Brass sheet is a product made from a copper alloy, the main alloying element in which is zinc. The scope of use of this type of rolled metal is very wide, which is explained by the characteristics of the brass used for its production.

Brass sheet grade L63 is in demand in the construction, electrical and mechanical engineering industries

Main characteristics

Brass sheet can be produced by cold or hot forming. To obtain such rolled products, manufacturers can use two types of brass:

- multicomponent (its chemical composition, in addition to copper (about 40%) and zinc (1–2%), contains alloying additives such as aluminum, tin, nickel and lead);

- two-component (contains only copper (60–97%) and zinc).

The popularity enjoyed by brass sheets among modern manufacturers is explained by a number of advantages that distinguish such a product. Let's list them.

- The simplicity of processing allows you to create blanks and finished products of almost any configuration from this type of rolled metal without significant labor costs.

- The exceptional decorative characteristics of the brass sheet are not lost during the operation of the finished product.

- On the modern market, brass sheets are available in a wide range of thicknesses (0.5–25 mm), which allows consumers of such products to choose the material that best suits their requirements. All such products comply with the requirements of the regulatory document (GOST 2208-2007).

- Products made from sheet brass are highly corrosion resistant and can be successfully used in contact even with very aggressive environments.

Cold rolling brass strip

Additional advantages of using such a material include the fact that brass, sheets and other types of rolled products from which can be successfully operated in a fairly wide temperature range (from –80 to +120°

), easy to polish (this is especially important for decorative items). Even complexly deformed brass products retain the unique structure of the original material and, accordingly, all its original characteristics.

Brass sheet, the requirements for the parameters and characteristics of which are specified by the provisions of GOST 2208-2007, does not resist wear well enough, but this disadvantage of this product is compensated by a whole list of its advantages. In particular, this should include good machinability using plastic deformation methods at any temperature, as well as good weldability using argon arc welding.

ANNEX 1

Information

THEORETICAL WEIGHT OF 1 m2 OF HOT-ROLLED AND COLD-ROLLED SHEETS AND STRIPS

Table 15

| Strip or sheet thickness, mm | Theoretical weight of 1 m2 sheet or strip, kg, from brass grades | Strip or sheet thickness, mm | Theoretical weight of 1 m2 sheet or strip, kg, from brass grades | ||

