In the modern world, more and more attention is paid to sanitary standards, both at the industrial and household levels. One of the latest useful developments in the field of plumbing services is septic tanks, which replaced cesspools. Therefore, I propose to consider how to make an aerator for a septic tank with your own hands - this is directly related to the possibility of the functioning of aerobic bacteria.

Purpose of units

Disinfection and disinfection of the contents of cesspools is carried out with active substances. Their danger to the environment and humans has been proven. Therefore, sensible owners are moving to a safe biological method of combating pollution using colonies of living bacteria. Feeding on organic matter from household and household waste, bacteria break it down into water, carbon dioxide and safe sludge.

Biological products for septic tanks contain one of two types of microbes - anaerobic, aerobic, or a combination of both (used in the simplest single-chamber structures). Heavy solid waste settles in the first chamber. They are carried out by anaerobic microorganisms that can survive without oxygen and decompose (oxidize) wastewater into low molecular weight compounds. Cleaner wastewater with small particles ends up in the second and third tanks of the septic tank. Aerobic bacteria are used for their processing, the vital activity of which is impossible without access to molecular oxygen. The activity of microorganisms increases with increasing volume of supply air.

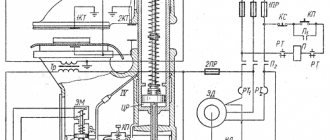

Compressors for autonomous septic tanks connected to aerators are necessary for uninterrupted pumping of oxygen through the volume of waste liquid with aerobic microflora. This is an electrical device for moving gaseous mixtures - it pumps air into the aerator. The latter is a perforated pipe or hose that is laid at the bottom of the tank. Through the holes in the pipe, the supplied air escapes from the aerator and moves upward. Along the way through the thickness of the liquid, part of the oxygen dissolves in it and ensures the vital activity of microorganisms.

Why is an aerator needed in the cleaning system?

It is this element that provides air supply inside the cleaning chamber, which increases the activity of microorganism colonies

The design of the water purification system is aimed at processing and purifying waste sewer streams from accumulations. The structure consists of a tank containing:

- pump;

- compressor for septic tank;

- piping system.

It’s clear why pumps and pipes are needed, but compressors for septic tanks raise questions. But it is this element that provides air supply inside the cleaning chamber, which helps to increase the activity of colonies of microorganisms responsible for processing and decomposing waste. Compressors for septic tanks, as shown in the video, force air masses inside, accelerating the process of dissolving biological accumulations.

Types and characteristics of used superchargers

The work process of compressing and moving air is ensured by periodically changing the internal volume of the device chamber. The principle of oxygen injection is decisive when dividing compressors into types.

Screw

The working pair consists of two rotors with multidirectional profiles of their surfaces, reminiscent of a meat grinder screw.

The meshing rotors rotate in a sealed chamber and compress the incoming air by sealing the gaps between the housing and the screw pair. Then the exhaust valve opens, and air is briefly released to the compressor outlet. The valve setting, the frequency of the profile turns and the area of the teeth determine the frequency of air release and the magnitude of its pressure.

Advantages of screw structures:

- Durability of working screws made of high-strength steel.

- Economical energy consumption.

- Work with minimal vibration.

- Small dimensions.

- Good controllability of automatic systems.

Types of devices for the cleaning system

Membrane compressors for septic tanks are considered more popular devices

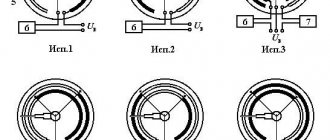

Manufacturers offer two types of devices: screw and membrane compressors for septic tanks.

A screw compressor for a septic tank is a device equipped with two rotors, which, through rotation, pump air masses into the chamber. Due to its small dimensions, the aeration unit is indicated for use in tanks with limited volume. During operation, the aerator makes virtually no noise and is also economical in energy consumption.

Important! The screw aerator into the sump can be dry compression and low-fill. Such models are not often used in household devices, as they are large in size and require frequent maintenance.

Membrane compressors for septic tanks are considered more popular devices. Ease of operation, minimal maintenance requirements, economical energy consumption, and affordable prices are clear advantages that the aerator has. The air flow in the devices is forced by the movements of the membrane, which operates from the movements of a piston connected to a hydraulic drive structure.

Important! A membrane-type aeration unit is considered more practical to use and has an extremely low noise threshold, which allows the use of membrane compressors for a septic tank in conditions close to home ownership.

What to consider when choosing

The effective operation of colonies of aerobic microorganisms depends on their stable supply of oxygen in the required quantities. Therefore, the main selection criteria are performance and pressure generated by the device.

The amount of pressure determines whether the air in the aerator can overcome the resistance of the liquid column and rise to the surface. The deeper the sump tank, the greater the outlet pressure the device must create. Most septic tanks have a depth of up to 2 m. They are equipped with compressors with a pressure range of 2-2.5 atm.

Productivity - the volume of air pumped per unit of time - depends on the power of the device. It becomes a determining factor in the productive treatment of wastewater by bacteria.

Remember! The active life of aerobic microorganisms is equally adversely affected by a lack and excess of oxygen concentration in water.

The volume of the tanks (with the exception of the volume of the first chamber with heavy waste, which contains anaerobic microorganisms) affects the required productivity of the device. For example, for containers of 2-3 m3 and 4 m3, blowers with a capacity of 60 l/min and 80 l/min, respectively, are suitable. The use of a more productive model will require the introduction of automation into the operating circuit to periodically stop the air injection process. This mode will reduce the durability of the device.

