Annealing is one of the main heat treatment operations designed to obtain certain properties of steel. It can serve as an intermediate step or perform the functions of the final technological process. Goals achieved using various types of annealing: reduce hardness, obtain a homogeneous structure convenient for subsequent machining operations, relieve internal stresses. Depending on the heating temperature, time and holding conditions, two main types of annealing are distinguished – types I and II, which, in turn, are divided into subtypes.

Annealing of steels of the first type - purpose, types, heating temperatures

Depending on the heating temperatures and the initial state of the alloy, during various types of annealing of the first type, processes of homogenization, recrystallization, elimination of residual stresses, and reduction of hardness occur. All these processes take place when alloys are heated both above and below the temperatures at which phase transformations occur. The main goals achieved with this type of heat treatment are the elimination of chemical and physical heterogeneity that occurs after welding, cutting, pressure treatment, and hardening.

Homogenization (diffusion) annealing

This type of heat treatment is used for alloyed ingots. It allows you to reduce dendritic or intracrystalline heterogeneity, which increases the susceptibility of the metal to negative phenomena during pressure treatment, including:

- brittle fracture;

- uneven properties in different directions;

- layered fracture;

- cracking;

- decrease in plasticity and viscosity.

Diffusion process mode:

- heating to high temperatures (up to +1200°C), at which the characteristics of the alloy structure are leveled in all directions;

- exposure – 15-20 hours;

- rapid cooling of the workpiece to 800-820°C, and then slower cooling in air.

As a result of the homogenization thermal process, coarse grains are obtained, which are crushed by further pressure treatment or heat treatment.

Recrystallization annealing of steel

This type of heat treatment is used on steel blanks or semi-finished products after cold working or between such operations. It consists of heating to temperatures exceeding the temperatures of recrystallization processes, holding and cooling. The operating temperature is determined by the carbon content in the alloy:

- 0.08-0.2% C–+680…700°C. Such steels are subjected to stamping, rolling, and drawing.

- High carbon alloy steel – +680…740°C. Usually these are calibrated rods made of chromium-containing nickel-free and chromium-nickel grades. Exposure – 0.5-1.5 hours.

To relieve stress

This type of heat treatment is used for castings, welded products, and workpieces after cutting, in which residual stresses appear as a result of non-uniform cooling and plastic deformations. Residual stresses provoke a number of negative consequences, including changes in dimensional parameters and deformation processes during storage, transportation and operation of products.

The stress relieving operation is carried out in the following temperature ranges:

- Lead screws, gears, worms: +570-600°C, holding for 2-3 hours after the main machining, +160…+180°C, holding for 2-2.5 hours after finishing measures carried out to relieve stress after grinding.

- Weld stress relief treatment: +650-700°C.

Residual stresses also decrease during recrystallization annealing, during which phase transformations occur.

Annealing to relieve residual stress

It is used for castings, welded joints, parts after cutting, etc., in which, during previous technological operations, due to uneven cooling, non-uniform plastic deformation, etc. residual stresses have arisen. They can cause dimensional changes, warping and cracks in parts during processing, operation and storage. Annealing is carried out at a temperature of 160...700 0C followed by slow cooling.

After the main machining, high-precision parts (lead screws, high-stress gears, worms, etc.) are subjected to annealing at 570...600 0C for 2...3 hours, and after final machining to relieve grinding stresses at a temperature of 160...180 0C 2…2.5 hours. Annealing to relieve welding stress is carried out at 650...700 0C.

Annealing of the second type > Continue >

Annealing of the second kind – processes with phase recrystallization

Annealing of the second type is carried out only at temperatures above the threshold for the onset of phase transformations. Varieties - complete, isothermal, incomplete.

Full

Complete annealing consists of heating above the critical temperature A3 (the end of recrystallization), holding until phase transformations are completely completed, and slow cooling. When heated to temperatures exceeding point A3 by 30-50°C, the steel, after complete annealing, acquires a single-phase austenitic structure with fine grains, providing increased toughness and ductility. At higher temperatures, the austenite grain increases in size, which reduces the characteristics of the semi-finished product.

The heating temperature and holding time in high-temperature conditions are determined by the type of workpieces, the method of placing them in the oven, and the height of the charge. To protect steel from oxidation and decarburization, annealing is carried out in protective atmospheres.

The cooling rate is determined by the chemical composition of the steel. The greater the stability of supercooled perlite the metal exhibits, the slower it needs to be cooled. Therefore, carbon steels are cooled at a rate of 100-150 degrees per hour, and alloy steels are cooled much more slowly - at a rate of 40-60 degrees per hour. After the decomposition of austenite in the ferritic region, cooling can be more intense. It can be implemented even in air. If the purpose of this type of heating is to relieve stress in parts of a complex configuration, then slow cooling in the furnace is carried out until normal temperatures are reached.

Full annealing is usually used for long products, shaped castings, and forgings made of medium-carbon steels.

