09.29.2015 Author: VT-METALL

Many people offer custom aluminum cutting services, but only in our company is this truly beneficial to the client. For several reasons: the entire process is automated, which ensures cutting quality, the equipment can operate continuously for bulk orders. In addition, deadlines are strictly adhered to. And all this at affordable prices, with the ability to order prompt delivery of finished products.

Since laser cutting of aluminum is one of the most high-tech processing methods, it is used most often. With its help, it is possible to obtain a neat, clean cut of metal, economical cutting of sheets, high productivity and saving time, which will affect the final price of the workpieces.

Cutting methods

There are many options for dividing metal into small parts. Conventionally, they are divided into mechanical and thermal. In the first case, metal cutting is carried out using sharp blades of certain tools, in the second - by heating the cutting surface in order to melt the surface.

Thermal methods include:

- plasma;

- waterjet;

- laser cutting.

Mechanical methods:

- milling cutting;

- saw;

- guillotine;

- Bulgarian

The features of each method are discussed below.

What does the price consist of?

As mentioned above, the popularity of laser cutting services is growing every year, especially since metal can be cut along a pre-drawn contour.

The cost of processing aluminum, the most problematic and popular material, is practically no different from other metals.

Video:

The cost is influenced by factors such as: the thickness of aluminum or its percentage in the alloy, volume and complexity of cutting parts.

Also urgency: the higher it is, the higher the cost of services and types of cutting.

Work on cutting parts can be carried out from material provided by the customer, which must meet the following requirements:

- 3000x1500 mm – maximum sheet size;

- The metal sheet must have technological margins of 10 centimeters on each side;

- The sheet must be clean, that is, without corrosion, dents and other defects, and it must also be degreased first if there are oily stains on it.

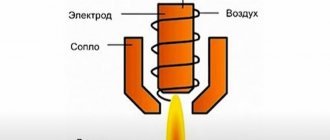

Plasma cutting

One of the best ways to get a perfectly straight cut. Plasma obtained by combining air with oxygen, argon, nitrogen, and hydrogen is suitable for cutting aluminum sheets. For example, for workpieces up to 20 mm thick, pure nitrogen is sufficient, and for workpieces up to 100 mm, nitrogen with oxygen taken in a 5:1 ratio. Argon and nitrogen should not be mixed as this combination is used for plasma cutting of alloy steel.

The resulting plasma stream removes particles of molten metal from the surface. Cutting speed depends on a number of factors, including:

- sheet steel thickness;

- gas pressure (flow);

- current strength of the plasma installation.

You can cut aluminum using plasma manually, but the mechanized method gives the user more options. Its advantages are high productivity and material savings. The disadvantage manifests itself at the end of the work - it is necessary to process the edges that have hardened after the cutting area has cooled.

What is the essence of this processing method?

In laser cutting, a highly concentrated beam of heat is applied very quickly to a specific area of the aluminum sheet. The process takes place instantly, accurately, with virtually no production waste, which allows for rational use of metal.

But at the same time, there are also nuances associated with the strong reflective property of aluminum. It is more difficult to cut on laser machines and requires high beam power. Therefore, the quality of cutting and its speed will directly depend on the equipment used, the thickness of the aluminum workpiece and the aluminum content in the alloy (percentage).

The complex technological cycle of aluminum cutting is carried out with high quality on our company’s machines. They are equipped with CNC, so the process is controlled from start to finish. There are pulse and continuous cutting modes that give equally high-quality results.

Waterjet cutting

The method with a stretch can be classified as thermal, since such an effect is almost absent. The waterjet unit has a pump that produces a high-pressure jet. Water is mixed with an abrasive (usually quartz sand), after which the mixture is fed at high speed to the cutting area. The thickness of the jet is 1/10 mm or slightly more; cutting into the surface, it cuts aluminum with ease.

Advantages of the method:

- high performance;

- during operation, the metal is not affected by pollutants, since they are removed by water flow;

- accuracy of work;

- quality of surface treatment.

Flaws:

- installation cost is millions of rubles;

- impossibility of using the method at home;

- rapid wear of equipment consumables.

Laser cutting

It is carried out by exposure to a laser beam generated by high-power equipment. Laser cutting of aluminum is considered the most popular method for a number of reasons:

- a minimum of time is spent on metal processing;

- saving material;

- almost complete absence of surface defects;

- It is easy to use a laser to cut even complex contours (sharp corners, diameters);

- modern installations are easily adjusted to certain conditions (for example, to the thickness of sheets);

- material deformations are excluded.

Cutting aluminum with a laser beam is possible on solid-state and gas-type devices. The latter are considered preferable because they operate continuously (the former only in pulse mode).

In parallel with the laser beam, an air flow is supplied to the processing site, blowing away molten pieces of metal from the edge. This ensures a smooth surface at the exit.

Experts recommend performing laser cutting at low speeds to reduce the likelihood of deformation to zero. It is recommended to use nitrogen for the same purpose.

