cutting

| Initial data | Machinability Ku | |||

| State | HB, MPa | sB, MPa | hard alloy | high speed steel |

| hot rolled | 124 | 400 | 1,8 | 1,6 |

Application of steel grade C255

Builders distinguish 4 groups of building metal structures, classified according to the degree of their responsibility and the conditions of their operation. The most demanding is the first group, which includes welded structures forced to work in particularly difficult conditions, including those exposed to fairly large vibration, dynamic and moving loads. In this case, it is allowed to use only the steel grade C255 we are considering, as well as C285, C345 or C375.

The first group includes such structures as elements of bridge spans, power transmission line supports, crane beams, unloading and bunker overpasses, transport galleries, trusses, etc.

Steel VSt3Gps – chemical composition

Mass fraction of elements no more than, %:

| Silicon | Manganese | Copper | Arsenic | Nickel | Sulfur | Carbon | Phosphorus | Chromium |

| 0,15 | 0,8–1,1 | 0,3 | 0,08 | 0,3 | 0,05 | 0,14–0,22 | 0,04 | 0,3 |

Steel S255: chemical composition and GOST standards for rental

Carbon steel C255 (carbon share is about 0.2%) is produced in accordance with GOST 27772-88, which determines the following composition of the chemical elements of the steel alloy:

- Fe – about 97%

- C – up to 0.22%

- Mn – up to 0.65%

- Si – 0.15-0.3%

- Ni – up to 0.3%

- Cr – up to 0.3%

- Cu – up to 0.3%

- S – up to 0.05%

- P – up to 0.04%

- N – up to 0.012%

Hot rolled shaped steel C255:

- GOST 8509 – equal angle angle

- GOST 8510 – unequal corner

- GOST 8239, 26020 – I-beam

- GOST 8240 – channel

- GOST 19425 – I-beam and special channel

In addition, carbon steel 255 is used for the production of rolled products:

- GOST 19903 – sheet

- GOST 82 – universal broadband

- GOST 8568 – sheet metal with lentil and rhombic corrugation

Bent profiles are also made from steel of this grade: according to GOST 7511, 8278, 8281, 8282, 8283, 9234, etc.

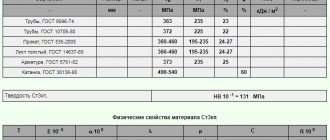

Material VSt3Gps – mechanical properties

| Assortment | Dimensions – thickness, diameter | Heat treatment mode | t | KCU | y | d5 | st | sв |

| mm | 0C | kJ/m2 | % | % | MPa | MPa | ||

| Rolled hot rolled steel.. | up to 20 | delivery status | 26 | 245 | 370–490 |

Mechanical properties of steel St3Gps

Mechanical properties of steel St3Gps according to GOST 535-2005 regulations is sold in the form of hot-rolled steel with a cross-section of up to 10 mm, from 10 to 20 mm, from 20 to 40 mm, from over 40 mm to 100 mm, and also from more than 100 mm. Rolled thickness: 10-20 mm, yield strength: > 245 MPa, tensile strength: 370-490 MPa, relative elongation: > 26%, bending until the sides are parallel: d=1.5a. Rolled thickness: 20-40 mm, yield strength: > 235 MPa, tensile strength: 370-490 MPa, relative elongation: > 25%, bending until the sides are parallel: d=2.5a. Rolled thickness: 40-100 mm, yield strength: > 225 MPa, tensile strength: 370-490 MPa, relative elongation: > 23%, bending until the sides are parallel: d=2.5a. Rolled thickness: > 100 mm, yield strength: > 205 MPa, tensile strength: 370-490 MPa, relative elongation: > 23%, bending until the sides are parallel: d = 2.5a. Rolled thickness: < 10 mm, yield strength: > 235 MPa, tensile strength: 370-490 MPa, relative elongation: > 26%, bending until the sides are parallel: d = 2.5a Below are the data in a tabular version:

| Type of delivery | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Rolled goods, GOST 535-2005 | 370-490 | 205-245 | 23-26 | |||||