Isothermal annealing

With this type of heat treatment, heating is carried out as for complete annealing. The difference between the process is rapid cooling to temperatures below the critical point A1, usually +660...680°C. At the temperature to which the steel was quickly cooled, isothermal exposure is carried out - up to 6 hours, during which the austenitic structure completely disintegrates. At the next stage, the semi-finished products are cooled in air.

The advantage of the isothermal process compared to the full one is the reduction in the operation period. This is especially true for alloyed grades. Another advantage is obtaining the most uniform structure over the entire cross-section of the workpiece. Workpieces that are planned to be processed by cutting are annealed at temperatures of 930-950°C, which ensure a slight coarsening of the grain and improved processing by the cutting tool.

Most often, isothermal annealing is applied to: forgings and small-sized rolled products made from alloy grades. For large cages (from 20 tons), isothermal annealing is not used, since in certain areas of the cage transformations are carried out under different temperature conditions.

For medium carbon spring steel with a carbon content of 0.6-0.9% C, a specialized isothermal treatment called patenting is used. This process serves to prepare the wire for multi-stage reduction during cold drawing.

The first stage is heating the workpieces to temperatures at which complete austenitization of the structure occurs (approximately +900°C), the second is immersion in salts with temperatures in the range of +450...+600°C.

The sorbitol or thin-plate troostite structures formed after such treatment provide:

- the possibility of significant compression during broaching;

- absence of breaks during cold deformations;

- high strength after finishing drawing.

Partial annealing

With incomplete annealing, metal products are heated slightly above the critical temperature A1. This type of heat treatment improves the cutting processing of semi-finished products from hypereutectoid (with a carbon content of more than 0.8%) alloy and carbon steels.

Stages of partial annealing in hypereutectoid steels:

- Heating to temperatures above point A1 by 10-30°C (usually +750...770°C). Provides almost complete recrystallization of the structure. During this process, the lamellar ferrite becomes spheroidal in shape. Therefore, this operation is often called spheroidization.

- Cooling to 600°C at speeds up to 60°C/hour. The more alloying additives in the steel, the slower the cooling should be.

- Cooling in air from +600°C to normal temperature.

Normalization annealing

Normalization (normalization annealing) is considered an intermediate process between hardening and annealing, since it allows one to obtain less fragility of the metal than with hardening and greater hardness than with other types of annealing. Therefore, normalization is a process widely used for the manufacture of mechanical engineering parts.

Normalization is often performed with rolling heating. Heating temperatures:

- hypoeutectoid steels - up to temperatures exceeding A3 by 40-50°C;

- hypereutectoid steels – 40-50°C above the Am point.

Next, a short holding period is carried out, during which phase transformations are completed, and cooling is done in air.

Normalization is accompanied by complete recrystallization and refinement of the structure formed after casting, forging, rolling, and stamping. For low-carbon steels, normalization is in demand instead of annealing in order to obtain increased hardness, improve cutting performance, and surface quality. For some alloy grades, normalization with air cooling replaces the quenching process. Heating for normalization of hot-rolled bars is often carried out with high-frequency currents.

Types of steel annealing. Annealing of the first and second kind.

⇐ PreviousPage 4 of 15Next ⇒

Annealing of the first kind is a heat treatment process that consists of heating a part to a temperature below phase transformations, holding it at this temperature and then slowly cooling it at a given rate.

This type of annealing is used to remove work hardening and internal stresses in parts subjected to cold deformation (cold rolling, cold stamping, drawing).

The temperature of recrystallization annealing of any metal is taken to be 50-100° C higher than the recrystallization temperature of the given metal. The recrystallization temperature of a given metal or alloy is taken equal to 0.4 melting temperature (measured from absolute zero).

Recrystallization consists in the fact that, starting from a certain temperature, when heated, intense movement of atoms in the metal occurs, which entails a change in the shape and size of deformed crystalline grains.

During the process of recrystallization, transformations occur similar to those that occur during primary crystallization and secondary recrystallization, i.e., new crystal centers are generated and their growth occurs simultaneously. Instead of elongated, flattened grains, small, spheroidal grains are formed, plastic properties increase, and the metal returns to its original properties.

The temperature of recrystallization annealing is different for different metals and alloys: it depends only on the recrystallization temperature of the given metal or alloy. For all steels, the recrystallization annealing temperature is always below the Ar1 temperature (see Fig. 30).

Annealing of the second type consists of heating the part to a temperature slightly above the critical temperature, holding it for a long time at this temperature, and then slowly cooling it at a given speed. Annealing is used to relieve internal stresses, improve machinability, eliminate structural heterogeneity and prepare for subsequent heat treatment.

Annealing of the second type, according to the heating and holding conditions, is divided into complete, incomplete and diffusion;

according to cooling conditions - for isothermal annealing and normalization;

according to the conditions of influence of external factors - for bright annealing and according to the conditions of structure changes - for spheroidizing annealing.

Diffusion annealing is used mainly for ingots and large castings of alloy steel to level out chemical heterogeneity and reduce segregation. Annealing is carried out by heating to 150-250 ° C above the Ac3 point, holding for a long time at this temperature and subsequent cooling at a given speed.

