Stainless steel, despite its properties, requires protective treatment. Applying paint to a stainless steel surface is associated with certain difficulties. The article will discuss how and with what to paint stainless steel; the advantages of powder paint and the subtleties of the painting process itself will be revealed.

Features of stainless steel

Corrosion-resistant steel is a widely used material. The variety of physical properties of stainless steel is explained by the addition of various impurities during its production. The characteristics of the material are affected by the amount and type of additives. Therefore, among the brands there are alloys that over time (with prolonged use in an aggressive environment) lose their anti-corrosion properties. For this reason, a problem arises regarding methods of protection, and painting becomes a solution. To understand how to paint stainless steel, you need to find out what properties this material has. Features of stainless steel in comparison with other metals and alloys:

- Increased strength. Due to its strength, steel copes with significant physical loads without losing its characteristics (primarily its shape).

- Impact resistance. Changes in operating conditions and aggressive environments do not lead to loss of properties, which increases the service life of stainless steel structures.

- High temperature resistance. Due to its heat resistance, steel does not lose its shape, does not change dimensions and retains its properties at high temperatures.

- Environmentally friendly. Minimized oxidation processes reduce the level of harmful effects on the environment. The absence of harmful impurities contributes to the fact that stainless steel is widely used in the food industry.

- Corrosion resistance. A number of alloys are not susceptible to rust even when exposed to alkali and acid.

- View. Stainless steel is clean, shiny and retains these properties for a long time.

Pay attention to: Painting the ceiling plinth with your own hands: choosing paint, step-by-step instructions

The specific grade of steel is selected taking into account the purpose of use. The abundance of additives makes it possible to obtain the necessary alloys. In some cases, additional processing is required, for example, painting stainless steel. The characteristics of the material being painted make it appropriate to use powder coatings.

Stainless steel

Free painting of 2 samples

Painting of 2 customer samples in any color according to the RAL catalog **

| Name | Cost of painting |

| Stainless steel painting | from 200 rub. |

| Additionally | |

| There is a surcharge for colored candy polishes | from 2800 rub. |

| Painting in two colors | +100% |

| Chemical and organic contamination, as well as traces of metal corrosion more than 10 microns | from 10% of the order value |

| Prefabricated and oversized products | individually |

| Urgency of order execution | individually |

| Painting more than 2 layers (primer, varnish, paint, etc.) | 100% layer |

| Minimum order value | 1500 rub. |

The cost of painting includes:

- Primary color painting

- Application of powder varnish (glossy, matte)

- Removal of fittings/installation

- The final cost of the service is determined only upon inspection

Due to its unsurpassed characteristics, stainless steel has become one of the materials that are widely used in the production of products for a wide variety of purposes. Painting “stainless steel” is a service that allows you to eliminate the development of corrosion processes and give the product an attractive appearance.

It is important to understand that “stainless steel” has poor adhesion, which determines a number of nuances when painting it. It is best to entrust such work to a company that specializes in services in this area: for example, TermoColor!

We have everything necessary to carry out all work at a decent professional level and provide the product with a beautiful, perfectly smooth surface.

What is powder paint

Powder coatings are mixtures of solid particles, consisting of many components. The basis is a powder-type polymer and a coloring pigment. Depending on the area of application of the paint, the components of the composition are different. The main additives are:

- fillers (aluminum oxide, titanium dioxide);

- hardeners (for example, epoxy resin);

- resins that create a protective film on the treated surface;

- acrylates.

Stainless steel paint in powder form does not contain solvents, so it is not a flammable or toxic paint composition. If the technology for painting a polished stainless steel surface is followed, the harmful impact on the environment and humans tends to zero. The advantage of powder paint is its flowability that persists over time; paintwork components do not thicken or stick together. This property eliminates the need to dilute the paint before use. Flowability also determines the surface treatment technology - the coloring composition is sprayed onto stainless steel. The paint particles receive a charge, while the workpiece carries the opposite charge. Therefore, the powder sticks to the surface. Subsequently, the adhered particles are subjected to heat treatment in an oven (polymerization).

Powder paint

Technology of painting stainless steel with ENAMERU paints.

1.1.Types of stainless steel painting.

- Stainless steel painting with primer

- Painting stainless steel with a high degree of gloss (Adding gloss varnish)

- Painting stainless steel in metallic colors with the addition of matte varnish

The listed types of painting differ in the composition of the paint layer, which is prepared by adding various additives to the base enamel Polycryl Enamal LE STL.

