A wire brush is an effective tool used for work at home, at work, and in industry. A device with wire piles of varying stiffness and diameter allows you to perform a wide range of procedures for mechanical processing of products. The brush can be used as an independent hand tool and as an attachment to power tools. Regardless of the type, such devices are also called wire brushes and cord brushes. This article provides complete information about metal brushes of different types and shapes.

Functions of wire brushes: for cleaning metal surfaces, for removing rust and paint

Metal brushes are used to solve many problems and are actively used in repair and construction work. Using cord brushes you can:

- grinding the surfaces of products made of different materials, but mainly metal;

- roughing and finishing;

- removal of various contaminants: stains, dirt, paint, varnish, rust, scale, slag;

- cleaning surfaces before welding;

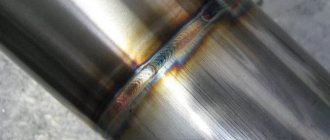

- polishing welding joints;

- removal of burrs;

- treatment of hard-to-reach places.

Brush attachment for angle grinders and paint removal

Preparing body parts

When removing rust, you first need to properly treat the affected parts of the body. This process plays an important role in removing rust, since the further result will depend on it.

Algorithm of actions:

- First, you will need to remove parts of the car body so that removing rust from the car is faster and does not cause inconvenience. Only those parts that are affected by body corrosion should be removed;

- Then the removed parts are firmly fixed on the work stand. Failure to follow this advice is fraught with consequences, such as accidental damage to the part;

- The outer surface must be sanded very carefully using an additional tool.

The main thing is to carefully remove the paint that covered parts of the vehicle. It is not necessary to remove the entire painted area; you can get by with a small area near which there are traces of rust. It is important that there is at least 5 cm to the “epicenter”.

These points will save time and money. But to carry out all the above steps, you need to use a special tool.

Types of iron brushes for metal: steel, brass

The wide range of functions performed by cord brushes makes them in demand among craftsmen of various qualifications. Therefore, manufacturers offer a wide range of brushes. Next, the main types of tools with metal bristles are reviewed and analyzed . For more detailed information about each type, it is recommended that you read other publications referenced in the article.

It is important to know that metal brushes include tools made from the following materials:

- steel: alloy, carbon, stainless, brass;

- alloys: brass.

In addition, it is worth remembering this important nuance. Often metal (or, more precisely, steel) brushes are called iron brushes. But this is not entirely true, since nothing is produced from pure iron. Alloys of iron and carbon are used to manufacture metal products. Depending on the amount of the second element, the result is either strong and brittle cast iron, or soft or ductile steel. In publications on our website, when we talk about iron brushes, we mean devices with steel bristles.

Reference. Brushes are included in the All-Russian Product Classification (OKPD) and are a separate group.

For an angle grinder

Metal brushes for grinders, also called attachments, are a universal solution. With their help, it is possible to carry out various processing operations.

Cup brush for angle grinders with bristles made of twisted metal wire. Photo MATRIX

The product is equipped with a special hole designed for attaching the brush to an angle grinder.

Important! The dimensions of the nozzle and the parameters of the unit must match. This also includes the rotation speed of the angle grinder.

Cord brushes for grinders (link to article about them) have different shapes and sizes.

For drill

Metal brushes for drills have some design features compared to attachments for grinders. Such products are equipped with a pin-type fastening , which is placed in a chuck (like a drill) and secured.

Flat brush for drill with metal twisted bristles. Photo MATRIX

Using a tool with such an attachment, you can grind, polish, and clean metal, concrete, stone, wood and other surfaces. Brushes for drills (link to an article about them) have more compact sizes (diameter) than attachments for grinders.

For screwdriver

Another popular type of attachment is screwdriver brushes. This type of device is often combined into one category with cord brushes for drills. Depending on the shape of the chosen brush, the performer has the opportunity to process various products.

Manual: five-row, small and others

Hand brushes are independent tools for work . Their operation does not require any additional equipment. The criteria for classifying metal cord brushes are:

- number of rows: from one to six:

Hand wire brush. Photo VseInstruments.ru

- material from which the body is made: plastic, plastic, wood, combined models are in demand;

Manual four-row metal brush TM Cobalt with a plastic body. Photo VseInstruments.ru

- size: standard and small hand brushes.

Hand brush with metal bristles and wooden handle, standard size. Photo STAYER MASTER

You can learn more about manual metal brushes here.

Harness

Brushes of this type are products whose pile is twisted into strands . The bristles are characterized by increased hardness and cruelty. Wire brushes allow you to perform particularly complex cleaning work, remove stubborn dirt and solve labor-intensive tasks. Wire cord brushes have a self-sharpening effect.

Radial brush for angle grinders with bristles made of twisted steel wire. Photo Practice

Round

There are a variety of types of attachments for power tools. One of the main criteria for classification is the shape of the product.

Cup metal brush for drill. Photo VseInstruments.ru

Despite the large number of models, all types of cord brushes: cup, conical, radial, disk - have a round configuration. It is important to remember that this statement does not apply to hand tools, which have completely different shapes.