Diffusion annealing produces a coarse-grained structure. To obtain a fine-grained structure after diffusion annealing, it is necessary to perform conventional full annealing.

Complete annealing is carried out by heating the steel 30-50°C above the critical point Ac3, holding at this temperature and slowly cooling to 400-500°C at a rate of 200°C per hour for carbon steels, 100°C per hour for low-alloy steels and 50 ° C per hour for high-alloy steels.

The structure of steel after annealing is equilibrium and stable.

Hypoeutectoid steel has a structure: ferrite and pearlite. Eutectoid steel has a pearlite structure, while hypereutectoid steel has pearlite and cementite.

The final structure of steel is greatly influenced by the cooling rate. The faster the cooling rate, the finer the pearlite grains will be and the less excess ferrite or cementite will be released.

Hot-deformable steel—forgings, stamped parts, rolled products, as well as ingots and shaped castings made of plain and alloy steel—are subjected to full annealing.

Partial annealing is carried out by heating the steel to a temperature in the range between points Ac1 and Ac3. Cooling conditions are the same as for full annealing. Partial annealing is used primarily for hypereutectoid steel, as well as long products and forgings made of hypoeutectoid steel before machining, to reduce internal stresses and improve machinability.

Spheroidizing annealing (on granular pearlite) consists of heating the steel above the critical temperature Ac1 by 20-30°C, holding it at this temperature and slowly cooling (25-30°C per hour) to a temperature of 600°C. The purpose of such annealing is to transfer the lamellar perlite into granular (globular). Typically, eutectoid and hypereutectoid steels are subjected to spheroidization, obtaining high values of relative elongation and relative contraction.

Isothermal annealing is a type of full annealing. It is mainly used for alloy steels. Economically, this process is very profitable, since the duration of conventional annealing is 13–15 hours, and isothermal annealing is 4–6 hours.

The process of isothermal annealing is as follows: the part is heated to a temperature above the critical point Ac3 by 30-50 ° C, maintained at this temperature, and then cooled relatively quickly to a temperature of 600-650 ° C. It is maintained at this temperature, which is necessary for complete decomposition austenite, followed by relatively rapid cooling (Fig. 32).

For all types of annealing, overheating and burning of steel is not allowed. Overheating of steel is a correctable defect: the coarse-grained structure formed during overheating can be corrected by repeated annealing. Overburning of steel is an irreparable defect, since the highly oxidized boundaries of crystalline grains lose their connection and the part is destroyed.

Hardening of steel.

Hardening is a common heat treatment process for steel parts. It is carried out by heating parts above the critical point Ac3 (hypoeutectoid steel) or Ac1 (hypoeutectoid steel) by 30-50 ° C, holding at this temperature and rapid cooling. The main purpose of steel hardening is to obtain high hardness, wear resistance and physical and mechanical properties.

A sharp increase in hardness and strength during hardening occurs due to phase transformations of the structure during heating and cooling and the formation of nonequilibrium solid structures—martensite, troostite and sorbitol.

The quality of hardening depends on the correct choice of hardening mode (heating temperature, holding time and cooling rate). The heating temperature for hardening depends on the chemical composition of the steel. For carbon steels, it is selected using the alloy state diagram.

Heating of the parts must be slow enough so that stresses and cracks do not occur. The heating time depends on the chemical composition of the steel, the shape and size of the parts. If heating is carried out in salt baths, then the heating rate is recommended to be 0.5 min per 1 mm of cross-section; if the part is heated in electric furnaces, then the heating time is recommended to be 15-20 min per 1 mm of cross-section of the sample. The holding time must be sufficient for the entire process of transformation of pearlite into austenite to be completed completely. The holding time is usually recommended to be 25% of the total heating time.

Cooling the part is the most critical stage of the operation. The cooling rate must be such as to ensure the production of the desired structure - martensite, troostite or sorbitol, i.e., to ensure the necessary mechanical properties of the workpiece.

The critical quenching rate is the cooling rate that ensures the formation of a structure—martensite or martensite and retained austenite.

When the cooling rate is less than critical, the structure of hardened steel will contain troostite along with martensite, and with a further decrease in the rate, troostite or sorbite structures without martensite are obtained. To obtain the martensite structure, it is necessary to supercool the austenite to the temperature at which the martensitic transformation of a given steel begins by rapidly cooling the steel (the temperature of the lowest stability of austenite is 550-650 ° C).

In the martensitic transformation temperature zone, i.e. below 300° C, on the contrary, it is more advantageous to use slow cooling, since structural stresses have time to level out, and the hardness of the resulting martensite practically does not decrease when held below the Mk point.

For successful heat treatment, the correct choice of quenching medium is of great importance.

For hardening medium-carbon steels, water at a temperature of 18 ° C can be recommended, and for most other steels - oil.

The ability of steel to be hardened to a certain depth is called hardenability. The hardening depth is taken to be the distance from the surface of the hardened part to the layer with a semi-martenent structure (50% martensite and 50% troostite).

