Knife device

Maintaining the correct sharpening angle is impossible without knowing the design of the knife blade. Typically it consists of the following parts:

- cutting edge - the sharp part of the knife;

- butt - the upper, widest part, which is often pressed down by hand for convenience;

- descent - from the butt to the cutting edge the blade narrows gradually, the lower converging part, located closer to the sharpened part, is called the descent;

- tip - the point at which the butt and blade meet;

- heel - the unsharpened part located near the junction of the blade and the handle.

One of the most important characteristics of a blade is the sharpening angle of the cutting edge. The smaller it is, the less effort you need to make for cutting, that is, the easier the knife enters the plane being cut. However, you should not reduce this parameter too much. After all, at a small angle, the blade becomes fragile and is quite easy to damage.

The lowest degree of sharpening (10°) in straight razors. The largest (40°) – in high-strength hunting and tactical (used in field or extreme conditions) knives. The optimal sharpening angle for kitchen knives is 25-30°.

A universal kitchen knife has medium dimensions and a blade length of 15 cm. A distinctive feature of a chef's knife is its wide 18-25 centimeter blade. The fillet tool, on the contrary, has a narrow, long blade. The Japanese santoku is similar in appearance to a chef's knife, but its tip is rounded and lowered, which allows you to cut any, even the most “capricious”, soft or porous products, for example, bread, with filigree precision. It is also indispensable when chopping vegetables or cutting meat.

The most common blade shape is lens-shaped (razor), with a thick spine and the thinnest cutting part. Light weight and sufficient rigidity make this blade the most convenient.

Finnish knives have a wedge-shaped blade. The wedge of other types of knives may have a smooth transition from the butt to the cutting edge or, on the contrary, pronounced ribs.

Device

Blade shapes

How to sharpen a hunting knife correctly?

You can use a variety of tools to sharpen hunting knives. So, usually knife manufacturing companies offer to purchase an additional special sharpener when purchasing. Often, special sheaths for hunting knives have convenient compartments for storing such sharpening devices. In field conditions, mechanical pocket sharpeners are the best choice. They come in a variety of sizes and shapes, but are always made from only the best materials so that you can restore the sharpness of your instrument with just a few simple movements.

If we talk about the shape of sharpeners from manufacturing companies, they can have the shape of round, light rods, up to 15 centimeters long and several centimeters in diameter. Such devices are housed in protective plastic cases and also have fastening elements that allow the sharpeners to be placed on a hunter’s belt or in a sheath. Tools of the same type can also have the form of plates. The material for the manufacture of cylindrical devices is ceramics, flat ones are made of diamond abrasive.

Pocket sharpeners from the manufacturer can also be a small tool of a round, rectangular or oval (with smoothed corners) shape that fits in the palm of your hand. In them, miniature plates of carbide or ceramic stones are located at an angle specified for sharpening in special recesses made in a plastic case.

The greatest effect can be achieved if you take advantage of manufacturers' offers and buy a knife sharpener case. It will help sharpen a hunting knife on a clamp with numbered sharpening angles, using whetstones of different colors, each of which indicates the size of the abrasive grains.

The additionally supplied special oil allows you to achieve perfect sharpening sharpness. This set of sharpeners is not pocket-sized. It is perfect for teaching beginners, and you can start using sharpeners by sharpening, for example, kitchen knives, and gradually master sharpening any cutting tools.

It should be noted that pocket sharpeners are the best choice directly for hunting, but thorough preparation of the tool for it should be done at home.

Shapes and sharpening angles

An experienced hunter or fisherman will never take with him a tool with a weak blade made of low-quality or too thin steel. In the kitchen, for slicing or cutting, they often use the first knives that come to hand, without even realizing that they are thereby complicating their work. After all, when using knives of a certain shape, with different sharpening angles, you can get a perfect cut and quickly and accurately cut meat or fish.

