Thin sheet metal is used in various fields of activity. The relevance of this material is constantly growing. There are several types of thin sheet metal. It is classified depending on the base and protective coatings used. Manufacturing and processing technology affects the properties, characteristics and applications of the material.

Thin sheet metal

Characteristics and release form

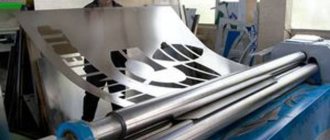

Thin sheet metal has an extensive dimensional grid, but the same cannot be said about the release form. It is produced in three versions: rolls, strips, sheets.

Rolls

Produced by large enterprises. Supplied for sale in ring rolls of different lengths and widths. Take up minimal space. Most metalworking machines are designed to work with coils. They are equipped with special unwinding mechanisms.

Strips

Narrow metal strips that are obtained by cutting steel rolls. Used for the manufacture of long products of small width.

Sheets

Standard release form. Sheets may have different characteristics, which are determined by GOSTs. They are suitable for home work and small-scale production. The main disadvantage of sheets is the large amount of waste during the production of various parts.

Sheets of metal (Photo: Instagram / maxmetall.kg)

Basic criteria for choosing a profile sheet for a roof

Today you can purchase corrugated sheeting without any difficulties for a roof of any configuration, especially when it comes to roofing tiles complete with additional elements. The latter include ridge strips, valleys for connecting multi-slope structures and all kinds of plugs, snow retainers and cornices. It is much more difficult to select a profile sheet from a photo in catalogs, since the waves can be of different heights and widths, with large or small steps between them.

Selecting a profile sheet

First of all, it should be taken into account that these waves are a kind of stiffening ribs, which means that the higher they are and the smaller their width, the higher the bending strength of the sheet. It is best to make it a rule to pay attention to the markings. If you see the letter H at the beginning of the designation, this will indicate that the sheet is load-bearing, roofing, with a fairly high level of rigidity. The letter C always refers to wall sheets that have less pronounced corrugated waves.

Material and properties

Thin sheet material is made from different types of metal. Each of them has certain properties and characteristics.

Cink Steel

Peculiarities:

- It is used when applied to other parts to protect them from rust.

- Sheets can be processed using hot and cold galvanizing methods.

- The zinc layer reliably protects the metal from corrosion.

The disadvantage is the low strength of the zinc layer.

Galfan coated steel

Galfan is a compound of aluminum and zinc alloy. Aluminum undergoes oxidation, which contributes to the formation of an oxide film. Moisture and oxygen do not pass through it. The oxide film is needed to protect the base and increase the service life of the zinc layer.

Aluzinc coated steel

The protective coating consists of zinc, aluminum, silicon. The active service life of finished products increases 5 times.

Zinc-titanium coated steel

To increase the strength of the protective coating, alloying additives are added to the composition - titanium, copper. Increases ductility and protection against rust formation. When molding and bending, the metal retains its qualities.

Polymer coated steel

In manufacturing, the basis is steel with an aluzinc coating. A phosphating layer and primer are applied on top of it. The finishing coating is polymer.

Steel coils (Photo: Instagram / absolut_metall35)

Complex products requiring skill and additional tools

If you have a welding machine, then you can make metal crafts of any complexity. Nothing will limit your imagination even if you purchase metal scissors. A small hammer and anvil make the process even more creative and varied. In this case, nothing limits either the skill of the craftsman or the flight of his imagination. Any idea can be realized, even using scrap metal.

Flat original designs

If you want to make a homemade product that will decorate your garden plot, the facade of a house or a fence, you can make a flat image of any animal, flower or other object.

In this case, you will need sharp cutting tools with which you can cut out the desired image. The main part of the work will be creating a suitable sketch.

After an object of suitable size has been created on paper or thick cardboard, you need to transfer it to metal.

Then use a cutting tool to cut out not only the outline. But, internal perforation is desirable. It is the internal holes in the flat sculpture that will help recreate the image in the most naturalistic way and give it some lightness.

