Alloy and carbon materials

This type of material is used for the production of rigid (power) elastic elements. The reason for this particular application was that the high modulus of elasticity of this steel greatly limits the elastic deformation of the part that will be made from spring steel. It is also important to note that this type of product is high-tech and at the same time quite affordable. In addition to being used in automobile and tractor construction, this type of material is also widely used for the manufacture of power elements in various devices. Most often, parts made from this steel are called by one general name - general purpose spring steels.

In order to ensure the necessary performance of power elastic elements, it is necessary that spring steel have a high limit of not only elasticity, but also endurance, as well as relaxation resistance.

Steel grades according to GOST 14959–79

These are steels with a high carbon content, but with low alloying. Gosstandart 14959 means alloyed alloy of the following grades:

- 3K-7 - used in the production of cold-drawn wire, from which non-hardening springs are made;

- 50ХГ – produce springs for cars and springs for railways. compositions;

- 50HGA - purpose in production as in the previous brand of spring steel;

- 50HGFA – produce special springs and spring parts for cars;

- 50ХСА – special-purpose springs and small parts for watch mechanisms;

- 50HFA - they produce parts with increased load, with the requirements of the highest stability and strength, which operate at high temperatures - up to 300 degrees.

- 51HFA – for spring wire;

- 55С2 - for the production of spring mechanisms and springs used in tractor construction, mechanical engineering, for railway rolling stock;

- 55С2А – produces auto springs, springs for trains;

- 55S2GF - for the production of very strong springs of a special type, autosprings;

- 55KhGR – produce spring strip steel, the thickness of which varies from 3 to 24 mm;

- 60G - for the production of round and smooth springs, rings and other spring-type products with high wear resistance and elasticity, for example, staples, bushings, tambourines for braking systems used in heavy engineering;

Interesting: torsion steel, grade 60C2 - high-load springs, friction discs, spring washers;

- 60С2А - produce the same products as from the previous type of steel;

- 60S2G – type of spring steel from which tractor and auto springs are produced;

- 60С2Н2А – produce responsible springs with a high load on the alloy;

- 60С2ХА – for the production of highly loaded spring products subject to constant load;

- 60S2HFA is a round steel with calibration elements, from which springs and spring plates are produced with high responsibility;

- 65 – produce parts with increased strength and elasticity, which are operated under high pressure, high static loads and strong vibration;

- 65G - produce parts that will work without shock loads;

- 65GA – hardened wire for springs;

- spring steel grade - 65S2VA, highly loaded leaf springs and springs;

- 68A – hardened wire for the production of spring devices with a caliber of 1.2-5.5 mm;

- 70 – parts for mechanical engineering that require increased wear resistance;

- 70G – for spring elements;

- 70G2 - produce digging knives and springs for various industries;

- 70С2ХА – spring elements for watch devices and large springs for special purposes;

- 70С3А – springs with high load;

- spring steel grade 70HGFA – wire for the production of spring elements with heat treatment;

- 75 – any spring and other parts used in mechanical engineering that are subject to heavy vibration loads;

- 80 – for producing flat parts;

- 85 – wear-resistant parts;

- SH, SL, SM, DN, DM – machine springs operating under static loads;

- KT-2 – for the production of cold-drawn wire, which is wound without heat treatment.

Properties

In order to meet requirements such as endurance, elasticity and relaxation resistance, materials with a high carbon content are used. The percentage of this substance in the product used should be in the range from 0.5 to 0.7%. It is also important to quench and temper this type of steel. These procedures must be carried out at temperatures from 420 to 520 degrees Celsius.

It is worth noting that spring steel, hardened to martensite, has a low elasticity coefficient. It increases significantly only during tempering, when a troosite structure is formed. The process guarantees an increase in the ductility of steel, as well as its fracture toughness. These two factors are important in order to reduce sensitivity to stress risers, as well as increase the endurance limit of the product. It can be added that isometric hardening to lower bainite is also characterized by positive qualities.

Spring steel for a knife has been the most common material for some time, especially among car owners. The production of sharp objects was indeed carried out from old springs that had become unusable for use in a vehicle. Knives made from such an unusual material were used both for various household needs and for ordinary cutting of food in the kitchen. The choice of this particular detail did not fall by chance. There were several reasons why spring steel became the main material for the homemade production of good knives.

The first reason is that due to the poor quality of roads, such a part as a spring often and quickly became unusable. Because of this, many car owners had an abundance of these units. The parts were just lying in garages. Availability was the first reason.

The second reason is the spring design, which included several sheets of carbon steel. It was from these elements that it was possible to make a pair of good knives.