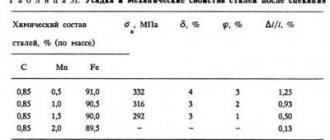

Table of standard values

Users are often interested in what angle to sharpen a kitchen knife. This parameter directly depends on the purpose of the tool. Examples of standard values are presented in the table of sharpening angles for kitchen, hunting knives and scissors.

| Knife type | Angle degree |

| Kitchen universal | 30-35 |

| Povarskaya | 20-25 |

| For meat | 25-30 |

| Table for vegetables and meat | 65-70 |

| For steaks and roast beef | 16-25 |

| Cutting | 25-30 |

| Sirloin | 10-15 |

| For cutting frozen fish and meat | 35-45 |

| Myasnitsky | 30-40 |

| For cleaning root vegetables | 20-25 |

| Bread-cutting | 15-22 |

| For vegetables and bread | 10-15 |

| Penman | 20-30 |

| Folding hunting | 40-45 |

| Shoe worker | 30-40 |

| Versatile for heavy duty work | 40-45 |

| Household scissors | 45-65 |

Sharpness directly depends on the inclination of the converging edges. At small angles you can sharpen knives even to razor sharpness. However, when cutting dense materials, such a blade will easily wrinkle. These knives are only suitable for slicing bread and vegetables. Therefore, knives are sharpened depending on the purpose of a particular tool.

An angle of 30-35° for kitchen knives is considered universal. However, it will be problematic to achieve high accuracy and speed of work using such tools. For slicing cooked foods, it is better to use a blade with an angle of 20-25°.

For knives intended for working with frozen foods, it is better to make the slope less, otherwise the thin blade will quickly break. Hunting and fishing knives have the highest degree of sharpening angle. Cutting accuracy is not as important here as increased strength.

Determination methods

How to determine the sharpening angle of any knife? This is not difficult to do. The most common methods:

- By securing the knife in scissors. This is an extremely simple method in which the surface of the blade to be sharpened must be placed between two blades of scissors. Next, the angle between the half-open panels is measured with a protractor. To prevent displacement, the bolt between them should first be tightened well. To obtain an accurate result, scissors with the maximum blade length are selected.

- Using a ruler-square. Initially, measurements are made in the same way as in the previous case, using scissors. Next, you need to circle the result on paper and place a square between the resulting lines.

- Using a board and paraffin. Melted paraffin is applied to the oiled edge of the board. Then a blade is stuck into it. After the wax has hardened and the blade has been removed, take a photo of the result. When the image is enlarged, the angle will be clearly visible and can be measured.

Using a ruler

Scissors

Using a board and paraffin

Choose a set: ceramic or metal knives

A metal and ceramic knife cannot replace each other. They only have a common purpose, but otherwise, the difference between them is significant. As a rule, everyone knows the advantages and disadvantages of ceramic knives, so let’s talk more about ceramic ones. They have the following advantages:

- The ceramic blade contains a hard material such as zirconium dioxide. The sharpness of a metal knife will last about a month, and the sharpness of a ceramic blade will last 10 times longer. Although, if you know how to properly use a knife, it will not need sharpening at all;

- A material such as ceramics is not porous. Thus, the taste of one cut product will not be transferred to another. If you chopped garlic or pepper, just rinse the knife under water and feel free to move on to another product;

- the density of the ceramic knife structure, as well as its minimal porosity, means that the device will be more hygienic and easier to clean;

- a ceramic knife is lighter in weight than a metal one, so the load on the shoulder and arm will be lower;

- Ceramic knives do not oxidize, do not rust, do not become magnetized and are scratch resistant.

Now let's discuss the disadvantages:

- fragility - you won’t be able to cut frozen meat or bones with a ceramic knife, because it's simply not designed for such purposes. If a metal blade falls to the floor, it may bend, and a ceramic blade may have its tip broken off;

- ceramic knives are not universal, and therefore are only suitable for certain actions in your kitchen;

- the cost of a ceramic knife is slightly higher than a metal one;

- tool for this .

Device for sharpening knives. Bar grain size

Choosing a decent sharpening tool is quite difficult and sometimes more difficult than choosing a knife. Today you can find many tools on the market for grinding, sharpening and straightening blades. These can be bars, sanding belts, grinding stones, electronic and mechanical sharpeners, etc. At the same time , sharpening a knife using any of these tools has its own characteristics. Naturally, a professional tool is quite expensive, but it’s not worth saving. A low-quality whetstone will not provide the proper level of sharpening and may even damage the knife.

