Copper sheet

Copper sheet is produced at the AVALDA plant in accordance with GOST 1173-2006, GOST 495-92 by cold-rolled and hot-rolled methods from copper GOST 859-2001.

Normal and increased manufacturing accuracy. If high thickness accuracy is required, the cold-rolled method is used. Copper sheet has excellent anti-corrosion properties, has good strength, is ductile, and is harmless when used by humans; there are cases that it is used in folk medicine. It is mainly used in the electrical industry due to its high electrical conductivity, electrical resistance at a temperature of 20°C is 0.15328 Ohm (second only to silver in these characteristics): contact connections, lugs, for cable products, busbars of bare and contact wires, electric generators, telephone and telegraph equipment and radio equipment; Copper sheets are used to make parts for heat exchangers, vacuum devices, and pipelines; in mechanical engineering, in the automotive and tractor industries (radiators, bearings), for the manufacture of chemical equipment.

Attention: Promotion for Sheet DPRL(N)M 6.0x600x1500 M1 GOST 1173-2006 at a price of 450 rubles per kg with VAT, sheet weight 48 kg, certificate, can be purchased in cash.

Copper density value

The density of this metal, which can be viewed in a special table, has a value equal to 8.93 * 10 3 kg/m 3. Also in the table you can see another, no less important than density, characteristic of copper: its specific gravity, which is also 8.93, but measured in grams per cm 3. As you can see, for copper the value of this parameter coincides with the density value, but do not think that this is typical for all metals.

The density of this, and any other metal, measured in kg/m3, directly affects the mass of products made from this material. But to determine the mass of a future product made of copper or its alloys, for example, brass, it is more convenient to use the value of their specific gravity rather than density.

