Mechanical properties of metals and alloys

The main mechanical properties of metals include strength , toughness , ductility , hardness , endurance, creep, wear resistance. They are the main characteristics of a metal or alloy .

Let's consider some terms used to characterize mechanical properties. Changes in size and shape that occur in a solid under the influence of external forces are called deformations, and the process that causes them is called deformation. Deformations that disappear upon unloading are called elastic, and those that do not disappear after the load is removed are called residual or plastic.

Voltage

is the magnitude of the internal forces that arise in a solid body under the influence of external forces.

The strength of a material is understood as its ability to resist deformation or destruction under the influence of static or dynamic loads. Strength is judged by the characteristics of mechanical properties obtained during mechanical tests. Static strength tests include tension, compression, bending, torsion, and indentation. Dynamic tests include tests for impact strength, endurance and wear resistance. Elasticity is the ability of materials to deform elastically, and plasticity is the ability to deform plastically without destruction.

Viscosity

- this is a property of a material that determines its ability to absorb mechanical energy with a gradual increase in plastic deformation until the destruction of the material. Materials must be both durable and ductile.

Hardness

is the ability of a material to resist the penetration of other bodies into it.

Endurance

- this is the ability of a material to withstand, without collapsing, a large number of repeatedly variable loads.

Wear resistance

is the ability of a material to resist surface destruction under the influence of external friction.

Creep

- this is the ability of a material to slowly and continuously plastically deform (crawl) under constant stress (especially at high temperatures).

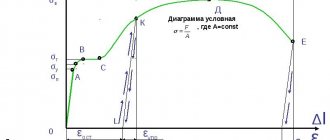

The behavior of some metals (for example, annealed steel) under tensile testing is shown in Fig. 3

. As the load increases, processes of elastic deformation first develop in the metal, and the elongation of the sample is insignificant. Then plastic flow of the metal is observed without increasing stress; this period is called fluidity. The stress at which the sample continues to deform without a noticeable increase in load is called the yield strength. With a further increase in load, hardening processes (hardening under load) develop in the metal. The highest stress preceding failure of the sample is called the tensile strength.

Rice. 3. Diagram of deformation during tensile testing of metals.

Tense state

- this is the state of a body under the influence of balanced forces, with established elastic equilibrium of all its particles. Residual stresses are stresses that remain in the body after the cessation of external forces, or that arise during rapid heating and cooling if the linear expansion or shrinkage of metal layers and body parts occurs unevenly.

Internal stresses are formed during rapid cooling or heating in temperature zones of transition from the plastic to elastic state of the metal. These temperatures for steel correspond to 400-600°. If the resulting internal stresses exceed the tensile strength, then cracks form in the parts; if they exceed the elastic limit, then warping of the part occurs.

Tensile strength in kg/mm2

is determined on a tensile testing machine as the ratio of the load P in kg required to destroy a standard sample (

Fig. 4, a

) to the cross-sectional area of the sample in mm2.

Rice. 4. Methods for testing the strength of materials: a - tensile; b - bending; c - impact strength; g - for hardness

Bending strength in kg/mm2

is determined by the destruction of the sample, which is installed on two supports (

Fig. 4, b

), loaded in the middle with a concentrated load P.

To establish the plasticity of a material, the relative elongation δ during tension or the deflection ƒ during bending is determined.

Relative elongation δ in %

determined on samples tested for tension. Divisions are applied to the sample (Fig. 4, a) and the distance between them is measured before testing (l0) and after destruction (l) and the elongation is determined

δ = l-lo / lo 100%

The bending deflection in mm is determined using a machine deflection meter, indicating the deflection ƒ formed on the sample at the moment of its destruction (Fig. 4, b).

Impact strength in kgm/cm2 is determined on samples ( Fig. 4, c

), subjected to destruction on a piledriver by the blow of a pendulum retracted to the side. To do this, the work of deformation in kGm is divided by the cross-sectional area of the sample in cm 2.

Brinell hardness (HH) is determined on the cleaned surface of the sample, into which a steel ball is pressed ( Fig. 4, d

) with a diameter of 5 or 10 mm under a corresponding load of 750 or 3000 kg and measure the diameter d of the resulting hole. The ratio of the load in kg to the hole area πd2 / 4 in mm2 gives the hardness number.

Indicators for mechanical properties for the main alloys are given in table. 1

.

Physical properties of metals

The mechanical and chemical properties of metals are most interdependent with each other, because it is the chemical composition of the metal or alloy, its internal structure (features of the crystal lattice) that dictate all its other parameters. If we talk about the mechanical and physical properties of metals, they are most often confused with each other, which is due to the similarity of these definitions.