Let's talk more about each tool:

- a quality bar will cost several tens of dollars. Firms that have proven themselves produce professional sharpening stones with different numbers of abrasive grains per 1 cubic mm. This number corresponds to the number indicated on the packaging. Each country has its own grit systems, for example FERA, GRIT, ANSI, etc. To properly sharpen a knife, you must have at least 2 whetstones. One will be needed for sharpening itself, and the other for grinding the blade. Ideally, the blade is sharpened with several whetstones. Domestic manufacturers produce bars without markings, so you have to make a choice at random;

- musats - these tools are designed for straightening the cutting edge of a knife; with the help of musats, the sharpness of the blade is maintained without sharpening. Visually, this tool is similar to a file; you can select and purchase musats in any store that sells knives. As a rule, they are used to edit a kitchen knife that is in regular use. This thing is quite useful, but if the knife no longer has its original sharpness, musats will not fix the problem, you will have to sharpen it;

- grinding belts, machines with felt and abrasive wheels. These are professional tools that are used to sharpen knives and polish blades. This is done at manufacturing plants or at special knife sharpening points. This is performed by professional workers who have the necessary knowledge and experience. If you have never encountered the production of knives, then it is better not to even try to sharpen your knife on a grinding wheel, because... there is a risk of simply damaging it. Steel is hardened at a certain temperature, and uncontrolled heating of your blade during sharpening on a wheel can permanently damage the blade. Factory sharpening makes the blade incredibly sharp, but it lasts less than hand sharpening or sharpening with an electric sharpener;

- mechanical sharpeners. These tools are usually used to sharpen a kitchen knife or household scissors. The advantages of such a tool are low cost and ease of use, but the quality of sharpening in the end is not the highest. The blade will sharpen quickly enough, but it will also lose its sharpness just as quickly. It is appropriate to use a mechanical sharpener only for kitchen knives, but for hunting and sporting blades it is worth using other methods;

- electric sharpeners. Recently, electric sharpeners have become increasingly popular. Electric sharpeners differ from their mechanical counterparts in that they can sharpen and polish a kitchen knife, a knife for sport, and a hunting knife with high quality. They automatically detect the required sharpening angle and are used for straight and wavy blades, as well as for screwdrivers and scissors. An electric sharpener will keep knives in good condition for many years, and can also quickly restore a very dull blade. Modern electric sharpeners are manufactured on the basis of patented systems that provide high-quality sharpening and grinding, as well as dressing knives for various purposes. As a rule, such devices could be found in reputable cafes and restaurants, but today they are publicly available.

Even with such a variety of tools that are suitable for household use, good results can be achieved with the help of professional whetstones and electric sharpeners.

How to sharpen a knife correctly

It is necessary to understand that good sharpening of any blade on a whetstone will require at least half an hour. Sharpening a forged long knife while maintaining an ideal geometric shape may well take up to 30 hours. Prepare for this in advance.

And finally, let’s talk about what rules exist for sharpening knives . You need to start sharpening with a rough stone and continue until a burr appears on the blade, i.e. a strip of metal from the edge and along the entire cutting edge. Then it is advisable to exchange the bar for another one with smaller grains, if there is one.

It is advisable to place your sharpening stone on a stationary surface (for example, on a table). This way you will ensure control over the process. To avoid scratches, place something under the sharpening stone. The longer the bar, the better - for example, 1.5-2 times longer than the blade. Start cutting across the block with the knife, cutting edge first. The direction of movement of the knife should be as close as possible to perpendicular to its edge.

It is very important to keep the angle as close to 90º as possible to ensure an even sharpening of the blade and give it excellent cutting properties. An angle of 20-25º should be maintained between the plane of the block and the working surface. It is necessary to try and keep this angle constant while sharpening. To do this, lift the handle slightly until you reach the point where the blade bends. If they sharpen a blade that is intended for chopping, then the angle may be different. It is only important that it does not change.

When reaching the end of the bar, you need to simultaneously reach the tip of the knife. Make sure that the blade does not break off, because... scratch the side surface. Such movements must be repeated several times on both sides of the blade. Don't put pressure on the whetstone to speed up the work, you won't gain anything and the sharpening won't speed up, but you may lose accuracy. Move the blade along the block carefully and evenly, without changing the angle. One careless move can ruin all your hard work. To hone this skill, you will need more than one knife - mastery will come with practice.

