Phases

So, all steels are an alloy of iron and carbon, however, even general purpose steels have some amounts of manganese and silicon, as well as phosphorus and sulfur . Carbon in such steels is present at a level of 0.05 to 1.0%.

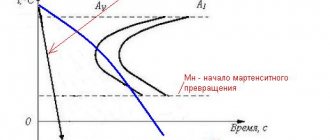

Iron is alloyed with carbon according to a special scenario; the mechanism of this alloy system is two-stage. The first stage is characterized by the combination of iron with 6.67% carbon, resulting in the formation of iron carbide, more often called cementite.

Therefore, ordinary steel at room temperature consists of cementite and ferrite. These are phases. If steel is heated to 725 degrees , then cementite dissolves in the iron and the next phase is formed - austenite. Any steel undergoes only three changes, while there can be many structures and mixtures thereof.

Low-alloy structural steel 10HSND for welded structures

Substitute

Steel 16G2AF

Type of delivery

- Long products, including shaped steel: GOST 19281-89, GOST 2590-88, GOST 2591-88, GOST 8239-89, GOST 8240-89, GOST 6713-91, GOST 535-88, GOST 5521-93, GOST 8509 -93, GOST 8510-86.

- Thick sheet GOST 19281-89, GOST 19903-74, GOST 5521-93, GOST 6713-91.

- Thin sheet GOST 17066-94, GOST 19903-74, GOST 19904-90, GOST 5521-93.

- Strip GOST 19281-89, GOST 5521-93

- Forgings and forged blanks GOST 1133-71

- Pipe OST 14-21-77

Decoding

- The number 10 indicates the approximate carbon content in hundredths of a percent, i.e. in steel 10ХСНД the average carbon content is 0.10%.

- The letter X indicates that the steel is alloyed with chromium (Cr).

- The letter C indicates that the steel is alloyed with silicon (Si).

- The letter H indicates that the steel is alloyed with nickel (Ni).

- The letter D indicates that the steel is alloyed with copper (Cu).

- The absence of numbers behind the letter designation indicates that the average content of the alloying element is up to 1.5%.

Characteristics and Application

Steel 10HSND is a low-alloy structural steel and belongs to the group of chromium-silicon-nickel and copper steels for metal structures, the structural class of the steel is pearlitic, well weldable. It is used for the manufacture of elements of welded metal structures and various parts that require increased strength and corrosion resistance with limited weight and operating at temperatures from -70 to 450°C.

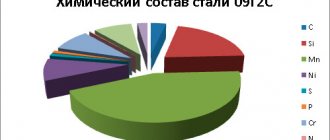

Chemical composition, % (GOST 19281-89)

| C, no more | Si | Mn | Cr | Ni | Cu | P | S | N | As |

| no more | |||||||||

| 0,12 | 0,8-1,1 | 0,5-0,8 | 0,6-0,9 | 0,5-0,8 | 0,4-0,6 | 0,035 | 0,040 | 0,008 | 0,08 |

Chemical composition, % (GOST 19281-2014)

| C, no more | Si | Mn | P | S | Cr | Ni | Cu | V | other elements |

| no more | |||||||||

| no more than 0.12 | 0,8-1,1 | 0,5-0,8 | 0,03 | 0,035 | 0,6-0,9 | 0,5-0,8 | 0,4-0,6 | no more than 0.12 | — |

NOTES:

- The mass fraction of As (arsenic) in steel should not exceed 0.08%.

- The mass fraction of N in steel not alloyed with N is allowed to be more than 0.012%. if the mass fraction of N does not exceed the nitrogen equivalent (Neq).

- Steel 10HSND must be deoxidized with aluminum in the range of 0.02-0.06%.

- Micro-alloyed steels Al, Ti and Nb are allowed based on the mass fraction of Al not exceeding 0.05%, Ti not exceeding 0.04%, Nb not exceeding 0.05%.