Physical properties are often inseparable from mechanical properties. For example, refractory metals are also the strongest. The main difference lies in the nature of the properties. Physical properties are those that appear at rest, mechanical properties only under external influence. The mechanical and technological properties of metals are no worse than others. For example, the mechanical property of a metal “strength” can be the result of its competent technological processing (for this purpose, “hardening” and “aging” are often used). The inverse relationship is no less important, for example, malleability is a manifestation of good impact toughness.

Drawing a conclusion, we can say that knowing some chemical, physical or technological properties, one can predict how the metal will behave under load (i.e. mechanically), and vice versa.

What are the differences between the mechanical properties of metals and alloys?

Do the mechanical properties of metals and alloys differ? Undoubtedly. After all, any metal alloy is initially created in order to obtain specific properties. Some combinations of alloying elements and the base metal in the alloy can instantly transform the alloyed element. So aluminum (not the strongest and hardest metal in the world) in combination with zinc and magnesium forms an alloy comparable in strength to steel. All this gives practically unlimited possibilities in obtaining substances that are closest to the required ones.

Special attention should be paid to the mechanical properties of deposited metals. Welded metal is considered to be metal that was used to weld two or more parts of a metal element or structure. This metal, like threads, connects the torn parts. The safety and reliability of the entire structure will depend on how the “seam” behaves under load. Based on this, it is extremely important that the properties of the deposited metal are no worse than those of the base metal.

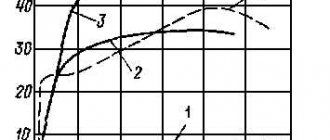

- 1. Deformation and destruction

- 2. Mechanical properties of metals

- 3. Methods of strengthening metals and alloys

LECTURE No. 6. Mechanical properties of metals

1. Deformation and destruction

The application of load causes deformation.

At the initial moment, loading, if it is not accompanied by phase (structural) changes, causes only elastic (reversible) deformation. Upon reaching a certain stress, the deformation (partially) becomes irreversible (plastic deformation), and the structure of the metal and, consequently, its properties change irreversibly. The dependence of deformation on stress is depicted by the so-called tensile diagram. Conditional voltage:

? = P / F0 (kgf/mm2),

where P is force;

F0

is the initial section, and the abscissa axis is the relative deformation:

? = ?l/l,

where ?l – length increment,

l

– initial length.

Tangent of the angle of inclination - straight line: tg ? = ? / ? = E – modulus of normal elasticity (in kgf/mm 2) – characterizes the rigidity of the material (resistance to elastic deformation), which is determined by the forces of interatomic interaction, depending to a first approximation on the melting temperature of the metal. Since alloying and heat treatment have very little effect on the melting point, the normal elastic modulus can be considered a structurally insensitive characteristic. All steels have E? 2?

10 4 kgf/mm 2, and for aluminum alloys

E ~

0.7? 10 4 kgf/mm 2.

Conditional stress at which the proportional relationship between ? and ?, is the elastic limit (or proportionality limit).

For technical purposes (except for elastic elements), a small deviation from the proportional dependence is not considered significant, and it is usually considered that plastic deformation occurs when the residual irreversible deformation ?pl. becomes equal to 0.2%. The conditional stress at which = 0.2% is called the yield strength

(in the diagram – ?0.2) and characterizes the resistance of the material to small plastic deformation.

The true stress reaches its maximum value at point Z

- at the final destruction of the sample.

For high-strength and low-plasticity materials ?B

> 150 kgf/mm 2, relative contraction ? (change in narrowing) at the site of rupture (destruction) is less than 40%, and is determined by ? according to the formula:

? = (Fо – Fх)Fо,

where F

0

is the cross section of the sample before failure;

Fx _

– section at the moment of maximum deformation.

Destruction

There can be two types, which can be called

“separation”

(repture) and

“destruction”

(wacture).

Separation is typical for highly plastic materials (usually high-purity metals), the deformation of which after reaching the point ? B

leads to 100% narrowing without the formation of a fracture surface. In all other cases, the narrowing reaches a certain value, after which the sample is destroyed with the formation of fracture surfaces.

Rice. 6. Types of torn samples: a – separation; b – failure with preliminary plastic deformation; c – fracture without preliminary plastic deformation.

The destruction process is preceded by: elastic deformation and plastic deformation.

2. Mechanical properties of metals

Mechanical properties

metals are determined by the following characteristics: elastic limit ?T, yield strength ?E, tensile strength relative elongation ?, relative contraction ? and elastic modulus E, impact strength, endurance limit, wear resistance.