The third reason is the high elasticity of spring steel, which allows processing of the material with only a minimal set of tools.

Why is spring alloy produced?

Both alloy steel and carbon steel can be used to produce parts; they have increased elasticity, toughness, endurance and ductility. Due to the properties of these types of steel, elastic destruction is limited.

Spring steels are affordable, technologically advanced, and have a high limit of relaxation resistance.

Interesting: to obtain high-quality products from carbon and alloy steel, it is hardened at a temperature of 420-520 degrees, which produces the effect of a troostite structure.

Spring steels resist fragile fracture and are characterized by increased ductility. They are used to produce products with high wear resistance, for example:

- clamping collets;

- brake rolling;

- edges;

- springs and leaf springs;

- thrust washers;

- bearing torsos;

- friction discs;

- gears.

Features of knives

A significant reason why this particular type of steel has become widely used for the production of knives is the composition of the product itself. In production, this composition was called spring steel 65G. As the name suggests, this material is widely used for the production of leaf springs, springs, washers, and some other parts. The cost of this particular grade of steel is considered one of the lowest among carbon materials. But at the same time, its characteristics, that is, strength, flexibility and impact strength, are at their best. In addition, the hardness of the steel itself has also increased. All these features of carbon metal also played a decisive role in the choice of material for creating knives.

Steel 60s2a spring

Stainless spring steel is cheap, has great elasticity, wear resistance, and does not have temper brittleness. This alloy does not deform under mechanical loads. It is used effectively at high humidity, as it has a stainless steel coating. It is used at a temperature of no more than 250 degrees, and is used for the production of rolled metal products.

Stainless steel is used to produce equipment in the marine industry, medicine, and food production. Its use in these industries is due to its corrosion-resistant alloy.

Interesting: stability is associated with a high content of molybdenum and chromium. The alloy has good resistance to cracking under heavy loads.

This grade of stainless, heat-resistant steel is used in the production of rolled thin sheets, seamless pipes and various tools for the food and chemical industries.

Steel 65G

Spring steel 65G is a structural high-carbon steel, which is supplied in accordance with GOST 14959. This grade belongs to the group of spring steels. The two most important requirements for this type of steel are high surface strength and increased elasticity. In order to achieve the required strength, up to 1% manganese is added to the metal composition. In addition, in order to achieve all the required indicators, it is necessary to carry out proper heat treatment of parts made from this grade.

The widespread and effective use of this type of steel is due to the fact that it belongs to the class of economically alloyed, that is, cheap. The main ingredients of this product are:

- carbon, the content of which ranges from 0.62 to 0.7%;

- manganese, the content of which does not exceed 0.9 to 1.2%;

- chromium and nickel content in the composition is from 0.25 to 0.3%.

Other components that make up steel are sulfur, copper, phosphorus, etc. These are impurities, the percentage of which is regulated by the state standard.

Properties of spring steel

The main characteristics of this type of steel are high resistance to elastic deformation and low residual elongation coefficient. This is due to the inadmissibility of increasing or decreasing the structural size of the spring.

Steel spring

Good structural and operational properties are achieved by drawing a pre-patented wire at low temperatures, while tightly tightening the material.

The patenting process is carried out in the interval between two hoods, the steel is heated above the temperature point of austenite formation and then cooled in a bath of molten lead, while the austenite transforms into thin-plate sorbitol and its mechanical strength increases.

To achieve the same physical and chemical properties over the entire cross-section of the material, spring steel must undergo a calcination process using a through method, this will ensure a homogeneous structure throughout the entire cross-section. This method is especially important for the manufacture of springs of large diameter, when uneven properties of the starting material can lead to destruction of the finished product.

Like any other material, spring steel is characterized by the presence of carbon in its composition. In this case, its content can vary between 0.50-0.80% by weight of the alloy. Additionally, the following alloying additives are used:

- silicon – up to 2.5%;

- manganese – up to 1.3%;

- tungsten – up to 1.3%;

- nickel – up to 1.7%.

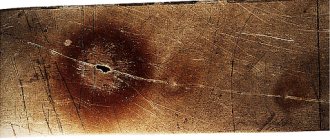

Microstructure of spring steel

It is worth noting that chromium and manganese, when alloyed together, increase the resistance of steel to low plastic deformations. Nickel and tungsten form a thin and uniform structure of the carbide fraction, which prevents dislocation.

Spring steel is very critical to deformations of the outer layer of the material, since these stresses are concentrators of possible defects in the finished product.

