Despite its name, the standard hydraulic lift table used in various businesses has much more in common with a forklift or elevator than with a conventional table. Nevertheless, similar designs (similar or similar in principle of operation) are widely used in everyday life, although not as a device for lifting heavy loads.

An example is transformable tables, a large assortment of which can be found in any large furniture store; If you have golden hands, experience (albeit small) in carpentry and a lot of free time, you can try to make such a lifting table with your own hands.

Properly made, such a table has a number of advantages, such as:

- Multifunctionality. A transforming table is characterized by adjustable parameters of length, width and height - the lifting mechanism itself plays an important role in this setting.

- Compact dimensions. When assembled, the structure takes up very little space, and when disassembled it turns into a spacious dining table, with enough space for everyone.

- Hidden functionality. Depending on the assembly features, the table may include hidden cabinets and shelves that can be used to store dishes and other things you need.

- Uniqueness. When making a table, you can use any size, any wood and any design delights, which will make the design original and unlike any analogues.

- Ease of use. Any lifting mechanism offered on the market is easy to install and operate. Its assembly and disassembly does not require the use of serious physical effort.

- Reliability. If properly assembled according to the correct drawings, the table will serve you for many years without the need for frequent repairs and diagnostic work.

Lifting mechanism

There are three types of table lifting mechanisms used in enterprises and at home:

- Transformation of the tabletop. At the same time, its dimensions change - length, width, height, and in some cases, configuration. Perfect for the situation already described, when you need to make a large table out of a small one.

- Raising/lowering table top. In such models, the shape and dimensions remain unchanged; Only the height of the table changes, which allows, for example, to quickly turn a small coffee table into a dining table and vice versa.

- Widespread transformation. Suitable for complex structures that only professionals can make. Here, all parts of the table are movable - both the table top and the legs, which allows you to significantly expand its functionality.

More on the topic: Advantages of telescopic lifts

As a result…

A vehicle lift is a simple design that helps during maintenance if there is no special lift or pit, and it can also be easily made independently. There are various types and types of such structures, including those that we looked at today - a standard passenger car lift, a tipper and an engine lift. The decision which one to make is yours.

Question

Write in the comments whether you think such lifts, made independently, are reliable or should you use factory ones?

Materials

No less important than the drawings and mechanisms is the material from which the lifting table parts are made. Its strength and reliability, resistance to damage and climatic influences, weight and dimensions of the structure depend on this. So, the most popular types of materials in manufacturing are:

- Chipboard. Combines low price, functionality and pleasant appearance. The material is easy to process, the lightest working surface for a circular saw.

- Fiberboard. Choose slabs with at least a middle plane! Then the material will be as easy to process as chipboard, which will make it possible to produce parts of any shape and size. Environmentally friendly.

- Natural wood. Significantly more durable, although expensive, material. Suitable only for the appropriate interior.

- Glass. It looks original and stylish, takes up little space, and has ample opportunities for decoration. However, it is very important to choose durable glass, otherwise the final structure will be too fragile; Tempered glass is not inferior in strength to hard wood.

- Metal. The most durable and heaviest material, harder than others to process. Not recommended for home installation; although some small models are relevant for such modern stylistic trends as loft and high-tech.

Components

Having decided on the type of mechanism and working material, let’s make a short list of parts that you can’t do without during assembly:

| № | Helpful information |

| 1 | Durable base board |

| 2 | Plywood for table top rim |

| 3 | Elements for creating legs - wooden blocks, metal pipes, corners |

| 4 | Parts for load-bearing walls |

| 5 | Power tools - drills, jigsaws, saws |

| 6 | Brushes for painting and varnishing |

| 7 | Brass hinges |

| 8 | Fasteners |

| 9 | Lots of sandpaper |

| 10 | Paint, varnish and stain |

Remember that this is only a standard set, and for each individual situation, especially depending on the required functionality (or technical specifications) of the table, it can change and expand.

Now let’s move on to the most important element, without which all the others will be completely useless:

Blueprints

The basis of any design work is a competent, carefully thought out and calculated drawing. You can get such a drawing in three ways:

- The first way (the easiest) is to find it on the Internet. However, just as the simplest path rarely leads to the desired result, so here, at the end of the work, you can get something that is not what you wanted at first - such drawings are rarely reliable and accurate.

