Sometimes large metal structures need additional cleaning from dirt, rust and plaque. To avoid spending a lot of time cleaning with a grinder and a grinding wheel, you can use sandblasting. There is a technology that allows not only to clean the material, but also to improve its characteristics. This is shot blasting. It is important to understand how it differs from classic sandblasting and what features this technology has.

Shot blasting

Process Features

Shot blasting is a mechanical method of processing metal surfaces using metal particles. Special equipment accelerates the shot to enormous speeds (100 m/s) and delivers it to the working surface through a shot blasting nozzle. In this way, the excess layer is removed from the metal. Its depth depends on the size of the abrasive particles and the power of the equipment.

Shot blasting involves the use of an abrasive material (shot). There are several types of abrasive particles that are suitable for different types of metals and alloys:

- Glass is the most economical type of shot that does not contaminate the surface being processed.

- Electrocorundum is the most expensive and effective type of abrasive material. Used to clean serious stains.

- Ceramic is a rarely used material for making shot. Used for final cleaning of metal surfaces.

- Plastic - this abrasive is used to clean glossy parts. Does not leave marks on the material.

- Cast iron - with this shot metal surfaces are cleaned of rust, plaque, and scale. This abrasive material is made from white cast iron.

- Aluminum is a type of abrasive material for shot blasting. Used for cleaning soft alloys.

- Steel - after processing metal surfaces with this type of shot, not only the layer of dirt, plaque, and rust is removed, but also the characteristics of the material are improved.

When working with high-hardness materials, you need to choose an abrasive that is not inferior in strength to the surface being processed.

Fraction selection

The result of shot blasting will depend on the choice of abrasive material. In addition to the above types, fractions also vary in shape, size and other criteria.

The peculiarity of the surface being processed is also one of the determining factors in choosing an abrasive. To calculate the economic benefits of shot blasting, it is also important to take into account such characteristics of shot as cyclic resistance, the value of which can vary significantly among different types.

There are situations when shot blasting parts is the only way to bring a metal surface into working condition. This is especially true for large-sized metal structures.

What parts can be processed?

Abrasive processing using special equipment is popular when cleaning old metal structures that have become rusty from exposure to environmental factors.

The next direction in which shot blasting is used is to remove coatings from metal surfaces. In this way, you can clean the products from layers of paint, plaque, and dirt. Using shot, a rough or matte surface is achieved, changing its structure.

What it is?

This is one of the most popular modern technologies, the essence of the process is the processing of metal using an accelerating gas flow of shot, the quality of which determines the speed and result of processing. Using this method, you can remove environmental influences, corrosion or old decorative coatings. After processing, the metal takes on a new look and becomes smoother. Unevenness and roughness are also eliminated.

Most often this technology is used to remove rust. The method is fast and reliable, which is why it is considered popular. It has been noticed that after treatment the service life is extended and the material becomes more durable.

Benefits of technology

The shot blasting procedure has a number of strengths:

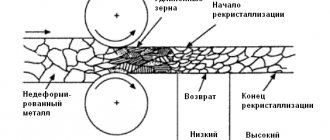

- When using steel, corundum or cast iron shot, the surface is hardened.

- The high hardness of the abrasive material makes it possible to clean homogeneous materials and alloys.

- Ability to create rough and matte surfaces.

- Effective cleaning of metal from rust, scale, paint, and plaque.

- With the help of industrial equipment, labor productivity increases.

Shot blasting can quickly process large metal structures without the use of excessive effort. However, it is important to choose the right abrasive material. If its hardness is lower than that of the surface being treated, the particles will crack.

Processing of large-sized metal structures

Types of shot blasting machines or installations

- Closed chambers - for processing parts and objects in a confined space. In turn, they are divided into inhabited and uninhabited.

- Open installations – for external treatment of external surfaces. The main areas of application are concrete floors and steel structures, such as bridges.

The principle of metal processing by the shot blasting method is the supply of a material-air mixture under high pressure. The shot is subsequently recovered. The closed cycle of operation of shot blasting equipment provides it with very high performance, efficiency and environmental friendliness. Modern equipment can also process large-sized products.

The abrasive plays a key role in this processing method. The shape, size of the shot, as well as the operating mode of the shot blasting machine, are selected based on the type of surface being processed.

To obtain the best result, it is important to choose the correct fraction in each specific case.

Shot Blasting Equipment

You can find various shot blasting machines for metal on sale. According to the principle of operation, they are similar to sandblasting units. An apparatus for cleaning metal surfaces consists of several key elements:

- Compressor - creates a powerful air flow that throws abrasive material out of the nozzle at high speed.

- Chamber for mixing air and shot. A hose comes from the compressor through which air enters the container with abrasive. In the chamber it is mixed with abrasive and comes out through another hose.

- Nozzle. The working part through which the shot comes out and processes the working surface. It is important that this element is made of carbide materials. Otherwise, the nozzle will quickly become unusable.

There are two types of equipment

- Manual machines are low-power machines that are used for processing metal structures. Used for light work. It can be equipped with special elements that suck up used shot, clean it of debris and reuse it.

- Shot blasting chambers are automated installations that are installed in enterprises. Used for processing similar parts. They are equipped with automatic control systems, collection of waste shot with the possibility of its reuse.

For private workshops, garages, car services, manual installations are used.

