Bolts, screws and studs

Bolts, screws and studs are made from various carbon steels - different steels have different strength classes. Although, sometimes it is possible to make bolts of different strength classes from the same steel, using different methods of processing the workpiece or additional heat treatment - hardening.

For example, from Steel 35 you can make bolts of several strength classes: strength class 5.6 - if you make bolts by turning on a lathe and milling machine: classes 6.6 and 6.8 - will be obtained by making bolts using the method of volumetric stamping on an upsetting press; and class 8.8 - if the bolts obtained by the listed methods are subjected to heat treatment - hardening.

The strength class for bolts, screws and studs made of carbon steel is indicated by two numbers separated by a dot. The approved strength range for bolts, screws and studs made of carbon steel contains 11 strength classes:

3.6; 4.6; 4.8; 5.6; 5.8; 6.6; 6.8; 8.8; 9.8; 10.9; 12.9

The first digit of the bolt strength class marking indicates 0.01 part of the nominal tensile strength - this is the tensile strength - measured in MPa (megapascals) or N/mm² (newtons per square millimeter). Also, the first digit of the strength class marking indicates ≈0.1 part of the nominal tensile strength if you measure the tensile strength in kgf/mm² (kilogram-force per square millimeter).

Example: Hairpin of strength class 5.8: Determining the tensile strength

5/0.01=500 MPa (or 500 N/mm²; or ≈50 kgf/mm²)

The second number denotes 0.1 part of the ratio of the yield strength (stress at which plastic deformation begins) to the nominal tensile strength (tensile strength) - thus, for a stud of strength class 10.9, the second number means that a stud belonging to this class , the minimum yield strength will be equal to 90% of the tensile strength, that is, it will be equal to: (10/0.01)×(9×0.1)=1000×0.9=900 MPa (or N/mm²; or ≈90 kgf/mm²)

Example: Hairpin of strength class 5.8: Determining the yield strength

500x0.8=400 MPa (or 400 N/mm²; or ≈40 kgf/mm²)

The yield strength value is the maximum permissible working load of a bolt, screw or stud before permanent deformation occurs. When calculating the load on bolts, screws or studs, 1/2 or 1/3 of the yield strength is used, that is, with a double or triple safety factor, respectively.

Strength classes and steel grades for bolts, screws and studs

Strength class

steel grade

Strength limit, MPa

Yield limit, MPa

Brinell hardness, HB

Source: metizmsk.ru

Bolt strength classes: marking, classification, GOST 7798-70

Fastening elements, presented in a wide variety on the modern market, are used both for simple connection of elements of various structures, and for increasing their reliability and ability to withstand significant loads. The strength class of the bolts that need to be selected depends on the purposes for which these elements are planned to be used.

Galvanized hex bolt with nut

12Х18 Н10Т

The composition of stainless steel includes chromium in a ratio of 19%, as well as nickel (11%), titanium (0.8%). Thanks to the presence of alloying elements, the metal is passivated and its anti-corrosion properties are strengthened. Due to the sufficient presence of nickel in the composition, it strengthens steel and allows it to withstand the effects of aggressive chemicals. Titanium also reduces the risk of crystalline corrosion forming. The metal becomes more viscous and ductile. Thanks to the high-quality combination of characteristics, it makes it possible to produce metal fasteners for various applications.

The importance of choosing the right fasteners

Bolts produced by modern industry can vary significantly in their strength classes, which depends mainly on the grade of steel that was used for their manufacture. That is why you should choose bolts corresponding to a particular class based on the tasks for which you plan to use them.

For example, for connecting elements of a light, unloaded structure, bolts of a lower strength class are suitable, but for fastening critical structures operating under significant loads, high-strength products are needed. The most notable of these structures are tower and gantry cranes, respectively, the bolts with the highest strength are called “crane” bolts. The characteristics of such fasteners, used to connect elements of the most critical structures, are regulated by the requirements of GOST 7817-70. Such bolts are made from high-strength steel, which is also specified in the regulatory document.

Fastening elements, as you know, come in several types: bolts, nuts, screws, studs. Each of these products has its own purpose. For their manufacture, steels of different strength classes are used. Accordingly, the markings of bolts, as well as fasteners of other types, will also differ.

Alloying additives in alloys

These are substances deliberately added to the melt to improve the properties of the alloy and bring its parameters to the required ones. Some of them are added in large quantities (more than a percent), others in very small quantities. I most often use the following alloying additives:

- Chromium. Used to increase hardenability and hardness. Share – 0.8-0.2%.

- Bor. Improves cold brittleness and radiation resistance. Share – 0.003%.

- Titanium. Added to improve the structure of Cr-Mn alloys. Share – 0.1%.

- Molybdenum. Increases strength characteristics and corrosion resistance, reduces fragility. Share – 0.15-0.45%.

- Vanadium. Improves strength parameters and elasticity. Share – 0.1-0.3%.

- Nickel. Promotes an increase in strength characteristics and hardenability, but at the same time leads to an increase in fragility. This effect is compensated by the simultaneous addition of molybdenum.

Metallurgists also use more complex combinations of alloying additives, achieving unique combinations of physical and mechanical properties of steel. The cost of such grades is several times (or even tens of times) higher than the cost of conventional low-carbon steels. They are used for particularly critical structures and assemblies.

Strength classes of threaded fasteners

The strength class of nuts, screws, bolts and studs is determined by their mechanical properties. According to GOST 1759.4-87 (ISO 898.1-78), fastening elements are divided into 11 categories according to their strength classes: 3.6; 4.6; 5.6; 5.8; 6.6; 6.8; 8.8; 9.8; 10.9; 12.9.