Using this method, you can create an original private house number plate. If you are not satisfied with the appearance of the metal, then you can decorate the product using paint of a suitable composition.

A teenager can be involved in such work as a master class, especially if he has a desire for applied work.

Three-dimensional sculpture

If you have sheet metal, you can make a three-dimensional sculpture to decorate the interior or garden area.

The design is similar to the previous product. The only difference is that here you need to cut out several elements that are attached at right angles.

The main point is to create a product that has a certain thickness. It can be different, depending on desire.

For a three-dimensional statue you need to make two identical blanks. And then the blanks for the end part, which will give volume to the entire structure.

When each element is cut out of metal, they must be combined into one whole. This is done by welding. But you will need to demonstrate certain skills and abilities. After all, a roughly made seam can ruin the appearance of the finished craft. True, if it was not possible to weld the structural elements too carefully, they can then be cleaned with a grinder. True, this will take some time and effort, so it is better to do everything more carefully right away.

Volumetric figure option

The use of flat sheet products, connected at right angles by insertion into grooves, allows you to create a three-dimensional model. The thickness of the groove must correspond to the thickness of the metal. Additional fastening is carried out by welding at the joints to impart rigidity to the structure.

Bending tools allow you to get away from linearity. Curved elements look more natural. The design takes on a naturalistic appearance. Coloring achieves diversity and the formation of a stylistic direction.

The fantasies of metal crafts are practically unlimited. You can get different variations from the photos below.

Kinds

Types of thin sheet steel:

- Roofing. Thickness - 0.5–0.8 mm.

- Tough. Thickness - 0.2–0.5 mm.

Types of tin:

- White. Covered with a layer of tin.

- Black. After production, the surfaces of the sheets turn black.

A layer of tin on tinplate is needed to protect metal surfaces from rust. Roofing steel can be coated with a layer of galvanization or oil paint.

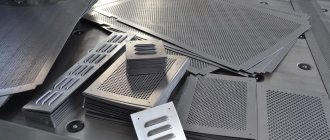

Thin sheet metal and wire are used in various fields of activity:

- Production of metal cassettes - perforated, solid, hollow, filled with thermal insulation.

- Production of ceiling and facade panels.

- Manufacturing of support pillars, metal structures, parapets, lamellas, fence sections, caps.

- Production of window openings and additional elements.

Other areas include the production of housings for machines, instruments, machine tools, cans, dishes, and drainpipes.

Drainpipes (Photo: Instagram / ventilacia_kms)

What can you make from an old bicycle for your garden?

Old bicycles were found on the balcony and attic, but it was a pity to throw them away. Then you can give them a new life by transforming them into something useful for the garden. For this purpose, it is not necessary that the vehicles be in a suitable condition.

You can use the remaining parts to create an unusual flower bed. It is formed by attaching a flowerpot with flowers to an accessible metal structure left over from a two-wheeled product.

Stand for cucumbers and other cultivated plants

Wheels from several bicycles are used for this. If rust is found on them, it is cleaned with sandpaper. The bicycle is covered with 2-3 layers of metal paint.

Some skip this stage to create the effect of the presence of antiquity. What is needed to create this metal craft for the garden:

- Bicycle wheels;

- Wooden block;

- Heavy and small stones to secure the structure;

- Comfortable shovel;

- Antiseptic;

- Stretch film;

- Wire;

- Strong hammer;

- Scissors.

Step-by-step instruction:

- A shovel is used to dig a hole for installing a wooden block at one of the ends. To protect against rotting, it is coated with an antiseptic in several layers. After drying, the edge chosen for immersion in the ground is wrapped in several layers of stretch film. This will provide insulation from moisture.

- Help will be required for installation. One holds the post, the other fills it with heavy and small stones. A strong hammer is used for compaction.

- If possible, the structure is filled with cement. If it is not there, then a mound of dense soil is created. It is carefully compacted.

