The drill is an indispensable assistant for the home craftsman. Initially, the tool was intended exclusively for drilling holes in various materials: wood, metal, plastic. Over time, the drill began to be used for mixing solutions, grinding surfaces, and screwing screws. However, the variety of uses of the drill does not end there. The modernization of this tool led to the invention of the magnetic drill. This tool allows you to drill very precise holes in metal materials.

Other ways to magnetize a screwdriver

The changing current inside the coil creates a magnetic field.

Using electricity: You can magnetize a screwdriver by wrapping an insulated conductive wire around the drive shaft and connecting that wire to a power source. This method only works with alternating current because the change in current strength and direction, known as flux, creates a magnetic field. If you try this method, which is not recommended, you will need a step-down transformer to convert the voltage from your outlet to a safe value of a few volts. It is dangerous to insert wires directly into an outlet. Never do this.

It is much safer to use a 9V battery, which is a constant current source. The current flows in one direction from the battery and its intensity remains constant, so there is no flow to create a magnetic field. However, you can build a charging solenoid by wrapping a wire around a short 1/2-inch copper water pipe that the screwdriver shaft can pass through freely. Connect the wire to the 9-volt battery and move the screwdriver back and forth inside the pipe to create flow. Use 16 to 22 AWG insulated wire and wrap it at least 20 times around the pipe for best results.

Using a Hammer: If you hit the shaft of a screwdriver with a hammer often enough, you can push the iron atoms in the steel enough to align them in one direction and create a magnetic field. This may take a while, but it's good to know if you need a magnetic screwdriver urgently and don't have any magnets available. Likewise, once a screwdriver becomes magnetized, hitting it with a hammer can disturb the iron atoms and equalize the magnetization.

https://www.hunker.com

Scope of use of magnetic machines

Although conventional drilling units are versatile, their capabilities are still limited. For example, the workpiece must be fixed strictly on the work table and have a suitable height. After all, even the largest machines have limited vertical lift of the drill. The distance of the drilled holes from the edge of the workpiece is also limited, because the support post is located close to the axis of the drill.

A drilling machine on a magnetic base does not have such limitations; it is compact and capable of performing a variety of operations. Thanks to its magnetic pad, it can be attached to any metal surface that needs processing. This machine can perform the following operations:

- drill holes of a given size;

- cut threads inside the part;

- milling;

- deployment;

- countersinking.

The type of tool with which it can be used depends on the device model. Twist drills and core cutters are used to make holes smaller than 32 mm in diameter on thin workpieces. To drill holes with a diameter of up to 150 mm, core drills and reinforced cutters are used.

The stand is based on a magnet with a power of up to approximately 26,000 N, thanks to which it is possible to fix it in a horizontal, inclined or vertical plane on a metal surface. If the surface lacks stability or is unsatisfactorily even for reliable fastening, it is possible to use vacuum or chain clamps.

Magnetic machines are widely used in industries that require drilling on large objects. These include: work in shipyards, bridge construction, construction of high-rise and other metal structures. Compactness and low weight allow the machine to be used in places where it is not possible to use an ordinary analogue.

Design and types of drilling rigs on a magnetic base

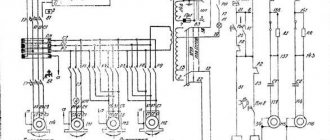

Drilling machines equipped with a stand with a magnetic base, depending on the type of main movement drive used, are divided into several categories:

- electrical;

- pneumatic;

- hydraulic.

Electric machines with a magnetic base are among the most common. Such installations are used in places where there is access to the electrical network and there is no explosive atmosphere. The drive of such a machine, which ensures the rotation of the cutting tool, is an electric motor, the power of which directly determines the functionality of the equipment. Among machines of this type, the most popular are compact models, the weight of which does not exceed 16 kg, and the engine power is 0.75–1.4 kW.