Hardening of this type is carried out at temperatures of 850–880 °C, but after such heat treatment the steel exhibits weak elastic properties due to the formation of martensite; to increase this type of properties, it is tempered at temperatures of the order of 420–510 °C, which promotes the formation of troostite and increased elastic deformation alloy to a tensile strength of 1200-1900 MPa and a yield strength of 1100-1200 MPa. At the same time, carrying out hardening isothermally - at a constant temperature - has a positive effect on the plasticity and viscosity of the material.

Steels of this type have good anti-corrosion properties due to the presence of alloying additives such as chromium and molybdenum in the alloy. This has a positive effect on the service life and prevents the formation of cracks during operation.

It is also worth noting several main disadvantages of spring steel:

- poor weldability - this is due to the destruction of the outer layer of the material and local overheating of the part;

- difficulty of cutting - some difficulties arise when trying to cut this type of steel, this is directly related to the high resistance to deformation.

Heat treatment

There are several heat treatment modes for this type of steel. Any of them is selected in accordance with the production requirements for the finished product. Most often, two heat treatment methods are used, which guarantee the required properties from a chemical and physical point of view. These methods include normalization and hardening followed by tempering.

When carrying out heat treatment, it is necessary to correctly select the temperature parameters, as well as the time needed to carry out the operation. To choose these characteristics correctly, you should start from what grade of steel is used. Since the material of grade 65G belongs to the hypoeutectide type, this product contains austenite, presented in the form of a solid mechanical mixture with a small amount of ferrite. Austenite is a harder material in terms of structure than ferrite. Therefore, to carry out heat treatment of 65G steel, it is necessary to create a lower quenching temperature range. Taking this fact into account, similar indicators for this type of metal range from 800 to 830 degrees Celsius.

Specifications of spring alloys

High- and medium-carbon types of these alloys are strengthened by fine cold destruction, allowing the introduction of shot blasting and water-abrasive methods. With this type of impact, residual compression forces are applied to the plane of the products.

In fact, any spring steel (non-corrosive, without special anti-corrosion properties) must undergo a high-heat operation using the through-hole method. Therefore, the finished metal product will have a troostite structure in its cut.

Oil hardening at a temperature of 830–880 degrees, combined with tempering at 410–480 degrees, guarantees an increase in the elasticity limit - the most important working property of the above steels. Isothermal hardening is often used, which provides not only high elasticity, but also increased plasticity, stability and viscosity of the substance.

Non-corrosive tape and wire made from alloys 70 and 65 are most often used to create machine springs. In the automotive industry, silicon spring steels of the spring rolling grade – 60С2А, 70С3А and 55С2 – are also dynamically used. They are prone to decarbonization, which reduces their elasticity and endurance characteristics. But due to the additives of chromium, vanadium and certain components, all these possible dangers are neutralized.

Areas of application for spring rolling of the most popular steel grades:

- springs for any devices and assemblies of the machine and automobile construction areas - 55S2, 50ХГ, 50ХГА;

- heavily loaded springs - 60 S2G, 60S2, 65S2VA, 60S2N2A;

- Wear-resistant springs are round and flat (a strip is used), operating at high vibrations - 80, 75.85.

In conclusion, a little about the disadvantages

- poor weldability;

- difficulty cutting.

Source of the article: https://solidiron.ru/steel/ressorno-pruzhinnye-stali-primenyaemye-v-promyshlennosti.html

Quenching mode

How to harden spring steel? It is necessary to create the desired temperature regime, select the correct time, and also correctly calculate the time and temperature of the vacation. In order to give the steel all the necessary characteristics that are set by the future technical conditions of the part, it is worth carrying out the necessary hardening. To select the appropriate mode for this procedure, rely on the following characteristics:

- Not only the hardening method is important, but also the equipment used to heat the steel.

- Select the required hardening temperature.

- Select a suitable time period for hardening steel.

- Select the desired environment for the hardening process.

- It is also important to choose the right technology for cooling the part after the hardening process.

Spring steel grades

Steel for the manufacture of springs is supplied in the form of strips. After this, blanks are cut from it, hardened, tempered and collected in the form of bags. Brands of spring steel, such as 65, 70, 75, 80, etc., are characterized by the fact that their relaxation resistance is low, this disadvantage is especially noticeable when the part is heated. These steel grades cannot be used for work in environments whose temperatures exceed 100 degrees Celsius.

There are cheap silicon grades 55C2, 60C2, 70SZA. They are used to make springs or leaf springs, the thickness of which will not exceed 18 mm.