- If cement was used, you must wait until it is completely dry. Then the wheels are connected to the post using wire.

Cucumbers will be able to curl around the wheels and be attached to a support to receive maximum sunlight. But this design will also be useful for other plants that can grow vertically and twine around objects: grapes, beans. However, the height of the wheels should be comfortable for unhindered harvesting.

If you liked exploring the possibilities of metal crafts, check out other materials on the site. There is still a lot of interesting things here.

Manufacturing

The production process includes several stages:

- Initial blanks for the production of sheets are prepared from cast steel. In production they are called slabs.

- The slabs are moved to industrial furnaces, where the billets are heated.

- The heated slabs are moved to the rolling line, where they are rolled out to the required thickness.

- The prepared strips are rolled into rolls and fed to the pickling shop. There they are cleaned of scale and can be processed by pickling or shot peening. Often processing methods are combined.

- The coils are fed to the cold rolled strip. The sheets are joined by welding. The edge is cut and oiling occurs.

- Chemical treatment is carried out.

- The metal is heated in an industrial furnace. Recrystallization occurs.

- The sheets are galvanized.

- Cooling and tempering of steel is carried out.

- When the parts are completely cooled, the steel sheets are straightened to obtain the required flatness.

After the production process is completed, the strips are oiled, rolled up, and sold.

Thin sheet steel is manufactured according to the requirements of GOST 19904-90. This document contains requirements for the characteristics of finished sheets:

- Thickness - from 0.35 mm to 5 mm.

- Length - from 1000 to 6000 mm.

- Width - from 500 to 2350 mm.

For rolls, the length is not regulated.

Industrial oven (Photo: Instagram / xg121)

Processing methods

To produce various parts from thin sheet metal, you need to choose a material processing technology and carry it out in compliance with certain features. Processing methods:

- Flexible. Can be manual or industrial. Manual bending is suitable for bending parts up to 0.6 mm thick. To work with more serious workpieces, you need to use industrial equipment.

- Welding. To process sheets of small thickness, electrodes of small diameter and length are used.

- Cutting. A technological operation that allows you to divide metal blanks into separate parts. There are several types of metal cutting, which differ in the equipment used, technical characteristics of the cuts, capabilities - laser, plasma, water jet, oxygen gas, mechanical.

When cutting metals, it is important to take into account the chemical composition of the alloy, the level of electrical conductivity, sheet thickness, heat resistance, and the presence of protective coatings.

Methods for manufacturing products from sheet metal

Lathes, milling machines, laser cutting and engraving equipment are used to process sheet metal products. To work with sheet metal, technologies of profiling, bending, stamping, welding, etc. are used.

Today, laser cutting is considered one of the most effective technologies for processing metal sheets. With its help, it is possible to obtain products that exactly meet the customer’s requirements, while in the process of cutting the metal its structure is not disturbed, the edges of the cut remain smooth, without burrs.

Laser cutting equipment makes it possible to produce high-quality parts with smooth edges and minimal error. In addition, using a laser you can not only cut sheet metal, but also engrave it, that is, apply images and inscriptions to the metal surface.

Due to numerical control and high precision of the laser beam, the images obtained using the appropriate equipment are of excellent quality and clarity.

Crafts

Thin sheet metal is used to make various crafts. Shape, size, products are limited by imagination. To work with metal sheets, it is better to use metal scissors rather than a grinder. Power tools can damage protective coatings, causing rust to spread to the cut areas.

Thin sheet metal is used in various industries. The variety of application areas is determined by the presence of different types of coatings, release forms, and standard sizes.

What metal crafts are created using welding?

In fact, everything, right down to artistic work in the form of sculptures of people or animals. But most often welding creates:

- Installation of all kinds of structures;

- Repair work is being carried out;

- Garden supplies are made.

Photos of available examples are offered on our website dnevnikmastera.ru. Almost all illustrations are accompanied by detailed master classes on making metal crafts using welding and other methods.