Home / Welding technique

Back

Reading time: 2 min

0

441

When it comes to welding work, the names of steel, cast iron or non-ferrous metals are mainly mentioned. But the development of new branches of technology requires the introduction of refractory metals from production, such as molybdenum and tantalum.

They stand out among materials due to their increased melting point, exceeding 2,500° C. However, their use is also justified by their resistance to corrosion and resistance to aggressive environments.

However, parts and structures made from such heat-resistant materials sometimes fail, which requires them to be joined by welding.

- Molybdenum

- Welding

- Tantalum

- Welding

Molybdenum: general information

Molybdenum is a refractory silver-colored metal. Melting point - 2623 degrees Celsius. Molybdenum is absolutely not subject to corrosion and destruction. Products made from molybdenum can be used either independently (for example, molybdenum wire) or as an alloying element. When molybdenum is added to steel, the metal acquires special strength characteristics. Also, steel alloyed with molybdenum is not subject to corrosion. Working with molybdenum requires thorough cleaning of the metal surface.

Molybdenum welding

To weld molybdenum, you must use a professional welding machine with flexible current adjustment. Since the final result largely depends on the correct current setting. If you make a mistake and set the wrong amperage, this will lead to subsequent failure of the welds. In general, the topic of adjusting the current when welding molybdenum causes a lot of controversy. The fact is that there are no uniform recommendations regarding current settings. Each time you need to experiment to find the optimal settings.

But what is known for sure is the technology with which molybdenum welding is possible. The most commonly used are arc welding in a shielding gas (argon or helium), as well as resistance welding. When arc welding, tungsten electrodes must be used. When soldering molybdenum, the use of solder is allowed. The solder can be copper or silver. No flux is used. The same methods are used to weld chrome-molybdenum steels. We recommend setting constant current and straight polarity.

During operation, an oxide film often forms, which makes welding difficult. To get rid of it, you can use acid by performing electrolysis. But there is a possibility that the metal surface will lose its aesthetic appeal. The shine will be uneven and the oxide film will not be completely removed.

Tantalum: general information

Tantalum is the same refractory metal as molybdenum. But the melting point is much higher - 3017 degrees. Tantalum is very rare in its pure form. But it can be found in many natural minerals. Tantalum itself is very durable, but at the same time ductile. Its ductility is similar to gold.

Initially, tantalum was used only in the production of wire used in incandescent lamps. But today the scope of its application is much wider. It, like molybdenum, is added to the composition of other metals to improve strength and anti-corrosion properties.

Tantalum welding

Welding molybdenum and tantalum are largely similar technological processes. And all because of the high melting point. So the recommendations regarding molybdenum welding can also be used when welding tantalum. Or when welding metals that contain tantalum.

To weld tantalum, it is necessary to use the same technologies as when working with molybdenum. Namely, gas-shielded tungsten arc welding or resistance welding. Sometimes carbon electrodes are used instead of tungsten electrodes. When resistance welding, the heating time should be minimal. Here it is also recommended to set constant current and straight polarity. The optimal current is 20-40A.

Here, as with molybdenum welding, it is important to properly clean the surface before welding. Also pay attention to the welding area. It must be well protected from oxygen. Cool the finished seam quickly. To clean tantalum from the oxide film, you can use the same etching in acid.

Welding technology for dissimilar metals and alloys

Most welded pairs of dissimilar metals or alloys are characterized by significant differences in melting temperature, density, coefficients of thermophysical properties, especially in linear expansion coefficients. The crystallographic characteristics also differ—the type of lattice and its parameters (Table 1).

For metals such as titanium, niobium, tantalum, molybdenum, additional difficulties arise due to the fact that when heated, these metals actively interact with atmospheric gases. When gases are absorbed, the properties of welded joints sharply deteriorate. In most cases, with limited mutual solubility for the main combinations of welded metals, it is extremely difficult to avoid the formation of stable intermetallic phases with high hardness and brittleness (Table 2).

