Aluminum injection molding is one of the popular metal processing processes, from which products of any desired (even the most complex) configuration are created using exposure to high temperatures. Aluminum die casting is used in production to create high-quality, durable and reliable parts with unique properties.

The described process is one of the fully mechanized manipulations, during which molten metal is fed into a special split mold under artificially created pressure using a piston moving at a fairly high speed.

This method of casting guarantees no shrinkage and a high level of precision in the work. In the process of such creation of parts, the existence of defective products is practically excluded. This is one of the most important advantages of the described process. Parts and other products created in this way have found application in:

- instrument making;

- mechanical engineering;

- aircraft manufacturing

Aluminum is a soft but very durable metal that is difficult to process in various ways, but has a fairly low melting point, which allows it to be cast even at home or in a small workshop. Of course, the most accurate, streamlined process is possible when using professional equipment installed in production workshops.

We will advise you on any questions!

Have a question?

Our services

Aluminum injection molding is one of the popular metal processing processes, from which products of any desired (even the most complex) configuration are created using exposure to high temperatures. Aluminum die casting is used in production to create high-quality, durable and reliable parts with unique properties.

The described process is one of the fully mechanized manipulations, during which molten metal is fed into a special split mold under artificially created pressure using a piston moving at a fairly high speed.

This method of casting guarantees no shrinkage and a high level of precision in the work. In the process of such creation of parts, the existence of defective products is practically excluded. This is one of the most important advantages of the described process. Parts and other products created in this way have found application in:

- instrument making;

- mechanical engineering;

- aircraft manufacturing

Aluminum is a soft but very durable metal that is difficult to process in various ways, but has a fairly low melting point, which allows it to be cast even at home or in a small workshop. Of course, the most accurate, streamlined process is possible when using professional equipment installed in production workshops.

Die casting of aluminum alloys - which alloys are better?

1. AK12 alloy , also called silumin, is a mixture of aluminum and silicon, to which a small amount of magnesium is added (up to 0.5%). The alloy is one of the hardest of the variety of aluminum-based mixtures. It is also characterized by low casting shrinkage and tightness. It is actively used for injection molding due to the fact that it does not crack during the creation of blanks. Used for the production of parts operating under light load.

2. Aluminum alloy AK12M2 is produced by adding a small amount of silicon (11 to 13%), copper (1.8-2%) and iron (0.6-0.9%) to molten aluminum, mainly to make the workpiece better separated from the form). It is mainly used for the production of aluminum ingots and shaped castings.

3. AK9 alloy is produced by mixing aluminum with silicon (85-90% + 8-11%) and adding a small amount of impurities: nickel (up to 0.3%), copper (up to 1%) and zinc (up to 0.5%) . The alloy is characterized by high strength, but does not differ in ductility. It is used for the production of aircraft parts, elements of complex instruments and other workpieces that can withstand high loads, but are not subject to increased vibrations.

4. Aluminum alloy AK9M2, due to the favorable ratio of aluminum, silicon and copper, has the most balanced ratio of hardness to ductility. Due to its physical properties, the alloy is actively used for the production of unloaded parts, housings and parts for various devices. May be subject to artificial aging and hardening.

5. AK5M2 alloy is considered one of the most popular in the aluminum-silicon-copper system. It is distinguished not only by its high strength and relative ductility, but also by its low cost. The alloy is used for “non-critical casting”: the production of aluminum cookware, shaped castings, unloaded parts, etc.

Aluminum die casting or die casting is a quick and relatively inexpensive way to produce large quantities of blanks and parts for the mechanical engineering, medical or food industries. Depending on the specific tasks, you can choose one or another alloy that most accurately meets the final operating conditions of the product.

What types of metal can be used for work

Using foundry equipment, you can produce parts and blanks from the following types of metal:

- cast iron;

- become;

- copper;

- aluminum;

- bronze;

- brass

Copper alloy casting machine

Steel is the most common metal for making various parts. The production equipment can process the following grades of metal:

- low alloy;

- highly alloyed;

- carbon;

- alloy steel.

This material is widely used in mechanical engineering and machine tools due to its high strength and ductility. Cast iron products are no less popular. The greatest demand is provided by furniture companies that produce cast iron furniture and decorative elements.

Castings from steel 110G13L

Aluminum is one of the most common types of metal; it is characterized by its malleability, lightness, and the addition of magnesium or copper to the composition provides high strength to the product. Modern equipment technologies make it possible to cast aluminum parts and blanks of any complexity and configuration (weighing from 100 grams to several tons).

What is aluminum die casting today?