1.2.Consumables used:

- Epoxy primer, quick-drying Enagrund EP 011

- Primer hardener Enatol Harter 123

- Paint Polycryl Enamal LE STL

- Hardener Enatol Harter 279

- Thinner Enathin 095

- Cleaner Enaclean 154

- Rags

- Masking tape

- Paint measuring jar

- Funnel filter

- Preparation table

1.3.Preparing steel for priming.

- Place on the preparation table

- Removing the protective film

- We check for scratches and defects.

- We seal the unpainted parts with masking tape.

- Matte the surface with Scotchbrite 1500

- We degrease with cleaner 154 using two pieces of rags, the first rag is soaked in cleaner 154, the second is a dry rag (wipes off the dissolved dirt after the first).

- We soak the steel for several minutes so that the cleaner completely evaporates.

1.4.Preparing steel for painting.

- Place on the preparation table

- Matte the surface with Scotchbrite 1500

- We degrease the steel with cleaner 154 using two pieces of rags, the first rag soaked in cleaner 154, the second a dry rag (wipes off dissolved dirt from the micropores of the soil after the first).

- We soak the steel for several minutes so that the cleaner completely evaporates.

1.5.Preparation of paint and primer.

1.5.1. General procedure for preparing soil 011

- Select the amount of soil we want to prepare (5 kg soil in disposable buckets)

- Place the measuring jar on the scale

- Add hardener 123 (100% of the net weight of the primer)

- Mix the soil well

1.5.2. General procedure for preparing paint.

- Find the desired recipe in the tinting program

- We select the amount of paint that we want to prepare (a multiple of 1 kg, i.e. if you need 100 grams, then enter 0.1 in the program)

- Place the measuring jar on the scale

- We gradually add components starting with the largest

- Mixing the paint

- Add hardener (15% of the net weight of the paint)

- Add solvent 095 (20% of the net weight of the paint)

- Mix the paint again

- We check the resulting color with the RAL catalog

1.5.3. Composition of components for painting steel with standard enamel:

- Paint Polycryl Enamal LE STL

- Hardener Enatol Harter 279 – 15%

- Solvent Enathin 095 – 20%

1.5.4. Painting steel with a high degree of gloss (Adding gloss varnish).

To increase the gloss of the paintwork, glossy varnish Polycryl Enalack 1495 is added to the Polycryl Enamal LE STL paint. The varnish can be added to the paint no more than 30%, otherwise the color will change. The amount of hardener also changes upward, because for varnish in its “Pure Form” it is 50%. The amount of varnish is added based on the resulting total weight of paint and varnish.

The composition of the components for preparing the paint will be as follows:

- Paint Polycryl Enamal LE STL

- Hardener Enatol Harter 279 20% – separately for varnish

- Hardener Enatol Harter 279 15% – separately for paint

- Solvent Enathin 095 – 20%

- Polycryl Enalack 1495 30%

1.5.5. The steel is painted in metallic colors with the addition of matte varnish.

To increase the density of the paint and varnish coating when painting metallics, matte varnish Polycryl Enalack 1485 is added to the Polycryl Enamal LE STL paint. The varnish can be added to the paint no more than 20%, otherwise the color will change.

The composition of the components for preparing the paint will be as follows:

- Paint Polycryl Enamal LE STL

- Hardener Enatol Harter 279 20% – separately for varnish

- Hardener Enatol Harter 279 15% – separately for paint

- Solvent Enathin 095 – 20%

- Polycryl Enalack 1485 20%

1.6. Steel priming

- Pour the soil through a filter funnel into the spray gun.

- Checking the settings of the spray gun

- Apply primer to the steel in one layer, 20-30 microns thick.

- We send the steel to a drying rack for 2 hours.

1.7. Steel painting

- Pour paint through a funnel filter into the spray gun.

- Checking the settings of the spray gun

- Apply paint to the steel in one layer, 80 microns thick.

- We send the steel to a drying rack for 12 hours.

1.8.Packaging of painted steel.

- We take the painted sample from the drying rack onto the preparation table.

- We remove painting livestock

- Wipe off dust with a dry cloth

- Cover with protective film

- 2.Errors in paint production and violation of painting technology.

- If you add too much varnish, the shade of the color changes, this is due to a change in the density of the paint.

- An error when pouring one of the components in the recipe will lead to the color being different from the base one. When mixed correctly, Feyco paint differs from others in its high color stability.

- If there is not enough hardener in the paint, the paint may become brittle and brittle, so that even with a slight mechanical impact the paint may break off.

