Corrugated sheets have been actively used in construction and in many other areas for several decades. This reliable material, the production of which requires a special machine for the production of corrugated sheets, is used as the main element of enclosing structures, it covers the roofs of building structures, cladding walls, and also solves a whole list of other problems associated with both capital and private construction.

Corrugated sheets are produced by cold rolling

The production of profiled sheets can be carried out using both mechanized and manual equipment, which, if desired, can be made with your own hands. Knowing all the nuances of such production, you can organize a profitable business for the production of profiled sheets that are in demand on the market or produce such material for your own needs at minimal cost.

Passivation and priming

The strip of now galvanized steel is then coated with a chromate conversion coating and preservative oil. This is a type of coating used to passivate steel products. It is needed to make the steel last even longer.

Steel is coated with a special layer of salts and oxides that prevent it from deteriorating.

Next, a primer coating is applied using a special painting machine.

It additionally protects the steel from destruction, providing strong adhesion between the polymer coating and the metal, leveling out defects on it.

The final stage is the application of the polymer.

Application of polymer

The polymer coating is applied using a U-shaped painting machine. It plays an important role for everyone who organizes their own production of corrugated sheets. This machine has two heads (A and B) for front coating and a lower head (C) for back coating.

The presence of two pairs of paint heads allows you to transition from one paint color to another without stopping the line. While one painting head is in operation, the second one can be prepared for subsequent painting with a different color.

After coating, the products are dried in a convector gas oven. This is necessary to achieve a metal temperature that will allow the solvent to evaporate, providing the necessary polymerization. The drying mode is set by the technologist.

The dried, painted metal is placed in an air-cooling chamber. This is done to reduce the temperature of the strip. Then it (the strip) is placed in a water cooling section, which will avoid temperature shock and deformation of the metal.

After applying the polymer layer, the colored strip passes through the belt feeding mechanism onto the winder mandrel to wind the strip into a roll.

Using a hydraulic trolley, the roll is removed from the winder and fed to storage stands. The dyed roll is then transported by overhead crane to a special area for packaging.

Protective layers of corrugated sheeting, ranging from passivating to polymer, are designed to prevent the occurrence of corrosion on steel.

The polymer coating provides the profiled sheet with the desired color, attractive appearance, and protects the steel from fading in the sun and from mechanical damage.

Production technology

The production of profiled sheets begins with calculations of the mathematical shape of the corrugation. The thickness of the raw material is also selected and the type of protective coating is chosen. After installing and debugging the roll forming equipment, you can launch the line and begin producing rolled metal. The technological stages of rolling profiled sheets are as follows:

- The metal roll is fed through a lift and fixed on the unwinder. After installation, the edge of the belt is released and the receiving part of the rolling machine is directed. It is important to ensure that the roll is securely attached to the device.

- The strip enters the rollers and gradually, passing through the stands, is bent in accordance with the specified parameters. It is impossible to give the metal a profile shape in one go, since the material tends to return to its previous position.

- At the end of the rolling line, a guillotine cuts the finished sheets to the specified length. The plates fall onto the roller table. Afterwards, you can begin coloring the finished product, if this was originally planned.

The finished corrugated sheet can be loaded into the packaging section of the workshop. There they mark and wrap stacks of profiled sheets in film. Finished and packaged products can be transferred to a warehouse for storage or removed from the workshop. If the production is fully automated, but to control the machine itself, no more than 3-4 people will be required, one of whom will work with the control unit. In the case of semi-automatic equipment, it will also be necessary to hire workers for the guillotine.

Quality checking

Next comes the quality control stage. This is what is needed to produce reliable corrugated sheets. has its own laboratory. Here they check the impact and bending strength, the hardness of the polymer coating, the adhesion of the coating to steel, the color difference in comparison with the standard, the gloss and thickness of the coating. The work is carried out by experienced and highly qualified employees. Thanks to constant monitoring, our customers can be confident in the quality of our products.