Knife grinding

You already know how to sharpen a knife correctly, but this is not the end of the job, because... After this, the blade must be polished to maintain its sharpness for a long time. The blade is polished in order to get rid of the burr - this way the sharpening will be durable, and the forming surfaces will become impeccably smooth. The movements during grinding remain the same, only you should choose a block with minimal grain.

In principle, an ordinary user who encounters such a tool only at home or for a hobby can do without information about grinding and polishing knives. But in grinding a knife lies the answer to questions such as: “Why do some knives cut better than others and hold an edge longer?”, “Why does this knife cut the product like butter, but when working with another knife, you need to make an effort?” etc.

Polishing and grinding of knives is the final treatment of the product after the knife blade is formed on an anvil, as well as using coarse abrasives. Grinding a knife is carried out in several stages:

- rough grinding;

- medium grinding;

- final polishing;

- polishing the knife.

In the 20th century the method of producing stainless steel became known. Before this, grinding was used as protection against corrosion of rusting steel. The bottom line is that the smoother the surface and the fewer scratches it has from sanding, the less likely it is for rust to occur. In addition, proper grinding with marks directed in one direction gave the blade a uniform matte finish. Polishing erased the marks almost to the point of invisibility and thereby imparted a mirror-like appearance.

In the 20th century Harry Brearley made the discovery that high levels of chromium oxide protect steel from rust. This is how stainless steel was invented. It seemed then that such a discovery would simplify the process of making knives, and many manufacturers abandoned polishing in the production process of inexpensive knives, leaving only grinding. But such steel does not rust only if the chromium oxide layer is intact. But it is gradually destroyed if the rules for using knives are not followed under the influence of an aggressive external environment. Of course, the product does not completely rust, but small black dots form on it in the marks that remain after grinding. This deteriorates both the appearance of the knife and the quality of the cut.

The production of high-quality knives from corrosion-resistant steel ends with the mandatory process of polishing the blade, which significantly increases the corrosion resistance of the product due to its very smooth surface. Such actions are carried out by all manufacturers who value their reputation.

These knives boast unsurpassed blade and cutting sharpness that lasts for a long time. The people of Japan, by virtue of their character, devoting all their strength to work and striving for beauty, also strive for perfection in the production of knives. Many people know about the popularity of Japanese knives around the world, especially kitchen knives. Many world chefs use such knives in their work.

The Japanese attach great importance to grinding and polishing the blade, even despite their superiority over other countries in the production of steel alloys. In addition to good performance, Japanese knives are very beautiful and are a work of art.

Checking methods, knife sharpening level

It doesn't matter what purpose you need a knife for: hunting or cooking. Its sharpness always remains relevant. A sharpened blade is not only an assistant in your business, but also working with it is safer than with a dull blade. Here you can give free rein to your imagination, but without forgetting about precautions, because... a sharp blade will not forgive mistakes. In addition to sharpness, the profile of the blade is also important. Many knives with a high sharpening angle will not cope with many tests, just like sharpening. First, look at the cutting edge in the light - a sharp blade will not give glare along the length. If there is glare, it means there are dull areas on the cutting edge. You can also see the blade using an optical instrument.

If you want to check your knife for quality of sharpening and sharpness, you can use the following tips:

- test on paper. This is the easiest and fastest test to check the sharpness of a blade - use a sheet of paper. Take a regular A4 sheet of paper in one hand and a knife in the other. Now try cutting a strip of paper from the edge of the sheet downwards or cutting the sheet in half. A sharp blade will easily cut the sheet into two parts. A dull blade will slide off the edge of the paper without catching it in any way, or will tear it into uneven pieces. For the test, you can also use a magazine sheet, which is thinner and therefore requires better sharpening of the blade;

- tomato test. This test can be used on any blade, although it is typically used to evaluate the sharpness of kitchen knives. You need to take a ripe tomato and, without making any effort, cut a slice from the edge of the vegetable. If the knife cuts a thin slice, easily and effortlessly passing through the skin, it means it is sharpened well. An unsharpened knife will slide off a round tomato without damaging it in any way. In this case, to get a piece of the vegetable, you will have to try and mash the tomato;