Table 1. Physical and mechanical properties of some alloys used in welding dissimilar metals

| Properties | Iron and alloys based on it | Aluminum alloys | Copper alloys | ||||||||

| Iron Armco | St3 joint venture | 09G2 | 10X SND | 12X 18N9T | AMn | AMg5V | AMgb | BrA Mts9-2 | BrK MP3-1 | BrB2 | |

| Density, g/cm3 | 7,80 | 7,85 | 7,85 | 7,85 | 7,9 | 2,73 | 2,65 | 2,65 | 8,2 | 8,4 | 8,2 |

| Temp. melting point, °С | 1535 | 1520 | 1530 | 1540 | 1450 | 650 | 570… 640 | 630 | 1050 | 1080 | 1050 |

| Linear expansion coefficient x106, 1/°С | 11,0 | 11,1 | 12,0 | 12,1 | 16,6 | 23,2 | 23,9 | 24,0 | 17,0 | 15,8 | 16,6 |

| Heat transfer coefficient water content (at 20 °C), W/(mK)xO2 | 0,8 | 0,67 | 0,5 | 0,46 | 0,16 | 1,88 | 1,25 | 1,22 | 0,71 | 0,46 | 0,83 |

| Hardness HB | 80 | 120… 150 | 140… 180 | 170… 190 | — | 30 | 65 | 70 | 80… 100 | 75 … 90 | 100/ 330* |

| Tensile strength, MPa | 250 | 380… 500 | 460… 520 | 560… 640 | 580 …650 | 100… 150 | 280… 300 | 320… 380 | 450 … 500 | 350… 400 | 500/ 1250* |

| Yield strength, MPa | 120 | 220… 360 | 340… 380 | 420… 500 | 240 … 300 | 50 | 150 | 160… 180 | 150 …200 | 220… 260 | 250/ 1150* |

| Relates. elongation, % | 40… 50 | 20… 32 | 18… 26 | 16…24 | 55 … 70 | 20 | 18 | 15… 20 | 20… 35 | 30 …40 | 35/ 24* |

| Modulus of elasticity, MPa x10-3 | 200 | 201 | 215 | 215 | 203 | 71 | 70 | 72 | 92 | 104 | 130 |

| *In the numerator - properties before heat treatment, in the denominator - after heat treatment. | |||||||||||

Table 2 Main options for welded pairs of dissimilar metals

| Connected metals | Welding methods used | Main features of physicochemical interaction | |

| formation of solutions | formation of persistent intermetallic compounds | ||

| Steel + aluminum, aluminum alloys | Argon-arc | Up to 33% Al in ?-Fe | FeAl3; Fe2Al5; Fe2Al7; FeAl |

| Steel + copper, copper alloys | Argon arc, submerged arc, electroslag, plasma jet, electron beam | Up to 8% Cu in ?-Fe; up to 1.4% Cu in ?-Fe | — |

| Steel + titanium | Argon-arc | 0.5% Fe in ?-Ti; up to 25% Fe in ?-Ti | FeTi; Fe2Ti |

| Steel + molybdenum | Same | Up to 6.7% Mo in ?-Fe | FeMo; Fe2Mo8 |

| Steel + niobium | “ | Up to l.8% Nb?-Fe; up to 1% Nb in ?-Fe | FeNb; Fe2Nb; Fe5Nb3 |

| Aluminum + copper | Argon-arc, along a layer of flux | Up to 9.8 Al in Cu | CuAl2 |

| Aluminum + titanium | Argon-arc | Up to 6% Al in ?-Ti | TiAl; TiAl3 |

| Titanium + tantalum | Same | Continuous series | — |

| Copper + titanium | “ | 2.1% Cu in ?-Ti; up to 17% Cu?-Ti | TiCu; Ti2Cu; Ti2Cu3 |

| Copper + molybdenum | Electron beam | Limited solubility | |

Welding steel with aluminum, copper, titanium and their alloys

Welding steel with aluminum and its alloys.

The process is complicated by the physical and chemical properties of aluminum. Tig welding is mainly performed with a tungsten electrode. The preparation of a steel part for welding involves a double-sided bevel of the edges at an angle of 70° for the butt joint, since at this bevel angle the strength of the connection reaches its maximum value. The welded edges are thoroughly cleaned mechanically, sandblasting or chemical etching, then an activating coating is applied to them. The use of shot blasting is unacceptable, as this will leave oxide inclusions on the metal surface. The cheapest coating is zinc, applied after mechanical processing.

