 440 | |

| 8.8 | 800 | 800* | 580** | |

| 9.8 | 900 | 900 | 650 | |

| 10.9 | 1000 | 1040 | 830 | |

| 12.9 | 1200 | 1220 | 970 | |

* For bolts with a diameter of more than 16 mm, the value is 830 N/mm2

** For bolts with a diameter of more than 16 mm, the value is 600 N/mm2

Stainless steel bolts, screws, socket head screws and studs.

For bolts, screws and studs made of stainless steel in accordance with GOST R ISO 3506-1, the strength class is indicated by the following numbers: 45; 50; 60; 70; 80; 110. Bolts, screws, studs made of different classes of stainless steels have their own strength class values. The tensile strength values, depending on the class of stainless steel, are given in the table below:

| Steel grade | Brand | Strength class | Tensile strength at gap, N/mm2 |

| Austenitic | A1, A2, A3, A4, A5 | 50 | 500 |

| 70 | 700 | ||

| 80 | 800 | ||

| Martensitic | C1 | 50 | 500 |

| 70 | 700 | ||

| 110 | 1100 | ||

| C3 | 80 | 800 | |

| C4 | 50 | 500 | |

| 70 | 700 | ||

| Ferritic | F | 45 | 450 |

| 60 | 600 |

Corrosion resistance of stainless steel

Stainless steel is able to maintain its anti-corrosion properties only in the presence of oxygen, under the influence of which a protective oxide layer of chromium (chrome oxide film) is formed on the surface of the stainless steel. Such a layer is able to isolate the surface of the metal and prevent it from interacting with aggressive substances. The layer always self-heals in the presence of oxygen, but if the chromium oxide layer is damaged or destroyed, corrosion inevitably occurs. There are several types of corrosion of stainless steel.

Crevice corrosion

This corrosion occurs in the gaps between the stainless steel and other material, for example, seals, gaskets, etc. Due to loose contact or severe surface roughness, an aggressive substance can penetrate into the gaps. The access of oxygen to such places is limited, and the protective oxide layer of stainless steel will be destroyed by the aggressive environment, without the ability to self-heal. The surface of the metal will begin to oxidize under the influence of an aggressive substance, and corrosion will occur, which will result in rust on the surface and further destruction of the stainless steel. The smoother the surface of the products and the smaller the gap between them, the less chance there is for crevice corrosion to occur. Often found on fasteners used in seawater, where current speed and lack of oxygen can accelerate crevice corrosion processes.

Pitting (pitting) corrosion

This type of corrosion occurs most often due to damage to the stainless steel surface, causing the protective oxide layer to become damaged. The unprotected surface of the stainless steel begins to interact with the environment, which will lead to the formation of dark spots or dots. If the first signs of corrosion are not removed, the stains will form rusty pits with subsequent destruction of the surface. Also, pitting corrosion can arise from the heterogeneity of the structure of the material or the presence of inclusions of other substances in the material, which often occurs when manufacturing technology is violated. Increased porosity of the structure, strong roughness and the presence of scale can also provoke this type of corrosion. An increase in temperature will significantly accelerate the process of pitting corrosion.

Galvanic corrosion

Any metal naturally has a certain electrical potential. If a conductive medium appears between the metals, then a movement of charged particles occurs from one metal to another, i.e. a current arises between them. The metal that donates electrons will be destroyed slowly or quickly, but the other metal will not undergo changes. Thus, a galvanic couple is formed. There are acceptable galvanic couples, the reaction between which is very weak and slow, and unacceptable ones, the reaction between which will quickly lead to the destruction of one of the metals. If we are talking about stainless steel fasteners, then they cannot be used in structures where a galvanic couple with copper and its alloys may occur. The surface layers of stainless steel in such a pair will quickly begin to form rust. It is also not recommended to use stainless steel with aluminum, but this recommendation only applies to the use of the two materials in a humid environment or in water. An increase in temperature accelerates the processes occurring in galvanic couples, which can aggravate the course of corrosion.

Magnet testing of stainless fasteners

Products made from martensitic and ferritic grade stainless steel are magnetic. Austenitic steel products can also be magnetic. If a magnet is attracted to products of grades A1-A5, then this is not an indicator of the quality of the material. This is also evidenced by the international standard ISO 3506 (GOST R ISO 3506 in the Russian Federation). According to the standard, all austenitic stainless steel fasteners are non-magnetic under normal conditions, but some magnetic properties may appear after cold working or other mechanical treatment. Each material is characterized by its ability to be magnetized, this also applies to stainless steels. Only a vacuum can be completely non-magnetic.

Conclusion

Currently, among stainless steel fasteners, the most popular are products made from austenitic steel grades A2 and A4, because they most often satisfy customer needs. To solve more complex problems where high strength is required, products made from C1 martensitic steel are used, but finding such products from suppliers will be much more difficult. Fasteners made of ferritic steel grade F1 are used extremely rarely for a specific client task.