Magnetic drilling machine EBM-360 powered by built-in battery

A pneumatic magnetic plate drilling machine is equipment in which the cutting tool rotates using the energy of compressed air. They work with such installations in places where there is no access to electricity, as well as in cases where the use of the latter is simply unacceptable due to safety requirements (for example, in an explosive environment).

The structural elements of such machines can be made of special alloys that do not produce a spark, which significantly increases the safety of this equipment.

The drive of hydraulic magnetic machines is a hydraulic motor, which is driven by the pressure of a special oil. Such machines, the structural elements of which are made of alloys that are not subject to corrosion, are used when performing work in conditions of high humidity or under water.

Since machines on a magnetic base are used primarily for drilling holes in large parts of considerable thickness, the working tool becomes very hot during operation. To neutralize the effects of strong heating, which can lead to tool breakage, almost all models of magnetic machines are equipped with an effective cooling system. The working fluid in such cooling systems is most often water, which is poured into a special container. Water is supplied to the processing zone automatically, for which the design of the machine includes a special tube and a compact pump.

The device of a drilling machine on a magnetic base

To protect the tool from damage in emergency situations, as well as to ensure the safety of the installation operator, modern models of magnetic machines are equipped with safety mechanisms. Many manufacturers use slipping clutches as such a mechanism, which are installed on the equipment gearbox. At the moment when a drill or core cutter gets stuck in the workpiece, the installation drive and the unit in which the tool is fixed are disconnected.

How to insert a drill correctly?

To correctly insert the drill into the chuck, you need to know the following. The hole intended for clamping the tool is no more than 2 cm deep. The deeper the drill is set, the more securely it will hold in the chuck. There are two types of chuck clamping mechanisms:

- manual, tightened by hand;

- key, wrapped with a key.

In recent years, household drill models have been equipped with a manual (quick-release) chuck - it is simpler in design and quicker to operate.

To install the drill in the chuck you need to follow these steps:

- Turn the cartridge counterclockwise. The jaws should move apart to a distance slightly larger than the diameter of the drill.

- Insert the drill bit between the jaws until it stops.

- Smoothly turn the chuck clockwise, making sure that the drill is clamped evenly on all sides.

- Tighten the jaws by hand or with a wrench.

Video: how to insert a drill and secure it

When fixing the drill in the chuck, considerable force can be applied, especially if the drill has a large diameter. It should be remembered that you will then have to do the reverse operation to remove the drill or replace it with another one. When clamping the drill, look for the “golden mean”: fasten the drill securely, but so that it can be removed from the chuck without any problems. The required effort is easily determined after a little practice - muscle memory kicks in.

Types of electromagnetic drills

The downforce, which depends on the volume of the electromagnet used, starts from 500 kg. The thicker the metal that needs to be processed, the higher the clamping force value the tool must have. Often in a metal structure it becomes necessary to drill a hole in the bottom. If you do this with a regular drill, you will need a lot of effort, time and new drills. Thanks to a magnetic drill, this operation can be completed in a matter of minutes, after first fixing the device on a metal base.

This is interesting! An important parameter of a magnetic drill is the drilling diameter. Its minimum value for any similar device is 1 mm, and the maximum depends on the massiveness of the unit.

The maximum hole diameter that can be drilled with the tool in question is 150 mm. To obtain such a hole you will need core drills for a magnetic drill. For such an unusual tool, special drills are used, equipped with a magnetic grip on the tail part.

Magnetic drills are divided into types depending on their mass indicators. The following types are distinguished:

- Ultramobile. The mass of such tools is 10 kg, and are used exclusively in cases where access for installing a stationary device is limited

- Mobile. Their weight ranges from 10 to 14 kg. Popular models that are in demand when working at heights. Their advantage is their relatively low weight and high downforce performance.

- Medium mobile. Their weight is up to 20 kg, and they are used when the metal structure is thick

- Heavy. The weight of such units reaches 25 kg. They are very inconvenient to transport, but at the same time they have a huge range of possibilities. The use of such tools is resorted to when all of the above modifications do not cope with the assigned tasks.