Mechanical properties

| GOST | Delivery status | Section, mm | conditional yield strength σ0.2, MPa | tensile strength σв, MPa | relative elongation after rupture δ5(δ4), % |

| no less | |||||

| GOST 19281-89 | Long and shaped rolled products | Up to 15 incl. | 390 | 530 | 19 |

| GOST 19282-89 | Leaf and strip | St.15 to 32 incl. | 390 | 530 | 19 |

| St.32 to 40 incl. | 390 | 530 | 19 | ||

| GOST 17066-94 | Hot rolled sheet | From 2 to 3.9 incl. | — | 530 | (15) |

Mechanical properties at elevated temperatures

| tsp, °С | conditional yield strength σ0.2, MPa | temporary tensile strength σв, MPa | relative elongation after rupture δ5, % | relative narrowing ψ, % |

| 20 | 410 | 540 | 36 | 71 |

| 100 | 360 | 500 | 33 | 71 |

| 200 | 330 | 470 | 28 | 70 |

| 300 | 305 | 480 | 28 | — |

| 400 | 295 | 490 | — | — |

| 500 | 265 | 370 | 30 | 77 |

| 600 | 195 | 215 | 35 | 87 |

| 700 | 140 | 160 | 47 | 94 |

| 800 | 59 | 78 | 71 | 87 |

| 900 | 59 | 78 | 70 | 95 |

NOTE. Sheet 20 mm thick after normalization

Mechanical properties during tensile testing of long and shaped rolled products made of 10HSND steel (GOST 19281-2014)

| Strength class | Rolled cross-section dimensions, mm | steel grade | Mechanical properties, no less | ||

| yield strength σ0.2, MPa | temporary resistance σв, MPa | relative elongation δ5, % | |||

| 345 | Up to 20.0 incl. St. 20.0 to 140.0 | 10HSND | 345 | 480 | 21 |

| 375 | Up to 20.0 incl. St. 20.0 to 50.0 | 375 | 510 | 21 | |

| 390 | Up to 20.0 incl. St. 20.0 to 50.0 | 390 | 530 | 18 | |

Mechanical properties during tensile testing of thick sheets, wide-band universal rolled products and bent sections made of steel 10ХСНД (GOST 19281-2014)

| Strength class | Product thickness, mm | steel grade | Mechanical properties, no less | ||

| yield strength σ0.2, MPa | temporary resistance σв, MPa | relative elongation δ5, % | |||

| 375 | Up to 50.0 incl. | 10HSND | 375 | 510 | 21 |

| 390 | Up to 50.0 incl. | 390 | 510 | 19 | |

Impact strength of long and shaped steel

| Strength class | Rolled cross-section dimensions, mm | steel grade | Impact strength, J/cm2, not less, at test temperature, °C | |||||||||

| -20 | -30 | -40 | -50 | -60 | -70 | 0 | -20 | -40 | After mechanical aging +20(-10/+15) | |||

| KCU | KCV | KCU | ||||||||||

| 390 | From 5.0 to 10.0 incl. | 10HSND | 49 | 49 | 49 | 34 | 34 | 34 | + | + | + | 29 |

Impact strength KC at subzero temperatures

| GOST | Delivery status | Section, mm | KSU, J/cm2 at temperature, °C | |

| -40 | -70 | |||

| KSU | ||||

| GOST 19281-89 | Long and shaped rolled products | From 5 to 10 | 49 | 34 |

| From 10 to 15 incl. | 39 | 29 | ||

| KSV | ||||

| GOST 19281-89 | Leaf and strip | From 5 to 10 | 49 | 34 |

| From 10 to 15 incl. | 39 | 29 | ||

| St. 15 to 32 incl. | 49 | 29 | ||

| St. 32 to 40 incl. | 49 | 29 | ||

Endurance limit in hot-rolled state

| Thickness, mm | σ-1, MPa | τ-1, MPa |

| 4-32 | 284 | 167 |

| 33-40 | 274 | 167 |

Technological properties

| Forging temperature, °C | start 1200, end 850. |

| Weldability | Weldable without restrictions. Welding method - RDS, ADS submerged arc and gas shield, ESW. |