- The second way (the most reliable) is to seek help from a specialist. At the moment, there are many construction companies, as well as individual craftsmen who are ready to provide you with any advice and services at your expense. Before contacting them, make a complete list of wishes, in particular regarding dimensions, material and design.

- The third way (at your own peril and risk) is to make the drawing yourself. Suitable only if you yourself are the master mentioned above. You can always find all possible help on the Internet, on forums and websites of construction stores.

After which comes the turn of the work itself - it is necessary to cut and saw the workpieces, treat them with stain and varnish, paint and dry them, then connect them according to the prepared drawing and install the lifting mechanism.

Frankly speaking, it is difficult to provide any universal instructions for making a lifting table - there are too many varieties, modifications and configurations, ranging from the simplest to complex multi-sectional structures with a large number of moving elements.

More on the topic: Description of the P-97MK “Leader” lift model

However, the transforming table is a reliable design that allows you to ergonomically use the workspace, providing comfort, ease of use and wide functionality.

Making homemade car lifts

Standard car lift

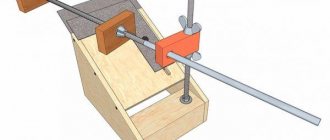

First of all, when making a standard car lift, according to the drawing, I made a base from a profile pipe with a cross-section of 60 by 80 millimeters, but you can use pipes of a larger cross-section.

The base is made in the shape of a rectangle, the width of which should be slightly larger than the width of the vehicle that will be lifted.

Next, frames are made from channel or profile pipes, the width of which is equal to the width of the base of the lift, but the height is arbitrary and depends on your planned height to which the car will be lifted.

Then I installed two of these U-shaped rectangular frames on the base.

I secured one end of one frame with a hinge to the base

The second end of the same frame is also attached using a hinge with the upper end of another frame, whose lower edge is installed in special grooves in the base

This way the frame will move along the base.

To move in the gutters, a nut is installed at the end of the fixed frame so that the threaded rod can be easily unscrewed or screwed in during rotation.

The far end of the rod was secured using hinges with the lower edge of the movable frame.

The threaded rod is made from high-quality metal rod with a diameter of 2 inches.

The thread on the rod and on the fixed nut must be trapezoidal or persistent, because these types of threads are designed to withstand heavy loads.

Thus, the rod is fixed in a fixed frame and, when rotated, moves the movable frame on rollers, along which the frame moves in special grooves of the base - as a result, the vehicle rises or lowers.

As a result, you will get a homemade car lift

Source ad-cd.net

Don't be confused, this lift is not a screw type, as it does not have a vertical load on the screw along the axis.

DIY car tipper

In some cases, a previously manufactured lift can be replaced with a tipper that is easier to manufacture and operate.

First of all, observing all the dimensions of the drawing and, most importantly, safety precautions, a shoe is made that will serve as a support for the future tipper jack.

Next, you need to make two 1.5 meter long stands from the metal corners.

Their assembly is carried out in the form of squares, and they are fastened by welding with a welding machine.

When making racks, take into account the distance through which the beam will be fixed.

Afterwards, holes are drilled in one of the racks to secure the support pipe, as well as for the tipper locking mechanism.

The next step is to make a platform for the beam.

It is made from a sheet of steel, the edges of which are bent in such a way as to form a box, to which the sides must then be welded.

Next, start creating a structure to support the vehicle when it rolls over.

It is made from beams, a beam from a square profile pipe and an angle, the length of which is equal to or greater than the length of the car.

If you do everything correctly, you will have a high-quality homemade car tipper.

Source ad-cd.net

Machine engine lift

If you need to lift not the entire car, but only its engine, you can consider the following type of homemade lifts.

To make it you will need:

- Bolts, hooks for fastening, star-shaped dowels and other small items;

- The steel cable is about half a centimeter thick.

- Iron chains, links with a diameter of 2 centimeters or more (such a large diameter for the chain to withstand the load).

- Metal corners (size 8x8x1 centimeters).

- Steel plate with a thickness of 1 centimeter.

- Worm-type gearbox (for home-made products, you can take a similar gearbox from disassembly or remove it from an unnecessary or inoperative mechanism, but its load capacity should start from 350 kg, and the transmission force indicator should start from 60 kg).