Today, aluminum injection molding is a full cycle of product production, which can begin from the design of linear equipment to the final product at the output.

The essence of the process is to fill a special mold made according to a template or custom order with molten aluminum. Aluminum die casting makes it possible to inexpensively produce quite complex products due to its low melting point. Finished parts can weigh from several grams to tens of kilograms and have a wide range of applications.

Why is pressure used in aluminum casting?

Aluminum die casting is done to increase mold filling speed, as well as expand product detailing capabilities. In modern production, pressure from 35 to 700 MPa is used for casting blanks from aluminum and other non-ferrous metals.

Similarly, today, at minimal cost, it is possible to cast custom-made aluminum parts for the automotive (aluminum engine blocks, small parts), medical and food industries, as well as numerous parts for the production of household appliances, plumbing equipment and much more.

Among the advantages of aluminum injection molding are high productivity, excellent surface quality of finished products (grade 5-8), as well as high precision detailing of the finished product (grade 3-7).

Characteristics

The unique properties of aluminum alloys make it possible to cast parts of large standard shapes without significant deformations. Aluminum castings are characterized by the strength and toughness of the material, which allows them to be used several times.

Aluminum has good electrical and thermal conductivity, does not allow surface oxidation, and is lightweight.

Application

Aluminum castings are used both as a semi-finished product and as finished parts in instrument and mechanical engineering, at enterprises of the military-industrial complex, shipbuilding and automotive industries, etc.

Preparation for the process

In the aluminum die casting process, molten metal is poured into specially prepared molds by forcing it through a piston.

A piston moving at high speed prevents the hot metal from changing its intended shape and completely eliminates air bubbles from its mass, ensuring no shrinkage.

The distribution of the hot mass of liquid aluminum occurs rapidly, the prepared mold is filled very quickly, after which the entire mass that filled it gradually hardens, exactly repeating the established configuration of the part.

When producing elements with cavities, machines are used that are equipped with special pistons that allow penetration into the filled mold.

The process of injection molding of aluminum alloys has become widespread, and parts manufactured in this way are in great demand due to the high malleability and ductility of the source material.

During work, so-called molds are used, in which the process of aluminum injection molding is carried out.

Work order

It is quite simple to set up the production of aluminum parts by casting at home, without the need to purchase expensive equipment.

Models that will participate in the casting process need to clean and lubricate the inner surface. If you use the “in the ground” method, preparation is also necessary.

In this case, you should check that the technological recess exactly follows the contours of the future part.

When performing work, an important parameter is the shrinkage of molten aluminum.

Shrinkage when pouring should be minimal, otherwise the dimensions of the part will not correspond to the specified ones.

In order for the shrinkage during solidification of aluminum to have a minimum value, it is necessary to make a small edging on the mold from clay, along which the molten metal is poured into it.

To melt aluminum, as a rule, a steel container and a special furnace are used.

The video below shows the casting of aluminum metal parts by hand.

Video:

In order to cast a wide variety of parts from aluminum, there is no need to purchase expensive equipment.

Everything you need for work can be found in the household.

At the same time, when performing work, do not forget about safety rules.

It is recommended to use special clothing that will protect the skin from possible burns.

Features of the production process

Aluminum die casting is used in production to produce parts of various sizes and shapes, as well as other castings. During the production process, molten aluminum heated to a temperature of 600˚ Celsius is fed under high pressure into a steel mold.

The main distinctive features and features of casting carried out in production workshops:

- rapid heating of the metal to the melting point;

- accurate supply of a certain amount of raw materials intended for casting;

- full automation of the production process;

- creating sufficiently high pressure to perform quality work.

All this allows us to obtain high-quality parts and components of machines and devices, manufactured with high precision and in the shortest possible time. Another distinctive feature that can be recognized as an advantage of manufacturing parts from aluminum using injection molding is high productivity with minimal labor intensity of the process.

Manufacturers take advantage of these positive qualities to create a large number of high-quality parts of various configurations intended for use in a wide variety of industrial applications.

The inherent advantage of aluminum injection molding also lies in the fact that the components of devices and other elements manufactured in this way practically do not require additional processing carried out mechanically.

To carry out all the necessary operations, the use of aluminum injection molding machines used in production workshops is especially popular among manufacturers.

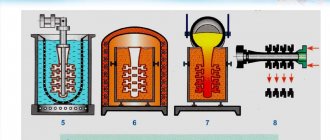

These are machines equipped with a compression chamber:

- hot;

- cold.

Many enterprises widely use horizontally installed cold pressing chambers into which molten aluminum is fed under pressure.