| Machinability | Kv tv.sp. = 1.12 and Kv b.st = 1.4 in the normalized and tempered state σв = 560 MPa |

| Tendency to temper brittleness | less inclined. |

| Flock sensitivity | insensitive. |

Brands of imported materials used in welded joints with steel 10HSND (STO 00220368-011-2007)

| Structural class | Steel grades | Brands of imported materials according to foreign standards |

| Pearlitic | 10HSND | ASTM SA-455 Gr70, ASTM SA-515 Gr70, ASTM SA-516 Gr70, ASTM SA-537 Gr70, ASTM SA-662 GrA(C), ASTM SA-662 GrB, ASTM SA-737 GrB, ASTM SA-738 GrA , ASTM SA-333 Gr3(6), ASTM SA-350 GrLF2, API 5L X56-65 |

The use of 10HSND steel in the manufacture of welded joints of pipeline fittings (ST TsKBA 025-2006)

| Material grade | Temperature of the working medium (wall), °C |

| 10HSND GOST 19281 | -70 to 475 |

Welding materials used in electric arc welding of steel 10HSND (ST TsKBA 025-2006)

| Base material grade | Electrode type according to GOST, TU (recommended brands of electrodes) | Application temperature, °C | Additional instructions |

| 10HSND GOST 19281 | E50A GOST 9467 (UONI-13/55) | Not lower than -60 | — |

| Below -60 to -70 | After welding heat treatment - normalization plus tempering | ||

| E50A GOST 9467 (VP-4, VP-6) | Below -60 to -70 | — |

Welding materials used for steel 10HSND when welding in shielding gases (ST TsKBA 025-2006)

| Grade of welded steel | Brand of welding wire according to GOST 2246, TU, recommended shielding gas or mixture of gases | Application temperature, °C | Additional instructions |

| 10HSND | Sv-08G2S Argon GOST 10157, carbon dioxide GOST 8050 or a mixture of argon and carbon dioxide ((75-85)% Ar + (15-25)% CO2) | Not lower than -40 | — |

| Below -40 to -70 | Subject to normalization plus vacation | ||

| Sv-08G2SNTYUR TU 14-1-3648 CO2, Ar, CO2 +Ar, | Not lower than -70 | — |

Welding materials for submerged arc welding of steel 10HSND (ST TsKBA 025-2006)

| Grade of welded steel | Wire grade according to GOST 2246, TU, Recommended flux grade according to GOST 9087 | Application temperature, °C | Additional instructions |

| 10HSND | Sv-10NYU TU 14-1-2219 Sv-10NMA, Sv-08GA, Sv-08G2S AN-348A, OSC-45, ANC-1 | Not lower than -60 | — |

| Below -60 to -70 | After welding heat treatment - normalization plus tempering |

Welding materials for welding steel 10ХСНД with dissimilar steels (ST TsKBA 025-2006)

| Grades of welded steels | Welding materials | Additional instructions | ||

| Electrodes, type according to GOST 10052 (recommended brands) | Welding wire, GOST 2246 or TU | |||

| Group A | Group B | |||

| 10Х18Н9Л 12Х18Н9ТЛ GOST 977 08Х18Н10Т 12Х18Н9Т 12Х18Н10Т 12Х18Н9 GOST 5632 08Х18Н10Т-ВД TU 14-1-3581 10Х18Н9 10Х18Н9-ВД 10Х18Н9-Ш Т U 108.11.937 15Х18Н12СЧТУ (EI 654) GOST 5632 10Х17Н13М3Т (EI 432) 10Х17Н13М2Т (EI 448) GOST 5632 | 10HSND | E-10Kh15N25M6AG2 (EA-395/9) E-10Kh25N13G2 (OZL-6, ZIO-8), E-11Kh15N25M6AG2 (NIAT-5, TsT-10) | Sv-07Х23Н13 | The welded joint is of unequal strength |

| E-10Х15Н25М6AG2 (EA-395/9) 582/23, 855/51 | Sv-10X16N25AM6 Sv-06X15N35G7M6B Sv-03X15N35G7M6B | The welded joint is of unequal strength. Welding materials are used for products under the jurisdiction of Rostechnadzor | ||

