One of the options for final metal processing is scraping. Using this operation, you can get a clean, smooth surface that will have no grooves or bulges. The main feature of this technique is that it allows you to remove very thin layers of metal - from 0.01 to 0.5 millimeters, depending on the type of tool and processing method.

The main disadvantage of scraping is that this procedure is difficult to mechanize, so it is performed by experienced mechanics. But what is scraping from a technological point of view? What are the features of this operation? This article will discuss these issues in detail.

Brief information about the operation

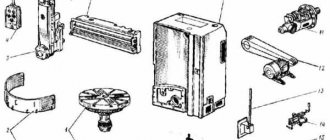

Scraping is a special type of metalworking that is performed using a special tool called a scraper. Scraping is usually performed for processing various metals (steel, cast iron, copper, aluminum, multi-component alloys). Although the scraper can be adapted for processing other surfaces - wood, plastic, soft stone. From a technical point of view, scraping is the scraping of layers from the surface of a part. A scraper is a hand tool with a wooden handle, one of the ends of which is pointed.

The scraper is usually three- or four-sided, although more complex tools are used for some processing options. Used for cleaning the surface of sheet metal, as well as for cleaning edges and ends, for applying drawings and inscriptions, for engraving metal products. Before scraping, a metal product can be coated with a special sealant compound, which has a good effect on the accuracy of the operation. The dimensions of the scraper are usually small (from 30 to 40 centimeters in length), since the tool must fit well in the hand.

The scraper tool is usually made of two types of steel:

- The main part of the tool is made of tool steels, which can withstand mechanical loads well under long-term stress. This steel withstands exposure to chemically active substances well, so the scraper does not corrode or crack. Tool steel is easy to produce, which reduces the price of the tool.

- Cutting inserts made of carbide steel can be installed at the ends of the tool. Such steel lends itself well to sharpening (with or without heating), but during operation it does not become dull and retains its shape for a long time, which allows the scraper to maintain its practical properties. Carbide steel is more expensive to produce, so it is usually used in the form of small plates inserted into the main part of the scraper.

Main advantages

The main advantage of scraping is the high wear resistance of the treated surface. The absence of abrasive particles has a positive effect on the integrity of the metal structure. The treated surface has a low coefficient of friction, which increases the service life of lubricants.

The quality of scraping can be determined without the use of expensive instrumentation. The indicator in this case will be ordinary paint, the number of spots of which can indicate the degree of treatment of the surface.

Technological features

Scraping has a number of technical features:

- High processing accuracy. The scraper tool is very precise, and with its help you can remove a layer of metal with a thickness of 0.01 to 0.5 millimeters. If a worker needs to cut a wider layer, he either uses a rougher tool or simply repeats the operation several times until he gets the desired results.

- Ability to work with complex shaped parts. The scraper blades are of different shapes, which allows you to work with both flat objects and various complex objects (say, with bearings or car parts). This makes the technology universal and easy to use.

- Impossibility of mechanization. Scraping is a fairly delicate and complex procedure, and appropriate experience is required to carry it out. For obvious reasons, scraping cannot be automated, which reduces the popularity of the technology (although the scraper can be connected to pneumatic devices).

Overhaul of turning tanks in St. Petersburg

Among metal-cutting machines, lathes constitute the largest group. Their wide technological capabilities allow:

- – obtain a variety of profiles on the end, external and internal surfaces of workpieces;

- – process cylindrical, conical, threaded, flat and shaped surfaces;

- – use not only cutters as cutting tools, but also various axial tools, such as drills, reamers, countersinks, etc.

The significant popularity and active use of lathes in the production process have led to a great demand for their repair services.

For more than 16 years, it has been servicing enterprises in St. Petersburg and the Leningrad region and carrying out major repairs of lathes, as well as other industrial equipment. The company's engineers have accumulated extensive experience in restoring the characteristics of machine tools to their original rated values; they have successfully completed more than 2,000 projects for the repair, maintenance and modernization of various machines and mechanisms.

Scraping technique

The scraping technique depends on the nature of the cutting tool and the shape of the workpiece. It is recommended to carry out the operation in a factory workshop in which equipment for fixing the workpiece is installed. These could be hems or abs. Before scraping, it is recommended that a person put on a work suit that will protect his clothes from particles of dust and dirt. There is no need to install a hood in the work shop, since the resulting metal debris does not pose a threat to health. After scraping, it is recommended to take a shower or bath to get rid of dust, dirt, and debris that may have stuck to the skin during the operation.

To work with flat, large surfaces, flat scrapers with a wide scraping plate are used. This will speed up the processing procedure and also make the surface smoother. If you are processing a narrow spare part (say, bearings) or applying a design, then it is recommended to use a scraper with a narrow nozzle. Such a nozzle will be able to get into hard-to-reach places, and will also make stripping very precise. Scraping wood and plastic is easy to do - you bring the tool to the edge of the surface to be processed, place the tool at a shallow depth and, using muscular movements, remove the outer surface layer by layer.

Scraping stages

Metal scraping requires dexterity and practical skills that a beginner may lack. Therefore, it is better to entrust this operation to an experienced locksmith. It is recommended to perform scraping of products on a wood slab, and the procedure itself looks like this:

- Before cleaning, prepare or buy in the store a paint mixture based on soot and motor oil. The mixture must be thick and sticky so that it can adhere to the surface of the part being treated. Apply the mixture using a swab to the entire surface of the wood slab and let it dry for 1-2 minutes. The mixture should be applied evenly over the entire area of the slab in 1 layer (otherwise the accuracy of control measures will be significantly reduced).