Copper sheet and its mass

| Name | Thickness, mm. | Width and length, mm. | Weight of one piece, kg. |

| Copper sheet | 0,4 | 600x1500 | 3,22 |

| Copper sheet | 0,5 | 600x1500 | 4,03 |

| Copper sheet | 0,6 | 600x1500 | 4,83 |

| Copper sheet | 0,7 | 600x1500 | 5,64 |

| Copper sheet | 0,8 | 600x1500 | 6,45 |

| Copper sheet | 0,9 | 600x1500 | 7,25 |

| Copper sheet | 1 | 600x1500 | 8,06 |

| Copper sheet | 1,1 | 600x1500 | 8,87 |

| Copper sheet | 1,2 | 600x1500 | 9,67 |

| Copper sheet | 1,3 | 600x1500 | 10,48 |

| Copper sheet | 1,4 | 600x1500 | 11,29 |

| Copper sheet | 1,5 | 600x1500 | 12,09 |

| Copper sheet | 1,6 | 600x1500 | 12,9 |

| Copper sheet | 1,8 | 600x1500 | 14,51 |

| Copper sheet | 2 | 600x1500 | 16,12 |

| Copper sheet | 2,2 | 600x1500 | 17,74 |

| Copper sheet | 2,5 | 600x1500 | 20,16 |

| Copper sheet | 3 | 600x1500 | 24,19 |

| Copper sheet | 3,5 | 600x1500 | 28,22 |

| Copper sheet | 4 | 600x1500 | 32,25 |

| Copper sheet | 4,5 | 600x1500 | 36,28 |

| Copper sheet | 5 | 600x1500 | 40,32 |

| Copper sheet | 5,5 | 600x1500 | 44,35 |

| Copper sheet | 6 | 600x1500 | 48,38 |

| Copper sheet | 6,5 | 600x1500 | 52,41 |

| Copper sheet | 7 | 600x1500 | 56,44 |

| Copper sheet | 8 | 600x1500 | 64,51 |

| Copper sheet | 9 | 600x1500 | 72,57 |

| Copper sheet | 10 | 600x1500 | 80,6 |

| Copper sheet | 11 | 600x1500 | 88,7 |

| Copper sheet | 12 | 600x1500 | 96,76 |

| Copper sheet | 13 | 600x1500 | 104,83 |

| Copper sheet | 14 | 600x1500 | 112,89 |

| Copper sheet | 15 | 600x1500 | 120,96 |

| Copper sheet | 16 | 600x1500 | 129,02 |

| Copper sheet | 17 | 600x1500 | 137,08 |

| Copper sheet | 18 | 600x1500 | 145,15 |

| Copper sheet | 19 | 600x1500 | 153,21 |

| Copper sheet | 20 | 600x1500 | 161,28 |

| Copper sheet | 22 | 600x1500 | 177,48 |

| Copper sheet | 24 | 600x1500 | 193,53 |

| Copper sheet | 25 | 600x1500 | 201,6 |

| Copper sheet | 30 | 600x1500 | 241,92 |

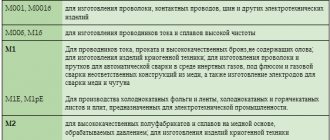

To buy copper sheet, you need to know the generally accepted abbreviations:

manufacturing method: cold rolled - D; hot rolled - G; manufacturing accuracy: for cold-rolled sheets: normal accuracy in width and length - L or N; increased accuracy in width and length - M; normal accuracy in width and increased accuracy in length - I; increased accuracy in width and normal in length - K; condition: soft - M; semi-solid - P; hard - T; length: An “X” is placed for missing data, except to indicate length (dimension).

For example: DPRL(N)M sheet 5.0x600x1500 M1 GOST 1173-2006: cold-rolled copper sheet of rectangular cross-section, normal accuracy in width and length, soft, size 5.0x600x1500 mm, made of M1 grade copper.

How much does metal weigh?

Specific gravity of metals in kilograms and tons.

| Metal | Weight of a cube (cubic meter), kg. | Weight of a cube (cubic meter), t. |

| Aluminum | 2689 | 2,689 |

| Tungsten | 19350 | 19,35 |

| Graphite | 1900-2300 | 1,9-2,3 |

| Iron | 7874 | 7,874 |

| Gold | 19320 | 19,32 |

| Potassium | 862 | 0,862 |

| Calcium | 1550 | 1,55 |

| Cobalt | 8900 | 8,90 |

| Lithium | 534 | 0,534 |

| Magnesium | 1738 | 1,738 |

| Copper | 8960 | 8,96 |

| Sodium | 971 | 0,971 |

| Nickel | 8910 | 8,91 |

| Tin (white) | 7290 | 7,29 |

| Platinum | 21450 | 21,45 |

| Plutonium | 19250 | 19,25 |

| Lead | 11336 | 11,336 |

| Silver | 10500 | 10,50 |

| Titanium | 4505 | 4,505 |

| Uranus | 19040 | 19,04 |

| Chromium | 7180 | 7,18 |

| Cesium | 1873 | 1,873 |

| Zirconium | 6450 | 6,45 |

Specific gravity of alloys in kilograms and tons.

Source

Sheet copper - properties

| Name | Copper condition | Tensile strength, MPa (kgf/mm2) | Relative elongation, %, not less | Brinell hardness |

| Copper sheet | Solid | Not less than 290 (30) | 3 | 95 |

| Copper sheet | Semi-solid | From 250 to 310 (from 25 to 32) | 12 | 75 |

| Copper sheet | Soft | From 200 to 260 (from 20 to 27) | 36 | 55 |

| Hot rolled copper sheet | absent | At least 200 (20) | 30 | 55 |

Melting point: 1083 °C; Casting temperature: 1150 - 1250 °C; Linear shrinkage: 2.1%; Lubricated friction coefficient: 0.011; Friction coefficient without lubrication: 0.43; Modulus of elasticity of the first kind: 1.28 MPa; Thermal conductivity coefficient: 387 W/(m*C); Density: 8.94 g/m3; Specific heat capacity of sheet copper: 390 J/(kg*C); Electrical resistivity: 17.8 Ohm m.

How much does a cube of copper weigh?