Working with the settings is elementary - parameters are set in the program in accordance with the drawing, the equipment is started, and the user waits for the end of the work. In addition to minimizing the use of human resources, the advantages of laser cutting are energy savings, as well as the low cost of equipment (compared to waterjet). There are few disadvantages, but they do exist:

- the key element is the laser; if it breaks down, all equipment becomes faulty and work stops;

- cutting speed is high, but not constant;

- a prerequisite is that the thickness of the aluminum does not exceed 20 mm.

Cutting of rolled aluminum.

We cut rolled aluminum alloys of any grade in all delivery conditions and thickness ranges. We carry out cutting of material, making holes, chamfers, etc. When processing, we take into account the characteristics of aluminum alloys: their ductility, fusibility and chemical activity at elevated temperatures. Accuracy and efficiency of execution are guaranteed.

Aluminum plates.

Aluminum plates in accordance with GOST 17232-99 have a thickness of 11-200 mm. Cutting semi-finished products of such dimensions is effectively handled using plasma and waterjet cutting. These methods produce clean, clean cuts with minimal waste and exceptional productivity. The high thermal conductivity of aluminum facilitates the task of cooling the heat-affected zone for massive workpieces.

Sheet aluminum.

Aluminum sheets do not exceed 10 mm in thickness. In this case, the choice of processing method is determined by the task facing the master:

- simple cutting of workpieces of small thickness is ensured on a guillotine;

- serial production of products with increased requirements for the accuracy of the surface formed by cutting involves the use of automated waterjet cutting technologies, laser or plasma;

- The methods given in the previous paragraph allow you to obtain products with complex contours.

Cooling the material when using thermal cutting methods avoids warping or melting of the product.

Aluminum circles.

Circles (cylindrical blanks) according to GOST 21488-97 can reach a diameter of 300 mm. The method of cutting round rolled products is selected depending on its thickness. Workpieces of small thickness are separated mainly by mechanical cutting methods - with a circular saw or on a band saw.

Aluminum rods.

The rods are similar in shape to circles, but their cross-sectional diameter is up to 80 mm. The task of cutting workpieces of this kind is handled using mechanical cutting. Coated products are processed in accordance with the manufacturer's instructions.

Milling

The uniqueness of the method is that it can work with complex surfaces, incl. with screws. It is imperative to configure the milling equipment specifically for working with aluminum, that is, select the type of cutter and its speed in accordance with the recommendations.

Modern CNC machines with 3D design capabilities are not inferior to laser and plasma devices in terms of cutting accuracy. They are used to create cast forms, volumetric aluminum products, and complex structures. However, there is a drawback in working with the equipment - the risk of deformation and the appearance of defects on the surface increases due to the high plasticity of the material.

Using different saws

Band saws and circular saws are suitable for cutting aluminum. Advantages of the first:

- small cutting width;

- possibility of angular processing;

- compactness.

If the user regularly faces the need to cut aluminum, he can find a home installation option that is small in size.

The design of modern devices includes useful devices, including a rotating saw frame, a thread (band) tension meter, a variator for smoothly changing cutting speeds, and a built-in saw blade cleaning system. The quality of the equipment is comparable to laser and plasma, only the master will save a lot (on money, work time and space).

Band saws allow cutting aluminum profiles with a diameter of up to 300 mm with an error of less than 0.5 mm. Therefore, they are used even at home.

The second type of saw used when cutting aluminum is a circular saw. They are divided into frontal and die-cutting, can look like a floor-standing or table-top machine, and have one or two working heads. Devices in the mid-price range have clamps for fixing the workpiece at an angle. The active element - a disk with a diameter of up to 550 mm - must have diamond coating on the teeth and indicate that it is suitable for cutting aluminum.

Advantages of working with circular saws:

- modern installations guarantee operator safety during operation;

- automatic cutting possible;

- smooth feeding of the cutting element;

- availability of waste compartments.

Disc material - high-speed steel (HSS marked). Some installations allow the workpiece to be rotated at an angle of up to 45 degrees for ease of operation.

Cutting with an angle grinder

The devices are known as “grinders”. It’s worth noting right away that cutting aluminum with a tool is difficult, since it has a soft, viscous structure. But processing the material is still possible, it just requires specific actions.

For example, when cutting thick aluminum sheets, kerosene is dripped onto the cut site so that the cutting disc does not get stuck in the metal. You also need to buy a circle suitable specifically for aluminum; otherwise, the efficiency and safety of work will be reduced.

The advantages of cutting with a grinder are speed, efficiency, and relatively thin cutting width. It is important for the user to remember that the force is applied only in the radial direction.

Aluminum is a special material with specific properties, so the cutting technology is chosen differently than for the same steel. The choice of processing method, process control, and correct setting of initial parameters (when working with automated installations) are important for the user. Mistakes are unacceptable - plastic and tough aluminum will not forgive a miscalculation.

If you know other effective ways of how and with what to cut aluminum, share your knowledge in the discussion about the material.

Aluminum cutting services

Aluminum cutting technologies in Moscow surprise not only with their variety, but also with their price range.

The simplest and cheapest methods are considered to be mechanical cutting - using manual and automatic saws or guillotine equipment. But these cutting technologies are not always highly accurate, and if cutting aluminum sheets is performed by a non-professional, there is a high risk of defects. If the quality and accuracy of work are the determining factors, cutting services are usually turned to “hot” technologies - gas, plasma and laser.