The rules for deciphering the strength class of bolts are quite simple. If the first digit of the designation is multiplied by 100, then you can find out the nominal tensile strength or tensile strength of the material (N/mm 2) to which the product corresponds. For example, a bolt of strength class 10.9 will have a tensile strength of 10/0.01 = 1000 N/mm 2.

By multiplying the second number after the point by 10, you can determine how the yield strength (the stress at which plastic deformation begins in the material) relates to the tensile strength or tensile strength (expressed as a percentage). For example, a grade 9.8 bolt has a minimum yield strength of 8 × 10 = 80%.

Pan Head Hex Bolt

The yield strength is the load value above which non-recoverable deformations begin in the material. When calculating the loads that will act on threaded fasteners, a two- or even three-fold margin from the yield strength is included.

High-strength bolts, whose tensile strength is equal to or greater than 800 MPa, are used not only for fastening elements of crane structures, but also in the construction of bridges, in the production of agricultural machinery, in railway connections and to solve a number of other problems. High-strength bolts are rated 8.8 or higher, and nuts are rated 8.0 or higher.

The parameter that determines what strength class the bolts will have is not only the grade of steel, but also the technology by which they are made. Bolts belonging to the high-strength category are mainly manufactured using the heading technology (cold and hot), the threads on them are formed by rolling on a special machine. After manufacturing, they are subjected to heat treatment, then a special coating is applied to them.

Hex Bolt with Flange

Automatic machines for cold and hot heading, which produce bolts of high strength classes, can be of various brands; some models allow the production of from 100 to 200 products per minute. The raw material for production is low-carbon and alloy steel wire, the carbon content of which does not exceed 0.4%.

The main steel grades used for the production of such fasteners are 10KP, 20KP, 10, 20, 35, 20G2R, 65G, 40Kh. The required mechanical properties are also imparted to these high-strength bolts by heat treatment carried out in electric furnaces, in which a special protective environment is created (with its help it is possible to avoid decarbonization of the steel).

Different types of bolts are also made from carbon steel, resulting in products belonging to different strength classes. Using various manufacturing technologies and heat treatment (hardening), bolts belonging to different strength classes can be produced from one grade of steel.

Classification by chemical composition

The main alloying additives are metals. By varying the quantitative composition of additives and their mass fraction, a wide variety of steel grades are obtained. Pure iron itself has low technical properties. Low mechanical strength and high susceptibility to corrosion require the introduction of additional substances into the alloy composition, which are aimed at improving one of the qualities, or several at once.

Often, the improvement of some characteristics entails the deterioration of others. Thus, high-alloy stainless steels may have low mechanical strength, while high-quality carbon steels, along with high strength, receive weakened corrosion properties.

As mentioned above, one of the classifications of steel grades is its chemical composition. The main components of all steels without exception are iron and carbon, the content of which should not exceed 2.14%. Depending on the amount and proportions of additives, the iron content in the composition should be at least 50%.

Based on the amount of carbon contained, steels are classified into three groups:

- Low-carbon – carbon content less than 0.25%;

- Medium carbon – 0.25-0.6% carbon;

- High carbon, with a carbon content of more than 0.6%.

An increase in the percentage of carbon increases the hardness of the metal, but at the same time its strength decreases.

To improve performance, a certain amount of chemical elements is introduced into the alloy. Such steels are called alloyed. For alloy steels there is also a division into three groups:

- Low alloy, containing additives up to 2.5%;

- Medium alloyed, which contain from 2.5 to 10% alloying elements;

- Highly alloyed. The content of alloying impurities varies from 10 to 50%.

The marking of steels reflects the presence and percentage of alloying additives. When deciphered, each element is assigned a specific letter, next to which there is a number corresponding to its content as a percentage. The absence of numbers indicates that the additive is present in the alloy in an amount of less than 1-1.5%. The presence of carbon in the composition is not reflected, since it is included in all compositions, but its content is indicated at the very beginning of the labeling.

The marking can also indicate the purpose of the alloy. Since this classification also uses letter designations, the order of their arrangement is regulated - at the beginning, middle and end of the marking.

Marking of bolts according to their strength class

The bolt marking system, the meaning of which can be viewed in special tables to determine which type of fastener is right for you, was developed by the International Organization for Standardization (ISO). All standards developed in Soviet times, as well as modern Russian regulatory documents, are based on the principles of this system.

Bolts and screws with a diameter of more than 6 mm are subject to mandatory marking. For fasteners of smaller diameter, markings are applied at the request of the manufacturer.

Markings are not applied to screws that have a Phillips or straight slot, and products that have a hex slot and any head shape are required to be marked.

Unstamped bolts and screws that are made by turning or cutting are also not subject to mandatory marking. Marking is applied to such products only when required by the customer of such products.

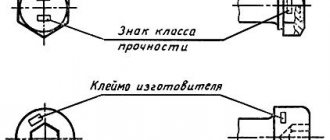

Standard location of markings on bolts

The place where the bolt or screw is marked is the end or side of its head. If the side part of the fastener is selected for this purpose, the markings should be applied with recessed marks. Convex markings in height should not exceed:

- 0.1 mm – for bolts and screws whose thread diameter does not exceed 8 mm;

- 0.2 mm – for fasteners whose thread diameter is in the range of 8–12 mm;

- 0.3 mm – for bolts and screws with a thread diameter greater than 12 mm.

The geometry of various types of threaded fasteners is regulated by individual GOST standards. As an example, we can consider products manufactured in accordance with GOST 7798-70. Such hexagonal head bolts, belonging to the category of normal precision products, are actively used in various fields of activity.

GOST 7798-70 specifies both the technical characteristics of such bolts and their geometric parameters. The materials of GOST 7798-70 can be found below.

Quality classification

Alloyed and unalloyed steel within each grade differs in quality, which depends on the production technology and the quality of the starting materials.