This is interesting! The need for a tool such as a magnetic drill at home is extremely low, unless your type of activity is related to metal structures. You can drill a hole in metal up to 5 mm thick using an ordinary electric drill with a high-quality steel drill bit.

A magnetic drill is somewhat reminiscent of a drilling machine, but the only difference is that the machines are stationary, unlike the units in question. Using a magnetic unit, you can process other materials, but the main condition is reliable fixation of the tool on a metal base.

What is a magnetic drill and where is it used?

A magnetic drill is an ordinary electric tool that is rigidly fixed to a magnetic frame. Such a tool is also called a drill on a magnetic bed, the use of which is in demand in industrial production and construction. Magnetic drills are intended not only for drilling metal, but also for the following actions:

- Thread cutting

- Carrying out different types of work with core and twist drills

- Countersink

- Scan

An electric drill on a magnetic bed is capable of performing all the same functions that are typical for a conventional tool, with the only exception of one difference - these functions are performed exclusively on metal products.

The fundamental element of a magnetic tool is a magnet. This magnet is shaped like a pillow, which is why the tool is often called a “magnetic drill.” The magnetic pad allows you to fix the drill on the magnetic base in which you plan to work with the tool. Why a magnet is needed on a drill, and what task it performs, not every experienced craftsman knows. The purpose of the magnet is to ensure reliable fixation of the equipment on the surface of the part. Reliable fixation of the tool eliminates the following inconveniences compared to conventional tools:

- Elimination of vibrations

- No need to apply physical force when pressing the tool against the part

- High accuracy in completing assigned tasks

This is interesting! Magnetic drills have found their active use in the field of mechanical engineering, shipbuilding, in the design of bridges and pipelines, as well as in the construction of various metal structures, railways, etc.

Working with metal requires not only powerful, but also massive equipment. A magnetic drill is a massive tool that costs from 40 thousand rubles. The product consists of a magnetic stand and a drilling machine. These elements are rigidly fixed to each other, and therefore there are no vibrations or other inconveniences when processing metal.

The weight of the tool starts from 10 kg, and directly depends on the volume of the electromagnet used. The larger the electromagnet, the higher the clamping force. For processing metal products, the tool can be mounted in any position, while ensuring reliable fixation.

What's good about this mechanism?

An electromagnetic drill adheres as tightly as possible to all processed surfaces. The pressing force of the soles to the surface ranges from 5 to 7 tons. This allows you to work safely even under the ceiling. Moreover, unlike the widespread drilling machines used in industry, the mass of an electromagnetic drill is small. It can be moved without much difficulty when working on a facade, on the eaves of a building or other vertical surface.

The soft start function ensures a high-quality, quiet start to work. Drills with a magnetic base have different operating speeds, adaptable to the hardness of the material being processed and the specifics of the task. The smallest possible hole diameter is 0.1 cm.

The role of magnetic drills is great at facilities associated with the production, storage, processing and transportation of hydrocarbons, as well as in the chemical industry. There, a high level of security is of particular importance. Since the drive of most of these drills is pneumatic, the risk of electrical sparks is reduced to zero. A drill with magnets on the sole can:

- in a short time, prepare a perfect hole where it is difficult to reach with a hand or electric tool;

- complete most of the assigned tasks in the shortest possible time;

- achieve impressive performance;

- save electrical energy.

Magnetic levitation machines Vector

Tools made in Belarus. They operate from a 220V electrical network, maximum power is 1.86 kW. Drilling depth up to 242 mm. Hole diameter up to 110 mm. Popular models in their segment priced from 36,900 to 133,230 rubles.