When cooling during the hardening process, internal stresses arise in the steel—thermal and structural. Thermal stresses arise as a result of uneven cooling, and structural stresses arise during the transformation of austenite into martensite, which is accompanied by a significant increase in volume. As a result of the creation of such stresses during hardening, defects of the following types may occur: cracks, warping, barreling, change in volume. Hardening defects also include soft spots, reduced hardness and strength of steel, decarburization, oxidation, overheating, burnout, etc.

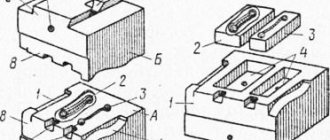

Proper immersion of parts in a quenching medium helps to avoid the formation of certain defects (leads, warping, cracks, etc.). When immersing parts, you can be guided by the following provisions (Fig. 33);:

a) immerse long parts (drills, reamers, broaches) in a strictly vertical position;

b) parts with a concave surface should be immersed in a quenching medium with the concave surface up, since otherwise a steam bag will form and the part will not be hardened in this place;

c) parts with thick and thin parts should be immersed in the quenching medium with the thick part;

d) immerse thin and flat parts with the narrow side.

Depending on the thickness of the hardened layer in parts, volumetric and surface hardening are distinguished. Depending on the cooling rate, they distinguish between stepwise and isothermal hardening, and depending on the heating method, hardening with heating in furnaces, high-frequency currents, gas flames and electric furnaces. Volumetric hardening (full) with continuous cooling is used for carbon steels (cooling in water) and for alloy steels (cooling in oil). This method involves immersing a heated part in a quenching medium and holding it until completely cooled. The disadvantage of this method is the occurrence of large thermal stresses due to the sharp temperature difference between the heated part and the cooling medium.

Step hardening is carried out by rapid cooling sequentially in two different cooling environments. The first cooling medium is molten salts or oil with a temperature 20-30 ° C above the temperature of the onset of martensitic transformation (point Mn) for a given steel. In a hot environment, parts are allowed to soak for a short time. Soaking in molten salts or oil should ensure temperature equalization across the cross section of the part, but not cause austenite decomposition. The second cooling medium is air. In this case, austenite transforms into martensite. The advantage of this method of hardening is the reduction of thermal stresses, and therefore cracks, leads and warping, as well as a good combination of high viscosity and strength. Step hardening is used for small parts (with a cross-section of 8-10 mm) made of carbon steel and for parts (with a cross-section of up to 30 mm) made of alloy steel.

Isothermal hardening, like step hardening, is carried out in two cooling environments. The temperature of the hot medium (salt, nitrate or alkaline baths) is different: it depends on the chemical composition of the steel, but is always (20-100 ° C) above the martensitic transformation point for a given steel.

The holding time must be sufficient for the complete transformation of austenite into acicular troostite. Final cooling to room temperature is carried out in air.

Isothermal hardening is widely used for parts made of high-alloy steels. After isothermal hardening, steel acquires high strength properties, that is, a combination of high toughness and strength.

Light hardening of steel parts for any type of hardening process is carried out in specially equipped furnaces using protective environments or in baths with molten layers. Baths for heating parts for hardening are usually made of sodium chloride at a temperature 30-50 ° C above the temperature of the Ac1_3 point.

Cooling of parts is carried out at a temperature of 180-200 ° C in a bath consisting of 75% caustic potassium and 25% caustic soda, with the addition of 6-8% water (by weight of the total salt). This mixture has a very high hardening ability.

After light hardening of the surface, the parts acquire a light silver-white color. In this case, there is no need to sandblast the parts and washing them in hot water is sufficient.

Self-tempering hardening is widely used in tool production. The process consists in the fact that the parts are kept in a cooling medium not until they are completely cooled, but at a certain moment they are removed from it in order to retain a certain amount of heat in the core of the part, due to which subsequent tempering is carried out.

Martensitic transformation.

Martensitic transformation, a polymorphic transformation in which a change in the relative arrangement of the atoms (or molecules) that make up the crystal occurs through their ordered movement, and the relative displacements of neighboring atoms are small compared to the interatomic distance [1]. The restructuring of the crystal lattice in microregions usually comes down to the deformation of its cell, and the final phase of the martensitic transformation can be considered as a uniformly deformed initial phase. The magnitude of the deformation is small (on the order of 1–10%) and, accordingly, the energy barrier that prevents the uniform transition of the initial phase to the final phase is small, compared to the binding energy in the crystal. A necessary condition for the martensitic transformation, which develops through the formation and growth of regions of a more stable phase in a metastable one, is the preservation of ordered contact between the phases. The ordered structure of interphase boundaries with a small barrier for a uniform phase transition ensures their low energy and high mobility. As a consequence, the excess energy required for the nucleation of crystals of a new phase (martensitic crystals) is small and, with some deviation from phase equilibrium, becomes comparable to the energy of defects present in the initial phase. Therefore, the nucleation of martensite crystals occurs at a high rate and may not require thermal fluctuations. Due to the influence of the formed phase on the initial phase, the energy barrier for moving the phase boundary is significantly less than for a homogeneous transition; with small deviations from equilibrium, it disappears - the crystal grows at a speed on the order of sound and without thermal activation (the transformation is possible at temperatures close to absolute zero).