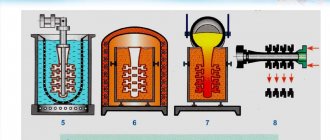

The process of galvanic and hot-dip galvanizing must be preceded by degreasing the part, washing and drying, etching in a sulfuric acid solution, followed by washing and drying. When hot-dip galvanizing, before lowering the part into a zinc bath having a temperature of 470 ... 520 ° C, it is necessary to flux the part in a saturated flux solution. The simplest flux consists of two components: 50% KF + 50% KCl. It is completely unacceptable to apply a zinc or aluminum coating using the shoeing method, since in this case the coating particles have time to oxidize and it is not possible to satisfactorily weld aluminum to steel.

During galvanic coating, the zinc layer should reach 30…40 microns, and during hot-dip galvanizing, 60…90 microns. In the latter case, the process of applying aluminum layers is greatly facilitated, especially on small parts. For austenitic steels (12Х18Н9Т, etc.), aluminizing is possible after mechanical cleaning without the use of flux. The optimal (in terms of joint strength) aluminizing mode is the temperature of the aluminum bath 750 ... 800 ° C. The holding time for aluminizing is up to 5 minutes (depending on the size of the part). It is also possible to aluminize steel parts using high frequency currents.

Welding technology involves the use of standard welding installations of the UDG-300 type using lanthanum tungsten electrodes with a diameter of 2 ... 5 mm and argon of the highest and first grades.

A peculiarity of welding aluminum with steel in comparison with the conventional process of argon arc welding of aluminum alloys is the location of the arc: at the beginning of surfacing the first weld - on the filler rod, and during the welding process - on the filler rod and the resulting bead (Fig. 1, a), since when Prolonged exposure to the heat of the arc on the steel surface causes premature burnout of the coating, which impedes the further welding process. After the initial part of the roller appears, the arc must be ignited again (after a break) on the aluminum roller. When butt welding, the arc is passed along the edge of the aluminum part, and the filler is carried along the edge of the steel part in such a way that liquid aluminum flows onto the surface of the steel coated with zinc or aluminized (Fig. 1, b).

With a thickness of the metal being welded up to 3 mm, the welding current is 110 ... 130 A, with a steel thickness of 6 ... 8 mm 130 ... 160 A, with a thickness of 9 ... 10 mm 180 ... 200 A; Only in this case is sufficient heating of the parts and the formation of the necessary connecting layer ensured.

AD1 wire is used as a filler material (pure aluminum with a small addition of silicon, which has a beneficial effect on the formation of a stable quality of the diffusion layer). An AMg6 alloy additive should not be used, since in this case magnesium takes part in the formation of the intermetallic layer, which reduces the strength of the joint. Apparently, the presence of magnesium atoms instead of aluminum atoms in the crystal lattice of one of the phases causes the presence of weak bonds - magnesium is practically insoluble in iron. Magnesium sharply accelerates the growth of a layer of brittle intermetallic compounds and intensifies the development of reactive diffusion processes.

Rice. 1 Technique for argon-arc surfacing of aluminum on steel: a - conducting an arc during argon-arc surfacing; b - the same, when butt welding; c-d- the sequence of applying beads

depending on the type of connection

Depending on the type of connection when welding, it is necessary to follow the sequence of applying weld beads 1 - 12, shown in Fig. 1, c, d and e, providing the necessary overlap. Alternating rollers on the front and back sides prevents overheating of the steel part and premature burnout of zinc from its surface.

The correct choice of welding speed is important, since it determines the interaction time of liquid aluminum with steel, i.e. determines the thickness and stability of the intermetallic layer. For the first layers, the welding speed is set to 7 ... 10 m/h, for subsequent layers (when the steel is sufficiently heated) - 12 ... 15 m/h. Under the considered welding conditions, the tensile strength of the joint at break corresponds to the strength of commercial aluminum (100 MPa).