Higher quality steel grades include 50HFA, 50HGFA. If we compare it with silicon-manganese and silicon materials, then during tempering the temperature is much higher - about 520 degrees. Due to this processing procedure, these steel grades are characterized by high heat resistance, as well as low sensitivity to notching.

Source of the article: https://fb.ru/article/336776/ressornaya-stal-opisanie-harakteristiki-marka-i-otzyivyi

UAZ spring. Standard and reinforced UAZ springs

The domestic UAZ spring is almost universal for the Patriot, Hunter and Pickup models, as well as their modifications. The elements differ only in the number of sheets, which affect the carrying capacity of the vehicle, as well as the difference in geometric dimensions. In this regard, it is quite possible to install four-leaf elements from the “Pickup” and “Cargo” on the “Patriot” and “Hunter”. The increase in carrying capacity will be about two hundred kilograms. Let's look at the features of standard and modified parts.

Spring steel knives

When choosing a knife, it is very important to consider the material from which it is made. After all, to perform various functions, the blade must not only be sharp, but also durable. In addition, you need to pay attention so that the blades do not become dull or bend under light load. These properties depend on the material from which the knives . Depending on the tasks that the knife must perform, be it a carving knife, a hunting knife or a tourist knife, the characteristics of the material differ.

Knives made from springs were undoubtedly the most popular among people who had anything to do with cars. They were actually made from the springs of old cars, since it was one of the most affordable materials. At the same time, knives were used both in the kitchen for cutting food and for household needs.

Nowadays, spring steel is not losing its position and is quite common in the production of knives.

Model 31512-2912012

This UAZ spring is a rear small-leaf part, which in the standard version was mounted on models 31512, 31514-10, 3160. The element is also suitable for “Patriots” and “Hunters”, as well as their modifications.

Distinctive characteristics of the node in question:

- Control load – 504.7 daN.

- The weight of the assembled unit is 16.5 kilograms.

- Element length – 1.35 m.

- The number of sheets is three pieces.

- The height of the package is 37.2 mm.

- Material grade – steel 50Х-ГФА.

Application of spring steel

Due to its versatility due to the characteristics of steel, a knife made from a spring is made both at home and in series. These can be kitchen knives that perfectly cut food and cut meat, military, tourist and survival knives that can open a can of canned food or sharpen a stake.

All-metal machetes and axes are also produced from 65G steel, since their blades are excellent for chopping. A sword can be forged inexpensively and quickly from leaf springs, and many reenactors use this steel in their hobby. Unfortunately, spring steel is prone to rust, so it is not suitable for scuba diving.

Kitchen knife

The spring knife is widely used in the kitchen. Back then, many had access to this material and tried to use it as much as possible. Good mass-produced knives were sometimes beyond the means of an ordinary family, but expensive devices were not required for cutting food. Therefore, universal knives were made from springs and with a variety of homemade handles made of epoxy resin, wood or ordinary electrical tape. Such knives are not famous for their outstanding characteristics, but they do their job perfectly.

Tourist knife

A spring knife is perfect for use in wild conditions. Usually the load on it is small. But, it is worth considering that if the steel was not sufficiently hardened, the blade will become dull at the very first tin can. Sharpening a stake is not a problem for such a knife, but you should be careful of moisture - spring steel is susceptible to corrosion.

Army knife

The excellent properties of spring steel make it possible to create good tactical knives. Due to the strength of this metal, they cut ropes and fabric without any problems, and can be used for household purposes, as well as for rescue work. But still, in military conditions, preference is given to stainless steel knives.

Axe, machete, sword

As for more impressive tools, their manufacture requires both sheet steel and specially purchased steel. 65G steel has such strength that it is used in bulldozer buckets, scrapers and other equipment. It is clear that the thickness of the material also affects the strength, so for the manufacture of larger tools you will need a spring from a truck or specially ordered at the factory.

With proper processing and proper care, spring steel makes excellent axes, which are useful on the farm for chopping small objects. A long sheet will also make an exotic weapon like a machete, which can easily handle branches or bushes. Thanks to the good toughness of 65G steel, even the most advanced machete can be made at home, straight, curved or serrated. The making of a sword occurs in the same way.

Making a knife from a spring at home

As already noted, due to the availability and ease of processing, spring steel knives can be made at home. At first glance, there is nothing complicated about this, but you still need to know some features that affect the quality of the output product. On the Internet you can find many videos describing the process of forging, hardening the blade and making the handle.

In general, spring steel can be used to make both professional edged weapons with remarkable characteristics and elegant shape, as well as ordinary knives for household needs, which are not inferior in durability and strength.