Nuts made of stainless steel.

For nuts made of corrosion-resistant stainless steel, in accordance with GOST ISO 3506-2-2014, the strength classes of nuts are established in the following order:

4.1. For nuts with a height ≥ 0.8d, where d is the outer diameter of the nut thread, the strength class consists of two numbers: 45; 50; 60; 70; 80; 110.

The number corresponds to 1/10 of the tensile strength in N/mm2.

4.2. For nuts with a height ≥ 0.45 d and <0.8 d, where d is the outer diameter of the nut thread, the strength class is indicated by three numbers 025; 035; 040; 055.

The first digit “0” indicates that the load capacity of the connection of this nut with a bolt is lower than that of the nuts specified in paragraph 4.1, therefore, with a load higher than the permissible one, thread shearing may occur. The next two digits represent the test load values reduced by 10 times. Nuts made from different classes of stainless steel have their own strength class values. The tensile strength values, depending on the class of stainless steel, are given in the table below:

| Steel grade | Brand | Strength class | Test load voltage, N/mm2, not less. | ||

| nuts with height ≥ 0.8d | nuts with height ≥ 0.45 d and <0.8 d | nuts with height ≥ 0.8d | nuts with height ≥ 0.45 d and <0.8 d | ||

| Austenitic | A1, A2, A3, A4, A5 | 50 | 025 | 500 | 250 |

| 70 | 035 | 700 | 350 | ||

| 80 | 040 | 800 | 400 | ||

| Martensitic | C1 | 50 | 025 | 500 | 250 |

| 70 | — | 700 | — | ||

| 110 | 055 | 1100 | 550 | ||

| C3 | 80 | 040 | 800 | 400 | |

| C4 | 50 | — | 500 | — | |

| 70 | 035 | 700 | 350 | ||

| Ferritic | F | 45 | 020 | 450 | 200 |

| 60 | 030 | 600 | 300 | ||

Strength classes of nuts and bolts with metric threads from 1 to 48 mm according to GOST 1759.5

In table 4 shows the recommended combinations of strength classes of mating parts for various thread diameters. In special cases, fasteners can be made from corrosion-resistant, heat-resistant, heat-resistant steels, as well as non-ferrous alloys. The strength class of the nuts is indicated by a number which, when multiplied by 100, gives the value of the stress from the test load in MPa.

As a rule, nuts of high strength classes can replace nuts of low strength classes. This replacement is recommended for bolt-nut connections, the stress in which will be higher than the yield strength, or the stress from the test load of the bolt.

Related Pages

- Cylindrical threads

- Tapered threads

- Metric thread

- Runs, undercuts, grooves and chamfers according to GOST 10549

- Thread persistent

- Trapezoidal thread

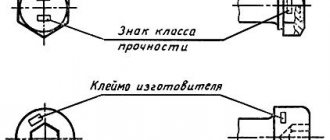

- Symbols of fasteners according to GOST 1759.0 (ST SEV 4203)

- General Purpose Hex Head Bolts

- General purpose screws

- Captive screws

- Set screws

- Special purpose bolts and screws

- Self-tapping screws for metal and plastics

- Locking the nut against the bolt with additional elements

- Locking the nuts relative to the body

- Locking the nut relative to the bolt due to additional friction, welding and plastic deformation

- Locking bolts. Preventing screws and nuts from being lost

- Locking screws

- Flange connection parts

- Flange connections for pipes and cylinder heads

- Flange connections for metal structure pipes

- Application examples for set screws

- Terminal connections

- Friction screw clamps

- Ties and stops

- Fastening machines to bases

Carbon steel hexagon socket set screws.

For set screws made of carbon unalloyed or alloyed steels , according to GOST ISO 898-5-2014, the following hardness designations are used: 14H, 22H, 33H and 45H.

The numerical part of the designation is the minimum Vickers hardness reduced by 10 times. The letter H stands for hardness.

The hardness class designation relative to Vickers hardness is given in the table below:

| Hardness class designation | 14N | 22N | 33N | 45N | |

| Vickers hardness HV | no less | 140 | 220 | 330 | 450 |

| no more | 290 | 300 | 440 | 560 | |

Strength parameters of stainless steel set screws

The concept of strength class is not used to indicate the strength of stainless steel set screws. The main mechanical characteristic is the hardness class. Marking the set screws is not necessary because most often there is no required area of the surface to apply it. Recognizing the brand and hardness class without documents will be a very difficult task.

| Hardness scale | Hardness class | |

| 12H | 21N | |

| Units of hardness | ||

| Vickers HV | From 125 to 209 | Not less than 210 |

| According to Brinell NV | From 123 to 213 | At least 214 |

| According to Rockwell HRB | From 70 to 95 | At least 96 |