Martensitic transformations are found in many crystalline materials: pure metals, numerous alloys, ionic, covalent and molecular crystals. Martensitic transformations have been most fully studied in iron-based alloys, in particular in connection with the hardening of steel. Great prospects for practical application are the possibility of large reversible shape changes during martensitic transformations (for example, the creation of “superelastic” alloys and products that restore their original shape when heated after plastic deformation - the “memory effect”), as well as the connection between martensitic transformations and the appearance of superconducting properties in some metals . Martensitic transformations (often in combination with diffusion redistribution of components and changes in atomic order) form the basis of numerous structural transformations, due to which, with the help of thermal and mechanical treatment, a directed change in the properties of crystalline materials is carried out. A significant contribution to the study of martensitic transformations was made by the work of Soviet scientists (G.V. Kurdyumov and his school).

Steel tempering.

Steel tempering is the final heat treatment operation that shapes the structure and, consequently, the properties of steel.

Tempering consists of heating steel to different temperatures (depending on the type of tempering, but always below the critical point Ac1), holding it at this temperature and cooling at different rates.

The purpose of tempering is to relieve internal stresses arising during the hardening process and obtain the necessary structure. Depending on the type of tempering, the structure of the steel can be martensite, troostite or sorbitol tempering.

Depending on the heating temperature of the hardened steel part, three types of tempering are distinguished: high, medium and low.

High tempering is carried out at heating temperatures above 350-600 ° C, but below the critical point Ac1. A structure is formed in the parts - tempered sorbitol; such tempering is used for structural steels.

Average tempering is carried out at heating temperatures of 350–500° C. A troostite tempering structure is formed in the parts; Such tempering is widely used for spring and spring steels.

Low tempering is carried out at temperatures of 150-250° C. The hardness of the part after hardening remains almost unchanged. Metal structure—tempered martensite; low tempering is used for carbon and alloy tool steels, which require high hardness (HRC 59-63) and wear resistance.

In addition to heating temperature, the main factor when tempering is exposure. The cooling rate is not important in most cases.

⇐ Previous4Next ⇒

Recommended pages:

Use the site search:

Annealing on granular pearlite

To obtain the structure of granular pearlite, pendulum annealing is carried out, after which eutectoid and hypereutectoid steels provide good machinability, the speed of the cutting process increases and the surface quality improves. This type of T/O is suitable for thin sheets before cold stamping and rods before cold drawing. The result is improved plastic properties.

The pendulum annealing mode consists of several heating cycles above the critical point A3 with slow cooling to +670...+700°C. Three such cycles make it possible to obtain a structure with 100% granular perlite. Final cooling is in air.

Homogenization annealing

Homogenization annealing is used for ingots and castings in which, under real crystallization conditions, a chemically inhomogeneous structure has formed, including dendritic segregation and the presence of nonequilibrium eutectics or other structural components (see lecture 3).

The purpose of homogenization annealing is to eliminate chemical inhomogeneities in the structure and, on this basis, increase the plasticity of the casting material, improve the manufacturability of ingots during pressure processing, increase the homogeneity of the structure of finished products and improve the complex of their properties.

Temperature

heating during homogenization annealing should be extremely high, close to the melting temperature.

This will allow you to minimize the exposure time. However, the upper limit of the annealing temperature regime is limited by the development of possible undesirable phenomena, such as excessive growth of grain size ( overheating

) or melting of grain boundaries enriched with impurities, which is accompanied by gas saturation, the formation of gas and shrinkage porosity, oxidation and the occurrence of cracks (

burnout

).

Practice shows that in most cases the annealing temperature can be preliminarily determined as (0.90 - 0.95) from the melting temperature in Kelvin. Then, for each specific alloy, it is refined on the basis of ongoing studies of the structure and properties of blanks and finished products. The optimal temperature is considered to be the one that, at minimal cost (short annealing time), ensures sufficient manufacturability of the workpiece material during pressure processing (pressing, rolling, etc.) and a given level of properties of the finished products.

Exposure duration

during homogenization annealing depends on the type of alloy, the technology for its production, the size of the workpieces and the amount of charge in the heating device (furnace). It consists of the duration of heating of the product along the thickness or the heating time across the cross-section of a large cage; the time required for the dissolution of nonequilibrium structural components in the alloy structure; and, finally, the time required to eliminate dendritic liquation.

Warm-up duration

is determined by thermotechnical calculations based on solving differential equations of thermal conductivity or by experimental methods by thermometering the charge in a furnace.

Time required for dissolution of nonequilibrium structural components

, can be determined by the empirical expression

t = a× mb

,

where a

and

b

are constants for a specific alloy and its production technology;

m

is the thickness of dissolving particles of nonequilibrium structural components.

The value of a

is largely determined by the size of the workpieces and products being processed, and the value of the exponent

b

is determined by the stability of nonequilibrium phases and the diffusion characteristics of the system.