Variety and use of alloys, required machines and molds

Products made of aluminum alloys are in high demand:

- Silumin is an alloy of aluminum and silicon. After adding magnesium to its composition, the final product becomes extremely durable. This is one of the most low-shrinkage and highly airtight alloys. It is not subject to cracking during manufacture and is used to create elements subject to light loads.

- In order to create shaped castings, an alloy is used, which, in addition to aluminum itself, includes copper, silicon and iron. This workpiece is perfectly separated from the mold and is highly durable.

- When creating high-strength elements, an aluminum alloy with the addition of silicon, nickel, copper and zinc is used.

A particular alloy is selected depending on the tasks to be performed by the manufactured parts and the loads that the finished elements will have to withstand.

All operations are carried out on specially created equipment, which can be used both in a production workshop and in a small private workshop.

Using special equipment for aluminum casting, you can create items necessary in everyday life and parts that are very important when assembling various machines and units.

To create the above alloys, it is necessary to use machines equipped with both cold and hot chambers designed to melt the metal. Machines with hot chambers are necessary in the production of alloys containing zinc. The molten metal is introduced into the internal space of the mold gradually. He fills out the entire form.

When working with alloys that contain magnesium and copper, castings are produced due to the fact that the molten composition is introduced into the mold under fairly high pressure. Its level in certain situations reaches 700 MPa. It is this production method that makes it possible to significantly increase labor productivity without increasing the labor intensity of the process, and parts manufactured in this way do not require mechanical processing.

The choice of equipment when creating a workshop or organizing a casting process is based on the characteristics of the technological process. When casting aluminum under pressure, it is as follows:

- In a hot furnace, the metal is heated to the melting point and turns into a liquid state.

- At this time, a special mold must be prepared in the workshop, the internal contour of which fully corresponds to the parameters of the future part.

- Molten metal is fed under high pressure into a prepared mold.

- After cooling, the finished product is removed from the split mold.

Today, some manufacturers use other casting methods. This can be casting into earth, sand or cement, but aluminum injection molding makes it possible to obtain a product with a minimum wall thickness of less than a millimeter. And everything can reach from 4 to 12 kg.

Aluminum injection molding machine

Casting is one of the methods of processing various metals. With it you can create objects of different sizes and configurations.

This is the simplest and most affordable method, which is carried out using special equipment.

Now many manufacturers offer mini construction.

Mini foundry

This means that an individual project of the production complex will be developed, the layout of the workshops, the placement of equipment, and the provision of all necessary communications.

Why is it beneficial to pay attention to ready-made turnkey complexes? Because:

- manufacturers accurately calculate the required production area;

- place communications as efficiently as possible;

- provide a full range of equipment setup services;

- By purchasing, you can immediately begin the production process.

Technical characteristics of foundry equipment

If the choice is made in favor of such a complex, then the next step in organizing a business will be to search for customers. Die-cast metal products are in great demand in almost all industries:

Sheet metal bending

- machine tool industry;

- automotive industry;

- instrument making;

- production of household appliances;

- shipbuilding;

- production of medical and dental equipment;

- jewelry art;

- production of home and garden decor items;

- construction materials industry.

The advantages of a mini-factory are its compact size and the ability to produce products in small batches. Often large enterprises are forced to refuse small wholesale customers, since reconfiguring equipment is quite problematic.

A mini-factory is an automated complex: in order to switch to a new type of manufactured products or metal blanks, you only need to make changes to the software package and make new molds. And the cost of non-standard parts made to order is several times higher than standard production.

Foundry

Another advantage of the mini ones is that they are designed so that they can process all types of metals, while the large-scale lines have separate workshops for this.

What types of metal can be used for work

Using foundry equipment, you can produce parts and blanks from the following types of metal:

- cast iron;

- become;

- copper;

- aluminum;

- bronze;

- brass

Copper Alloy Casting Machine

Steel is the most common metal for making various parts. The production equipment can process the following grades of metal:

- low alloy;

- highly alloyed;

- carbon;

- alloy steel.

This material is widely used in mechanical engineering and machine tools due to its high strength and ductility.

Cast iron products are no less popular.

The greatest demand is provided by furniture companies that produce cast iron furniture and decorative elements.

Castings from steel 110G13L

Aluminum is one of the most common types of metal; it is characterized by its malleability, lightness, and the addition of magnesium or copper to the composition provides high strength to the product. Modern equipment technologies make it possible to cast aluminum parts and blanks of any complexity and configuration (weighing from 100 grams to several tons).

Casting methods

Depending on the brand of metal, type, size, shape of the future casting, the most suitable and economically feasible casting method is selected. Currently, there are about 50 techniques, but the following are considered the most common:

- chill casting;

- injection molding;

- into sand molds;

- by lost wax models.