Buy a magnetic drilling machine from “Kupistanok” on favorable terms. We will advise and help with the choice. We will select the optimal models in terms of price, performance and performance characteristics. We will deliver in 1-2 days in Moscow and the region. We will recommend TC for delivery to the regions. In special cases, we are ready to deliver the goods on the day of payment. Any questions left - call. Ready to place an order - send details to

How to magnetize a screwdriver with a magnetizer

Touching the steel shaft of any screwdriver to a permanent magnet will magnetize the steel for about 3 months. Any magnet will do, but strong ones work better than weak ones. At a minimum, you should use a magnet with a pulling force of 1/4 to 1 pound. Neodymium magnets, available at any hardware store, work best. The hardware store most likely also sells screwdriver magnetizers specifically designed for this purpose.

You can buy a magnetizing screwdriver, which is basically a magnet in a plastic casing.

- Clean the screwdriver or threaded head with a rag to remove any rust or dirt. You may want to use paint thinner or a lubricant such as WD-40 if the shaft is particularly oily.

- Hold the screwdriver or threaded end, touch with one hand, and then attach the magnet to the shaft. If it "sticks" the shaft is iron material and you are ready to go. If you don't feel any attraction, you won't be able to permanently magnetize the tool.

- Slide the magnet along the shaft from the base to the tip. Turn the shaft 1/4 turn and repeat the movement in the same direction, starting from the base to the tip. Continue until you have turned the shaft a full turn.

- Check the magnetic strength by using a screwdriver to grab the screw. If the attraction is not strong enough, repeat steps 2 and 3.

- If necessary, demagnetize the screwdriver by passing the magnet along the shaft in the opposite direction.

tips

If the magnet does not stick to the screwdriver shaft, the shaft is made of a non-ferromagnetic material such as titanium. Many of these materials are paramagnetic, meaning that they can act like magnets as long as they are in contact with a permanent magnet. If you want to make a titanium threaded drill bit for your magnetic drill, use it together with a magnetic bit holder.

How to operate magnetic drilling machines

Very unpleasant consequences arise if the drill jams.

To avoid this:

- clean the place where the drill will be placed;

- carefully outline where they will drill;

- check the reliability of the device;

- Before starting the drill, make sure that there is a supply of coolant in the tank.

When removing the device from the base, first turn off the power supply to the pad, supporting the drill so that it does not fall. If you have to drill into non-magnetic metal, special vacuum support plates are used. As with any other drilling machines, it is necessary to check the serviceability of the housing and the insulation of the wires before starting work.

In the next video you will find an overview of Hi-Tech Instrument magnetic drilling machines.

Popular Brands of Magnetic Base Drilling Machines

The leaders in the production of drilling equipment equipped with a magnetic base are the companies BDS, ALFRA, Eibenstock, DeWalt, RUKO, Magrtron, Metabo, Nitto Kohki. The machines of the listed brands are distinguished by high functionality and exceptional operational reliability, which, naturally, is reflected in their cost, which is significantly higher than the prices of analogues of Chinese and domestic production.

If we talk about budget models of magnetic drilling machines, we can highlight Russian machines produced under the Vityaz and Hi-Tech brands. The equipment of these brands optimally combines decent performance characteristics and reliability with an affordable price for consumers.

Only ferromagnetic materials can be magnetized

The atoms align with the permanent magnet's field.

You can purchase a magnetized screwdriver or screwdriver bits, but there's no point in spending the money because it's easy enough to magnetize a screwdriver yourself. However, there is one condition: the drive shaft must be made of a ferromagnetic material, which means it must contain iron, nickel, cobalt or a rare earth element such as gadolinium or ruthenium.

Fortunately, almost all screwdrivers and bits are made from a steel alloy that contains iron, the most famous ferromagnetic material. Special screwdrivers made from non-ferromagnetic materials such as superhard titanium or titanium alloys cannot be magnetized.

Features of operation and selection of tools

The magnetic drill is equipped with powerful electric motors, the parameters of which range from 1 kW and above. If the drill jams while drilling a metal base, the consequences are as follows:

- Failure of drills, the cost of which is quite high

- Motor jamming, the cost of which is half the price of the tool

- Injury by a person working with a tool

To avoid all these consequences, manufacturers equip products with a slipping clutch or sliding device. To use the tool, you must follow these steps:

- Before installing the tool on a metal base, you need to clean the contact area. This will ensure high-quality and reliable engagement.