Hardness,

determined by the simplest non-destructive methods, depends mainly on the carbon content and heat treatment conditions of the steel.

For a rough estimate of strength, you can use the following relationship: ?B = HB/3.

During operation, all metal parts of machines are exposed to various external loads, which can be applied smoothly, gradually (statically) or instantly (dynamically). By acting on parts, external loads change their shape, i.e. they deform. The property of materials made of metal and alloys to return to their original shape after the cessation of external forces is called elasticity,

and deformation that disappears after the load is removed is called

elastic.

If great forces are applied to a metal part and after the cessation of their action it does not take its original shape, but remains deformed, then such deformation is called

plastic.

The ability of metal materials and parts to deform under the influence of external loads without collapsing, and to maintain a changed shape after the force ceases, is called

plasticity.

Metal materials that are not capable of plastic deformation are called

brittle.

An important property of materials and parts made of metals, along with elasticity and plasticity, is strength.

Depending on the operating conditions, metal parts or tools must have certain mechanical properties - strength, elasticity, ductility.

During long-term operation, metal parts of machines are subjected to repeated, variable loads.

(tension – compression).

At stresses less than the yield strength or elastic limit, they can suddenly fail. This phenomenon is called metal fatigue.

The endurance (fatigue) limit is the maximum stress that materials and metal parts can withstand without breaking, under a sufficiently large number of repeatedly alternating loads (cycles).

For steel samples, this characteristic is set at 10 million cycles, for non-ferrous metals - at 100 million cycles. Is the limit of endurance indicated by a Greek letter? –1 and measured in Pa.

During operation, many machine parts heat up to high temperatures, reaching 1000 °C or more. For such parts, an important characteristic is heat resistance

– the ability of materials made of metals and alloys to maintain the required strength at high temperatures.

In metals and alloys that operate for a long time under load at high temperatures, the phenomenon of creep is observed,

i.e., continuous plastic deformation under the influence of a constant load (the metal “creeps”).

3. Methods of strengthening metals and alloys

Surface hardening of metals and alloys is widely used in many industries, in particular in modern mechanical engineering. It makes it possible to obtain high hardness and wear resistance of the surface layer while maintaining a sufficiently viscous core, and helps to increase durability and fatigue strength. Some surface hardening methods are highly productive. In some cases, they are used with great efficiency instead of conventional heat treatment methods. There are a large number of parts for which the properties of the surface metal layer have different requirements than the properties of the internal layers. For example, gear teeth experience strong friction during operation, so they must have great hardness, but have low hardness and good toughness so that the teeth are not destroyed by shocks and impacts. Therefore, gear teeth must be hard on the surface and tough at the core.

The most common method of hardening the surface layer of metals and alloys is surface hardening,

in which only part of the surface layer of parts acquires high hardness. The rest is not hardened and retains the structure and properties that were before hardening. Currently, surface hardening with induction heating using high-frequency currents is most widespread. This high-performance progressive heat treatment method improves the mechanical properties of steel, including yield strength, fatigue and hardness, eliminates the possibility of decarburization, and reduces the risk of oxidation of the surface of products and their deformation.

Parts of complex shape, band saws, cutting tools (mills, drills), levers, axles are subjected to pulse surface hardening. To do this, the hardened part of the part is heated to a temperature exceeding the temperature of the usual heating of this material for hardening, and then cooled at high speed due to heat removal into the rest of the part without the use of cooling media. As a result of pulse hardening, a hardened “white” layer is obtained, which is stable when tempered up to a temperature of 450 °C, has a fine-grained structure, high hardness and wear resistance.

Table of contents

Cheat sheets for exams and tests

| See also... |

| Materials Science Cheat Sheets |

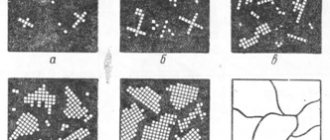

| Features of the atomic-crystalline structure of metals |

| Crystallization of metals |

| The mechanism of the metal crystallization process |

| Alloys - mechanical mixtures |

| Methodology for constructing 2-component phase diagrams |

| Alloys – solid solutions |

| Phase diagram of alloys with unlimited solubility |

| Phase diagram of alloys with limited solubility |

| Segment rule |

| Kurnakov's law |

| Mechanical properties of metals and methods for their determination |

| Iron-carbon alloys |

| State diagram of iron - carbon alloys |

| Processes during structure formation of iron-carbon alloys |

| Cast iron. Chemical composition, classification and purpose of gray cast iron |

| The influence of cooling rate on the graphitization process in gray cast irons |