Specific gravity of metals in kilograms and tons.

| Metal | Weight of a cube (cubic meter), kg. | Weight of a cube (cubic meter), t. |

| Aluminum | 2689 | 2,689 |

| Tungsten | 19350 | 19,35 |

| Graphite | 1900-2300 | 1,9-2,3 |

| Iron | 7874 | 7,874 |

| Gold | 19320 | 19,32 |

| Potassium | 862 | 0,862 |

| Calcium | 1550 | 1,55 |

| Cobalt | 8900 | 8,90 |

| Lithium | 534 | 0,534 |

| Magnesium | 1738 | 1,738 |

| Copper | 8960 | 8,96 |

| Sodium | 971 | 0,971 |

| Nickel | 8910 | 8,91 |

| Tin (white) | 7290 | 7,29 |

| Platinum | 21450 | 21,45 |

| Plutonium | 19250 | 19,25 |

| Lead | 11336 | 11,336 |

| Silver | 10500 | 10,50 |

| Titanium | 4505 | 4,505 |

| Uranus | 19040 | 19,04 |

| Chromium | 7180 | 7,18 |

| Cesium | 1873 | 1,873 |

| Zirconium | 6450 | 6,45 |

Specific gravity of alloys in kilograms and tons.

The density of copper (pure), the surface of which has a reddish tint and a pinkish tint at the fracture, is high. Accordingly, this metal also has a significant specific gravity. Due to its unique properties, primarily excellent electrical and thermal conductivity, copper is actively used for the production of elements of electronic and electrical systems, as well as products for other purposes. In addition to pure copper, its minerals are also of great importance for many industries. Despite the fact that there are more than 170 types of such minerals in nature, only 17 of them have found active use.

Copper is widely used in manufacturing

Copper sheet - chemical composition

| Copper sheet alloy grade | Cu | Cu+Ag | Bi | Fe | Ni | Zn | Sn | Sb | As | Pb | S | O | P | Ag |

| M00b | 99,99 | — | 0,0005 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,0003 | 0,002 |

| M0b | — | 99,97 | 0,001 | 0,004 | 0,002 | 0,003 | 0,002 | 0,002 | 0,002 | 0,003 | 0,003 | 0,001 | 0,002 | — |

| M1b | — | 99,95 | 0,001 | 0,004 | 0,002 | 0,003 | 0,002 | 0,002 | 0,002 | 0,004 | 0,004 | 0,003 | 0,002 | — |

| M00 | 99,96 | — | 0,0005 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,001 | 0,002 | 0,03 | 0,0005 | 0,002 |

| M0 | — | 99,93 | 0,0005 | 0,004 | 0,002 | 0,003 | 0,001 | 0,002 | 0,001 | 0,003 | 0,003 | 0,04 | — | — |

| M1 | — | 99,9 | 0,001 | 0,005 | 0,002 | 0,004 | 0,002 | 0,002 | 0,002 | 0,005 | 0,004 | 0,05 | — | — |

| M1p | — | 99,9 | 0,001 | 0,005 | 0,002 | 0,005 | 0,002 | 0,002 | 0,002 | 0,005 | 0,005 | 0,01 | 0,002 — 0,012 | — |

| M1f | — | 99,9 | 0,001 | 0,005 | 0,002 | 0,005 | 0,002 | 0,002 | 0,002 | 0,005 | 0,005 | — | 0,012 — 0,04 | — |

| M2r | — | 99,7 | 0,002 | 0,05 | 0,2 | — | 0,05 | 0,005 | 0,01 | 0,01 | 0,01 | 0,01 | 0,005 — 0,06 | — |

| M3r | 99,5 | 0,003 | 0,05 | 0,2 | — | 0,05 | 0,05 | 0,05 | 0,03 | 0,01 | 0,01 | 0,005 — 0,06 | — | |

| M2 | — | 99,7 | 0,002 | 0,05 | 0,2 | — | 0,05 | 0,005 | 0,01 | 0,01 | 0,01 | 0,07 | — | — |

| M3 | — | 99,5 | 0,003 | 0,05 | 0,2 | — | 0,05 | 0,05 | 0,01 | 0,05 | 0,01 | 0,08 | — | — |

Buy copper sheet at a wholesale price at the AVALDA metallurgical plant by phone or order via e-mail, Online order.

Back

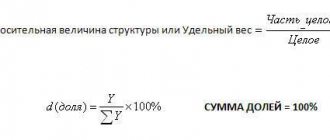

Specific Gravity Calculation

Today, many methods and algorithms have been developed for measuring and calculating not only density, but also specific gravity, which make it possible to determine this important parameter even without the help of tables. Knowing the specific gravity, which differs between different alloys of copper and pure metal, as well as the density value, you can effectively select materials for the production of parts with given parameters. It is very important to carry out such measures at the design stage of devices in which it is planned to use parts made of copper and its alloys.