Temperature of preliminary and accompanying heating and tempering when welding structures made of steel 10HSND (ST TsKBA 025-2006)

| Grades of welded steels | Thickness of welded edges, mm | Temperature of preliminary and accompanying, °C | Interval between the end of welding and the start of tempering, hour | Temperature, °C | |

| welding | surfacing with austenitic class materials | ||||

| 10HSND | Up to 30 | Not required | Not required | Not limited | Not required |

| Over 30 | 150 | 150 | 630-660 | ||

The use of steel 10HSND for the manufacture of pressure vessels (PB 03-576-03)

| Steel grade, standard or specification designation | Technical requirements | Working conditions | Test types and requirements | |

| Wall temperature, °C | Medium pressure, MPa (kgf/cm2), no more | |||

| Sheet steel | ||||

| 10HSND, GOST 19281 | GOST 19281 | -40 to 400 | Not limited | GOST 19281 |

NOTE:

- Sheets in accordance with GOST 19281 must be supplied with mandatory compliance with paragraphs. 2.2.1,2.2.2, 2.2.3, 2.2.7, 2.2.9, 2.2.12 GOST, and the macrostructure must be monitored in accordance with GOST 5520 from a batch of sheets.

- Tests are carried out sheet by sheet at operating temperatures below -30 °C, above 200 °C or at a pressure of more than 5 MPa (50 kgf/cm2) with a sheet thickness of 12 mm or more.

- GOST 19281 applies to rolled products made of high-strength steels used for vessels that are not subject to heat treatment. The possibility of using rolled steel in accordance with GOST 19281 for vessels subjected to heat treatment must be agreed upon with a specialized research organization.

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | |||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | |

| 10HSND | — | 40 | 39 | 38 | 36 | 34 | 31 | 29 |

Young's modulus (normal elasticity) E, GPa

| Steel grade | At test temperature, °C | |||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | |

| 10HSND | — | 197 | 201 | 195 | 188 | 180 | 169 | 156 | 135 | 123 |

Find out more

Structural alloyed steel 38KhN3MFA…

Steel S355K

Steel 12ХН3А structural alloyed chrome-ni...

Structural alloy steel 36Kh2N2MFA…

Features of welding low-alloy steels

Welding of structural steels 15HSND, 15GS, 14G2, 14G2AF, 16G2AF

For welding low-alloy steel grades 15HSND, 15GS, 14G2, 14G2AF, 16G2AF, etc. Manual arc welding with E50A or E44A electrodes is well suited. But the highest quality welded joints are obtained when welding with UONI-13/55 and DSK-50 electrodes. But, the best results are obtained when welding with direct current with reverse polarity. At the same time, welding must be carried out at low currents, 40-50 A per millimeter of electrode diameter.

Automatic arc welding of these steel grades is performed using Sv-08GA or Sv-10GA welding wire under AN-348-A or OSTS-45 fluxes.

Metal structures made from steels 15HSND, 15GS, 14G2, 14G2AF, 16 G2AF can be welded at an ambient temperature of at least -10°C. If the ambient temperature is in the range from -10°C to -25°C, then preheating is necessary during welding. The heating width of the welding zone is 100-120 mm on both sides of the seam. Preheating temperature 100-150°C. At ambient temperatures lower than -25°C, welding of the above steels is not permissible.

Welding low-alloy steels 09G2S, 10G2S1, 10G2S1D

Assessment of the weldability of steel grades such as 09G2S, 10G2S1, 10G2S1D, etc. can be given a good one (see the table of weldability of steels), and this is due to the fact that they are not subject to hardening, are not prone to overheating and are resistant to the formation of hot and cold cracks in the weld and heat-affected zone. Welding of low-alloy structural steels of these grades can be performed either by manual or automatic arc welding.