Scheme of a casting and rolling unit for production from various alloy steels

A chill mold is a model mold into which molten metal is poured; after cooling, a finished product is obtained.

This is the most popular casting method, however, it requires great professionalism at the stage of making the mold, since accuracy is important here, because the final result will depend on the quality of the mold.

Lined die casting machines

For large-scale production, this method is most profitable, since the mold is made once, and can be used for up to several thousand. When casting in a chill mold, the minimum wall thickness of the part should be 3 mm, and the mass of the product should be from 20 g to 50 kg.

Injection molding is also one of the popular methods. Specialized automatic machines are used for it. For various metal alloys, either the low pressure or high pressure method is used. The technology is simple:

- the metal is melted in a furnace;

- is fed under pressure into a special mold, which has the outlines of the future casting. The pressure can be in the range from 8 to 700 MPa;

- After cooling, the finished product is obtained.

Converter for steelIn this way, it is possible to produce castings with a minimum wall thickness of 0.8 mm and a weight of 4 g to 12 kg.

Casting in earthen or sand molds is one of the most ancient methods, but it is successfully used to this day.

First, a model is made, with which an imprint is made in a sand-clay mixture.

In this case, allowances should be made for subsequent machining of the product. The model itself can be wooden, plastic or metal.

This method is suitable for monolithic and large parts; it can be used to cast products weighing up to 40 tons.

Components of a mini-plant and their technical characteristics

The Russian one proposes to organize a turnkey mini-foundry for metal casting using the chill method.

Such a complex can work with aluminum, copper, steel and their alloys.

The machines can cast products of any shape and configuration thanks to the ability to independently produce matrix molds.

KURTZ casting machine

The mini kit includes the following equipment:

- reverberatory furnace - it is necessary for melting metal. Technical characteristics: energy carrier option - gas, electricity, spent fuel, diesel fuel;

- energy consumption – 1 gas cylinder for 20 hours of operation or 30 kW/h;

- Bunker capacity – up to 1 t;

- productivity – up to 600 kg/h;

Reverberatory furnace for mini foundry

- chilling machine - necessary for direct casting of products. It can be of two types: single-position - for products that do not have reverse angles. The form can only open in one direction;

- multi-position – designed for parts of complex shapes, the mold opens up and down.

Chilling machine 82A505

Specifications:

- power consumption – up to 2.5 kW/h;

- applied compression force – up to 190 t;

- chill mold - a mold for future products - if necessary, it can be manufactured by the company according to individual drawings.

Review of some options for turnkey production complexes

In addition to equipment that uses chill molds, there are other production complexes.

Press machine for metal casting.

It is designed to work with molds and is most often used in the manufacture of non-ferrous metal parts. Characteristics:

Continuous casting machine

- created pressure – from 33 to 135 MPa;

- power consumption – 30 kW/h;

- maximum weight of one casting – 6 kg (aluminium);

- cost – 700,000 rubles.

The turnkey machine complex PR-1000 from AB Universal is designed for casting non-ferrous metals, characterized by complete melting, slag-free casting, and precise filling of molds - this ensures high quality of finished products. Characteristics:

Development of the design of a horizontal continuous casting machine for non-ferrous metals

- crucible volume – up to 2000 cm3;

- maximum weight of one casting – up to 5.4 kg (aluminum);

- maximum height of the flask – 400 mm;

- flask diameter – up to 500 mm;

- power – 30 kW;

- dimensions – 2000*1500*850 mm;

- cost – 1,500,000 rubles.

Devices

Aluminum die casting machines have a number of special technical characteristics. Knowing some parameters and choosing the most suitable equipment to work on:

- Performance. The cost of an aluminum die casting machine directly depends on how many parts it can produce in one hour and, when used in production mode, in 8-10 working hours. The higher the productivity, the higher the cost of the machine.

- Mass of castings. This characteristic also depends on what pumps, engines, pistons and tips the device should be equipped with.

- Dimensions and weight of equipment. The choice depends entirely on the size of the production facility and the total production area.

Machines designed for aluminum injection molding are directly related to large-scale production equipment, although modern manufacturers also offer equipment designed for use in mini-factories. The cost of the car plays a big role in the choice. It is based on the combination of all the above qualities that equipment used both in production and in a small workshop must have.

Most modern models of aluminum die casting machines are equipped with a computer unit, numerous sensors capable of reading and analyzing data on operations, and a high-quality hydraulic system. You can make the right choice only by comparing the capabilities of the purchased equipment and the user’s needs.