Disk

Disc cord brushes (along with cup-shaped ones) are the most common. They allow processing of surfaces located in narrow and hard-to-reach places.

Disc brush for drill with bristles made of twisted steel brass-plated wire, diameter 100 m. Trademark DEXX. Photo Instrumentomania

Completion of work

After all the parts of the car have been processed and the rust has been dealt with, the session of painting over the damaged areas begins.

The painting process is simple:

- The treated part of the part is coated with a primer.

- After the primer layer has dried, a control primer layer is applied on top.

- Using a compressor and a spray gun, paint is applied in an even layer. At this moment, the main thing is not to make sure that unnecessary smudges do not appear.

- Dry the parts at room temperature for 36-48 hours (depending on the paint).

The result is finished parts that need to be put in place. If the processing was carried out along the perimeter of the body, then the work is done according to the same principle.

That's all you need to know about cleaning metal surfaces from rust. To avoid such problems in the future, you need to carefully monitor the operating conditions of the car. Then the likelihood of such problems becomes extremely low.

Bristles made of other materials: nylon

The pile of hand brushes and attachments is also made of polymers, in particular nylon.

Disc brush with nylon bristles. Photo InstrumLend.ru:

Nylon brushes are characterized by delicate processing and are therefore suitable for working with wood and soft metals. Nylon brushes are the optimal solution in cases where the aesthetic appearance of the product is an important factor.

Removing thick layers of paintwork

An indispensable tool when working on surfaces with large damage (for example, after straightening), as well as on surfaces that have previously been repaired and have thick layers of old repair materials on them, is an angle grinder, popularly called a “grinder”.

For example, a Rodcraft 7150 pneumatic grinder or an electric rotary sander Festool RAS 115.04 E.

Cleaning with Festool RAS 115.04 E

The most commonly used materials for this task are fiber discs: regular or with Velcro fastening. For Sia, these are siamet and siatop circles, respectively. These are very aggressive materials, so they can easily cope with the removal of thick layers of paintwork. However, these materials should be used carefully so as not to leave too rough marks on the metal surface. After working with coarse wheels, be sure to grind the surface with finer abrasive materials, taking into account the grinding steps (the difference in grain should be no more than 100 units).

siamet fiber cleaning wheel

Velcro stripping fiber discs siatop

The recommended speed for working with siamet wheels is 10,000 rpm. For siatop discs, the speed should be limited to 8000 rpm, as at higher speeds the Velcro on the edges of the discs may burn.

Wiping wheel based on synthetic fibers SCM

Special cleaning wheels based on synthetic SCM fibers also do an excellent job of removing thick layers of paintwork materials. Due to their structure, these wheels are almost not clogged with paint particles and leave virtually no marks on the metal, which makes it possible to avoid regrinding the surface with finer abrasives to avoid subsidence. As mentioned above, these circles are also great for eliminating small defects.

The grain size of these materials is indicated by the letter “K”. They have three gradations: K060 (coarse), K100 (medium) and K150 (fine). To attach these circles, the same plate is suitable as for fiber circles with Velcro. Operating speed - no more than 85000 rpm.

Very good for removing old paintwork and stripping flap discs. Sia has siaflap wheels. Due to the fan-shaped arrangement of the abrasive blades, such discs wear evenly and do not clog. They last 6 or more times longer than regular circles! Operating speed with 115 mm discs is up to 13,000 rpm.

siaflap cleaning flap disc

Manufacturers of metal bristles: STAYER MASTER and other brands

Since metal cord brushes are in high demand, many manufacturers offer similar tools to customers. Buyers are provided with Russian and foreign trademarks. Some enterprises produce and sell only hand brushes, others - exclusively attachments for power tools. Companies producing different types predominate. The following is a small part of the most famous and large enterprises and brands:

- STAYER MASTER;

- FIT;

- KROFT;

- MATRIX;

- Anchor.

For convenience, we have collected companies in the “Where to buy brushes” section.

Characteristics and application of angle drill bits

The category of angle drill attachments includes several types of removable devices for performing various operations. Some bits are designed to create holes in places where a tool with a regular drill cannot reach. There are nozzles with adjustable and stationary angles. In the second case, the device is rotated 90° and fixed in this position.

Corner fixtures can also be used as stops. In fact, this attachment simultaneously performs two functions: it limits the depth of the hole being formed and ensures the required position of the drill, resulting in an accurate angle.

Angle attachments for drills are stationary and adjustable

In addition, you can find a screwdriver attachment for a drill on sale. It has a more complex structure than the usual version. Such devices allow you to tighten fasteners (screws) at different angles.

Important! The attachment for tightening fasteners can only be used with those tool models in which it is possible to reduce the speed of rotation.

Angle-type nozzles are usually sold in kits that include tips of various diameters. Thanks to this, you can install screws and self-tapping screws of different sizes. In rare cases, there are removable attachments that allow you to turn an electric drill into an angle grinder.