- Determine where to drill the hole. In this case, it is not at all necessary to mark it with a core, since the tool does not move from its place when drilling

- After installing the tool on a metal or non-metallic base, you need to check the reliability of the connection

- After this, a nozzle of the required diameter is installed in the tool chuck, and the presence of coolant in the tank is checked, if the device has such a function.

- To activate the tool, you need to press a button, and then manually or automatically adjust the force of pressing the drill to the surface being processed. An additional electric motor in the design of the device allows you to automatically press the nozzle to the workpiece

- To reduce friction during the drilling process, special lubricants and coolants are used. These fluids reduce the load on the electric motor and also extend the life of the tool.

To remove the tool from the metal base, you need to turn off the power supply to the electromagnetic pad while holding the device.

This is interesting! If you need to drill a hole in non-magnetic materials, then for such cases there are special vacuum fastening plates.

If you plan to buy a magnetic drill, you should first decide for what purpose the tool is needed. One of the most important criteria for choosing a tool is its weight. The higher the weight of the device, the higher the cost. The cost is also affected by auxiliary functions such as water cooling, different speed modes, and convenient power buttons.

The instrument discussed in the material belongs to the professional category. Such instruments are produced by different manufacturers, which are: Euroboor, Metabo, Rotabroach, MBR. When choosing, be sure to make sure that the tool is equipped with convenient power buttons and a handle for transportation.

https://youtube.com/watch?v=cJ_d1CYJCf4%3F

Publications on the topic

Welding machines - types, differences and which one is better to choose

Laser level how to use lessons and training

How to lubricate the rotary hammer gearbox and how to do it correctly

Screwdriver belt attachment for quick installation of drywall

Drilling machines with magnetic base Magtron

Magtron magnetic electric machines made in England with a holding force of up to 1800 kgf. With their help you can drill a hole up to 280 mm deep. The diameter of the resulting holes varies from 32 (twist drill) to 100 mm (core drill). The most powerful Magtron model at 1.8 kW. Bestseller - Magtron UA 5000. Smooth drilling process with automatic speed adjustment according to the load. It is possible to drill a large number of holes automatically.

Magnetic drilling machine BDS MABasic 200 – simplicity and reliability

Simplicity of design, ease of use, moderately powerful and high-speed motor, along with low weight allow a magnetic drill to perform production operations in hard-to-reach places. It is possible to work with spiral or annular drills.

The machine is equipped with a standard chuck for reliable fixation of the cutting tool and quick change to another size. The attractive force of the electromagnet allows you to install the machine in any position.

Pros:

- A good unit for the money, it fully performs its functions.

- High-quality performance, price.

- A combination of lightness and power.

Minuses:

Single speed, sometimes lacks power in cold weather.

What to consider when choosing a magnetic drilling machine

Since drilling machines equipped with a magnetic base must be extremely mobile, the main characteristic of such equipment is its weight. That is why modern manufacturers equip these machines with lightweight commutator-type electric motors.

The power of the electric motor, which is installed on a magnetic drilling machine as a drive, can vary between 0.6–3 kW. Most models of such machines have electric motors whose shaft rotation speed does not exceed 1100 rpm. This is explained by the fact that at higher tool speeds it is almost impossible to ensure effective cooling. The only exceptions are Japanese-made machines, in which conical drills made of carbide steel are used as cutting tools.

Budget models of drilling machines with a magnetic base are equipped with motors that provide a rotation speed of 250–600 rpm. Such revolutions are quite enough to effectively drill holes with a diameter of 18–38 mm.

Securing the drilling rig to the surface

Strong fixation of the unit with a magnetic cushion and surface is possible subject to strict compliance with a number of requirements. The most important of them is the mass of the part with an allowable thickness of more than 6 mm. When the machine operates, vibration occurs, which, if sufficiently intense, can move the device from the surface of an oversized workpiece.