For aluminum alloys, for example, the value of b

ranges from 1.2 to 2.5, with average values equal to 2, which indicates predominantly diffusion kinetics of dissolution of nonequilibrium structural components in such alloys.

Third

The component of the holding time during homogenization annealing is determined by the time spent

on homogenization of the solid solution

, which in the initial state or after the end of dissolution is characterized by a nonequilibrium structural component of chemical heterogeneity over the cross section of each grain (intracrystalline or dendritic liquation).

Heating rate and cooling rate -

additional technological parameters of homogenization annealing. Ingots and shaped castings, especially complex shapes, should be heated slowly, usually with a furnace, to avoid the occurrence of thermal stresses that can lead to cracking or warping of the products.

For the same reason, cooling is often carried out slowly (together with the furnace). When assigning cooling modes, the greatest importance is given to taking into account the phase transformations developing during cooling. In this case, methods and cooling rates are used in which, as a result of the development of phase transformations, the plasticity of the alloys further increases. For example, after annealing steel ingots, cooling is usually carried out slowly (together with the furnace) at a rate of several degrees to several tens of degrees per hour. The resulting pearlite structures are characterized by a rather coarse lamellar structure with low strength but high plastic characteristics.

On the contrary, it is recommended to cool ingots made of thermally hardenable aluminum alloys after homogenization annealing at an accelerated rate (for example, in air), thereby preventing secondary precipitation of usually brittle phase components along the grain boundaries of the solid solution.

After a long homogenizing soak, castings from cast aluminum alloys are cooled very quickly - in water, which completely prevents the release of excess phase. In addition, this combination of homogenization annealing and rapid “quenching” cooling eliminates the need for new heating for quenching, reducing the overall duration of the casting production cycle.

Sometimes they use placing hot ingots in an annealing furnace that are not completely cooled in a crystallizer or mold, feeding ingots from an annealing furnace to a hot rolling operation, excluding cooling operations after annealing the ingots and reheating them for pressure treatment. This reduces the overall duration of annealing and increases the overall efficiency of the processes for obtaining products.

Alloy steels containing

chromium, molybdenum, vanadium, tungsten, titanium, etc., are annealed at temperatures of 1050 - 1250 ° C in large cages with exposure from 8 to 20 hours. Heating and cooling are very slow (up to 10 - 20 ° / h). The total cycle duration reaches 160 - 180 hours.

Aluminum alloys

annealed at temperatures from 440 to 640 °C depending on the chemical composition of the alloys. Mostly this temperature is 5 - 40 °C lower than the nonequilibrium solidus temperature of a particular alloy. Thus, for duralumins D1 and D16, whose nonequilibrium solidus temperatures are 509 and 508 °C, the homogenization annealing temperature ranges are respectively: 470 - 500 °C and 470 - 495 °C. For high-strength alloy V95 with a nonequilibrium solidus temperature of 475 °C, the annealing temperature is 440 - 470 °C. For an alloy of the aluminum-magnesium system, grade AMg6, which has a nonequilibrium solidus temperature of 460 °C, the annealing temperature is very close to the solidus - 450 - 460 °C. For a low-alloy AMts alloy, 650 and 600 - 640 °C, respectively. The holding time during annealing ranges from several hours to several tens of hours. For alloys of the duralumin type this time is from 8 to 36 hours, for alloys of the Al - Mg systems up to 48 hours.

Cooling of ingots or billets made of aluminum alloys is usually carried out in air. When using continuous furnaces, ingot billets are fed directly to rolling mills for hot plastic deformation, cooled from the annealing temperature to the deformation temperature. Castings from aluminum alloys are cooled after homogenization in water, combining annealing with hardening.

Magnesium alloys

homogenize at temperatures of 390 - 415 °C. The holding time is 18 - 24 hours. As for aluminum alloys, a combination of homogenization annealing with heating under pressure treatment (for ingots) and hardening (for castings) is often used. A feature of magnesium alloys is their high chemical activity in contact with atmospheric oxygen, and therefore there is always a danger of self-ignition. Therefore, it is advisable to heat ingots or castings to annealing temperatures in protective environments, the simplest of which is a mixture of air and sulfur dioxide.

For both aluminum and magnesium alloys, high-temperature homogenization is sometimes used (at temperatures several degrees higher than the nonequilibrium solidus temperature), which sharply increases the degree of homogenization of ingots and castings and increases the ductility of the alloys by at least 1.5-3 times.

Homogenization annealing is used for ingots and castings in which, under real crystallization conditions, a chemically inhomogeneous structure has formed, including dendritic segregation and the presence of nonequilibrium eutectics or other structural components (see lecture 3).

The purpose of homogenization annealing is to eliminate chemical inhomogeneities in the structure and, on this basis, increase the plasticity of the casting material, improve the manufacturability of ingots during pressure processing, increase the homogeneity of the structure of finished products and improve the complex of their properties.

Temperature

heating during homogenization annealing should be extremely high, close to the melting temperature.