| Malleable cast irons and ductile cast irons |

| The first major transformation of steel (pearlite -> austenite) |

| The second main transformation of steel (austenite -> pearlite) |

| Martensitic transformation and its features |

| Fourth main transformation (martensite transformation during tempering) |

| Steel annealing, types of annealing, mode, purpose |

| Normalization of steels |

| Hardening of steel. Conditions for complete hardening of steels. |

| Tempering of carbon steels |

| Determination of critical points in steel by test hardening. |

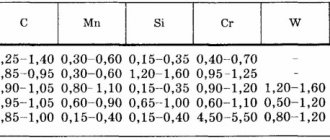

| Alloy steels, chemical composition features |

| Classification of alloy steels |

| Features of heat treatment of tool high-speed steels |

| Steel Cementation |

| Heat treatment after carburization |

| Nitriding |

| Hardening with high frequency currents |

| Temper brittleness of alloy steels |

| Tool steels |

| Die steels for cold and hot deformation of metal |

| Polymers and their classification |

| All Pages |

Page 12 of 38

Mechanical properties of metals and methods for their determination.

The main mechanical properties are strength, elasticity, viscosity, hardness. Knowing the mechanical properties, the designer reasonably selects the appropriate material that ensures the reliability and durability of structures with minimal weight.

Mechanical properties determine the behavior of a material during deformation and destruction under external loads.

Depending on the loading conditions, mechanical properties can be determined by:

1. static loading – the load on the sample increases slowly and smoothly.

2. dynamic loading – the load increases at high speed and has an impact character.

3. repeated, variable or cyclic loading - the load during the test changes many times in magnitude or in magnitude and direction.

To obtain comparable results, samples and methods of mechanical testing are regulated by GOSTs.

In a static tensile test: GOST 1497, strength and ductility characteristics are obtained.

Strength is the ability of a material to resist deformation and destruction.

Tests are carried out on special machines that record a tensile diagram expressing the dependence of the elongation of the sample (mm) on the effective load P, i.e. .

But to obtain data on mechanical properties, they reconstruct: the dependence of relative elongation on stress

Rice. 6.7. Tension diagram: a – absolute, b – relative; c – scheme for determining the conditional yield strength

Let us analyze the processes that occur in the sample material as the load increases.

Section oa in the diagram corresponds to the elastic deformation of the material when Hooke’s law is observed. The stress corresponding to the elastic limiting deformation at point a is called the limit of proportionality.

Limit of proportionality () – the maximum stress up to which the linear relationship between strain and stress is maintained.

At stresses above the proportionality limit, uniform plastic deformation occurs (elongation or narrowing of the cross-section).

Each stress corresponds to a residual elongation, which is obtained by drawing a line parallel to oa from the corresponding point of the elongation diagram.

Since it is practically impossible to establish the transition point to the inelastic state, a conditional elasticity limit is established - the maximum stress up to which the sample receives only elastic deformation. The stress at which the residual deformation is very small (0.005...0.05%) is considered.

The designation indicates the value of residual deformation.

The yield strength characterizes the resistance of a material to small plastic deformations.

Depending on the nature of the material, a physical or conditional yield strength is used.

The physical yield strength is the stress at which an increase in deformation occurs under constant load (the presence of a horizontal area on the tensile diagram). Used for very plastic materials.

But the majority of metals and alloys do not have a yield plateau.

Conditional yield strength is the stress that causes permanent deformation

Physical or proof stress are important design characteristics of a material. The stresses acting in the part must be below the yield strength.

Plastic deformation, uniform throughout the entire volume, continues until the ultimate strength value.

At point b, a neck begins to form in the weakest point—severe local fatigue of the sample.

Tensile strength is the stress corresponding to the maximum load that the sample can withstand before failure (temporary tensile strength).

Neck formation is typical for plastic materials that have a tension diagram with a maximum.

Ultimate strength characterizes strength as resistance to significant uniform plastic deformation. Beyond point B, due to the development of the neck, the load drops and destruction occurs at point C.

True fracture resistance is the maximum stress that the material can withstand at the moment preceding the failure of the sample (Fig. 6.8).

True fracture resistance is significantly greater than the ultimate strength, since it is determined relative to the final cross-sectional area of the sample.

Rice. 6.8. True Tension Chart

is the final cross-sectional area of the sample.

True stress is defined as the ratio of load to cross-sectional area at a given time.

The tensile test also determines the plasticity characteristics.

Plasticity is the ability of a material to undergo plastic deformation, i.e. the ability to obtain a residual change in shape and size without breaking the continuity.