Operating principle

The use of shot blasting involves the correct use of specialized equipment. For example, sandblasting works on the principle that air with abrasive comes out of the installation nozzle at high speed. The cleaning speed depends on the power of the compressor and the selected material from which the shot is made.

Shot blasting shot

Safety precautions

Shot blasting requires compliance with safety precautions:

- Work in a protective suit. Eyes, nose, ears must be closed.

- Before starting work, check the tightness of all connections and the condition of the nozzle.

- Turn off the unit if there is any extraneous noise or failure of any of the device elements.

When working with small abrasive particles, there is a risk of harm to the body due to the dust released during work.

How long will it take to process?

The time spent on shot blasting depends on many factors:

- Workload. The surface area of the part directly affects the time taken.

- Surface type. Polymer coating in several layers and chrome take much longer to remove than, for example, rust or remnants of old paint.

- Complexity of design. Parts with complex shapes have more hard-to-reach places, which will also require additional time.

- Employee qualifications.

Using a specific example, processing a car wheel with a shot blasting machine will take from half an hour to several hours. Restoring the surface of larger body parts is a correspondingly longer process.

Features of the work

Shot blasting of metal is an industrial cleaning technology that is used when working with homogeneous metals and alloys.

Before you start cleaning, you need to select the power of the compressor, the size of the abrasive particles, and the material from which the shot is made. These indicators affect the quality of cleaning and the creation of texture. Shot blasting is a technological process for cleaning metal surfaces. With its help, you can not only remove layers of rust, dirt, and scale, but also improve the characteristics of the material.

Application area

Shot blasting is used not only for cleaning metal structures, but also when processing concrete, brick and even wooden surfaces during construction and repair work. Using this technology, large containers and tanks can be cleaned from the inside. But still, the main purpose of this technology is to clean metal structures and prepare them for applying paint and varnish coatings to them.

Thus, the main tasks that shot blasting performs can be classified as follows:

- cleaning metal coatings from plaque, rust, scale, traces of old paint, dirt and grease stains,

- creating a microrelief on the metal surface that will improve the adhesion of the material to various applied coatings,

- improving the strength of metal structures and increasing resistance to constant loads.

After thorough shot blasting and degreasing, the metal surface becomes ready for coating.

The service using this technology that is most in demand is the processing of metal structures. This is the most optimal option for cleaning car wheels in terms of price, quality, reliability and other criteria. This method, using a high-speed abrasive jet, allows you to clean the disc completely, even in the most difficult to reach places. After such treatment, the anti-corrosion and paint coating will be applied much better.

Rights

A 4th category shot blaster has the right to:

3.1. Get acquainted with the draft decisions of the enterprise management concerning its activities.

3.2. Submit proposals for improvement of work related to the responsibilities provided for by this job description for management's consideration.

3.3. Inform your immediate supervisor about all shortcomings in the production activities of the enterprise (its structural divisions) identified during the performance of your official duties and make proposals for their elimination.

3.4. Request personally or on behalf of the immediate supervisor from heads of departments of the enterprise and specialists information and documents necessary to perform their job duties.

3.5. Involve specialists from all (individual) structural divisions of the Company in solving the tasks assigned to him (if this is provided for by the regulations on structural divisions, if not, with the permission of the head of the Company).

3.6. Require the management of the enterprise to provide assistance in the performance of their official duties and rights.

Preparing the surface for coating

Cleaning removes unwanted materials and leaves the surface ready for coating. Using abrasive blasting, metal structures are removed

- old paint,

- rust

- and other contaminants.

In addition, blast cleaning removes the secondary scale that forms on new steel.

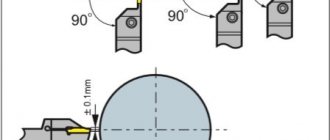

Angular abrasive particles roughen the surface and create a profile, or notch. Most paint manufacturers specify what the profile should be to ensure effective application of their product.

Prices for services

The cost of shot blasting is slightly higher than the cost of sandblasting; it depends on several factors:

- Difficulty in product configuration.

- Required surface finish.

- Thickness of the coating layer to be removed.

- The total surface area of the workpiece.

On average, the cost of processing one square meter is 350-400 rubles; if the order volume increases, the price may be slightly reduced.

Today, shot blasting of the surface of metal products is considered one of the most promising types of metalworking.

The emergence of automated cameras can significantly expand the scope of technology and improve the quality of work.

Responsibility and performance evaluation

4.1. A 4th category shot blaster bears administrative, disciplinary and material (and in some cases provided for by the legislation of the Russian Federation, criminal) responsibility for:

4.1.1. Failure to carry out or improperly carry out official instructions from the immediate supervisor.

4.1.2. Failure to perform or improper performance of one's job functions and assigned tasks.

4.1.3. Illegal use of granted official powers, as well as their use for personal purposes.

4.1.4. Inaccurate information about the status of the work assigned to him.

4.1.5. Failure to take measures to suppress identified violations of safety regulations, fire safety and other rules that pose a threat to the activities of the enterprise and its employees.

4.1.6. Failure to ensure compliance with labor discipline.

4.2. The assessment of the work of a 4th category shot blaster is carried out:

4.2.1. By the immediate supervisor - regularly, in the course of the employee’s daily performance of his labor functions.

4.2.2. The certification commission of the enterprise - periodically, but at least once every two years, based on documented results of work for the evaluation period.

4.3. The main criterion for assessing the work of a 4th category shot blaster is the quality, completeness and timeliness of his performance of the tasks provided for in these instructions.