Specific gravity, the value of which (as well as density) can be seen in the table, is the ratio of the weight of a product made either from metal or from any other homogeneous material to its volume. This relationship is expressed by the formula γ = P/V, where the letter γ denotes specific gravity.

Specific gravity and density, which are inherently different characteristics of a metal, should not be confused, although they have the same meaning for copper.

Knowing the specific gravity of copper and using the formula for calculating this value γ = P/V, you can determine the mass of a copper billet having a different cross-section. To do this, it is necessary to multiply the specific gravity value for copper and the volume of the workpiece in question, which is not particularly difficult to determine by calculation.

Units of specific gravity

Different units are used to express the specific gravity of copper in different measurement systems.

- In the GHS system, this parameter is measured in 1 dyne/cm3.

- The MKSS system uses a unit of measurement of 1 kg/m 3.

The SI system uses a unit of measurement of 1n/m3.

If you are faced with different units of measurement for this parameter of copper or its alloys, then it is not difficult to convert them into each other. To do this, you can use a simple conversion formula, which looks like this: 0.1 dyne/cm3 = 1 n/m3 = 0.102 kg/m3.

Copper ore before processing

Determination of the mass of 1 pm of rolled metal

For stainless steel pipe: m = ?*(d – s)*s*?/1000

For the “black” pipe: m = (d – s)*s/40.55

where: m – theoretical. weight of one linear meter of pipe in kg, ? = 3.14 (constant value), d – outer diameter in mm, s – wall thickness in mm, ? – density in g/cub. cm.

where: m – theoretical. mass of 1 p/m of circle in kg, ? = 3.14 (constant value), d – outer diameter in mm, ? – steel density in g/cubic meter. cm.

| Determination of the theoretical mass of one sheet |

where: m – theoretical. weight of 1 p/m sheet in kg, V – sheet volume = Thickness x Width x Length, mm, ? – steel density in g/cubic meter. cm, 1E6 – the number 10 to the 6th power.

| Determining the approximate number of sheets in one ton |

Where: ? – steel density in g/cubic meter. cm V – sheet volume = Thickness x Width x Length, mm,

Density of different steel grades (according to GOST 9941-81)

| steel grade | Density, ?, g/cm3 | steel grade | Density, ?, g/cm3 |

| 04Х18Н10 | 7,90 | 08Х18Н10 | 7,90 |

| 08Х20Н14С2 | 7,70 | 08Х17Т | 7,70 |

| 10Х17Н13М2Т | 8,00 | 08Х13 | 7,70 |

| 08Х18Н12Б | 7,90 | 12Х13 | 7,70 |

| 10Х23Н18 | 7,95 | 12Х17 | 7,70 |

| 08Х18Н10Т | 7,90 | 15Х25Т | 7,60 |

| 08Х18Н12Т | 7,95 | 12Х18Н9 | 7,90 |

Calculate weight using specific gravity value

To calculate the weight of the workpiece, you need to determine its cross-sectional area, and then multiply it by the length of the part and by the specific gravity.

Let's calculate the weight of a rod made of copper-nickel alloy MNZH5-1, the diameter of which is 30 millimeters and the length is 50 meters.

We calculate the cross-sectional area using the formula S = πR 2, therefore: S = 3.1415 15 2 = 706.84 mm 2 = 7.068 cm 2

Knowing the specific gravity of the copper-nickel alloy MNZH5-1, which is equal to 8.7 g/cm 3, we obtain: M = 7.068 8.7 5000 = 307458 grams = 307.458 kg

Let's calculate the weight of 28 sheets of copper alloy M2, the thickness of which is 6 mm and the dimensions are 1500x2000 mm.

The volume of one sheet will be: V = 6 1500 2000 = 18000000 mm 3 = 18000 cm 3

Now, knowing that the specific gravity of 1 cm 3 of M3 copper is 8.94 g/cm 3, we can find out the weight of one sheet: M = 8.94 18000 = 160920 g = 160.92 kg

The mass of all 28 rolled sheets will be: M = 160.92 · 28 = 4505.76 kg