This property is used in metal forming.

Characteristics:

· relative elongation.

and – initial and final length of the sample.

– absolute elongation of the sample, determined by measuring the sample after rupture.

· relative narrowing

— initial cross-sectional area

- cross-sectional area in the neck after rupture.

Relative narrowing more accurately characterizes plasticity and serves as a technological characteristic for sheet stamping.

Plastic materials are more reliable in operation, because... they are less likely to undergo dangerous brittle failure.

Hardness is the resistance of a material to penetration into its surface by a standard body (indenter) that does not deform during testing.

Widespread use is explained by the fact that special samples are not required.

This is a non-destructive testing method. The main method for assessing the quality of heat treatment of a product. Hardness is judged either by the depth of penetration of the indenter (Rockwell method) or by the size of the indentation mark (Brinell, Vickers, microhardness methods).

In all cases, plastic deformation of the material occurs. The greater the material's resistance to plastic deformation, the higher the hardness.

The most widely used methods are Brinell, Rockwell, Vickers and microhardness. The test circuits are shown in Fig. 7.1.

Rice. 7.1. Schemes for determining hardness: a – according to Brinell; b – according to Rockwell; c – according to Vickers

The test is carried out on a Brinell hardness tester (Fig. 7.1 a)

A hardened steel ball with a diameter of D 2.5 is used as an indenter; 5; 10 mm, depending on the thickness of the product.

Load P, depending on the diameter of the ball and the measured hardness: for heat-treated steel and cast iron - , cast bronze and brass - , aluminum and other very soft metals - .

Holding time: for steel and cast iron – 10 s, for brass and bronze – 30 s.

The resulting print is measured in two directions using a Brinell magnifying glass.

Hardness is defined as the ratio of the applied load P to the spherical surface of the indentation F:

Standard conditions are D = 10 mm; P = 3000 kgf; = 10 s. In this case, Brinell hardness is designated HB 250, in other cases the conditions are indicated: HB D / P /, HB 5/ 250 / 30 – 80.

Based on pressing into the surface of the tip under a certain load (Fig. 7.1 b)

The indenter for soft materials (up to HB 230) is a steel ball with a diameter of 1/16” (1.6 mm), for harder materials – a diamond cone.

Loading is carried out in two stages. First, a preload (10 kf) is applied to bring the tip into close contact with the sample. Then the main load P1 is applied, and the total working load P acts for some time. After the main load is removed, the hardness value is determined by the depth of residual indentation of the tip h under load.

Depending on the nature of the material, three hardness scales are used (Table 7.1)

Table 7.1. Scales for determining Rockwell hardness

Hardness concept

The hardness of a material is its resistance to destruction when a harder material is introduced into the outer layer. In other words, the ability to resist deforming forces (elastic or plastic deformation).

The hardness of metals is determined by introducing a solid body called an indenter into a sample. The role of the indenter is performed by: a metal ball of high hardness; diamond cone or pyramid.

After exposure to the indenter, an imprint remains on the surface of the test sample or part, the size of which determines the hardness. In practice, kinematic, dynamic, and static methods of measuring hardness are used.

The kinematic method is based on the compilation of a diagram based on continuously recorded readings that change as the tool is pressed into the sample. Here the kinematics of the entire process is traced, and not just the final result.

The dynamic method is as follows. The measuring tool acts on the part. The reverse reaction allows you to calculate the expended kinetic energy. This method allows you to test the hardness of not only the surface, but also a certain volume of metal.

Static methods are non-destructive methods that allow you to determine the properties of metals. The methods are based on smooth indentation and subsequent holding for some time. The parameters are regulated by methods and standards.

The applied load can be applied:

- pressing;

- scratching;

- cutting;

- rebound

Machine-building enterprises currently use the Brinell, Rockwell, Vickers methods, as well as the microhardness method, to determine the hardness of materials.

Based on the tests carried out, a table is compiled indicating the materials, the applied loads and the results obtained.

What are physical properties?

The physical properties of the material include density, porosity, water absorption, moisture release, hygroscopicity, water permeability, frost resistance, thermal conductivity, sound absorption, fire resistance, fire resistance and some others.

Interesting materials:

Where is gambling allowed? Where are all the games saved? How to adapt the game for Windows 10? How to get free diamonds in Cooking Fever? How to get free games on Xbox? How to get cardamom for free in the game My Coffee Shop? How to quickly switch game mode in Minecraft? How to quickly level up in the game Hay Day? How often were the 5th grade Olympic Games held? How often were the Olympic Games held? How many days did they last? History 5th grade?