For manual welding, electrodes of the E50A and E55A brands are well suited. For automatic welding, welding wire of the Sv-08GA, Sv-10GA or Sv-10G2 brands is used. To protect the welding zone, fluxes AN-348-A or OSTS-45 are used.

Welding of sheets made of steels 09G2S, 10G2S1, 10G2S1D, with a thickness of less than 40 mm, is carried out without cutting the edges. And, subject to the technology and welding conditions, the mechanical properties of the weld are almost as good as the mechanical properties of the base metal. The uniform strength of the weld is due to the transition of alloying elements from the electrode wire into the metal of the weld.

Automatic and semi-automatic welding in shielding gases

Carbon and low-alloy structural steels are welded with special silicon-manganese and chromium-manganese-silicon wires. Despite the different chemical composition and different mechanical properties of carbon and low-alloy steels, they can be welded with the same silicon-manganese wires Sv-08GS and Sv-08G2S.

Moreover, it is recommended to weld boiling carbon and low-alloy steels with wire with a higher manganese content. If products made from low-alloy steels containing chromium and nickel must be resistant to corrosion (for example, in sea water), they should be welded with chromium-silicon-manganese wire (Table 70).

Table 70. Recommended electrode wires for carbon dioxide welding of carbon and low-alloy steels.

| Steel | Requirements for welds and connections | Recommended Electrode Wires |

| St3sp, St4, steel 35, steel 40 | Uniform strength and high ductility | Sv-08G2S Sv-08GS |

| Steel 45, 20ХГС | Equal strength | CB-10Xg2C, Sv-08G2S |

| 10HSND, 15HSND, 10KHSND, 14KHS. 09G2. 14G2 and the like | Uniform strength and high ductility | Sv-08G2S |

| 10HSND, 10GSND, 15HSND | Uniform strength, ductility and corrosion resistance in sea water | Sv-10HG2S |

In table 71 and 72 provide data characterizing the mechanical properties of weld metal on carbon and low-alloy steels.

Table 71. Mechanical properties of the metal of three-layer welds made by arc welding in carbon dioxide on carbon steels.

| Steel | Wire | Yield strength kg/mm2 | Tensile strength kg/mm2 | Relative extension, % | Relative narrowing, % | Impact strength of weld metal (kg-m/cm2) at temperature, °C | Impact strength of weld metal at 20 °C after mechanical aging kg*m/cm2 | ||

| +20 | -20 | —40 | |||||||

| St3kp | Sv-08GS | 39 | 53 | 25 | 54 | 12 | 10 | 7 | 6 |

| St3kp | Sv-08G2S | 43 | 57 | 26 | 58 | 12 | 8 | 6 | 5 |

| St3sp | Sv-08GS | 40 | 54 | 24 | 54 | 11 | 6 | 5 | 6 |

| St3sp | Sv-08G2 | 44 | 57 | 22 | 51 | 13 | 9 | 5 | 6 |

| St4 | Sv-08GS | 38 | 54 | 24 | 52 | 12 | 8 | 7 | 7 |

| St4 | Sv-08G2S | 45 | 57 | 26 | 54 | 12 | 8 | 8 | 6 |

| Steel 36 | Sv-08G2S | 40 | 60 | 22 | 40 | 8 | 5 | — | — |

| Steel 40 | Sv-08G2S | 48 | 68 | 24 | 42 | 6,5 | 5 | 3 | — |

Note. Steel grades 35 and 40 were welded with a double-sided seam in two passes using wire with a diameter of 3 mm at the following mode: welding current 720-740A, arc voltage 36-38V; welding speed 40 m/h The remaining steels were welded in three layers with wire with a diameter of 2 mm at the mode: welding current 300-340A, arc voltage 28-30V welding speed 20 m/h.