The area of the workpiece plays an important role. For reliable fixation, the surface to which the machine will be attached must be no less than the area of the magnet. The magnet also has less strong adhesion to painted surfaces.

If the reliability of fastening the installation to the part is not trustworthy, additionally use fixing belts. When working with pipelines, you also need to use additional means of fixation - a chain platform. A machine on a magnetic levitation is attached to its upper, flat part, and the structure itself is attached using a pair of chains.

There is now a large range of drilling machines that can be mounted on non-metallic surfaces. The coupling is provided by a vacuum, which is created by a special pump. Such installations can only work on perfectly flat surfaces.

Basic drill malfunctions and ways to eliminate them

No matter how perfect the technology, sooner or later, there comes a time when the technological resource is exhausted, and one or another part requires replacement.

An electric drill is no exception. Here is a list of possible, most common problems:

- Motor malfunction (power supply is OK, but the motor does not rotate).

- Wear or burning of the carbon brushes (the brushes spark strongly when the device is operating).

- Failure of the engine support bearings (the hum of the motor is heard, but there is no rotation, or the cartridge rotates intermittently, with a grinding noise).

In addition, the reasons for the unstable operation of the electric drill may be related to the integrity of the power cord or a stuck start button. Such problems can be solved by replacing the cable and preventatively cleaning the button from debris and dust.

To repair a drill at home, you will need many special tools, including electrical ones. If they are not there, it is cheaper to send the drill to a service center for repairs. Replacing carbon brushes is within the capabilities of a home craftsman. In all new drill models, the designers have provided quick access to the brush attachment point and easy replacement.

The brushes are hidden under a cover above the engine commutator.

Main modifications and their characteristics

It is appropriate to start the review of magnetic drill models with the Russian development - “Vector MS-36”. This drilling machine is lightweight and affordable. Thanks to design innovations, it was possible to solve the problem of fastening to uneven metal. Engineers were also able to ensure stable operation in rooms with low ceilings. The machine is completely protected from overloads during operation.

The characteristic features of the Vector are: low weight, ease of control, ease of movement to a new location; but at the same time only one unchangeable operating speed is available. If you need the highest possible speed, use an Extratool DX-35 drill. This device is capable of working with both classic twist and core drills. It is highly efficient and allows operators to set the desired pressure level. As in the previous device, the supply of coolant to the working area is ensured; but for many people the price of the system will seem excessively high.

A simple and stable device - BDS MaBasic 200.

The characteristic advantages of this design are:

- easy mastering of operating principles;

- optimal motor power;

- high speed of revolutions;

- the ability to perform work in hard-to-reach areas;

- possibility of using spiral or ring drills.

The chuck is completely standard, which ensures stable fixation of cutting devices. If necessary, changing cartridges to the desired size is very easy. The attractive power of the electromagnet is large enough to allow the machine to be placed in an arbitrary location. Judging by the reviews, the device fully justifies its price. However, there are two weaknesses: a rigidly set speed and a lack of power in the cold season.

Element 30 Rotabroach is a mobile and relatively lightweight device with a high-power motor. Thanks to the improvement of the gearbox, the system is made more reliable and can operate longer. The power supply comes from a standard voltage of 220 V. Along with high-quality assembly and decent overload protection, there is also a drawback - the small drilling diameter. But to buy the lightest magnetic drill, you need to give preference to Eco 30.

In addition to the reduced size, the ability to work in narrow aisles is ensured by the special design of the gearbox. The manufacturer guarantees that the magnetic attraction will be 1.2 tons. Despite its compact size, the Eco 30 is equipped with a very powerful motor that is capable of delivering increased force to the twist drill. As a result, it can punch a larger hole

Judging by the reviews, the drill is equipped with a strong, comfortable handle; importantly, consumers cannot name significant negative properties

How to choose a budget magnetic drilling machine

If you consider the option of purchasing a budget drilling machine equipped with a magnetic base, then you should pay attention to two models presented on the domestic market: Mab 100 from the BDS company and Vityaz 40P. Both of these machines are in the same price category, have decent functionality, reliability and are easy to use.