- hand hair test. In this case, the testing ground will be her own hand, namely her hair. Despite its dubiousness, it is very effective for checking the sharpness level of a knife. Run the knife against the hair growth along your arm, but do not touch the skin. It is not difficult to guess that a sharp knife will cut hair. A dull blade will bend the hairs without cutting them. The test is very good, but there are some nuances. It poses a danger to people prone to injury. After testing, a hairless arm will look unattractive. And in general, there is a risk of being completely without hair if you decide to test your entire collection of knives;

- thumb test. To apply such a test, practice and knowledge of the features of a knife blade are required. Lightly and carefully move the pad of your thumb across the blade of the knife, but not along the edge, because. you can cut yourself. A sharp blade will have a crisp edge, while a dull blade will feel more rounded to the touch. This test may take some time to gain experience with. This way you can tell the difference between a really well-sharpened knife. This skill will be useful in the future and in life.

To summarize all of the above, sharpening a knife turns out to be a very difficult task. To sharpen a knife professionally, you need patience and attentiveness, because... One wrong move can ruin the job. Knowledge of theory about the correct sharpening of knives is not enough; only with practice will real skill come. In addition, this activity is not cheap, because... a good bar costs a lot of money, but a low-quality bar will not give you the desired result. An alternative is to use electric sharpeners. Such devices will provide good sharpening quality and preserve the cutting properties of the knife for a long time.

The cost of electric sharpeners is higher than that of whetstones, but they will save you from the lengthy sharpening process. And sometimes the total cost of several bars with different grain sizes may ultimately be higher than the cost of an electric device. The use of electric sharpeners will save your energy, time, nerves and keep your knives in good condition for many years.

" Sharpening Knives" read 2388 times

Angle Holding Devices

To ensure that the sharpening angle does not change during operation, the blade must be well secured. There is a huge range of sharpening tools available on the market. The best devices for home use are mechanical sharpening systems with removable stones and the ability to set the angle. The following devices will help maintain the correct sharpening angle of a kitchen knife:

- A stand-holder for stones, on one side of which a certain adjustable slope is provided. Such devices allow you to raise the blade above the surface level and firmly fix it motionless. Since the tool will constantly come into contact with abrasive suspension and moisture, it is better to purchase a stand made of materials that are resistant to corrosion.

- A sharpening machine of the Ruixin Touch Pro type, which is a stand with a clamp (stop) in the form of a plate. The tool is fixed using a bolt with 2 washers, which allows you to set any sharpening angle of the knives as accurately as possible.

Electric sharpeners for home use only have one standard degree of angle (about 30°). Therefore, it is not recommended to use them for knives with a smaller sharpened angle.

Ruixin Touch Pro Steel

Stand holder

Table of sharpening angles for different types of knives

In order to perform high-quality processing and maintenance of tools, it is necessary to maintain the basic sharpening angles of knives for various types of tasks with their use. To control the correct sharpening of corners, you can use a table that presents recommended values for various types of knives:

| Knife types | Sharpening angles |

| Dining rooms for serving | 55° — 60° |

| Kitchen household | 30° — 35° |

| Kitchen professional | 25° — 30° |

| Chefs professional | 20° — 25° |

| Cutting for fish | 25° |

| Cutting machines for meat and large fish | 30° |

| Vegetable cutters | 35° |

| Fruit | 10° — 15° |

| Cutting for root vegetables | 22° — 25° |

| Boning machines for meat | 25° — 30° |

| Chopping axes | 25° — 30° |

| Sirloin | 10° — 15° |

| Penknives | 20° — 25° |

| Tourist / hunting, priority is spiciness | 30° — 35° |

| Tourist / hunting, wear resistance is a priority | 40° — 45° |

| Shoe repair | 30° — 40° |

| Shoe cutting machines | 20° — 25° |

| Universal carpentry | 30° — 45° |

| Chopping (machete) | 45° — 60° |

Features of Japanese models

The method of sharpening Japanese kitchen knives differs from European ones. Such tools are given ideal sharpness by a special method in which the blade is processed not on both sides, but only on one side. Thanks to this, the cutting edge becomes as thin as possible. This method is also convenient because the blade can last for a very long time without sharpening. Even with active use, the knife will remain sharp for a long time.

The only drawback is that if handled improperly, the thin blade may move slightly to the side. However, even with a large bend it is quite difficult to damage it. The type of steel used for manufacturing allows you to quickly restore its shape.

