Selecting a countersink for mounting a countersunk screw

Press releases 01/15/2020 10:53

Countersunk head screws are fasteners that are widely used in mechanical engineering, instrument making, furniture manufacturing, electrical engineering and many other industries. Their design allows you to maintain a smooth surface at the junction of parts. Thanks to this, the fastener remains invisible and does not create interference.

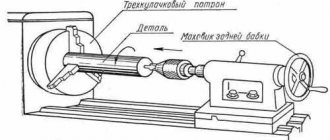

Installation of the fastener is carried out in a pre-prepared hole with internal threads made in the parts to be connected. To install a countersunk screw, the mounting socket undergoes so-called countersinking, during which a cone-shaped recess is made on its output part, corresponding to the shape of the head. To perform this operation, a special tool is used - a conical countersink. It allows you to perform countersinking with a hand drill or on a metalworking machine.

How to make a countersink

Countersinks are manufactured based on the Russian standard GOST 14953-80 or foreign standards DIN 334, DIN 335 and others. Their main parameters are the outer diameter of the head and the cone angle. The outer diameter of the countersinks ranges from 5 to 80 mm. The cone angle of countersinks produced according to the Russian standard is 60, 90, 120°. The most common screws in Russia are countersunk head screws with an angle of 90°. American hardware often has a head angle of 82°, screws with British threads have an angle of 100°.

The hole must be countersunk exactly to a depth equal to the height of the head of the countersunk screw. The angle of the countersink cone must be precisely matched to the angle of the head of the fastener. Only if these conditions are met will the hardware, when screwed, sit flush with the surface of the base. If the countersink is selected incorrectly, the fastening element will not fit into the countersunk. If you select a smaller tool, the screw head will protrude above the surface. If you choose a larger countersink, the plane of the upper surface of the head will plunge into the mounting hole.

Given these conditions, it is important to select the correct countersink for processing mounting holes for countersunk screws. The selection of tools for machining holes is carried out according to the tables of the relevant standards. The tables indicate the countersink dimensions corresponding to the main characteristics of the screw:

- thread diameter;

- head diameter;

- head height.

The countersinking tool is selected specifically for each screw size. This allows you to ensure exact compliance of the mounting hole with its geometry and achieve optimal quality of hardware installation.

| Tags: countersunk screw, installation, countersink |

| If you find an error in the text, highlight it and press Ctrl + Enter |

[ ]

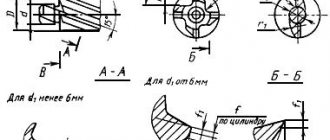

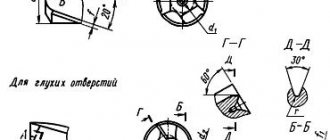

There are two main types of conical countersinks:

with cross hole

This is a cone-shaped cutting tool equipped with a hole passing through the side of the cone. The hole forms two cutting edges on the cone and is a channel for removing chips during the cutting process. This tool is best suited for working with wood, plastic and other soft materials. It is also advisable to use it to remove burrs left after a previous operation.

with multiple cutting edges

This is a multi-blade tool for working on metal, the working conical part of which consists of 3 to 12 cutting edges. Made from hardened high-speed steel. The larger the diameter of the cone, the more cutting edges it has. The tail part, with which it is attached to the cartridge, can be cylindrical, conical (Morse cone) or hexagonal (bit).

Note: Countersinks should be distinguished from countersinks, since this metal-cutting tool is designed to solve other technological problems, namely, to improve the surface quality of drilled holes.

Materials and protective coatings

The following types of materials are usually used for the production of countersunk screws:

- carbon and alloy steels;

- stainless steels;

- alloys of non-ferrous metals.

The material is selected according to the required strength characteristics and operating conditions of the products, for example, exposure to moisture and aggressive environments. In accordance with GOST 17475-80, there are 11 strength classes for this type of hardware. Screws made from carbon and alloy steel are usually coated with a protective coating, which prevents corrosion of the metal and significantly extends the life of the fastener. Most often, zinc coating is performed. Many fasteners, especially those designed for increased loads, are produced with a zinc lamellar coating.

How to choose the countersink size?

In order for the screw to fit perfectly into the countersunk, it is important to select the correct conical countersink for the head of the hardware and countersink the hole to an exact depth equal to the height of the head. The angle of the tool must correspond to the angle of the head cone, and its diameter must correspond to the diameter of the head. If you take a countersink that is too large, the head will sink into the “crater” of the hole, and if it is smaller, then it will protrude above the plane, which also does not look aesthetically pleasing.

The GOST 12876-67 standard specifies the dimensions of the supporting surfaces for fasteners with countersunk and semi-countersunk heads. Based on this data, we have compiled a table that will help you quickly determine which countersink is suitable for a particular screw thread diameter.

Table 1. Countersink size for the screw head (including tolerances).

| Thread diameter d, mm | Standard head sizes | Countersink diameter, mm | Maximum deviations, mm | |||

| Diameter, mm | Height, mm | D1 (to H13) | D2 (by H12) | D3 (to H14) | ||

| 2.0 | 3.8 | 1.2 | 4.3 | 4.6 | 4.3 | — |

| 2.5 | 4.7 | 1.5 | 5.6 | 5.7 | 5 | — |

| 3 | 5.6 | 1.65 | 6.3 | 6.6 | 6 | 7 |

| 3.5 | 6.5 | 1.93 | 7.3 | 7.6 | 7 | — |

| 4 | 7.4 | 2.2 | 8.3 | 8.6 | 8 | 9 |

| 5 | 9.2 | 2.5 | 10.4 | 10.4 | 10 | 11.5 |

| 6 | 11 | 3 | 12.4 | 12.4 | 11.5 | 14.5 |

| 8 | 14.5 | 4 | 16.5 | 16.4 | 15 | 18.5 |

| 10 | 18 | 5 | 20.5 | 20.4 | 19 | 22 |

| 12 | 21.5 | 6 | 24.0 | 24.4 | 23 | 26 |

| 14 | 25 | 7 | 28.0 | 28.4 | 26 | — |

| 16 | 28.5 | 8 | 31.0 | 32.4 | 30 | — |

| 18 | 32.5 | 9 | 35.0 | 36.4 | 34 | — |

| 20 | 36 | 10 | 39.0 | 40.4 | 37 | — |