The quality of steel is particularly affected by impurities that remain in it during the reduction of iron from ore concentrates. Phosphorus and sulfur mainly negatively affect the quality of steel. According to their content, steel of ordinary quality and high-quality steel are classified, at the end of which there is the letter A. The phosphorus content in high-quality steel does not exceed 0.025%.

Features of connection using threads

- Reliability due to the use of special metric threads and profile versatility. Numerous studies confirm that with the correctly selected bolt strength class and tightening torque, such a connection can withstand heavy loads and is also reliably protected from self-unscrewing.

- Withstands transverse and axial loads. Made from special grades of steel, the bolts resist loads well in any direction.

- Easy installation and dismantling of structures. Despite the fact that after some time it can be difficult to unscrew a threaded connection (due to metal corrosion), it is quite possible to do this with the help of special solvents.

- Low cost of work, which is significantly lower than the cost of welding. Many structures are built today using bolts because it requires less time and effort.

It should be noted that a small drawback of a threaded connection can be considered a strong concentration of stress at the valley of the profile of the thread itself. For this reason, the bolt marking must be selected correctly, in exact accordance with the load experienced by the part. This will reduce the risk of both self-loosening due to loose tightening and nut breakage/thread cutting due to extreme stress.

Ploughshare bolt with countersunk head

We must not forget that today all kinds of locking means are also actively used, including locknuts and spring washers.

Types of steels and features of their markings

Various areas of application of steel require that it have strictly defined properties - physical, chemical. In one case, the highest possible wear resistance is required, in others, increased resistance to corrosion, in others, attention is paid to magnetic properties.

There are many types. The bulk of the smelted metal goes into the production of structural steel, which includes the following types:

- Construction Low alloy steel with good weldability. The main purpose is the production of building structures.

- Spring. They have high elasticity, fatigue strength, and fracture resistance. Used for the production of springs and leaf springs.

- Bearing. The main criterion is high wear resistance, strength, low fluidity. It is used for the production of units and components of bearings for various purposes.

- Corrosion resistant (stainless). High-alloy steel with increased resistance to aggressive substances.

- Heat resistant. It is distinguished by its ability to work for a long time under load at elevated temperatures. Area of application: engine parts, including gas turbine engines.

- Instrumental. Used for the production of metal and woodworking and measuring instruments.

- Fast cutting. For the manufacture of tools for metalworking equipment.

- Cementable. It is used in the manufacture of parts and assemblies operating under high dynamic loads under conditions of surface wear.

Read also: How much is a 10n capacitor?

When deciphering the designations, it is necessary to take into account that each of the types corresponds to a strictly defined letter in the marking.

Types of threaded fastening

To make a threaded connection, you need at least two parts, one of which has an external thread and the other has an internal thread. There are several structural types of threads.

Through holes are drilled in the parts to be connected, after which a bolt is inserted inside, which is tightened on the other side with a nut.

In this type of connection, the role of the nut is played by the part itself, in which a hole is first drilled, then a thread is applied, after which another part is fastened using a bolt or screw. If you use self-tapping screws, then it is not necessary to drill a preliminary hole, since the part itself automatically makes a thread when screwed.

Using studs

One end of such a pin is screwed into the component part, and a suitable nut is screwed onto the second in a special way.

Stud with screw-in end

08Х18Н10

Heat-resistant steel, which contains nickel (up to 11%), chromium (up to 19%), successfully combines the following properties:

- environmentally friendly material;

- resistant to corrosion;

- mechanical resistance;

- does not magnetize;

- withstands high loads.

For most consumers, this brand has gained popularity under the name A2. The steel firmly retains its original characteristics even when exposed to temperatures of + 425 degrees.

How to properly tighten and loosen a bolt

Most often, when tightening bolted connections on various structures in the household, ordinary wrenches are used - socket, open-end and box-end wrenches. However, in this case, it is difficult to accurately determine the tightening torque, so in industrial production and repair shops, experienced mechanics use special torque wrenches or pneumatic impact wrenches, the main advantage of which is the ability to set the required tightening level, depending on the type of mechanism.

To unscrew the bolt, the same keys are used, however, in old designs, most often the bolts “stick” strongly to the nut due to corrosion. For safe unscrewing, several simple methods are used:

- use of aerosol-type penetrating lubricant WD-40;

- lightly tapping the rusty bolt with a hammer to destroy the rust in the profile of the threaded connection;

- Turn the nut slightly in the direction of tightening (just a few degrees).

Threaded connections are used in many structures and mechanisms, since in practice they have proven their high reliability and efficiency. The correct type of bolt, tightened to the required tightening torque, is able to cope with the load throughout the entire life of the mechanism.

Source: met-all.org

Strength classes of stainless steel fasteners

The mechanical characteristics of bolts, screws, and studs made of stainless steel are regulated by GOST R ISO 3506-1-2009. This standard classifies stainless fasteners according to strength classes, which are usually designated by two numbers: 50, 70, 80 and written with a hyphen with the steel grade: A1-50, A2-70, A4-80. What do these numbers mean? – this is 1/10 of the minimum tensile strength.

For the production of stainless fasteners, steel grades A2 (food grade) or A4 (acid resistant), designated as such in the EN ISO system, or their approximate analogues AISI 304 (12X18H10) and AISI 316 (03X17N14M2) are most often used. Fasteners made from corrosion-resistant alloys of the austenitic group are not hardened by hardening, unlike products made from ferrous metals. Their main alloying components are chromium and nickel, as well as molybdenum (for grade A4). The percentage of these and other additives determines the degree of corrosion resistance of the fastener, maximum operating loads and other properties.

Types of tensile strength

Tensile strength is one of the main mechanical parameters of steel, as well as any other structural material.