The strength of the connection can be increased by increasing the working cross-section of the seam or by using combined coatings. The resulting welded joints are suitable for withstanding static loads and have a high endurance limit under the action of alternating bending loads (Fig. 2). The endurance limit of the samples with a base of 107 cycles is 50 ... 60 MPa, i.e. at the level usual for AMg6 alloy. The destruction of samples, as a rule, occurs on the AMg6 alloy at the external concentrator. Only at high stresses do individual samples fail along the seam. Welded joints have a high density during hydraulic, pneumatic and vacuum tests, as well as high corrosion properties in sea water in the presence of paint and varnish coatings on their surface. The use of combined steel coatings—copper-zinc and nickel-zinc—increases the strength properties of the welded joint. In this case, a layer of copper or nickel with a thickness of 4 ... 5 microns and a second layer of zinc with a thickness of 30 ... 40 microns are applied. The connecting layer of intermetallic compounds of complex composition is somewhat less thick and hard. The tensile strength of the welded joint (in the presence of a convex seam) is 140 ... 223 MPa. When welding high-alloy steel type 18-8 with aluminum, if the steel has only a zinc coating 50 microns thick, a joint strength of 213 ... 287 MPa is achieved. If aluminizing is carried out on a zinc sublayer with a thickness of 25 ... 30 microns according to the previously indicated technology, a joint strength of 295 ... 328 MPa is achieved.

Rice. 2 Results of fatigue tests of welded joints made of AMg6 alloy and steel

In cryogenic equipment designs, many small-diameter pipelines made of aluminum alloys and 12Х18Н10Т steel are used. For the manufacture of pipelines, bimetallic adapters made of these metals are required. Adapters are produced by fusion welding aluminum with pre-aluminated steel. However, this method has its drawbacks: the labor-intensive process, harmful working conditions during aluminizing, and insufficient operational reliability.

A more promising method is low-pressure arc butt welding of thin-walled pipes made of dissimilar metals. The advantage of this method is that welding is carried out in a vacuum chamber in an inert gas environment. During the welding process, only one of the metals being joined is melted - aluminum. Oxides from the ends of the joined surfaces are removed immediately before welding using the cathodic cleaning method. In addition, before welding, during short-term heating, the parts being welded do not contact each other, which allows the ends of the parts to be heated to any (including different) temperatures required for welding, without fear of interaction processes.

Joints are formed through a process of upsetting, in which molten metal is squeezed out of the joint area, resulting in a rapid decrease in temperature at the contact point. The welding duration does not exceed tenths of a second.

In table Figure 3 shows the welding modes for welding a pipe made of steel 12Х18Н10Т 0 10 mm with a wall thickness of 1 mm with pipes made of aluminum AD1 0 12 mm with a wall thickness of 2 mm.

Using metallographic methods, it was established that, regardless of the welding mode, the welded joints are distinguished by good density; no pores, cracks, or looseness were observed at the aluminum-steel interface. On samples welded in a soft mode, the boundary is uneven due to the melting of the steel during welding. In the transition zone along the entire line of contact between the metals, a continuous light gray layer with a thickness of 2 ... 4 microns is observed. In some areas, the thickness of the brittle layer can increase to 5 ... 6 microns.

Table 3 Parameters of the process of welding joints of pipes made of steel 12Х18Н10Т with pipes made of aluminum AD1

| Mode | Heating | Welding | ||||

| current, A | pulse duration, s | pause between pulses, s | current, A | pulse duration, s | pause between pulses, s | |

| Soft | 500 | 0,10 | 0,30 | 180 | 0,56 | 0,64 |

| Hard | 500 | 0,08 | 0,30 | 220 | 0,36 | 0,40 |

These are, as a rule, isolated areas where noticeable melting of the steel occurred and removal into burrs was difficult. The microhardness of the interlayer is 9400 ... 9300 HV. In the structure of the aluminum component of the welded joint in the border region (at a depth of up to 100 μm from the fusion line), eutectic precipitates are observed along the grain boundaries. Moreover, near the interface the number of eutectics is much greater. The microhardness in this area is 150 ... 200 HV higher than the hardness of the base metal.