| L90, L85, L80 | L68, L63, LS59-1, LMts58-2, LO62-1 | L90, L85, L80 | L68, L63, LS59-1, LMts58-2, LO62-1 | ||

| 0,4 | 3,48 | 3,40 | 4,5 | 39,15 | 38,15 |

| 0,5 | 4,35 | 4,25 | 5,0 | 43,50 | 42,50 |

| 0,6 | 5,22 | 5,10 | 5,5 | 47,85 | 46,75 |

| 0,7 | 6,09 | 6,05 | 6,0 | 52,20 | 51,00 |

| 0,8 | 6,96 | 6,80 | 6,5 | 56,55 | 55,25 |

| 0,9 | 7,83 | 7,65 | 7,0 | 60,90 | 59,50 |

| 1,0 | 8,70 | 8,50 | 7,5 | 65,25 | 63,75 |

| 1,1 | 9,57 | 9,35 | 8,0 | 69,60 | 68,00 |

| 1,2 | 10,44 | 10,20 | 9,0 | 78,30 | 76,50 |

| 1,3 | 11,31 | 11,05 | 10,0 | 87,00 | 85,00 |

| 1,35 | 11,75 | 11,48 | 11,0 | 95,70 | 93,50 |

| 1,4 | 12,18 | 11,90 | 12,0 | 104,40 | 110,50 |

| 1,5 | 13,05 | 12,75 | 13,0 | 113,10 | 120,00 |

| 1,6 | 13,92 | 13,60 | 14,0 | 121,80 | 119,00 |

| 1,65 | 14,36 | 14,03 | 15,0 | 130,50 | 127,00 |

| 1,8 | 15,65 | 15,30 | 16,0 | 139,20 | 136,00 |

| 2,0 | 17,40 | 17,00 | 17,0 | 147,90 | 144,50 |

| 2,2 | 19,14 | 18,70 | 18,0 | 156,60 | 153,00 |

| 2,25 | 19,58 | 19,13 | 19,0 | 165,30 | 161,50 |

| 2,5 | 21,75 | 21,25 | 20,0 | 174,00 | 170,00 |

| 2,75 | 23,93 | 23,38 | 21,0 | 182,70 | 178,50 |

| 3,0 | 26,10 | 25,50 | 22,0 | 191,40 | 187,00 |

| 3,5 | 30,45 | 29,75 | 25,0 | 217,50 | 212,50 |

| 4,0 | 34,80 | 34,00 | |||

Note. When calculating the theoretical mass, the density of brass of grades L90, L85, L80 was taken equal to 8.7 g/cm3, and of brass of grades L68, L63, LS59-1, LMts58-2 and LO62-1 - equal to 8.5 g/cm3.

Where is it used?

Brass sheets, the entire range of which is specified by the provisions of GOST 2208-2007, are successfully used in almost all industries, as well as in the domestic sphere. Today, almost no machine-building and chemical enterprises, plants in the energy and oil refining industries can do without products made from such material.

Many products for which brass sheet is used are produced using the cold forming method. If necessary, brass sheets can be easily perforated; this procedure does not require expensive tools or special equipment. The decorative characteristics that distinguish this material allow it to be used for the manufacture of elements of furniture and advertising structures, and the design of facades of building structures for various purposes. Its low weight allows the use of brass sheets to create design elements and advertising structures.

Brass trim panels for decorative decoration of switches or sockets

In the domestic sphere, when performing repairs and decorating premises for various purposes, brass sheet metal is also used quite actively. In recent years, due to the growing popularity of interiors decorated in a classical style, brass sheets are often used to decorate the flood zone - the area of the floor directly adjacent to the fireplace.

Such a flood zone, which is subject to more wear and tear than the rest of the floor surface, must also ensure the safety of using the heating device. At the same time, the flood zone should be in no way inferior to the decorative characteristics of the fireplace itself, which often plays the role of the main element of the interior.

Brass sheet will provide durable and practical protection for the fireplace area of the fireplace or stove

Brass is ideal for decorating this area. Firstly, this material has a very beautiful and noble color, secondly, it is not flammable and can reliably protect the main floor covering from fire, thirdly, such a coating of the flood zone can be polished at any time if abrasions appear from too intense use .

Of course, designing a flood zone is not the only area of application of brass sheets in everyday life. From such sheets, which can be selected based on the assortment specified by the provisions of GOST 2208-2007, containers for various purposes are made (such containers can be successfully used even in contact with aggressive environments), elements of furniture structures and objects that perform decorative functions.

A thin brass strip is great for making a variety of decorative elements with your own hands.

Regulations

You can familiarize yourself with the GOST requirements for rolled brass sheets by downloading the document in pdf format from the link below.

GOST 2208-2007 Brass foil, tapes, strips, sheets and plates. Specifications

The current regulatory document, the provisions of which stipulate the requirements for rolled brass sheets, is GOST 2208-2007. GOST 2208-2007 also describes the range of such products. According to the requirements of this regulatory document, rolled brass sheets can be:

- by degree of accuracy - normal, high and increased accuracy;

- by product sizes - measured, unmeasured and multiple measured lengths;

- according to the degree of hardness - soft, semi-hard, hard and especially hard.

Types of rolled brass

Depending on the brand of brass, sheets can be produced using cold- or hot-rolled technology. For the production of sheet metal using hot-rolled technology in accordance with the provisions of GOST 2208-2007, brass grades such as L63, LMts58-2, LS59-1 and LO62-1 are used. To implement cold-rolled technology, brass alloys L68, L85 and L90 are used. At the same time, the regulatory document (2208-2007) allows that L63 brass can also be processed by the cold-rolled method.