Workplace of a process engineer for conducting tests.

produces profiled sheets with polymer coating (painted and galvanized) and without it (galvanized only). Painted corrugated sheeting is a more aesthetically pleasing material than galvanized sheeting. It is used in various fields of application: from cladding facades to the construction of durable permanent fencing. The decorative layer of coated corrugated sheets protects from external natural influences - sun, rain and snow.

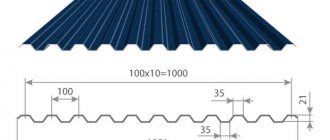

Dimensions of corrugated sheeting of all brands, technical characteristics, types of trapezoids in production

| Profiled sheet C8 For walls, facade, fence

| Profiled sheet C10 For walls, facade, fence

| Profiled sheet S20, MP20 For roofing, walls, facade, fence

|

| Profiled sheet C21 For roofing, walls, facade, fence

| Profiled sheet MP35 For roofing, walls, facade, fence

| Profiled sheeting NS35 For roofing, ceilings, load-bearing

|

| Profiled sheet C44 For roof, facade, walls

| Profiled sheeting NS44 For roofing, ceilings, load-bearing

| Profiled sheet N57 For roofing, ceilings, load-bearing

|

| Profiled sheet N60 For roofing and load-bearing structures

| Profiled sheet N75 For roofing and load-bearing structures

| Profiled sheet N114 For roofing and load-bearing structures

|

Profiling

The automated process of manufacturing corrugated sheet steel can be described in a few phrases. The roll is installed on an unwinder, which ensures correct and uniform feeding of the sheet. The end of the sheet is inserted into the forming machine of the rolling mill. The main parameters are entered into the automatic control system, which include the rolling speed and the number of corrugated sheets. After adjusting the parameters, the equipment starts up. The profile on the sheet appears gradually, passing through many shafts. By the end of the rolling line it turns into a full-fledged profiled sheet. After profiling, the product is cut with hydraulic shears according to the required parameters. Produced on high-tech lines and having gone through all stages of strict control, corrugated sheets meet the highest quality standards.

Types of equipment for the production of corrugated sheets

Any equipment for the production of corrugated sheets operates according to a standard scheme. To give it the required configuration, a flat steel sheet is driven through a system of rollers equipped with a machine used for the production of corrugated sheets. As a result of this technological operation, the flat steel sheet is deformed, acquiring the required geometric shape.

The dimensions and shape of the rolls depend on the configuration of the profiled sheet produced on the machine

As mentioned above, the main raw material from which profiled sheets are made is sheet steel supplied from manufacturing plants in rolls. If the steel sheet rolled into such a roll has a small thickness, then unfolding it will not be a big problem: this can even be done manually. The situation is completely different if it is necessary to use sheet steel of considerable thickness for the profiled sheet. In this case, the machine used for the production of profiled sheets needs to be equipped with an additional device that will be responsible for bending sheet metal of considerable thickness.

The machine for corrugated sheeting, depending on the required performance, can be equipped with a manual or mechanized drive. Of course, the manual machine for the production of corrugated sheets has a simpler design. Meanwhile, when deciding to use such equipment, you should keep in mind that working on a manual machine for the production of profiled sheets requires significant physical effort, so using such a device for the production of profiled sheets of significant thickness is problematic.

Manual profile bending machine LSP-2000 is designed for the production of profiled sheets or brackets from metal up to 0.55 mm thick

Meanwhile, manufacturing at home a machine equipped with a mechanized drive for the production of corrugated sheets is also associated with certain difficulties. The fact is that such equipment for corrugated sheeting must have a device that ensures cutting of profiled sheets into products of a certain length. To perform this technological operation, ordinary guillotine shears are not suitable, since this requires devices whose working bodies in their shape completely correspond to the configuration of the profiled steel sheet.