In Fig. Figure 3 presents the results of micro-X-ray spectral analysis. As follows from the distribution curves, the main alloying elements of steel are present in the transition zone. Their content in the intermetallic layer: 30 ... 32% Fe; 3 ... 7% Cr; 2 ... 3% Ni; the rest is aluminum. In aluminum, in eutectic precipitates along grain boundaries, there is an increased content of iron, nickel and, to a lesser extent, chromium, which is associated with the diffusion of these elements during welding. With additional etching, a metal sublayer of variable width (from 120 to 170 µm) is discovered in the steel, directly adjacent to the intermetallic layer and differing in structure and hardness from the base metal. Its microhardness is slightly higher than the hardness of the base metal and amounts to 4500…. 4800 HV.

The graph of microhardness distribution in the transition zone of welded joints shows that under more severe conditions, the width of the zone of increased hardness in the border regions of both steel and aluminum decreases. This can be explained by the fact that a small increase in welding current leads to a significant reduction in the interaction time of the metals being joined during welding.

The width of the brittle intermetallic layer in joints obtained in a more rigid mode is smaller and amounts to 1.5 ... 3.0 μm. In fairly extended areas, an additional narrow layer is formed in the structure of the transition zone, adjacent to the intermetallic side of the steel, with a width of 2 to 6 microns and a microhardness of 7000 HV. Welded joints made under more rigid conditions are characterized by greater structural stability.

During mechanical tests, the temporary tensile strength of all damaged joints is not lower than the strength of the base metal of AD1 aluminum in the annealed state.

Rice.

3 Change in the concentration of chemical elements in the transition zone of welded joints

Welding steel with copper and its alloys.

In equilibrium at room temperature, copper dissolves in ?-Fe in an amount of up to 0.3%, and iron in copper in an amount of up to 0.2%. No brittle intermetallic compounds are formed. Due to high cooling rates during welding, a supersaturated solid solution of copper and iron is formed in the transition layer, but at a content of up to 2 ... 2.5% Fe, structurally free iron is not detected. The fusion boundary between steel and copper is sharp, with inclusions of a phase enriched in iron of various sizes. On the side of the steel adjacent to the seam, the grain size increases within a zone with a width of 1.5 ... 2.5 mm. The microhardness of the fusion zone reaches 5800 ... 6200 HV.

The presence of carbon in steel worsens the mutual solubility of iron and copper, while manganese and silicon improve it. Manganese reduces the critical point Ac3 and expands the region of the α-solid solution, in which copper dissolves in a much larger amount, and silicon deoxidizes the weld pool and strengthens the grains of the solid solution.

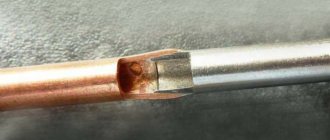

Difficulties in welding and surfacing of copper on steel are associated with its physical and chemical properties, the high affinity of copper for oxygen, the low melting point of copper, significant absorption of gases by liquid copper, different values of the coefficients of thermal conductivity, linear expansion, etc. One of the main possible defects during welding should be considered the formation of cracks in the steel under the copper layer, filled with copper or its alloys (Fig. 4, a). This phenomenon is explained by the wedging effect of liquid copper penetrating into microtears in the steel along the grain boundaries under the simultaneous action of thermal tensile stresses.

In carbon and low-alloy steels (St3, 10KhSND, etc.) there are few cracks and their sizes are small, but in steels that have an austenitic structure, in particular type 18-8, the number and size of cracks increase sharply. For steels of type 18-8, an effective barrier to these cracks is the introduction of a ferrite phase. When the ferrite content is over 30% in steel type 18-8, copper penetration into the steel is not observed; this is explained by the fact that ferrite is not wetted by copper and copper penetration into microtears does not occur.

To reduce the risk of the formation of these cracks, it is recommended to weld at a minimum heat input, using nickel alloy MNZh 5-1 or bronze BrAMts 9-2 as a filler metal. The presence of nickel and aluminum reduces the activity of liquid metal in micro-tears on steel, which reduces the risk of deep cracks forming in steel.