Depending on the production technology, the sizes of rolled sheets differ, which is also stipulated in GOST 2208-2007. Thus, GOST specifies the following values of the geometric parameters of a brass sheet:

- thickness: hot rolled – 5–25 mm; cold rolled – 0.4–12 mm;

- width: hot rolled – 500–2500 mm (deviation no more than 20 mm); cold rolled – 300–1000 mm;

- length: hot rolled – 1000–4000 mm (deviation no more than 30 mm); cold rolled – 1410–2000 mm.

The standard of 2007 also stipulates the theoretical weight of one square meter of rolled brass sheets, which, depending on the grade of the alloy, can be in the range of 3.4–217.5 kg. This weight is calculated based on the density of the brass from which the sheet is made.

Theoretical mass per square meter of brass strips, strips, sheets and foil used

The provisions of the regulatory document stipulate not only the geometric parameters of brass sheets and their theoretical weight, but also the hardness of the product, which can vary depending on the version in which it is presented (soft, semi-hard, hard and especially hard).

Brinell hardness of brass alloys

TRANSPORTATION AND STORAGE

4.1. Sheets and strips are transported by all types of transport in covered vehicles in accordance with the rules for the transportation of goods in force on transport of this type, and the conditions for loading and securing goods, approved by the Ministry of Railways of the USSR.

Transportation of sheets and strips by rail is carried out in small, low-tonnage and wagonload shipments.

When the length of sheets or strips is more than 3 m and the weight of the cargo package is more than 1250 kg, transportation is carried out in covered cars or on open rolling stock in containers in accordance with GOST 18477 or according to regulatory and technical documentation.

In the absence of overload on the way, it is allowed to transport sheets and strips in containers in accordance with GOST 18477 or according to regulatory and technical documentation in packaged form without packing in boxes and without protection with wooden shields.

4.2. Sheets are stored indoors. During storage, sheets and strips must be protected from moisture, mechanical damage and exposure to active chemicals. Subject to the specified storage conditions, the consumer properties of sheets and strips do not change during storage.

Quality requirements

The above GOST also lists the requirements for the quality characteristics of rolled brass sheets. This should include:

- the presence of tarnish, darkening, defects of various types, serious contamination and other defects on the surface of the sheet;

- the amount of permissible deflection of sheets;

- quality of cutting edges of sheets;

- the value of the relative elongation of the product;

- the value of temporary tensile strength.

Checking the quality of cutting wide brass blades into strips

The regulatory document stipulates that rolled brass sheets, the thickness of which does not exceed one centimeter, must be subjected to bending tests, which are carried out along the rolling line. In this case, products that have been subjected to such a test are not subsequently tested for tensile strength.

CONTROL METHODS

3.1. To analyze the chemical composition of sheets and strips, one sample is cut from each selected sheet or from each selected strip.

Selection and preparation of samples for chemical analysis are carried out in accordance with GOST 24231.

The analysis of the chemical composition is carried out according to GOST 25086, GOST 1652.1 - GOST 1652.13 and GOST 9716.1 - GOST 9716.3 or other methods that are not inferior in accuracy to those indicated.

In case of disagreement, the analysis of the chemical composition is carried out according to GOST 25086, GOST 1652.1 - GOST 1652.13.

3.2. The quality of the surface and edge of sheets and strips is checked by inspection without the use of magnifying devices.

3.3. The thickness of sheets and strips is measured with a micrometer according to GOST 6507 or GOST 4381.

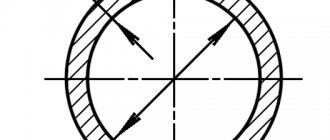

The thickness of sheets and strips is measured at a distance of at least 100 mm from the top of the corner and at least 15 mm from the edge of the sheet or 10 mm from the edge of the strip.

Control of the thickness of sheets or strips is carried out with an acceptance defect level AQL

=4%.

The thickness of sheets and strips is measured on each selected sheet or on each selected strip at points located evenly and randomly along the perimeter of the sheet or strip.

Number of sheets or strips in a batch ( M

), pcs., calculated by the formula

where P

– batch weight, kg;

g

— density of the material, g/cm3;

N

– sheet (strip) thickness, mm;

b

– sheet (strip) width, mm;

l

– length of sheet (strip), mm.