Two popular models of magnetic drilling machines

The engine equipped with the Mab 100 machine has a power of 0.8 kW, and it transmits rotation to the tool through a single-stage gearbox. The machine spindle can make a working stroke to a depth of up to 80 mm. The magnetic base of the installation has dimensions of 80x160 cm. Spiral and crown type tools can be installed on the machine, the shanks of which are made in the common size of ¾ inches.

Technical parameters of drilling machine BDS MAB 100

Due to the use of a gearbox with reverse speed in the Vityaz 40P machine, the functionality of this model is slightly higher than that of the Mab 100. The use of such a gearbox allows this equipment to be used for cutting threads in holes with a diameter of up to 16 mm.

The reverse gearbox is not the only advantage of such a machine; it has a more powerful motor (1.05 kW), and its spindle can make a working stroke to a depth of up to 150 mm. When using a tool with crowns on this machine, you can drill holes with a diameter of 12–40 mm, and when using twist drills – 1–16 mm.

Technical characteristics of the magnetic drilling machine “Vityaz-40R”

Can a drill be used as a screwdriver?

Structurally, a screwdriver is a miniature drill, so many people are interested in whether a drill can be used as a screwdriver. However, one more unit has been added to the design of the latter. This is a force adjustment mechanism that prevents excessive tightening of the screw, breaking of the head or slot, as well as licking of the bit. When the screw is screwed in, the tool stops rotating the chuck. A drill simply does not have such a function, which, however, does not prevent it from being used instead of a screwdriver.

Screwdriver: ring with numbers regulates the tightening force of the screw

Sometimes a drill instead of a screwdriver becomes indispensable, especially if you need to screw long screws into hardwood. Battery-powered models have a low-power motor, which does not always cope. But a 400-600 W drill can easily screw in self-tapping screws of almost any length.

How to tighten screws and self-tapping screws with a drill

Before tightening screws with a drill, you need to take into account several features of this mode of operation of the tool and adhere to the recommendations mentioned below.

- Don't use cheap bits. Due to not the most optimal mode of use, cheap attachments become unusable too prematurely. A 5 UAH bit may not be enough even for a dozen screws if the wood is hard.

- Adjust the rotation speed. If the start button is equipped with a wheel for adjusting the speed, you need to reduce it to the minimum value. The fact is that the rotation speed of the chuck of a screwdriver is several times lower than that of a drill. If there is no wheel and the speed depends only on the force of pressing, you should not immediately “push on the gas”: you need to press start smoothly.

- Hold the tool firmly in the direction of the screw. If you tighten the screws with a drill, you need to constantly press on their head with a bat so that it does not slip off the slot. If you loosen the pressure during the tightening process, the bit may come off. This is not scary, but in such a situation the bit wears out, and if it jumps out of the head to the side, the part can be scratched or deformed.

- Stop correctly. The main advantage of a screwdriver is the lack of inertia. As soon as the screw is tightened (or the tool becomes too heavy), or the worker releases the button, the chuck will stop. The drill continues to spin by inertia even after the power supply is stopped. Therefore, to prevent the screw head from breaking off and reduce bit wear, you need to monitor the immersion of the screw. As soon as it is screwed in, you need to remove the bit from the slot of the quick drive head with a short movement.

If you follow the advice, the process of tightening the screws will go without complications. Once you get the hang of it, you can screw in screws with a drill faster than with a specially designed tool. But the answer to the question of whether an impact drill can be used as a screwdriver is somewhat more complicated. The fact is that impact drills are larger and heavier than regular ones. When you turn off the impact mode, you can safely use the tool instead of a screwdriver, but fatigue will set in much faster.