| Thick sheet, GOST 14637-89 | 370-490 | 205-245 | 23-26 |

At elevated temperatures

| t | KCU | y | d5 | s0.2 | sв |

| 0C | J/cm2 | % | % | MPa | MPa |

| The sheet is hot rolled. thickness 12–50 mm | |||||

| 20 | 58–68 | 26–39 | 225–390 | 410–570 | |

| 200 | 215–390 | ||||

| 300 | 215–360 | ||||

| 400 | 195–265 | ||||

| 500 | 65–76 | 175–245 | 300–500 | ||

Construction steel grades - analogues and replacement

| Strength class | steel grade | Strength class | steel grade |

| S235 | St3kp2 St 3sp5 St3ps5 | S275 | St3ps |

| S255 | St3Gsp St3Gps | S285 | St3sp St3Gps St3Gsp |

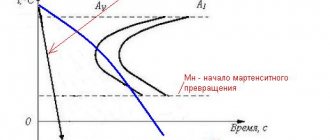

One of the important characteristics of construction rolled steel 3 is its resistance to brittle fracture. To confirm these properties, samples of steel sheets undergo impact bending tests at decreasing temperatures.

The level of resistance to brittle fracture of rolled sheets in accordance with GOST 27772 is guaranteed by the required value of impact strength (KCU - when tested for impact bending with a U concentrator). For steels smelted according to EN standards, this value is the fracture coefficient (KV).

Impact strength, J/cm2

| Assortment | Dimensions – thickness, diameter, mm | KCU at temperatures | ||||

| -400С | -300С | -200С | 00С | +200С | ||

| Sheet in delivery condition | 12–20 | 25–111 | 34–125 | 54–129 | 87–195 | |

| 30 | 16–69 | 23–96 | 60–98 | 87–132 | ||

| 40 | 10–36 | 20–46 | 93–103 | 94–103 | 162–179 | |

| 50 | 7–30 | 19–56 | 18–84 | 71–130 | 130–173 | |

| Rolled shaped products | 10–20 | 17–132 | 32–146 | 77–204 | 116–219 | |

Supply St3Gps

Supplied in the form of long products, including shaped steel according to the regulations of GOST 2590-88 Hot-rolled round steel , GOST 2591-88 Hot-rolled square steel , GOST 8239-89 Hot-rolled steel I-beams , GOST 19771-93 Equal-flange bent steel angles, GOST 19772 -93 Bent steel angles, unequal flanges , GOST 8278-83 Bent steel channels, equal flanges , GOST 8281-80 , unequal , GOST 8283-93 steel trough equal flange profiles , GOST 380-94 Carbon steel of ordinary quality , GOST 85 09-93 Steel corners hot-rolled equal flange , GOST 8510-86 rolled steel angles unequal-flanged , GOST 8240-97 Hot-rolled steel channels , GOST 535-88 Rolled bars and shaped carbon steel of ordinary quality , GOST 2879-88 Rolled hot-rolled hexagonal steel, GOST 19903-2015 Hot rolled sheet products , GOST 19904-90 Cold-rolled sheets , GOST 16523-97 Rolled thin sheets of high-quality and ordinary quality carbon steel for general purpose, GOST 503-81 Cold-rolled low-carbon steel strip, GOST 103-76 Hot-rolled steel strip , GOST 82-70 Hot-rolled steel Wide-band universal, GOST 3282-74 Wire Steel low-carbon general purposes , GOST 17305-71 Carbon structural steel wires, GOST 10705-80 steel power steel pipes , GOST 10706-76 Pipes steel eight-dimensional , GOST 3262-75 Pipes steel water and gap-pipes .

| Classification, nomenclature and general norms | GOST 380-2005; |

| Long and shaped rolled products | GOST 535-2005; GOST 8239-89; GOST 5422-73; GOST 8510-86; GOST 8509-93; GOST 2879-2006; GOST 2591-2006; GOST 2590-2006; GOST 19425-74; GOST 19240-73; GOST 9234-74; GOST 11474-76; GOST 8240-97; |

| Sheets and strips | GOST 14918-80; GOST 103-2006; GOST 19903-74; GOST 14637-89; |

| Ribbons | GOST 3560-73; |

| Steel pipes and connecting parts for them | GOST 3262-75; GOST 20295-85; GOST 24950-81; |

Brand VSt3Gps – physical properties

| t | r | R 109 | E 10-5 | l | a 106 | C |

| 0C | kg/m3 | Ohm m | MPa | W/(m deg) | 1/Grad | J/ (kg deg) |

| 20 | 7850 |

Legend

Mechanical properties

| HRСе | HB | KCU | y | d5 | sT | sв |

| MPa | kJ/m2 | % | % | MPa | MPa | |

| Rockwell hardness | Brinell hardness | Impact strength | Relative narrowing | Elongation at break | Yield strength | Short-term strength limit |

| Ku | s0.2 | t-1 | s-1 |

| Relative machinability factor | Proof of yield strength with 0.2% tolerance when loaded to plastic strain value | Torsional endurance limit (symmetrical cycle) | Endurance limit under compression-tension (symmetrical cycle) |

| N | number of deformation/stress cycles sustained by an object under load before fatigue failure/crack appears |

Carbon steel of ordinary quality GOST 380-88

Application area.