The profile is formed on a specialized line at a rolling mill

There are two technologies that can be used to produce corrugated sheets using specialized equipment. The first of them is called simultaneous profiling and involves immediately deforming both sides of the steel sheet used to make the profiled sheet. Machines for the production of corrugated sheets, operating on the principle of sequential profiling, separately deform each side of the steel sheet.

The greatest efficiency in the production of corrugated sheets is a specialized line for the production of corrugated sheets, the structure of which already contains all the necessary equipment.

Slicing and packaging

Lastly, the sheets are cut to the required length. All dimensions of corrugated sheets depend on the type of profile; the required length of sheets is indicated by the customer.

Our equipment allows us to make sheets of any size in the range from 0.5 to 12 meters.

Modern high-precision equipment allows us to eliminate the “human factor” from production. All necessary parameters for the manufacture of the product are set by the operator in the automatic control system. Highly qualified personnel work in the workshops for the production of corrugated sheets.

The quality of finished products is controlled by quality control department. Before production begins and at the end of the finished product, samples are taken. The input section operator (using electric scissors) takes a sample from the first roll of a new batch and passes it to the quality control inspector. Quality control is also carried out according to GOST.

Modern equipment allows us to eliminate the “human factor” from production.

The finished corrugated sheet is placed on pallets, covered with bubble wrap and secured with metal ties.

After packaging, orders are placed in a warehouse, from where they are then sent to the end consumer.

Corrugated sheets are well suited for roofs, facades and fences.

Production line structure

To ensure high quality of products, corrugated sheet production lines must be equipped with the following mechanisms and devices.

- In such a line, a mechanism is required that ensures the fixation of rolls of sheet steel, as well as their unwinding. The production of steel profiled sheets on an industrial scale involves the use of sheet metal rolls as raw materials, the weight of which can reach up to ten tons. It is almost impossible to manipulate such rolls without the use of special devices.

- A special device allows you to automatically regulate the degree of sagging of the workpiece between the unwinding mechanism and the receiving part of the machine. A line for the production of corrugated sheets, as a rule, processes sheet metal at high speed, which simply does not allow manual adjustment of the sagging of the workpieces.

- To ensure high productivity and the required quality of manufactured products, professional equipment for the production of metal profiles is equipped with several groups of work rolls. These groups of rolls, called stands, perform various functions as part of an automated line for the production of profiled sheets. Typically, these stands, consisting of a varying number of work rolls, are used to load sheet metal into the processing area of the equipment, to perform work operations and to unload the finished product from the machine.

- The production line has a drive mechanism that must have sufficient power to ensure high productivity of technological operations associated with the production of profiled sheets by rolling.

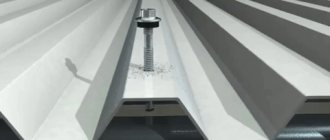

- The cutting device that is equipped with professional equipment for the production of corrugated sheets must ensure high-quality cutting of the finished product, without the formation of burrs and bends on its edges. The presence of such defects significantly reduces the cost of the finished product.

- A machine for the production of corrugated sheets on an industrial scale must also be equipped with a compartment in which finished products are stored.

Structure of an automatic corrugated sheet production line

A production line intended for the production of corrugated sheets can be controlled by an automated system or a simpler device that is not able to provide the required level of automation of the technological process. Meanwhile, even operators with a low level of qualifications can use a machine for corrugated sheeting, controlled by a simpler device.

Result:

Since the 19th century, corrugated sheets have become one of the most popular building materials. We have everything you need to produce profiled sheets. We make reliable profiled sheets for roofs, facades and fences. Qualified employees and the presence of our own laboratory guarantee quality control of corrugated sheets at every stage of its production. Thanks to our own production, we are able to provide affordable prices for corrugated sheets. Select the desired profiled sheet and order it in our online store.

* Detailed information about warranty periods for products can be obtained on the website metallprofil.ru in the “Documents” section.