Rice. 4 Surfacing of copper on steel:

I - surfacing with a plasma jet with a current-carrying filler wire and a double independent arc;

II - surfacing by melting the lining (tungsten electrode);

III - automatic surfacing with a submerged strip electrode;

IV - surfacing with a lying electrode under a layer of flux;

V - surfacing with a coated electrode of the “Komsomolets” type;

VI - automatic surfacing with submerged arc electrode wire

Copper, brass and bronze are successfully welded to steel using all fusion welding methods in the same modes as steel parts of the corresponding sections, but the arc from the joint is slightly shifted towards copper or its alloys.

For welding copper, bronze BrAMts 9-2, BrKMts 3-1, brass L90 with steels type St3sp; St4sp; 10; 09G2 is used: a) for manual welding - electrodes with a Komsomolets type coating; b) for submerged arc welding - OSTS-45, AN-26, etc. fluxes and wire grades M1, M2 and BrKMts 3-1, etc.; c) for welding in an inert shielding gas environment - wire grades BrKMts 3-1, BrAMts 9-2, MNZh 5-1. In some cases, preheating of the product is necessary.

The MNZh 5-1 alloy is welded with carbon and low-alloy steels using electrodes with a rod made of the MNZH 5-1 alloy with a ZT coating, and when welding under the OSTS-45 submerged arc or in shielding gases - with an electrode wire of the MNZH 5-1 grade.

When welding, the uniform strength of the welded joint (for non-ferrous metal) is ensured under the action of a static load. Welded joints have satisfactory ductility. Thus, for connecting M3r copper or MNZh 5-1 alloy with St4sp steel during manual welding, the bending angle is 40 ... 85 °, and with argon arc 110 ... 180 °.

The higher quality of welded joints during argon-arc welding with MNZh 5-1 alloys is explained by the fact that in this case the iron content in the weld metal does not exceed 8 ... 10%, and in manual welding it reaches 50 ... 55%.

In Fig. Figure 4, b shows the iron content in the deposited metal using different surfacing methods. Optimal conditions for surfacing copper on steel require that there is no melting of the steel, that it is well wetted (for this, its temperature exceeds 1100 ° C) and the duration of contact of copper with steel at this temperature is at least 0.01 ... 0.015 s.

To join copper and its alloys to steel, it is recommended to use argon arc welding with a tungsten electrode, and for surfacing non-ferrous metals on steel - plasma jet surfacing with a current-carrying filler wire. Welded joints have a fairly high endurance limit.

Welding steel with titanium.

One of the main tasks when welding titanium with steels is the selection of welding materials, methods and welding modes in which the formation of brittle intermetallic phases FeTi and Fe2Ti would be prevented or sharply suppressed.

Direct welding of titanium to steel does not give positive results. Practical applications include welding in argon with a tungsten electrode and welding through intermediate inserts. Good results were obtained using a combined insert consisting of technical tantalum (a, = 700 MPa) and heat-treatable bronze BrB2 (see Table 1).

Bronze is welded to carbon or austenitic steel by argon arc welding with a non-consumable electrode, and tantalum to titanium is welded in chambers with a controlled atmosphere. The tensile strength of the joint in bronze is 490 MPa, when hardening bronze it is 605 MPa (hardening before welding).

Combined inserts made of BrB2 bronze and niobium are used for argon arc welding with a tungsten electrode in a chamber with a controlled atmosphere of titanium OT4-1 with a thickness of 0.8 and 2 mm. The strength of the connection with a thickness of 0.8 mm ?в = 530 ... 660 MPa, bending angle 72 ... 180° with a thickness of 2 mm ?в = 400 ... 450 MPa, bending angle 41 ... 61°.

Welding of dissimilar non-ferrous metals and alloys

Welding of aluminum and its alloys with copper.

In addition to the significant difference in the physicochemical properties of aluminum and copper, welding of these metals is complicated by the formation of a brittle intermetallic phase.

Typically, welding is performed with a tungsten electrode in argon and a layer of flux. To improve the welding process, after cleaning copper it is necessary to apply a coating layer that activates the surface of a more refractory metal and improves the wettability of the copper surface with aluminum. The best is a zinc coating with a thickness of 50 ... 60 microns, applied by the galvanic method. The technology for welding aluminum with copper is the same as for aluminum with steel, i.e. the arc is shifted to a more thermally conductive metal, in this case copper, by 0.5 ... 0.6 of the thickness of the metal being welded (Table 4).