First you need to decide for what purposes and what exactly will be done. If it's a kitchen knife, any sheet will do. And if you want to make a machete, sword or ax, then it is better to choose a spring from a truck. Of course, to make knives with the best characteristics, it is better to purchase steel from a manufacturer. For household purposes, old used material is useful. The leaf spring can be from 5 to 8 mm thick, depending on the car. Truck steel is traditionally stronger, so it should be used for long, strong blades.

Standard UAZ spring type 3163-2912010-02

This standard low-leaf element has the following characteristics:

- Ultimate load, Pk, daN – 504.7.

- The weight of the assembled part is 17.3 kg.

- The total length is 1.42 meters.

- The height of the package is 37.2 mm.

- The number of sheets is three pieces.

- Manufacturing material – steel type 50HGFA.

The UAZ Patriot springs in question are also suitable for models 315148, 315143, 315196, Hunter, Simbir and Cargo. This part differs from its analogue 315112-2912012 in length and tightening clamp, as well as the presence of gaskets between the sheets.

Four-sheet version 3153-2912010

A rear leaf spring of this type is mounted on UAZ models under the index: 3153, 3159, 3162. The part can be used on models 315148, 315143, Hunter, Patriot, 3163, 2362, Cargo. The modification in question is very popular among owners of cars from Ulyanovsk manufacturers.

Below are its main parameters:

- Control load, Pk, daN – 643.8.

- The weight of the assembled element is 21.4 kg.

- The total/calculated length of the part is 1.42/1.35 m.

- The height of the package is 49.6 millimeters.

- The number of sheets is four pieces.

- The material of manufacture is steel grade 5-HGFA.

Modification 3162-2912010

This UAZ spring is a standard part that is mounted on the rear axle of almost all cars of this brand, including Patriot, Bars, Hunter and Cargo. This spring is quite rare on sale, and therefore is not particularly popular among owners.

- Ultimate load, Pk, daN – 643.75.

- Weight when assembled: 21.4 kg.

- The total/calculated length of the part is 1.42/1.35 m.

- The height of the package is 49.6 mm.

- Number of sheets – four pcs.

- Manufacturing material – steel 50HGFA.

Spring from Moskvich. does it make sense to forge?

Hello, dear ones! Help me decide: I have a “humpbacked” Moskvich spring, does it make sense to reforge it on itself or anneal it, level it, etc. Sheets are a full package, do they differ in quality (short-long) With respect and gratitude to those who responded!

The springs, as I understand it, were running? Then there was information on this topic that in tired springs there are microcracks that are undetectable by the eye. Total - straightened, forged, hardened, burst. Do you need it? On the other hand, when producing “sergeant’s” katanas, the Japanese considered monometal, boiled on itself a couple of times, to be of higher quality than the same “simply forged.” On the third hand, for “just knives” anything will do.

Good material. 65G, I think. it will definitely work. And about the cracks. Well, he can really weld it with him and forge it thoroughly.

Old Muscovites had 65G. For indestructible knives (Leukku, Kukri) - this is it. But for delicate cutting, IMHO, not very good.

THANK YOU! Please write a few words about proper reforging for yourself! Best regards,

Correctly, this is not here, this is to Kuznetsov. And so, if it’s stupid from experience, then boiling it twice (a couple of dozen layers) is more than enough. Well, pull the blade back without overheating, if you’re not too lazy.

I looked in the book for Moskvich 407/403. Steel 50HGA

I looked in the book for Moskvich 407/403. Steel 50HGA

65G is not born on car springs. 65G is used for small things, which the spring does not belong to. there are collets, small springs, and other trinkets.

65G is not born on car springs.

Characteristics of material 65G

Brand: 65G Substitute: 70, U8A, 70G, 60S2A, 9ХС, 50ХФА, 60С2, 55С2 Classification: Structural spring steel Application: springs, leaf springs, thrust washers, brake bands, friction discs, gears, flanges, bearing housings, clamping and feed collets and other parts that require increased wear resistance, and parts that operate without shock loads.

this is all very cool. there's only one thing to eat there.

working without shock loads.

Udod

Old Muscovites had 65G. For indestructible knives (Leukku, Kukri) - this is it. But for delicate cutting, IMHO, not very good.

AND “DILICATELY” CUT EVEN VERY VERY MUCH. SINCERELY .

AND “DILICATELY” CUT EVEN VERY VERY MUCH. SINCERELY .

I believe that the biggest myth about springs is that they are made from 65G steel. Almost everyone understands this, spring = 65G. And in order to find this same 65G in the springs, you’ll have to “run around”!

Oh, yes, on topic - of course you can forge!