Initial conditions

aazinusFORUMHOUSE Member

The house stands on a bolt, the floating foundation is a caisson until it leaks. High water: off-season – 30 cm; in summer - 70 cm, in drought, it went up to 1.5 meters. Five people live in the house, sometimes seven. It had to be done in winter. I refused to pour concrete. In addition, pouring concrete into a swamp requires good pumps for pumping. According to calculations, the volume of discharge is 7×150=1050 liters, in total – cubic meters. Safety factor (cleaning time) – 3.5 days. The volume of the septic tank (more correctly, local treatment station, VOC) is 3-3.5 m³.

After studying the forum, aazinus chose a design scheme with aeration:

- the first cube is a settling tank;

- the second is aerated;

- the third is aerated, but weaker, so that the sludge settles.

Popular brands

Biological treatment plants of many domestic manufacturers are equipped with an installed air compressor. With rare exceptions, these are membrane-type models from Japanese brands Secoh and Hiblow. The specialization of both companies is the production of power plants and units using innovative technologies. Thanks to constant updating and improvement of design, brand products are distinguished by stable quality, reliability, and reasonable prices.

Secoh models are distinguished by:

- Low power consumption.

- Minimal pulsation with continuous air supply.

- Silencer chamber provided by design.

- Light weight.

- Compact.

- Waterproof housing.

- No overheating during long-term uninterrupted operation.

- Easy to maintain without professional training.

Characteristics of the well-known model EL-60: air flow - 60 l/min, maximum pressure - 2.5 atm, power consumption - 42 W, noise level - 33 dB, dimensions - 268.5x201x216 mm, weight - 8.5 kg. Options of higher power, without a significant increase in size, are obtained by integrating two compressors into a single housing.

The Hiblow HP-60 model of the same performance is characterized by the following parameters: pressure - 1.47 atm, power - 51 W, noise - 35 dB, dimensions - 280x190x171 mm, weight - 7 kg.

Compressor equipment from the following manufacturers also deserves attention: Friess and Thomas (Germany), Faggiolati and Doseuro (Italy), Matala (Taiwan), Hydrig (Russia).

Homemade aeration devices

For septic tanks with small tank volumes, a low-performance blower (up to 20 l/min) is suitable. Craftsmen have learned to use compressors from refrigerators and cars to aerate such structures. Cheap, accessible, simple.

A perforated hose is easy to make from a plastic pipe. One end of the homemade aerator is put on the outlet pipe of the supercharger, the other is sealed or hermetically sealed with a plug. Enough holes are made in the body of the pipe to work correctly with the used aggregate model.

The disadvantage of such devices is their small working resource. They are not designed for continuous operation. With the air flow, lubricant quickly leaves the device; installing oil traps has little effect on the situation. When using a homemade device, you need to be prepared for its failure, be able to fix common breakdowns, and perform the necessary maintenance. And in case of critical breakdowns, it is advisable to have a serial model with the necessary parameters in mind.

Modernization of the settling chamber

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank. To do this you will need:

- determine the location for the new section;

- dig a hole where to install a container or concrete ring;

- install a homemade or purchased compressor made for a septic tank;

- Be sure to install a perforated pipe sealed at the bottom into the aeration tank.

Important! Such a pipe can be made from any suitable length. Drill holes, spacing them evenly and observe the appearance of air bubbles on the surface during startup - this means that the compressor installed for septic tanks is working normally.

By adding a mixing structure to the entire installation, it is possible to improve the distribution of masses so that the air flow flows evenly, this will improve the process of decomposition and recycling of accumulations. As a means of post-treatment, it would be a good idea to install an additional chamber where the wastewater will settle and be clarified.

Self-installation

When upgrading and making your own septic tank, you can install the compressor yourself. The selected model is installed on a special frame or platform located above the wastewater level in the tank. The method of fastening depends on the features of the purchased or homemade design. Following the manufacturer's instructions, the outlet pipe of the device is connected to the aerator pipe. After connecting to the power supply and checking its functionality, the supercharger is covered with a protective cover. After sealing, the septic tank is ready to start.

The connection of the new device must be carried out by specialists. The customer will only have to accept the completed work. Another advantage of this option is a guarantee for the quality of installation and proper functioning of the device.

Need to know! Owners of autonomous treatment systems from well-known companies - Topas, Unilos, DKS, Tank and others - receive fully equipped deep cleaning stations for use. There is no need to select and install a compressor. Its repair and replacement after the expiration of the warranty period is entrusted to the specialists of the service center.

Features of operation and maintenance

The air unit will delight you with uninterrupted and reliable operation, subject to the basic operating rules:

- The device must be grounded.

- The compressor is located in a moisture-proof box.

- The suction zone and cooling system of the device are fenced off from vapors and gases rising from the tanks.

- The electrical circuit must provide protection against sudden changes in network voltage.

- The unit's air inlet filter requires periodic cleaning.

- Careful handling without falls or mechanical damage to the device during operation and when removing it before storing the septic tank.

- Do not overfill or flood the treatment tank.

The membrane-type products used require periodic replacement of the working element due to loss of elasticity and physical wear. Replacement is carried out independently (after the warranty period has expired) or by a specialist. It is advisable to prepare the necessary repair kit in advance. If there is no practical experience, the sequence of work on replacing the membrane is studied by watching a thematic video.

Overheating and frequent activation of the thermal relay are signs of contamination of the device with organic deposits that enter inside with sewer gases and fumes. Complete disassembly, cleaning and flushing of the unit will be required.

Other recommendations are indicated by the manufacturer in the accompanying operating instructions.