Table 72. Mechanical properties of three-layer welds made in carbon dioxide with wire with a diameter of 2 mm on low-alloy steels.

| Steel | Wire | Yield strength kg/mm2 | Tensile strength kg/mm2 | Relative extension, % | Relative narrowing, % | Impact strength of weld metal (kg-m/cm2) at temperature, °C | Impact strength of weld metal at 20°C after mechanical aging kg*m/cm2 | ||

| +20 | -20 | —40 | |||||||

| 14ХГС | Sv-08G2S | 39 | 56 | 25 | 56 | 10 | 8 | 7 | 6 |

| 10HSND (SHL-4) | Sv-08G2S | 48 | 65 | 24 | 50 | 10 | 8 | 6 | 7 |

| 10HSND (SHL-4) | Sv-08GS | 43 | 60 | 26 | 64 | 12 | 9 | 8 | 7 |

| 15HSND (SHL-1, NL-2) | Sv-08G2S | 41 | 57 | 31 | 62 | 10 | 6 | 5,5 | 8 |

| 09G2 | Sv-08G2S | 36 | 49 | 34 | 70 | 15 | 11 | 8 | 7 |

| 10HSND | Sv-08HGS | 41 | 58 | 26 | 64 | 14 | — | 10 | 7 |

| 10HGSND | Sv-10HG2S | 51 | 67 | 23 | 59 | 11 | 7 | 7 | 4 |

| 14Х2ГМР | Sv-10KhGSN2MYU | 78 | 88 | 17 | 55 | 10 | 9 | 8 | — |

Thin-sheet carbon steels and small-sized parts made from these steels can also be welded using Sv-12GS wire with a diameter of up to 1.2 mm.

- Back

- Forward

Welding 10HSND+18KhGT

We will take another different path:

Chapter XX

Dissimilar metal welding technology

Weldability Basics

Combined welded structures made of dissimilar steels are divided into structures made of homogeneous steel, welded with electrodes of a different class; structures made of dissimilar steels and bimetallic structures. Structures made from dissimilar steels, in turn, are divided into units made from steels of the same structural class and into units made from steels of different structural classes. Welded assemblies made of steels of the same structural class can be made of pearlitic steel of different alloys; martensitic; martensitic-ferritic and ferritic steels of different alloys and austenitic steels of different alloys. Welded assemblies made of steels of the same structural class can be used for operation at normal temperatures (building structures, general mechanical engineering assemblies, hydraulic turbine assemblies); low temperature (assemblies of cryogenic installations); high temperatures (components of power machines, nuclear power plants) and in aggressive environments at high temperatures (components of petroleum engineering and chemical apparatus). Welded assemblies made of steels of different structural classes are made in the following combination: pearlitic steels with martensitic, martensitic-ferritic and ferritic; pearlitic steels with austenitic ones; martensitic, martensitic-ferritic and ferritic steels with austenitic ones. Welded assemblies made of steels of different structural classes can also be used for work at normal, low and high temperatures and for work in aggressive environments at high temperatures. Based on the combination of steels in one welded joint, two main groups of structures can be distinguished: with welded joints of steels of the same structural class, but of different alloying, and with welded joints of steels of different structural classes. Before welding dissimilar steels, it is necessary to consider the following: 1. Do the elements contained in the steel have mutual solubility; if there is no mutual solubility of the elements, then in this case an intermediate metal is used, the elements of which have good mutual solubility with both steels being welded. 2. The presence of phase and structural transformations during cooling, leading to the formation of cold cracks. 3. The presence of different coefficients of linear and volumetric expansion of steels. A general solution to eliminate the last two cases is the use of various types of thermal influences (preliminary and concomitant heating and subsequent heat treatment of welded joints), as well as the use of various inserts that have close linear and volumetric expansion to the steels being welded.”

Taken from the resource www.oSvarke.Info

Post edited by AVN: 14 September 2014 00:39