- Now take the part that will be processed, and then attach it to the blockboard coated with paint. After a couple of minutes, remove it from the stove and look at the color spots that formed after applying the part. White dry spots indicate that the part has a large depression or crack at the application site (scraping is useless and even harmful for them). Black spots indicate that the surface is uniform and does not contain depressions. Gray color indicates the presence of small protrusions - these are the ones that require scraping.

- Sharpen the tool and begin removing rough edges using a scraper. During work, it is recommended to make movements “from yourself”, and the scraper itself should be held at an angle of 30-45 degrees relative to the plane of the object. Forward movements must be made with firm pressure to cut off excess metal. By controlling the degree of pressure, you can control the cutting depth. The tool should be returned back calmly, without pressure. The optimal tool stroke is 2-3 centimeters, and as the metal surface is leveled, the stroke should be reduced to 0.5-1 centimeters.

- Using a clean rag, remove any metal debris that may have formed during processing from the surface of the part being treated. Also be sure to dry the wood board and apply a new coat of paint. Now again attach the workpiece to the surface of the table with the applied paint. After a few minutes, remove the part and pay attention to the color of the stains. If there are gray spots left on the table, the scraping operation should be repeated. If the part is small, then you don’t have to apply paint - instead, you can use an unused area of the slab (this reduces work time and reduces paint costs).

How to choose a metal lathe

The functionality of metal-cutting equipment is practically unlimited. If necessary, you can buy both a turning-milling machine and a turning-turret with a copying device and program control. It all depends on the need for specific parts and their accuracy class.

As a rule, for home use, they buy or assemble simple lathes with their own hands, which allow them to perform simple but necessary operations - turning shafts, making pulleys and cones, making shaped parts, drilling and basic milling work. Each machine is selected to suit the needs as much as possible, then it will operate under optimal load conditions and will serve for a long time and reliably.

Solid state relay - operating principle, Electric planers, quality rating

Lapping and scraping - what's the difference?

The lapping procedure is similar to scraping in some respects. This operation is also used to level the surface of an object, and it is usually used for metal processing (although the technology can be adapted to work with wood, plastic or soft stone). However, there are many more differences between lapping and scraping than there are similarities. The main difference is that abrasive materials are used for lapping, and not a special scraper tool. In addition, lapping is not suitable for small spare parts or objects of complex shape (while scraping can cope with this task).

Abrasives

Abrasives are various materials that, due to their structure, are used for grinding and polishing metal, wood, and plastic products. The principle of operation of abrasives is similar to a scraper - to level the surface of an object, the upper layers of the object are simply cut off. The accuracy of abrasive processing can be either low or very high (it ranges from 0.001 to 1 millimeter). Depending on the structure, there are 2 main classes of abrasives:

- Soft abrasives. This category includes homogeneous mixtures or pastes suitable for grinding. Examples of soft abrasives are diamond pastes, diamond chips, GOI pastes. Soft polishing abrasives produce a more gentle, gentle effect on the material, which is why they are used for polishing ductile metals. These are copper, its alloys, aluminum, cast iron, annealed steel. They are also used for processing non-metallic materials (say, for working with wood or plastic).

- Hard abrasives. This group includes both individual substances and special objects made by man directly for grinding. Examples of hard abrasives are sandpaper (with or without the addition of diamond dust), quartz, corundum, electrocorundum, silicon carbide. Hard abrasives have a coarser, non-uniform structure, so they are used for grinding hard metal materials. These are steel, hard varieties of cast iron, and some types of aluminum. Hard abrasives can be used to process wood and plastic, but the processing must be done carefully so as not to damage the part. If desired, a combination of hard and soft abrasives can be used to achieve optimal results.

Lapping stages

Lapping metal requires not only an abrasive, but also a lapping tool, as well as coolants and lubricants. The lapping tool usually acts as a press, which presses the abrasive onto the metal and moves it for polishing. Gasoline, water, kerosene, and mineral oils are used as cooling/wetting agents. The grinding procedure itself is simple:

- First, a soft or hard abrasive is applied to the lapping press, the workpiece is placed on top, and then it is caricatured. Plates, bars, and rollers can be used for caricature (depending on the shape of the object). If the abrasive falls out of the tool under the influence of gravity, a sticky lubricant can be applied to the surface, which will hold the grinding particles.

- After caricature, you can start grinding. To do this, lapping plates, bars or rollers begin to rotate in one or different directions. Due to this, the contact of the abrasive with the surface of the treated surface increases, which can lead to cutting off the upper layers of the metal. The depth of processing is usually directly dependent on the processing time - the longer the lapping takes, the wider the layer of metal that will be cut using lapping will be.

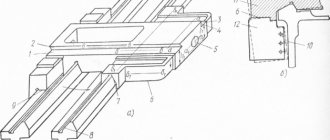

Types of beds

The bed is a different design in cross-sectional shape with:

- ring type profile;

- box profile;

- box profile and longitudinal stiffeners;

- box-type profile and stiffener located diagonally;

- open profile type;

- open profile and double walls.

In the longitudinal direction, the bed is a base with:

- square windows;

- windows and stiffener diagonally in one direction;

- stiffening ribs in both directions (like the letter X);

- one-piece body design.