- When the thickness of the “Wet layer of paint” (immediately after application) is below 80 microns. Especially at low temperatures, the paint may peel off along with the protective film.

- If the solvent is overfilled, the paint will be too fluid, which will cause paint smudges on the vertical elements.

- If the grease is not properly degreased with cleaner 154, craters will appear, also called “fish eyes”. Also, poor degreasing can lead to paint peeling off along with the film.

- Sealing an under-dried profile will result in traces of oil from the protective film remaining on the paint.

If you follow the painting technology, you will not have problems during application; even fine dust in the air will not bother you, since ENAMERU paints dry “from dust” in five minutes.

Source: biz.enameru.com

Difficulties in painting stainless steel

Powder coating of stainless steel is a method that meets the characteristics of the surface being treated. Smooth steel rejects the approach of using conventional liquid paints and varnishes, since the latter simply do not adhere to it. The adhesion of stainless steel is low, which adds to the complexity of painting. The solution to the problem is the choice of an adequate coloring composition and adherence to technology. At home, painting stainless steel with powder is difficult. Additional equipment will be required, namely an installation for imparting a charge to paint particles, a spray gun, and an oven for polymerizing the paint composition. It is commercially available, but if you have the skills and experience, you can make it yourself. Powder coating is a technology most often used in industrial settings.

Powder painting

How to paint metal products

Currently, the following coatings are used for application to metal:

- Oily . A common choice for metal painting. Before applying the base layer, pre-coating with a special primer is required. The toxicity of the material and its pungent odor make it possible to use it only in well-ventilated areas.

- Epoxy . They consist of two components - silicone resin and hardener. They are very toxic, therefore they are used only for external work; in addition, the application process is quite complex and requires the performer to have a fairly good knowledge of the technology.

- Alkyd . They have good covering ability, which allows them to be applied directly to a previously prepared metal surface without additional priming. Used for interior and exterior work.

- Acrylic . Latest generation polymer coatings. Due to their ease of application and non-toxicity, they are becoming increasingly popular. They require a careful approach to preparing the surface for painting.

- Rubber . Specially designed for outdoor use, they provide excellent protection for roofs and other metal surfaces that are exposed to precipitation.

All of the above compositions can be used in various situations and are widely used.

The powder method of painting metal products should also be mentioned. It creates high-strength coatings, but can only be carried out in a production workshop, since powder painting technology requires special equipment and conditions.

If you have to choose a paint to coat a metal product, first evaluate the expected consumption, the degree of labor required to prepare the surface, the toxicity level of the composition, its durability, the presence of additional properties and cost.

In addition, in order to increase the service life of the coating and ensure its reliability, additional materials are sometimes used when preparing the surface for painting:

- Primer-enamel. A universal paint that combines the functions of primer, paint and corrosion protection.

- To treat areas affected by corrosion - epoxy resins with special additives . When applied, they form a durable film that prevents rust from spreading further. Apply directly to rusty areas without prior preparation.

- Anti-corrosion coatings . Protect the treated surface from moisture and oxygen.

- Hammer compounds . They create the effect of numerous hammer blows and are used as a decorative technique in interior design. Resistant to external influences. To create this effect, epoxy, alkyd, and acrylic coatings can be used.

- Forging mixtures . They consist of polymers that give the coatings excellent wear resistance. Easy to apply.

- Nitro paint . It is highly toxic and is usually sold in cans. Quick-drying composition.

- Heat-resistant coatings – special varnishes and enamels for painting stoves and similar products.

The powder coating method, invented in 1950, is a fundamentally different technological process for painting metal products. There is no liquid component here, although from the outside the application process is similar to spraying with compressed air, but there is no suspension of paint in the air - the so-called “fog”.

The powder composition is attracted to the part due to electricity. A positive high voltage charge is applied to the part, and a negative high voltage charge is applied to the paint. Since opposite charges attract, particles of powder paint uniformly adhere to the metal. After this, the part is heated to a temperature of +200...+250 °C, the powder melts, spreading over the surface and forming a thin elastic layer several tens of microns wide. This layer turns out to be very dense and durable.

The cost of powder paint is one and a half to two times higher than traditional painting methods due to the use of expensive equipment and the specifics of the technological process. But because powder coating is extremely durable and of the highest quality, it has completely replaced traditional painting in some metal manufacturing industries.

Preparatory stage

Powder paint for stainless steel should be applied to the prepared surface. The preliminary stage involves the following:

- Inspection of processed parts to identify defects (scratches, chips). Shallow imperfections on a smooth stainless steel surface can be preserved to improve adhesion.