Carbon steel of ordinary quality is intended for the production of hot-rolled products: long-rolled, shaped, thick-sheet, thin-sheet, wide-rolled and cold-rolled thin-sheet, as well as ingots, blooms, slabs, rounds, rolled and continuously cast billets, pipes, forgings and stampings, strips, wires, hardware and etc.

Classification.

Carbon steel of ordinary quality is produced in the following grades: St0, St1kp, St1ps, St1sp, St2kp, St2ps, St2sp, St3kp, St3ps, St3sp, St3Gps, St3Gsp, St4kp, St4sp, St4ps, St5ps, St5sp, St5Gps, St6ps, St6sp.

The letters St stand for steel.

The numbers 0,1, 2, 3, 4, 5, 6 are the conventional brand number depending on the chemical composition. Increasing the number means increasing carbon content and tensile strength.

The degree of deoxidation of steel is indicated by letters after the numbers:

kp – boiling;

ps – semi-calm;

sp – calm;

| steel grade | Substitute | Recommended Application | Weldability |

| St 0 | No | For minor structural elements and non-essential parts: decking, fittings, washers, railings, casings, cladding, etc. | Weldable without restrictions. |

| St2ps St2kp St2sp | St2sp St2ps | Non-critical parts that require increased ductility, lightly loaded elements of welded structures operating under constant loads and positive temperatures. | Weldable without restrictions. For thicknesses greater than 36 mm. Preheating and subsequent heat treatment are recommended. |

| St3kp | ST3ps | For minor and lightly loaded elements of welded elements and non-welded structures operating in the temperature range from - 10 to 400 degrees Celsius. | Weldable without restrictions. For thicknesses greater than 36 mm. Preheating and subsequent heat treatment are recommended. |

| St3ps | St3sp | Load-bearing and non-load-bearing elements of welded and non-welded structures and parts operating at positive temperatures. Shaped and sheet metal (5th category) with a thickness of up to 10 mm for load-bearing elements of welded structures operating under variable loads in the range from -40 to +425 degrees Celsius for St3ps and a thickness of up to 25 mm. For St3sp, St3ps with rolled thickness from 10 to 25mm. - for load-bearing elements of welded structures operating at temperatures from -40 to + 425 degrees, subject to delivery with guaranteed weldability, St3sp with rolled metal thickness over 25 mm - for load-bearing elements of welded structures operating at temperatures from -40 to + 425 degrees Celsius , subject to delivery with guaranteed weldability. | Weldable without restrictions. For thicknesses greater than 36 mm. Preheating and subsequent heat treatment are recommended. |

| St3sp | St3ps | ||

| St3Gps | St3ps St18Gps | Shaped and sheet metal with a thickness from 10 to 36mm. for load-bearing elements of welded structures operating under variable loads in the range from -40 to + 425 degrees Celsius, and for load-bearing elements of welded structures operating at temperatures from -40 to +425 degrees with guaranteed weldability. | Weldable without restrictions. For thicknesses greater than 36 mm, preheating and subsequent heat treatment are recommended. |

| St4kp | No | Welded, riveted and bolted structures of increased strength in the form of long, shaped and sheet products, as well as for lightly loaded parts. | |

| St4ps | St4sp | Welded, riveted and bolted structures of increased strength in the form of long, shaped and sheet products, as well as for lightly loaded parts such as shafts, axles, bushings, etc. | Limited weldability. |

| St5ps St5sp | St6sp St4sp | Parts of riveted structures: bolts, nuts, handles, rods, rollers, bushings, wedges, axles, levers, stops, pins, fingers, rods, rods, sprockets, tubular sockets, flanges and other parts operating in the range of 0 to + 425 degrees Celsius, forgings with a cross-section up to 800mm. | Limited weldability. Preheating and subsequent heat treatment are recommended. |

| St6ps | For high-strength parts: axles, shafts, pins, pistons, etc. | Limited weldability. Preheating and subsequent heat treatment are recommended. | |

| St6sp | St5sp | For high-strength parts: axles, shafts, pins and other parts in a heat-treated state, as well as for bar reinforcement with periodic profiles. | Limited weldability. Preheating and subsequent heat treatment are recommended. |