This value is used in strength calculations of parts and structures; based on it, it is decided whether a given material is applicable in a particular area or whether a more durable one needs to be selected.

The following types of tensile strength are distinguished:

- compression - determines the ability of a material to resist the pressure of an external force;

- bending - affects the flexibility of parts;

- torsion - shows how suitable the material is for loaded drive shafts that transmit torque;

- stretching

Types of material strength tests

The scientific name for the parameter used in standards and other official documents is tensile strength.

Calculation of loads for stainless steel bolts

Knowing the strength characteristics of austenitic alloys, it is not difficult to calculate the maximum load on bolts using the formula. For example, an M12, A2-70 bolt is taken.

Np0.2 = As x Rp0.2 = 84.3 x 450 = 37935 N

, Where:

As

– design cross-sectional area M12 (see GOST R ISO 3506 Table A.1.)

Rp0.2

– yield strength

To determine the calculated working load, the resulting value must be divided by at least 20: 37935 / 20 = 1896 kg, and for greater confidence in the safety of the bolt kit, it is better to divide by 30.

Strength class is the most important characteristic of stainless steel, prescribed in the national standard GOST R ISO 3506-1-2009, which should be taken into account when calculating the load on a bolted or stud joint.

Source: krepcom.ru

Proof of Yield

In addition to the tensile strength, the related concept of yield strength, denoted σt, is widely used in engineering calculations. It is equal to the amount of tensile strength that must be created in the material in order for the deformation to continue to increase without increasing the load. This state of the material immediately precedes its destruction.

At the microlevel, at such stresses, interatomic bonds in the crystal lattice begin to break, and the specific load on the remaining bonds increases.

Strength of steel fasteners

All elements with external metric threads, such as bolts, screws, studs, vary in strength class ranging from 3.6 to 12.9. This value is contained in the marking and is usually applied to the head of the fastener. The higher it is, the stronger the fastener.

Let's look at an example. The fastener is marked 8.8. The first number shows the tensile strength and determines the nominal tensile strength (measured in N/sq.mm). To find out whether the fastening element corresponds to the load placed on it, you need to multiply 8 by 100 - we get 800 (N/sq.mm). This is the minimum tensile strength. If the load is below this value, the element will withstand. The second number indicates the yield strength, that is, the tension leading to plastic deformation of the fastener. It is determined as follows: the minimum tensile strength is multiplied by the ratio of the second number divided by 10. We get: 400x0.8 = 320 (N/sq.mm). If the load exceeds this value, an irreversible change in the shape and structure of the element will begin - it will begin to flow, that is, deform.

Note: the tensile strength and yield strength can be indicated not only in newtons per square millimeter (N/sq.mm), but also in megapascals (MPa).

There is a conditional distinction between metric fasteners depending on their purpose.

- For lightly loaded connections, products with strength classes 4.8 and 5.8 are suitable. Such elements are made of structural carbon steel (grades 10 and 20).

- For critical loaded connections, fasteners marked 8.8 are intended. This is one of the most common types of products, made from hardened steel (grades 35 and 20G2R).

- For particularly heavy structures, elements with strength classes of 10.9 and 12.9 are used. This is the most durable fastener that can withstand multiple installation/disassembly cycles. Moreover, it may have smaller dimensions than products of lower strength classes. It is made of alloy steel (grades 40Х and 20Г2Р).

Note: when determining the design load on a metric fastener, it is necessary to include a safety margin so that the connection is as reliable as possible.

Classification by deoxidation method

When steel is smelted, a certain amount of oxygen remains in it as part of the iron oxides. To reduce the amount of oxygen and restore iron from oxides, a deoxidation reaction is used, in which compounds that are more active in interacting with oxygen than iron are added to the molten metal. During the reaction, the released oxygen also reacts with carbon, resulting in the formation of carbon dioxide, which is released in the form of bubbles.

Depending on the amount of deoxidizing agents and the duration of the process, three types of the final alloy can be distinguished:

- Boiling steel. As a result of the minimal use of additives and reaction time, the yield of finished products is increased, which, at the same time, is of low quality;

- Calm steel. Metal that has completely undergone deoxidation processes. It is of high quality, but expensive to produce due to the high cost of reagents and reduced product yield;

- Semi-quiet steel. An intermediate option with the optimal combination of quality and cost.

When producing an assortment of steel grades from metal of varying degrees of deoxidation, special marking of materials is used, respectively, with the symbols “sp”, “kp” and “ps”.

Nut strength classes

For these elements, the strength class is designated in the same way as for steel bolts, screws and studs. The only difference is that the markings on the nuts start from class 8.0. The marking is applied to the end part. Products with a low strength class are not marked and are used for structures with light loads.

When selecting nuts for threaded fasteners, take into account the following relationship:

- nuts of class 5.0 and thread diameter M16 are suitable for bolts of class 3.6 - 4.8;

- nuts of class 6.0 and thread diameter M48 are suitable for bolts of class 4.5 - 5.8;

- nuts of class 8.0 are combined with bolts with a strength of 8.8 with a suitable type of thread (such products are made of carbon or alloy steel, suitable for critical connections);

- nuts of class 10.0, 12.0 are used with bolts of strength 10.9 and 12.9, respectively (made of alloy steel and hardened, used for highly loaded structures and fastening heavy elements).

Note: there are nuts that are not intended for fastening connections under load - 0 is placed at the beginning of the marking, for example, the strength class can be 04 or 05.

The correct selection of nuts and bolts according to their strength class and compliance with the tightening torque guarantee a reliable and durable connection. It is not in danger of destruction or thread breakage.

How is strength testing performed?

Strength tests for tensile strength are carried out on special test benches. One end of the test sample is fixedly fixed in them, and a drive mount, electromechanical or hydraulic, is attached to the other. This drive creates a smoothly increasing force that acts to break the sample, or to bend or twist it.