- Making the material being painted rough. If we are talking about small parts, then a metal brush is suitable for processing. In other cases, it is better to use a grinder with an appropriate attachment. A medium-grit abrasive disc will do.

- Cleaning the part from processing products. A wet cloth is suitable for removal. The part must be thoroughly wiped.

- Degreasing. Grease stains on stainless steel will impair paint adhesion, so alkaline or acidic compounds are used. When degreasing with such compounds, it is necessary to observe safety precautions (ventilate the room, wear gloves and a respirator). At home, you can degrease the part using a soda solution (4 grams of soda per 100 ml of water).

- Drying the part before painting.

Pay attention to: How and with what to paint penoplex

Personal protective equipment is required during the preparatory stage and during painting.

Cleaning and degreasing the surface

Price list for powder coating services

On our website you can familiarize yourself not only with powder coating of metal in Moscow, but also with a detailed price list for this service. As you know, the main criterion for evaluating powder coating of metal products is the price per meter. But it is suitable for calculating powder coating of sheets and other large-area products. If you need to apply a powder coat to a metal product of complex shape, the cost of powder coating the metal per m2 cannot be determined. In this case, the price of the service will be calculated individually, but always to the benefit of the customer.

Painting process

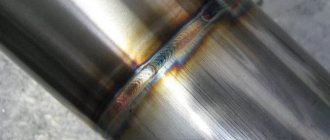

In industrial conditions, before painting, the parts being processed are washed in chambers and dried in ovens; a conveyor process is organized there. At home, prepared stainless steel can be dried on a table or on a radiator. The powder is applied by spraying from a gun. The equipment is made in such a way that the paint particles receive one charge, and the part being painted receives the opposite charge. Under such conditions, the powder adheres to the stainless steel in an even layer. Industrial painting is completed quickly, but at home this process will take longer. The technology for applying paint on stainless steel in powder form involves electrostatic or turbostatic spraying. The first option involves an external charge source, the second method allows particles to be charged by rubbing them against the walls of the turbine. The second stage of painting is melting the paint in an oven at a temperature of 150-220 degrees. Powder particles melt at high temperatures and form a film on stainless steel, which subsequently hardens. Industrial polymerization chambers are designed for changing reflow conditions (sudden increase and decrease in temperature, inclusion of recirculation of air flows, etc.). Do-it-yourself ovens are more primitive, but purchasing industrial equipment for personal (usually single) purposes is impractical.

Powder coating process

Powder painting of stainless steel at NAYADA

Our company offers a rich color palette of paints. You can order one-color or two-color painting of metal products in any shades from the RAL catalog. The original color effects such as metallic, super gloss black, gold chameleon, as well as imitation of natural wood, stone, and crocodile skin look especially expensive and beautiful. All types of coatings are given a three-year guarantee: if the paint peels off during this time, we will carry out a second set of painting works free of charge.

Is it possible to paint metal?

Metal structures are often made of black iron. Since this material oxidizes very quickly, it must be protected from moisture and rust. For this purpose, special anti-corrosion compounds or metal paint can be used.

Galvanized metals, thanks to a layer of zinc and chromium, are already protected from rust. The protective layer retains its integrity for up to 15 years. If you want to increase this figure, the surfaces can be additionally painted.

Painted disc

Types of coloring compositions

Varieties:

- Oily. Suitable for decorative finishing of surfaces indoors and outdoors. Made from organic substances. Before applying oil paint, you need to cover the working surface with primer. The main disadvantage is the persistent pungent odor. Such enamels can only be used in ventilated areas.

- Epoxy. Manufactured on the basis of silicone resin. In order for the composition to set, different hardeners are used. Can only be used for exterior painting as they are highly toxic. It is difficult to work with epoxy paints, but the finished coating reliably protects surfaces from rust.

- Acrylic. The basis of such paints are polymers. Suitable for painting metal parts indoors.

- Alkyd. Used for external and internal work. Easy to apply, no primer required.

- Rubber. Special dyes used to coat the external sides of building walls and roofs. Withstands prolonged exposure to moisture and ultraviolet radiation.

For metal, you need to choose paints that protect against rust. Before painting, the surfaces must be coated with a primer containing a high zinc content.

How to calculate paint consumption?

The paint consumption for metal can be found on the container. It is indicated on the back of the label or front side. If for some reason there is no designation, you need to know that 1 liter is enough for about 14 m2.

Consumption depends on the application method, the presence of complex elements, surface structure, and type of paint.