The strength of the connection is equal to the strength of technical aluminum (80 ... 100 MPa), the electrical resistivity of the seam is slightly higher (0.037 Ohm*m) than that of aluminum (0.0313 Ohm*m). Welded joints do not change their strength during prolonged heating to a temperature of 150 °C. With higher heating, the strength of the connection decreases due to a sharp increase in the layer of brittle intermetallic compounds.

At the junction boundary, on the copper side, a layer of intermetallic compounds (CuAl2) with a thickness of 3 ... 10 μm is formed, on the aluminum side, a strip of a solid solution of copper in aluminum of the same size. The microhardness of the intermetallic layer adjacent to copper reaches 4500 ... 5500 HV. The presence of this zone determines the relatively low strength of the connection. If the thickness of the intermetallic layer is less than 1 micron, it does not affect the strength of the connection.

The strength of the joint, as in steel-aluminum joints, increases when the weld metal is alloyed with silicon (4...5%) and zinc (6...8%), since these elements suppress the growth of the intermetallic layer.

To ensure stable strength of welded joints along the copper edge being welded, a bevel at an angle of 45... is required. 60° (Fig. 5, a). When welding M1 copper with A5 grade aluminum over a layer of standard flux used for welding aluminum (AN-A1) with a metal thickness of up to 20 mm, use AD1 grade wire with a diameter of 2.5 mm. When welding, the electrode must be shifted from the bevel by 5 ... 7 mm towards the copper. When welding along a flux layer, the strength of the welded joint is 70 ... 80 MPa, the electrical conductivity remains at the level of the electrical conductivity of aluminum.

Table 4 Recommended welding modes for aluminum and copper

| Welding | Tol schina meta lla, mm | Current strength. A | Strain zhenie, V | Welding speed, m/h | Displacement of the electrode from the joint to copper, mm | Diameter, mm | Argon consumption, l/min | Number of layers | |

| elek troda | prisa Dock wire loki | ||||||||

| Argono arc tungsten wave electrode | 3 | 160 … 180 | 14 … 15 | 10… 12 | 15 … 2 | 4 | 2 | 7 … 8 | 2 |

| 6 | 270 … 290 | 15 … 16 | 7… 8 | 3 … 4 | 5 | 2,5 | 8 … 10 | 2 | |

| 8 | 320 … 330 | 16 … 18 | — | — | 6 | 3 | 10 … 12 | 2 | |

| Automatic by flux layer AN-A1 | 10 | 380 … 400 | 38 … 40 | 21,5 | 5 … 6 | 2,5 | — | — | 1 |

| 12 | 390 … 410 | 39 … 42 | 21,5 | 6 …7 | 2,5 | — | — | 1 | |

Welding aluminum alloy with titanium OT4.

Typically, argon arc welding with a tungsten electrode is used, before which the titanium edges are cleaned of the γ-layer and impurities and aluminized in pure aluminum at an aluminum temperature of 800 ... 830 ° C for 1 ... 3 minutes. In this case, the period of formation of the connection between aluminum and titanium is less than the retardation period, and brittle intermetallic compounds along the connection line do not have time to form.

The edges are pre-cut according to Fig. 13.12, b. Before welding, a layer of pure aluminum (5 ... 8 mm) is fused onto the aluminized edges using AB00 wire with a diameter of 5 ... 8 mm. The connection is welded using the usual method, like an aluminum alloy. The tensile strength of the welded joint of the OT4 + AMg6 alloys depends on the aluminum layer and is 110 ... 270 MPa, the bending angle is 17 ... 30°.

Rice. 5 Welding aluminum with copper and titanium:

a - the strength of the connection between aluminum and copper, depending on the cutting of the copper edge: 1 - V-shaped; 2 - K-shaped; b - preparation of titanium edges for welding it with an aluminum alloy

Welding titanium with copper and its joints.

Welding is complicated by large differences in properties and the formation of brittle intermetallic compounds (see Table 2). The most successful fusion welding is when using intermediate inserts made of specially melted titanium alloys alloyed with molybdenum or niobium, which lower the transformation temperature ?-? and provide a homogeneous titanium alloy with a stable structure, not very different from the structure of copper. You can use combined inserts made of Ti + 30% Nb alloys and VT15 alloys).