The electronic control system records the tensile force and relative elongation, and other types of deformation of the sample.

About the strength of washers

The properties of these elements are not determined by tensile strength and fluidity, since their main task is to uniformly distribute the load on the supporting surface. An analogue of strength is their hardness - the value can range from 35 to 45 HRC. The purpose of the elements is determined by the material of manufacture and the protective coating. Uncoated elements are used in places where there is no exposure to moisture; zinc or oxidized coating makes it possible to use fasteners outdoors without the threat of corrosion.

25Х1МФ

A relaxation-resistant material that can withstand the highest temperatures and is manufactured on the basis of state standard 20072-74. Such fasteners can easily work in the range of -40 to +500 degrees. This type of steel has the following characteristics:

- reliable crystal lattice;

- spontaneously reduces pressure and, as a result, mechanical stress decreases;

- long period of use;

- not fragile;

- effective hardening property.

A high level of durability, strength, and anti-corrosion properties appears due to the inclusion of additives such as nickel, chromium, and manganese.

Marking of stainless steel elements

Separately, it should be said about the fasteners made of stainless steel. It has a special marking. For example, A2-70, where A-2 is the steel grade, 70 is the tensile strength. To calculate the tensile strength, you need to multiply the indicated value by 10: we get 700 MPa (which corresponds to the strength class of carbon steel fasteners 5.6).

We hope that this article will be useful when choosing fasteners for a specific type of work. You will be able to determine if a metric fastener is suitable for the load and type of construction. You can order bolts, screws, studs, nuts and washers in our online store. It’s easy to select suitable elements - the product cards provide detailed information about each of them.

Source: www.vseinstrumenti.ru

Carbon steel grade st3sp - ordinary quality

Substitutes

Foreign analogues

| Germany DIN | RSt37-2, USt37-2 |

| USA (AISI, ASTM) | A238/C |

| France (AFNOR) | E 24-2 |

| UK BS | 40B |

| Czech Republic (CSN) | 11375 |

| Poland PN/H | St3SV, St3SJ, St3S4U |

Decoding steel St3sp

- The letters “B” indicate that this steel, supplied according to mechanical properties and with separate requirements for chemical composition,

- The letters "St" stand for "Steel"

- number 3 indicates the conventional brand number depending on the chemical composition,

- the letters "sp" - calm (degree of steel deoxidation),

- If the letter “sp” is followed by a number, then it indicates the category. If there is no number, then steel category 1. Depending on the category, steel has different standardized indicators (see below).

Type of delivery

- Long products, including shaped steel: GOST 2590-88, GOST 2591-88, GOST 535-88, GOST 2879-88, GOST 19771-93, GOST 19772-93, GOST 8278-83, GOST 8281-80, GOST 8282 -83, GOST 8283-93, GOST 380-94, GOST 8509-93, GOST 8510-86, GOST 8239-89.

- Thick sheet GOST 19903-74.

- Thin sheet GOST 19903-74.

- Tape GOST 503-81, GOST 6009-74.

- Strip GOST 103-76, GOST 82-70, GOST 535-88.

- Forgings and forged blanks GOST 8479-70.

- Pipes GOST 8734-75, GOST 10706-76, GOST 10705-80.

Characteristics, application and purpose

St3sp steel belongs to structural carbon steels of ordinary quality for general purpose and is used for the manufacture of the following parts and structures:

- Load-bearing elements of welded and non-welded structures and parts operating at positive temperatures.

- Shaped and sheet products (5th category) - for load-bearing elements of welded structures operating under variable loads: with a thickness of rolled products up to 25 mm in the temperature range from -40 to +425 °C;

- for rolled products with thickness over 25 mm in the range from -20 to +425 °C, subject to delivery with guaranteed weldability.

According to the international standard ISO 630:1995, St3sp steel is designated E 235-C (Fe 360-C)

Steel 3 is a widely used steel in the petroleum, petrochemical and oil and gas industries. Welded and stamped products can be made from steel of this grade:

- frames,

- frames

- heavy oilfield equipment skids

- bases (blocks)

- parts of drilling and production derricks and masts

- brake bands

- pulleys

- Cam couplings for drilling rigs

- keys

- stubs

- mud pump covers

- racks

- brackets

- gear housings

- drilling rig frames, etc.

Temperature of critical points, °C

Chemical composition, % (GOST 380-94)

Chemical composition, % (GOST 380-2005)

| steel grade | Mass fraction of chemical elements | ||

| carbon | manganese | silicon | |

| St3sp | 0,14-0,22 | 0,40-0,65 | 0,15-0,30 |

- The mass fraction of chromium, nickel and copper in St3sp steel should be no more than 0.30% each.

- The mass fraction of sulfur in St3sp steel should be no more than 0.050%, phosphorus - no more than 0.040%.

- The mass fraction of nitrogen in steel should be no more than:

- smelted in electric furnaces - 0.012%;

- open hearth and converter - 0.010%.

- The mass fraction of arsenic should be no more than 0.080%.

Standardized indicators of St3sp steel by rolled category (GOST 535-2005)

| Category | Chemical composition | Temporary resistance σв | Yield strength σt | Relative elongation δ5 | Cold bending | Impact strength | ||||

| KCU | KCV | |||||||||

| At temperature, °C | After mechanical aging | At temperature, °C | ||||||||

| + 20 | -20 | + 20 | -20 | |||||||

| 1 | — | + | + | + | + | — | — | — | — | — |

| 2 | + | + | + | + | + | — | — | — | — | — |

| 3 | + | + | + | + | + | + | — | — | — | — |

| 4 | + | + | + | + | + | — | + | — | — | — |

| 5 | + | + | + | + | + | — | + | + | — | — |

| 6 | + | + | + | + | + | — | — | — | + | — |

| 7 | + | + | + | + | + | — | — | — | — | + |

- The “+” sign means that the indicator is normalized, the “-” sign means that the indicator is not normalized.