The peculiarity of such tools is an expanded blade, especially at the heel, and a lowered butt (the upper part of the blade), providing ease of cutting and a smooth cutting edge. With their help, you can very quickly cut vegetables or meat into perfectly smooth and thin pieces.

Unlike European models, Japanese ones have more compact rounded handles. You no longer have to constantly tilt the tool with its tip down while trying to hold it in your hand. The thin handle leaves enough room for a comfortable grip.

What sharpening angle is optimal for such a tool? In most cases it is 15-18°. But there are also special types of Japanese knives that require sharpening up to 40°. It is better to do this manually using a water stone. A Japanese blade and a machine are incompatible things.

Magnetic models of Japanese instruments do not need to be sharpened. Thanks to the special steel, which easily restores the bonds of the crystal lattice, after some time they sharpen themselves again.

You can even determine the sharpness of the blade visually. If the edge casts glare in the light, this means that there are still unsharpened areas on it.

Why do you need a sharpener?

A living relic of our days is the Finnish hunting knife. Not a gangster Finnish knife, sometimes of a bizarre shape, but a Finnish-type hunting knife, on the left in the figure. Traditional hunting knives (center and left) are similar in shape, but the difference between them is very large.

Finnish knife and classic hunting knives

The blade of a Finnish knife is forged from cast iron, which can be smelted right in your yard from swamp ore in a furnace-furnace, without resorting to the blast furnace process, puddling, and other methods of converting cast iron into iron and steel. The viscosity of crinkly iron is excellent; it is very difficult to break a blade made from it. But the hardness is also low, somewhere around HRS55, the knife becomes dull quite quickly. Finnish hunters did not care about this: a blade of such hardness can be sharpened (sharpened) by beating on many natural stones, and there were always enough smoothed moraine boulders in Fennoscandia.

They sharpen a knife by beating it in much the same way as beating a scythe, only the whetstone is motionless and the blade is moved. First, they pull it along the whetstone with the butt away from you, then they turn it over and pull it with the butt towards you. The position of the cutting edge (CR) on the whetstone is always dragging; quick movements: shirk-shirk! During each movement, you need to keep the contact patch of the blade with the touchstone (see below), but the requirements for maintaining the angle of inclination are not so strict. Learning to sharpen a knife by beating is not very difficult, and with some skill you can create a smoothly running profile on the blade, see below. However, the Finnish knife is, in general, a dead end in the evolution of a cutting tool, surviving in special natural conditions.

A good knife has never been cheap, and in extreme situations, the durability of the blade, combined with the toughness of the blade, became vital factors. Therefore, even in ancient times, they learned to harden knife blades from the surface and cement them: the core remained viscous, not brittle, and a hard, red-hot crust formed on the outside, see next. rice.:

Structure of a knife blade with surface hardening and carburization

It is still possible to sharpen a knife with a cemented blade, but you need a skill that is not given to everyone. And the abrasive is already needed from a special type of stone - lithographic grunstein slate. There is little of it in nature; Grünstein is still considered a strategic raw material. There is no artificial grenstein and it is not expected. It’s as easy as shelling pears to ruin a cemented knife with inept beating - a little somewhere the cementation bark will be stripped down to raw metal (this is not visible to the eye), the knife will only have to be thrown away, the blade will immediately become dull and begin to crumble.

Note: if you have an antique scythe whetstone of a slightly greenish color lying around somewhere, do not throw it away, it is a valuable rarity.

Service knives do not require the same durability and toughness as hunting and hiking knives, and they should cost much less. As a result, special steels and powder metallurgy are widely used in the production of utility knives. The blade of an “eternal” kitchen knife is structured like a rodent’s incisor: in longitudinal layers, the hardness of which decreases from the core outward. In any case, you have to sharpen the knife less often, but chipping is definitely ruled out - the blade immediately becomes discolored.

Why does the knife get dull?

Naturally, tools made from high-quality steel do not become dull so quickly. But even the most high-tech metal can wear out. Factors that lead to loss of blade sharpness:

- Inappropriate use: for example, bending metal clips, nails.

- Frequent work with dense materials (bones and tendons).

- Improper storage, in which the blade is constantly in contact with other metal devices. Friction against metals causes the thin edge of the blade to lose its sharpness. Therefore, it is better to store blades on special stands or magnetic holders.