This will allow you to minimize the exposure time. However, the upper limit of the annealing temperature regime is limited by the development of possible undesirable phenomena, such as excessive growth of grain size ( overheating

) or melting of grain boundaries enriched with impurities, which is accompanied by gas saturation, the formation of gas and shrinkage porosity, oxidation and the occurrence of cracks (

burnout

).

Practice shows that in most cases the annealing temperature can be preliminarily determined as (0.90 - 0.95) from the melting temperature in Kelvin. Then, for each specific alloy, it is refined on the basis of ongoing studies of the structure and properties of blanks and finished products. The optimal temperature is considered to be the one that, at minimal cost (short annealing time), ensures sufficient manufacturability of the workpiece material during pressure processing (pressing, rolling, etc.) and a given level of properties of the finished products.

Exposure duration

during homogenization annealing depends on the type of alloy, the technology for its production, the size of the workpieces and the amount of charge in the heating device (furnace). It consists of the duration of heating of the product along the thickness or the heating time across the cross-section of a large cage; the time required for the dissolution of nonequilibrium structural components in the alloy structure; and, finally, the time required to eliminate dendritic liquation.

Warm-up duration

is determined by thermotechnical calculations based on solving differential equations of thermal conductivity or by experimental methods by thermometering the charge in a furnace.

Time required for dissolution of nonequilibrium structural components

, can be determined by the empirical expression

t = a× mb

,

where a

and

b

are constants for a specific alloy and its production technology;

m

is the thickness of dissolving particles of nonequilibrium structural components.

The value of a

is largely determined by the size of the workpieces and products being processed, and the value of the exponent

b

is determined by the stability of nonequilibrium phases and the diffusion characteristics of the system.

For aluminum alloys, for example, the value of b

ranges from 1.2 to 2.5, with average values equal to 2, which indicates predominantly diffusion kinetics of dissolution of nonequilibrium structural components in such alloys.

Third

The component of the holding time during homogenization annealing is determined by the time spent

on homogenization of the solid solution

, which in the initial state or after the end of dissolution is characterized by a nonequilibrium structural component of chemical heterogeneity over the cross section of each grain (intracrystalline or dendritic liquation).

Heating rate and cooling rate -

additional technological parameters of homogenization annealing. Ingots and shaped castings, especially complex shapes, should be heated slowly, usually with a furnace, to avoid the occurrence of thermal stresses that can lead to cracking or warping of the products.

For the same reason, cooling is often carried out slowly (together with the furnace). When assigning cooling modes, the greatest importance is given to taking into account the phase transformations developing during cooling. In this case, methods and cooling rates are used in which, as a result of the development of phase transformations, the plasticity of the alloys further increases. For example, after annealing steel ingots, cooling is usually carried out slowly (together with the furnace) at a rate of several degrees to several tens of degrees per hour. The resulting pearlite structures are characterized by a rather coarse lamellar structure with low strength but high plastic characteristics.

On the contrary, it is recommended to cool ingots made of thermally hardenable aluminum alloys after homogenization annealing at an accelerated rate (for example, in air), thereby preventing secondary precipitation of usually brittle phase components along the grain boundaries of the solid solution.

After a long homogenizing soak, castings from cast aluminum alloys are cooled very quickly - in water, which completely prevents the release of excess phase. In addition, this combination of homogenization annealing and rapid “quenching” cooling eliminates the need for new heating for quenching, reducing the overall duration of the casting production cycle.

Sometimes they use placing hot ingots in an annealing furnace that are not completely cooled in a crystallizer or mold, feeding ingots from an annealing furnace to a hot rolling operation, excluding cooling operations after annealing the ingots and reheating them for pressure treatment. This reduces the overall duration of annealing and increases the overall efficiency of the processes for obtaining products.

Alloy steels containing

chromium, molybdenum, vanadium, tungsten, titanium, etc., are annealed at temperatures of 1050 - 1250 ° C in large cages with exposure from 8 to 20 hours. Heating and cooling are very slow (up to 10 - 20 ° / h). The total cycle duration reaches 160 - 180 hours.

Aluminum alloys

annealed at temperatures from 440 to 640 °C depending on the chemical composition of the alloys. Mostly this temperature is 5 - 40 °C lower than the nonequilibrium solidus temperature of a particular alloy. Thus, for duralumins D1 and D16, whose nonequilibrium solidus temperatures are 509 and 508 °C, the homogenization annealing temperature ranges are respectively: 470 - 500 °C and 470 - 495 °C. For high-strength alloy V95 with a nonequilibrium solidus temperature of 475 °C, the annealing temperature is 440 - 470 °C. For an alloy of the aluminum-magnesium system, grade AMg6, which has a nonequilibrium solidus temperature of 460 °C, the annealing temperature is very close to the solidus - 450 - 460 °C. For a low-alloy AMts alloy, 650 and 600 - 640 °C, respectively. The holding time during annealing ranges from several hours to several tens of hours. For alloys of the duralumin type this time is from 8 to 36 hours, for alloys of the Al - Mg systems up to 48 hours.