- The chemical composition of steel according to heat analysis or in finished rolled products is in accordance with the order.

Parameters for the use of electric-welded straight-seam pipes made of St3sp steel (GOST 32569-2013)

| Steel grade, strength class, standard or specifications | StZsp5 GOST 380 | StZsp4-5 GOST 380 | StZsp4 GOST 380 | ||||

| Technical requirements for pipes (standard or specifications) | GOST 10705 group B | GOST 10706 group B | TU 14-3-377-87 | TU 14-3-1399-95 | GOST 10706 group B | ||

| Nominal diameter, mm | 10-500 | 450-1400 | 200-400 | 200, 350, 400, 500 | 400-1400 | ||

| Types of tests and requirements (standard or specifications) | GOST 10705 | GOST 10706 | TU 14-3-377-87 | TU 14-3-1399-95 | GOST 10706 | ||

| Transported medium (see designations in table 5.1) | Group B, C environments | Group B media Group B media, except LPG | Group B media, except steam and hot water | All media except group A(a) and LPG | Group B media, except LPG | ||

| Pipeline design parameters | Maximum pressure, MPa | ≤1,6 | ≤2,5 | ≤1,6 | |||

| Maximum temperature, °C | 300 | 200 | 300 | 200 | |||

| Pipe wall thickness, mm | — | ≤12 | — | ≤10 | — | ||

| Minimum temperature depending on the pipe wall thickness with stress in the wall from internal pressure [σ], °C | more than 0.35[σ] | minus 20 | |||||

| no more than 0.35[σ] | minus 40 | ||||||

NOTE. Groups of media, see table 5.1 GOST 32569-2013

Parameters for the use of electric-welded spiral-welded pipes made of St3sp steel (GOST 32569-2013)

| Steel grade, strength class, standard or specifications | StZspZ, StZsp2 GOST 380 | StZsp5 GOST 380 | ||

| Technical requirements for pipes (standard or specifications) | TU 14-3-943-80 | TU 14-3-954-80 | ||

| Nominal diameter, mm | 200-500 | 500-1400 | ||

| Types of tests and requirements (standard or specifications) | TU 14-3-943-80 | TU 14-3-954-80 taking into account the requirements of clause 2.2.10 GOST 32569-2013 | ||

| Transported medium (see designations in table 5.1) | All media except group A and LPG | All media except group A and LPG | ||

| Pipeline design parameters | Maximum pressure, MPa | ≤1,6 | ≤2,5 | |

| Maximum temperature, °C | 200 | 300 | ||

| Pipe wall thickness, mm | ≤6 | ≤12 | ||

| Minimum temperature depending on the pipe wall thickness with stress in the wall from internal pressure [σ], °C | more than 0.35[σ] | minus 30 | minus 20 | |

| no more than 0.35[σ] | — | minus 20 | ||

NOTE. Groups of media, see table 5.1 GOST 32569-2013

Application of St3sp steel for fasteners (GOST 32569-2013)

| steel grade | Technical requirements | Acceptable operating parameters | Purpose | |

| Wall temperature, °C | Medium pressure, MPa (kgf/cm2), no more | |||

| StZsp4 GOST 380 | STP 26.260.2043 | -20 to +300 | 2,5 (25) | Studs, bolts, nuts |

| 10 (100) | Washers | |||

Conditions for using St3sp steel for bodies, covers, flanges, membranes and valve assembly made from rolled products, forgings (stampings) (GOST 33260-2015)

| Material | ND for supply | Temperature of the working medium (wall), °C | Additional instructions for use |

| St3sp GOST 380 | Forgings GOST 8479 Long products GOST 535, categories 3-5 | -30 to 300 | For welded fittings for pressure PN≤2.5 MPa (25 kgf/cm2) |

| Sheet GOST 14637, categories 3-6 | -20 to 300 | For welded fittings for pressure PN 5 MPa (50 kgf/cm2). For categories 4, 5, sheet thickness for St3sp is no more than 25 mm; for category 3 sheet thickness no more than 40 mm |

Resistance of structural materials against crevice erosion (GOST 33260-2015)

| Durability group | Point | Erosion resistance against steel 12X18H10T | Material |

| Unstable | 6 | 0,005-0,05 | Steel VSt3sp3 and its welded joints. |

NOTE. The coefficient of erosion resistance of a material is the ratio of the rate of erosive wear of the material to the rate of erosive wear of steel 12Х18Н10Т (taken as 1).

Mechanical properties of rolled products under tension, as well as cold bending test conditions (GOST 535-2005)

| steel grade | St3sp | |

| Tensile strength σв, N/mm2 (kgf/mm2), for rolled thickness, mm | up to 10 incl. | 380-490 (39-50) |

| St.10 | 370-480 (38-49) | |

| Yield strength σт, N/mm2 (kgf/mm2), for rolled thickness, mm (not less) | up to 10 incl. | 255(26) |

| St. 10 to 20 incl. | 245(25) | |

| St. 20 to 40 incl. | 235(24) | |

| over 40 to 100 incl. | 225(23) | |

| St. 100 | 205(21) | |

| Relative elongation δ5, %, for rolled thicknesses, mm (not less) | up to 20 incl. | 26 |

| over 20 to 40 incl. | 25 | |

| St.40 | 23 | |

| Bending until the sides are parallel (a - sample thickness, d - mandrel diameter), for rolling thicknesses, mm | up to 20 incl. | d = a |

| St.20 | d = 2a | |

- By agreement between the manufacturer and the consumer, the following is allowed:

- reduction in yield strength by 10 N/mm2 (1 kgf/mm2) for shaped steel with a thickness of over 20 mm;

- reduction in relative elongation by 1% (abs.) for shaped rolled products of all thicknesses.