The number of controlled areas in a sheet or strip ( N

), pcs., calculated by the formula

The results of measuring the thickness of sheets or strips that do not correspond to the maximum deviations given in table. 1, 4, 7, should not differ from the permissible values by more than half the tolerance range.

3.4. Measurement of the width, length and bevel of the cut of sheets, width and length of strips is carried out with a metal ruler in accordance with GOST 427 or a metal measuring tape in accordance with GOST 7502, or with a caliper in accordance with GOST 166. The width is measured in one place at a distance of 100 mm from the edge of the sheet or strip.

Measurement of the bevel of the cut is carried out according to GOST 26877.

3.5. Measurement of deflection of sheets and strips is carried out according to GOST 26877.

3.6. The bending test is carried out according to GOST 14019.

3.7. Crescentness is measured according to GOST 26877.

3.8. For tensile tests, one sample is cut from each selected sheet or each selected strip. Sampling - according to GOST 24047.

Tensile testing of sheets and strips with a thickness of 0.4 to 3 mm is carried out according to GOST 11701 on samples of type I or II with an initial calculated length, width of 20 or 15 mm.

Tensile testing of sheets and strips with a thickness of 3 mm or more is carried out according to GOST 1497 on samples of type I or II with a width of 20 mm for sheets and strips with a thickness of up to 7 mm inclusive and a width of 30 mm for sheets and strips with a thickness of more than 77 mm. The initial estimated length of the samples is .

3.9. The manufacturer is allowed to use other measuring instruments and test methods that provide the necessary accuracy established in this standard.

In case of disagreement, the measuring instruments and control methods established in paragraphs are used. 3.2 – 3.8.

Rules for labeling, packaging and transportation

Each batch of rolled brass sheets, regardless of its total weight and the number of products in it, must be delivered to the warehouse or consumer with a special label indicating the following information:

- batch number, number of products in it and their total weight;

- trademark and name of the manufacturer;

- mark on product inspection by the quality department:

- brand of brass from which the rolled product is made.

Marking scheme for brass sheets, strips, foil and tapes

Before they are released to the warehouse or to the consumer, brass sheets are placed in bundles of a certain weight. In this case, rolled products with a thickness of up to 1.5 mm are placed in special boxes, which should ensure their protection from mechanical damage. Packs of brass sheets with a thickness of more than 1.5 mm can be stored and transported without additional protective packaging. GOST stipulates both the dimensions of bundles formed from rolled brass and their weight, which cannot exceed 1250 kg.

APPENDIX 2

Information

HARDNESS OF COLD-ROLLED SHEET AND STRIP

Table 16

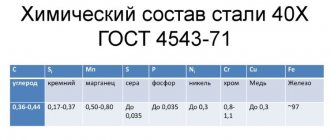

| Brass grade | Material condition | Brinell hardness |

| L90 | Soft | 60 |

| Semi-solid | 85 | |

| Solid | 110 | |

| L85 | Soft | 65 |

| Semi-solid | 95 | |

| Solid | 110 | |

| L80 | Soft | 65 |

| Semi-solid | 95 | |

| Solid | 120 | |

| L68 | soft | 70 |

| Semi-solid | 105 | |

| Solid | 125 | |

| Extra hard | 155 | |

| L63 | Soft | 70 |

| Semi-solid | 105 | |

| Solid | 135 | |

| Extra hard | 160 | |

| Spring-hard | 180 | |

| LS59-1 | Soft | 100 |

| Solid | 200 | |

| LMts58-2 | Soft | 85 |

| Semi-solid | 100 | |

| Solid | 120 | |

| LO62-1 | Solid | 145 |

Perforated brass sheets

Modern industry also produces perforated sheets of brass alloys, which are used primarily for decorative purposes.

Perforated brass sheet is often used to hide heating appliances on both walls and floors

Such sheets, on the surface of which perforations of various configurations can be made, are actively used for the manufacture of:

- elements of furniture, trade and exhibition equipment;

- interior items;

- details of the design of building facades;

- small architectural forms and other elements for the formation of landscape design.