Cooling of ingots or billets made of aluminum alloys is usually carried out in air. When using continuous furnaces, ingot billets are fed directly to rolling mills for hot plastic deformation, cooled from the annealing temperature to the deformation temperature. Castings from aluminum alloys are cooled after homogenization in water, combining annealing with hardening.

Magnesium alloys

homogenize at temperatures of 390 - 415 °C. The holding time is 18 - 24 hours. As for aluminum alloys, a combination of homogenization annealing with heating under pressure treatment (for ingots) and hardening (for castings) is often used. A feature of magnesium alloys is their high chemical activity in contact with atmospheric oxygen, and therefore there is always a danger of self-ignition. Therefore, it is advisable to heat ingots or castings to annealing temperatures in protective environments, the simplest of which is a mixture of air and sulfur dioxide.

For both aluminum and magnesium alloys, high-temperature homogenization is sometimes used (at temperatures several degrees higher than the nonequilibrium solidus temperature), which sharply increases the degree of homogenization of ingots and castings and increases the ductility of the alloys by at least 1.5-3 times.

Below are the sources used in compiling the summary on the topic “Annealing”

Lectures on the course “Materials Science”. Lecture 13. Fundamentals of the theory of heat treatment of steel (continued). Technological features and capabilities of annealing and normalization.

Annealing, reducing hardness and increasing plasticity and toughness by obtaining an equilibrium fine-grained structure, allows you to: - improve the workpiece machinability by pressure and cutting; — correct the structure of welds overheated during pressure treatment and steel casting; — prepare the structure for further heat treatment.

Characteristic is slow cooling at a rate of 30...100°C/h.

Annealing of the first kind

1. Diffusion (homogenizing). It is used to eliminate segregation and equalize the chemical composition. It is based on diffusion. As a result of heating, the composition is leveled and excess carbides are dissolved. Mainly used for alloy steels.

2. Recrystallization annealing is carried out to relieve stress after cold plastic deformation. The duration depends on the dimensions of the product.

3. Annealing to relieve stress after hot processing (casting, welding, cutting, when high dimensional accuracy is required). The heating temperature is selected depending on the purpose and is in a wide range: T=160...700°C. The duration depends on the dimensions of the product.

Annealing of the second kind

Designed to change the phase composition.

It is a preparatory operation to which castings, forgings, and rolled products are subjected. Annealing reduces hardness and strength, improves machinability in cutting medium and high carbon steels.

Depending on the heating temperature, annealing is distinguished: 1. complete, with a heating temperature 30...50 ° C above the critical temperature A3. Тк=А3+(30…50)°С

Carried out for hypoeutectoid steels to correct the structure.

At this heating temperature, the austenite is fine-grained, and after cooling the steel has the same fine-grained structure.

Normalization is a type of annealing.

Heat treatment, in which the product is heated to an austenitic state, 30...50°C above A3 or AST, followed by cooling in air. Тк=А3+(30…50)°С Or Тк=AST+(30…50)°С

Normalization is more often used as an intermediate operation that improves the structure.

For low-carbon steels, normalization is used instead of annealing. For medium-carbon steels, normalization or high-temper normalization is used instead of high-temper quenching. In this case, the mechanical properties are somewhat lower, but the product is subject to less deformation, and cracks are eliminated.

2. incomplete, with a heating temperature 30...50°C higher than the critical temperature A1. Тк=А1+(30…50)°С

Used for hypereutectoid steels.

Partial annealing is mandatory for tool steels.

Bogodukhov S.I., Grebenyuk V.F., Sinyukhin A.V. Materials science course in questions and answers: textbook. 2nd ed., rev. and additional.. – M.: Publishing house “Machine Building”, 2005. – 288 p.

Annealing consists of heating the metal, holding it, and then slowly cooling it (together with the furnace). Annealing brings the metal closer to equilibrium.

First-order annealing is carried out to obtain a structure that is more equilibrium than the initial one, without relating this goal to the presence or absence of phase recrystallization. Examples of first-order annealing are recrystallization annealing and diffusion annealing.

During recrystallization annealing, deformation-hardened metal is heated slightly above the recrystallization temperature threshold. As a result of annealing, the material acquires the same mechanical properties as it had before deformation.

Diffusion (homogenizing) annealing is carried out by heating to high temperatures (in relation to steels - much higher than Ac3 or Ast), which implies intense diffusion of atoms. For example, castings are subjected to such annealing to eliminate dendritic segregation (homogenization of the alloy). During annealing of the second kind, at least partial phase recrystallization certainly occurs. Annealing of the second type includes incomplete annealing and complete annealing.

In case of incomplete annealing, heating is carried out to temperature Ac1 (below Ac3 or Ast). Partial recrystallization of the alloy occurs (the pearlite component changes). More often, partial annealing is used for hypereutectoid steels (spheroidizing annealing).

When fully annealed, the steel is heated to Ac3 or Ast. Complete recrystallization of the alloy occurs.

If, during complete quenching (full annealing), the heated workpiece is cooled in still air, then such heat treatment is called normalization.