- It is allowed to exceed the upper limit of tensile strength by 49.0 N/mm2 (5 kgf/mm2), and by agreement with the consumer - without limiting the upper limit of tensile strength, provided that other standards are met. At the request of the consumer, exceeding the upper limit of temporary resistance is not allowed.

Impact strength of rolled products (GOST 535-2005)

| steel grade | St3sp | ||

| Rolled thickness, mm | St. 5.0 to 10.0 incl. | ||

| KCU, J/cm2 (kgf*m/cm2), not less | Sample type according to GOST 9454 | 2,3 | |

| At temperature, °C | +20 | 108(11) | |

| -20 | 49(5) | ||

| After mechanical aging | 49(5) | ||

| KCV, J/cm2 (kgf*m/cm2), not less | Sample type according to GOST 9454 | 12,13 | |

| At temperature, °C | +20 | 34(3,5) | |

| -20 | — | ||

- The “-” sign means that the indicator is not standardized.

- Determination of the impact strength of round rolled products is carried out starting from a diameter of 12 mm, square - starting from the square side of 11 mm.

- It is allowed to reduce the value of impact strength on one sample by 30%, while the average value must not be lower than the standards specified in this table.

- Impact strength KCV is determined for rolled products with a thickness of up to 20 mm inclusive.

Mechanical properties of rolled products

| GOST | Delivery status | Section, mm | σ0.2, MPa | σв, MPa | δ5(δ4),% |

| no less | |||||

| GOST 380-94 | Hot rolled products | Up to 20 | 245 | 370-480 | 26 |

| St. 20 to 40 | 235 | 25 | |||

| St. 40 to 100 | 225 | 23 | |||

| St. 100 | 205 | 23 | |||

| GOST 16523-89 (transverse samples) | Hot rolled sheet | Up to 2.0 incl. | — | 370-480 | (20) |

| St. 2.0 to 3.9 incl. | (22) | ||||

| Cold rolled sheet | Up to 2.0 incl. | — | 370-480 | (22) | |

| St. 2.0 to 3.9 incl. | (24) | ||||

Mechanical properties of forgings

| GOST | Heat treatment | Section, mm | σ0.2, MPa | σв, MPa | δ5,% | ψ, % | KCU, J/cm2 | Hardness HB |

| no less | ||||||||

| GOST 8479-70 | Normalization | Up to 100 | 175 | 353 | 28 | 55 | 64 | 101-143 |

| 100-300 | 175 | 353 | 24 | 50 | 59 | |||

| Up to 100 | 195 | 392 | 26 | 55 | 59 | 111-156 | ||

| 100-300 | 195 | 392 | 23 | 50 | 54 | |||

Impact strength KCU (GOST 380-94)

| Type of rental | Pattern cutting direction | Section, mm | KCU, J/cm2 | ||

| +20 °C | -20 °C | after mechanical aging | |||

| no less | |||||

| Sheet | Transverse | 5-9 | 78 | 39 | 39 |

| 10-25 | 68 | 29 | 29 | ||

| 26-40 | 49 | — | — | ||

| Wide band | Longitudinal | 5-9 | 98 | 49 | 49 |

| 10-25 | 78 | 29 | 29 | ||

| 26-40 | 68 | — | — | ||

| Varietal and shaped | Same | 5-9 | 108 | 49 | 49 |

| 10-25 | 98 | 29 | 29 | ||

| 26-40 | 88 | — | — | ||

Mechanical properties at elevated temperatures

| tsp, °C | σ0.2, MPa | σв, MPa | δ5,% | ψ, % | KCU, J/cm2 |

| Hot rolled billet dimensions 140×120 mm | |||||

| 20 | 220 | 445 | 33 | 59 | 154 |

| 300 | 205 | — | — | — | 199 |

| 500 | 180 | 285 | 34 | 80 | 119 |

| Hot-rolled sheets and shapes up to 30 mm thick | |||||

| 20 | 205-340 | 420-520 | 28-37 | 56-68 | — |

| 200 | 215-285 | — | — | — | — |

| 300 | 05-265 | — | — | — | — |

| 400 | 155-255 | 275-490 | 34-43 | 60-73 | — |

| 500 | 125-175 | 215-390 | 36-43 | 60-73 | — |

| A sample with a diameter of 6 mm and a length of 30 mm is forged and normalized. Deformation speed 16 mm/min, strain rate 0.009 1/s | |||||

| 700 | 73 | 100 | 57 | 96 | — |

| 800 | 51 | 63 | 95 | 95 | — |

| 900 | 38 | 65 | 84 | 100 | — |

| 1000 | 25 | 43 | 79 | 100 | — |

| 1100 | 19 | 31 | 80 | 100 | — |

| 1200 | 14 | 25 | 84 | 100 | — |

Endurance limit

NOTE. Sheet 40 mm thick in hot-rolled condition.

Technological properties

Forging temperature, °C: beginning 1300, end 750. Cooling in air.

Cutting machinability - Kv tv.spl = 1.8 and Kv b.st = 1.6 in the hot-rolled state at HB 124 and σw = 400 MPa.

Flock sensitivity - not sensitive.

Tendency to temper brittleness - not prone.

Welding

Weldability - weldable without restrictions; welding methods: RDS, ADS with flux and gas protection, ESW and KTS. For thicknesses above 36 mm, heating and subsequent heat treatment are recommended.

It is allowed to use steel st3sp for welded connections of pipeline fittings at a temperature of the working medium (wall) from -20 to 300 °C.