- Cutting on excessively hard surfaces (glass, ceramic, or stone cutting boards). When working, it is better to use a regular wooden cutting board. It is acceptable to use plastic; professional kitchen boards are made from this material.

- Frequent cutting of materials of heterogeneous structure, in which the blade experiences resistance under lateral load.

- Using aggressive chemicals that destroy metal or too hot water when washing.

For ductile carbon steels, the sharpening angle of the knives can be made a little smaller without fear of jamming the edge. If handled correctly, the blade can go a long time without sharpening, if the blade is made of high-quality steel with a high hardness index. If the cutting edge is dull, it needs to be corrected in time, because it is easier to get hurt with a dull knife than with a sharp one.

Rules for using a whetstone

To ensure the desired cutting qualities of the knife, the following recommendations should be taken into account:

- Soak the stone in water for 15 - 20 minutes;

- to work you need a table in a well-lit place or with a lamp;

- to prevent the stone from slipping and damaging the table covering, place a cloth or paper on the table;

- to visually determine the sharpening angle of the knife, the blade is applied to the sharpening stone;

- the blade being sharpened is directed away from you at the selected angle;

- with gentle pressure, a reciprocating movement is produced, simulating cutting off a thin film from a grindstone along its entire plane. In this case, the blade moves relative to the block from the handle to the tip and back;

- the selected sharpening angle is maintained during each stroke of the stone;

- the blade and stone are periodically moistened with water and cleaned;

- after 20 - 30 repetitions on both sides of the blade, the cutting edge is inspected. When sharpened with a razor, it is not visible to the naked eye;

- The sharpness of the blade is checked on a sheet of paper by cutting it from top to bottom. A sufficiently sharp blade cuts and does not tear paper.

Folk remedies for washing dishes - benefits, savings or a waste of time

Serreytornaya

If one- and two-sided sharpening can be classified as a smooth variety, then the serrated edge has teeth - the blade looks like a saw. The notches have a semicircular shape, so that sharp protrusions are obtained on the edge side.

This blade easily cuts hard material with a minimum amount of crumbs/sawdust.

Serrated edge - The blade is similar to a saw.

This processing is used in the manufacture of kitchen accessories, hunting and tourist knives, and sling cutters. You won't be able to make such an edge by hand - you need special tools.

As an option, for hunting and tourist models, the so-called combined version is used - from the tip to the middle or 2/3 of the blade, a smooth double-sided sharpening is done, and then serrated sharpening is carried out to the bolster. Serrated teeth can also be located on the butt of the blade.

Such options are universal - the tool can both rip, cut and pierce the material. The type of edge and functionality of the knife determine the choice of steel - it can be either hard (hunting and tourist knives for fine slicing) or tough (for chopping).

Types of sharpening

There are several types of knife sharpening:

| Types of knife sharpening | Description |

| Lenticular | The edge of the blade is sharpened, and the bend of the blade can also be processed. With such sharpening, blades are distinguished by a high level of cutting ability; they are able to “work” even on thick material, and, if necessary, serve as a chopping or piercing tool. Lens-shaped sharpening is carried out exclusively by hand, therefore it is used only in the production of professional knives - kitchen, hunting, tactical. |

| Razor sharpening (flat) | It is carried out at a minimum degree (10-20) and is suitable for processing only surgical instruments, razor accessories, and blades for fine cutting. In everyday life, such sharpening is done for hunting knives for special purposes - for example, skinning knives, fishing knives. |

| Wedge sharpening | It is rarely used, because after it the cutting ability of the tool increases, but the strength of its blade decreases. During the process, the side surfaces of the blade must be grinded and polished, but at home this is quite problematic. |

| Pentagonal sharpening | It is widely used for kitchen and travel knives; even household devices for this process often perform just this type of knife sharpening. After it, the blade slightly loses its tactical abilities, but its service life does not decrease. |

| Double-sided asymmetric sharpening | Combines enhancing the tactical and physical abilities of knives. The result will be ease of cutting even the hardest products, flawless chopping of material without any effort. This type of sharpening is often used in the manufacture of Japanese kitchen knives, which are of high quality. A special feature of knives with double-sided asymmetric sharpening is that the edge of the blade does not enter the cut on the product, but is constantly held on top. |

There are many ways to sharpen knives, they will differ depending on the tool used for this.