These alloys, when welded with MZ copper, provide a joint strength of 220 ... 225 MPa and a bending angle of 140 .... 180°, and when welding with bronze 260 ... 280 MPa and bending angle 100 ... 160°. In the interlayer along the connection line, the hardness reaches 4700 ... 4800 HV, while the hardness of BrKh0.8 bronze is 1200 HV.

Welding niobium, tantalum and molybdenum

with steel and alloys of non-ferrous metals. The fundamental possibility of welding niobium, tantalum and molybdenum with steels and non-ferrous alloys is partially shown above, since these metals are used as intermediate inserts when welding titanium with steel, aluminum and copper.

Tantalum and niobium have properties close to titanium and, when welded with it, form solid solutions without brittle joints. Niobium also welds satisfactorily with copper and copper alloys, with which it forms limited solutions. Tantalum does not form solutions or compounds with copper. Beryllium bronze BrB2 is usually used. Welding is performed with a tungsten electrode under inert shielding gases, often in chambers with a controlled atmosphere and an electron beam.

Bimetal welding.

Currently, it is known to use bimetallic workpieces made of carbon and corrosion-resistant steel with aluminum alloys, steel and copper-nickel alloy MNZh 5-1, steel 12Х18Н9Т and titanium alloy OT4, OT4-1 for welding dissimilar metals.

In bimetallic rolled products made of carbon and low-alloy steel and aluminum alloys AMgZ and AMgb, the thickness ratio in the stack is 1:1 and 1.5:1. The aluminum alloy is combined with steel when rolled over a sublayer of pure aluminum. The bimetal's shear strength is 70...90 MPa and tensile strength is 100...150 MPa.

Rice. 6 Options for welded joints when using inserts from rolled bimetal

In Fig. Figure 6 shows recommended options for various connections using bimetal. The strength of the welded joint largely depends on the adhesion strength of the bimetal layers and, consequently, on the area of the bimetallic insert. However, the lack of design of the joints and the lack of means for quality control of the adhesion of bimetal layers often lead to the fact that connections of this type do not have a vacuum tightness.

To prevent the appearance of brittle intermetallic compounds inside the bimetal when heated during the welding process, it is necessary to strictly maintain the welding mode. For bimetal with a thickness of 10 ... 12 mm, the following mode is recommended: on the aluminum alloy side, argon arc welding with a tungsten electrode in mode I = 140 ... 160 A, Ud = 14 ... 18 V, Vw = 6 ... 7 m/h; on the steel side, welding in CO2 at mode I = 100 ... 130 A, Ud = 18 ... 20 V, Vw = 17 ... 20 m/h.

The formation of brittle intermetallic compounds in the bimetal St3sp, 12Х18Н9Т and AMg6 alloy is most likely when the connection line is heated above a temperature of 450 °C. When heated to a temperature of 550 °C and above, the bimetal delaminates. It is recommended to start welding from the aluminum side and, after cooling the entire assembly, from the steel side.

Fusion welding of semi-finished multilayer material.

In the manufacture of new technology products, structural materials are required that have increased reliability, a long service life with sufficient mechanical properties of the base metal and welded joint. Multilayer semi-finished products based on high-strength aluminum alloys, titanium and magnesium alloys, obtained by joint hot rolling, meet the requirements.

A significant difference in the physicochemical properties of aluminum and magnesium alloys, their metallurgical incompatibility, even during the production of a multilayer semi-finished product, leads to the formation and growth of brittle intermetallic compounds that negatively affect the quality of the semi-finished product, even to the point of spontaneous destruction. This phenomenon can be eliminated by introducing technological layers. For example, the introduction of a layer of technical aluminum on the side of the aluminum alloy and technical titanium on the side of the magnesium alloy.

For example, the four-layer semi-finished product AMg6 + Ad1 + VT 1-0 + + MA2-1 contains a limited area of layer separation

Sections of the site on welding equipment:

- Manual arc welding machines

- Semi-automatic welding machines

- Argon arc welding machines