Welding materials for electric arc welding

| Base material grade | Electrode type according to GOST, TU (recommended brands of electrodes) | Application temperature, °C | Additional instructions |

| St3sp | E42, E46 GOST 9467 (ANO-4, ANO-5,OZS-6) | Not lower than -15 | — |

| E42A, E46A GOST 9467 (UONI-13/45, UONI-13/45A, 0ZS-2, SM-11) | Not lower than -30 | — | |

| E50A GOST 9467 (UONI-13/55) | below -30 to -40 | After welding, heat treatment - normalization plus tempering (630–660) °C, 2 hours |

Welding materials for gas shielded welding

| Base material grade | Welding wire grade according to GOST 2246, TU, recommended shielding gas or mixture of gases | Application temperature, °C |

| St3sp | Sv-08G2S Carbon dioxide GOST 8050, argon GOST 10157 | -20 to 300 |

Welding materials for submerged arc welding

| Base material grade | Welding wire grade according to GOST 2246, TU, Recommended flux grade according to GOST 9087 | Additional instructions | ||

| Electrodes, type according to GOST 10052 (recommended brands) | Welding wire, GOST 2246 or TU | |||

| Group A | Group B | |||

| 10Х18Н9Л, 12Х18Н9ТЛ GOST 977 08Х18Н10Т, 12Х18Н9Т, 12Х18Н10Т, 12Х18Н9 GOST 5632 08Х18Н10Т-VD TU 14-1-3581 10Х18Н9, 10Х18Н9-VD, 10Х1 8N9-Sh TU 108.11.937 15Х18Н12СЧТУ (EI 654) GOST 5632 10Х17Н13М3Т (EI 432) 10Х17Н13М2Т ( EI 448) GOST 5632 | St3sp GOST 380 | E-10Kh15N25M6AG2 (EA-395/9) E-10Kh25N13G2 (OZL-6, ZIO-8), E-11Kh15N25M6AG2 (NIAT-5, TsT-10) | Sv-07Х23Н13 | The welded joint is of unequal strength |

| E-10Х15Н25М6AG2 (EA-395/9) 582/23, 855/51 | Sv-10X16N25AM6 Sv-06X15N35G7M6B Sv-03X15N35G7M6B | The welded joint is of unequal strength. Welding materials are used for products under the jurisdiction of Rostechnadzor | ||

Welding materials for welding steel st3sp with other steels

| Grades of welded steels | Welding materials | Application temperature, °C |

| St3sp | Sv-08, Sv-08A AN-348A, OSTS-45 ANTS-1 | Not lower than -20 |

Temperature of preliminary and accompanying heating and tempering when welding structures made of steel st3sp

| Grades of welded steels | Thickness of welded edges, mm | Temperature of preliminary and accompanying heating, °C | Interval between the end of welding and the start of tempering, hour | Temperature, °C | |

| welding | surfacing with austenitic class materials | ||||

| St3sp | Up to 36 | Not required | Not required | Not limited | Not required |

| Over 36 to 100 | 630-660 | ||||

| Over 100 | 100 | ||||

Recommended welding modes for correcting weld defects

| Welding materials | Main material | Diameter of electrode, wire, mm | Welding current strength, A | Arc voltage, V |

| USENI 13/45A* USENI 13/55 | St3sp | 3,0 4,0 5,0 | From 100 to 130 From 160 to 210 From 220 to 280 | From 22 to 26 |

| Sv-08G2S | 1,6 | From 100 to 120 | From 12 to 14 | |

| 2,0 | From 140 to 160 |

NOTE. * - along with the electrode brand UONI 13/..., it is possible to use the brand UONII 13/..., depending on the designation of the brand in the specifications of the electrode manufacturer.

Modes of electric arc welding of samples and products

| Electrode brand | Main material | Electrode diameter, mm | Welding current strength, A | Arc voltage, V |

| USENI 13/45A*, USENI 13/55 | St3sp | 3 4 5 | From 110 to 130 From 160 to 210 From 220 to 280 | From 22 to 26 |

NOTE. * - along with the electrode brand UONI 13/..., it is possible to use the brand UONII 13/..., depending on the designation of the brand in the specifications of the electrode manufacturer.

Modes of argon arc welding of samples for incoming inspection of welding materials

| Electrode brand | Main material | Electrode diameter, mm | Welding current strength, A | Arc voltage, V |

| Sv-08G2S | St3sp | 1,6 2,0 3,0 | From 100 to 120 From 150 to 170 From 200 to 240 | From 12 to 14 |

Linear expansion coefficient α*106, K-1

| steel grade | Temperature, K (°C) | |||||||||||

| 323 (50) | 373 (100) | 423 (150) | 473 (200) | 523 (250) | 573 (300) | 623 (350) | 673 (400) | 723 (450) | 773 (500) | 823 (550) | 873 (600) | |

| St3sp5 | 11,5 | 11,9 | 12,2 | 12,5 | 12,8 | 13,1 | 13,4 | 13,6 | 13,8 | 14,0 | 14,2 | 14,4 |

Young's modulus (normal elasticity) E, GPa

| steel grade | Temperature, K (°C) | ||||||||||

| 293 (20) | 323 (50) | 373 (100) | 423 (150) | 473 (200) | 523 (250) | 573 (300) | 623 (350) | 673 (400) | 723 (450) | 773 (500) | |

| St3sp5, | 200 (2,04) | 197 (2,01) | 195 (1,99) | 192 (1,96) | 190 (1,94) | 185 (1,88) | 180 (1,84) | 175 (1,79) | 170 (1,73) | 165 (1,68) | 160 (1,63) |

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | |||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | |

| St3sp | — | 55 | 54 | 50 | 45 | 39 | 34 | 30 |