The assembly of the structure must be carried out strictly according to the instructions in compliance with safety precautions.

First you need to attach metal corners to the walls that are located opposite the hood of the car whose engine needs to be raised.

Next, you need to install a steel plate on top of the corners; they should be connected using prepared bolts.

Afterwards, a worm gearbox is installed, which should be fixed with a key on the drive shaft, while a key of smaller diameter should be installed on the output shaft of the gearbox.

Next, you need to make holes in the steel plate, the diameter of which should fit your chain, and then mount the entire chain mechanism.

Finally, you should work on the locking mechanism, holes for which, after a certain distance, are made in the lift frame.

As a result, you should have the following homemade car engine lift

Source ytimg.com

The lift is operated as follows:

- First, the bolts, nuts and other fastenings of the vehicle engine are removed.

- Next, the loops of the steel cable are brought to the engine and the structure is coupled to it.

- With a little effort, the chains are moved, which rotate the drive shaft, causing the engine to rise to the required height, after which it is fixed.

I recommend the following video, in which the author independently makes a scissor-type car lift:

Ramp for pallet wrapper

What is a pallet wrapper? This is equipment that almost no enterprise involved in the storage and transportation of various goods can do without; it is used to wrap products in a special protective stretch film, while the cargo itself is placed on a wooden pallet or pallet.

You've probably seen the products of such packers in stores, although hardly anyone paid any serious attention to it - just think, boxes or bottles in film on a wooden box!

Meanwhile, proper winding helps protect the cargo from climatic and shock influences, and rigid fastening on the pallet will not allow the goods to spill onto the ground and get lost during transportation.

But let's be consistent. So, first of all, there are two types of pallet wrappers:

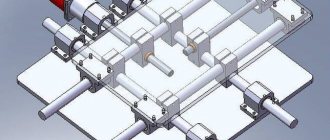

Types of guides

The accuracy of the machine is the task of the guide rods. They are divided into two types:

- slip;

- rolling - involve the use of bearings.

The first type is used on machines of low power and not requiring high productivity. These include woodworking, turning, drilling and benchtop machines.

Homemade guides for a CNC machine are made using a linear method; they can be roller or ball. Regardless of the type, they must have the following characteristics:

- saving the specified parameters;

- smooth movement;

- efficiency;

- low friction.

In most cases, cylindrical rods are used as parts for sliding bushings; they must be ground. Some craftsmen advise making the mechanism without bushings, but due to this manipulation the accuracy of the products will be reduced, and the rods will have a shorter service life.

Automatic pallet packers

The most widely used models on the packaging market, the main advantage of which is productivity and quality of work. The device is fully automated and does not require direct operator control - he just needs to place the load on the working platform, check for the presence of film and film and press a button on the remote control.

After this, the device turns on; at the same time, a movable mechanical “arm” begins to rotate, at the base of which rolls of film are fixed, carrying out a smooth and widespread winding of the load. At the same time, it is possible to adjust both the speed of movement of the “hand” and the level of film tension, which allows you to significantly reduce its costs (two to three times!). After which the load is removed from the platform, a new one is installed and the process is repeated.

Automatic pallet packers operate both autonomously and as part of a conveyor belt - this is especially beneficial when working in large industries with a large turnover of goods.

More on the topic: How do skip hoists work?

The only disadvantages of this type of device are the inability to work with cargo of non-standard, too small and large dimensions, as well as the high price (however, this will not be a problem for wealthy enterprises - besides, the initial costs will undoubtedly quickly pay off).

We recommend to buy

CNC machines from furniture rods

An excellent option when you need to achieve thorough processing, especially in woodworking machines for the production of furniture in small batches, in belt sanding machines, milling machines based on a ready-made low-power milling machine. Furniture parts are inexpensive, although they have a shorter service life than similar sliding elements from printers or typewriters.

An example of using furniture rods on a format boring machine is shown in the photo. It is clear that the dimensions of the bed and movable table are adjusted depending on the purpose. However, if you use ball-type furniture on a drilling machine, there will be no demolition, since the load and frequency of work on a router or drilling machine are significantly different from the loads on a format-cutting machine.

There is always a way out, and based on the examples given, it is quite possible to select sliding guides for your CNC machine with the desired parameters. Good luck with your work!