Galvanized mesh for fences

Fences made from mesh are very popular; they are indispensable in cases where you need a reliable fence with good light transmission and a low price. In addition, modern fences made of welded galvanized mesh are very attractive, durable and easy to install with your own hands.

Classic country fence made of galvanized welded mesh

What does the market offer?

In the modern construction market today there are three types of chain-link, differing in material:

- A black wire chain-link can last no more than three years. Moreover, already on the fourth day after its installation, rust may already appear. Such a fence is often installed as temporary with the prospect that in the future a fence will be erected from a different material. If such a grid is left, then it will need to be renewed with paint every five years.

- The galvanized analogue of ferrous metal mesh is completely resistant to corrosion, which is why it is considered more popular.

- Another type of mesh made from chain-link is plasticized. It is also made of metal wire, but coated with a polymer, which has a protective effect against corrosion. In appearance, it is much more aesthetically pleasing than the previous two types and is not at all afraid of moisture. This material appeared on the domestic construction market not so long ago and is already very popular in summer cottages.

Advantages of galvanized mesh

They produce galvanized mesh from metal wire. Its rods are arranged perpendicularly and are fastened at the connection points by welding. The cells of the welded mesh are made rectangular, square, less often diamond-shaped, trapezoidal or other shapes.

The wire for the mesh is galvanized or with an additional polymer coating. Fencing made of welded galvanized mesh has its advantages:

- Affordable price;

- Simple and quick installation of the mesh can be done with your own hands;

- Light weight, does not require foundation construction;

- Transparency and good visibility allow it to be used at protected sites;

Fence design made of galvanized mesh and metal corners

Attaching chain-link mesh to metal posts with hooks

Simple from the implementation side - installing a chain-link mesh on metal posts with hooks. These elements act as a kind of hooks.

You can attach the chain-link to metal posts using this method yourself. The mesh clings to the hook in the lower and upper parts. Then the roll is unwound and the web is stretched until it stops. The hook is hooked on the next post.

You can install the hooks yourself. To do this, you should accurately mark the location of the hook installation on each fence support. The upper and lower parts must be positioned with maximum horizontal accuracy. In another case, the canvas may be skewed. This will cause sagging and poor-quality hanging of the chain-link mesh on the metal pole.

These parts can only be attached by welding. Therefore, to perform such an installation, you will also need skills in working with a welding machine.

There are ready-made iron posts for sale for installing a chain-link fence. Such products have a higher cost, but are not without their advantages:

- The hooks are fastened as securely as possible, the seams are of high quality and properly polished, without burrs or distortions.

- Precise distances between the hooks eliminate deformation of the chain-link mesh when hanging it and stretching it between metal posts.

- The presence of a polymer coating solves the problem of painting the support before installation (buried part) and after installation (aerial part).

- High-quality polymer paint increases the service life of a chain-link fence.

- Additionally, such products are equipped with plugs for the upper end of the pipe. This prevents moisture from entering the column cavity and subsequent rusting.

Types of welded mesh fences

Depending on the type of coating, welded mesh fencing is available in the following types:

- Non-galvanized mesh. The simplest version of a mesh welded from steel wire with a diameter of 1.2–10 mm. It has a low price and is susceptible to corrosion.

- This mesh will have to be painted periodically to improve its appearance and provide additional protection.

Rolls of non-galvanized mesh size 50x50 Also, galvanized mesh can be produced in the following types:

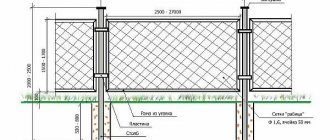

Drawing of a section of a fence made of galvanized mesh

- Galvanized mesh in rolls. The weight of the roll can be from 50 to 500 kg. The height of a fence made of rolled mesh is available up to two meters. The length of the mesh in the package can be from 15 to 33 m.

- Sectional (quick-release) fence mesh. Such a fence can be assembled very quickly with your own hands. The welded mesh is placed in a rectangular frame made of a profile pipe or angle. A fence made of sections is more durable and attractive. Sectional fencing is the most in demand both in urban environments and in the private sector.

- Decorative welded mesh 3D for fences. A new type of galvanized fence made of welded sections. How to attach a gate to a brick pillar? The design is made of curved rods that create a three-dimensional effect; it looks very unusual and beautiful. This version of the fence uses a PVC layer and decorative wavy sections along the edges or in the middle of the canvas. Another option is made in the form of twisted and corrugated wires.

Decorative fencing made of welded mesh can often be seen around city parks; it looks organic in combination with the vegetation around playgrounds and private cottages.

Return to contents

Types of chain link

To attach the chain-link mesh to the profile pipe, you need to select the optimal type of mesh material. These products are classified as follows:

- without zinc coating;

- galvanized;

- with PVC coating.

Tension fastening method

In the manufacture of non-galvanized chain-link, wire made of black low-carbon steel without a protective coating, 1 or 5 mm thick, is used. The main disadvantage of such products is their high susceptibility to corrosion and, accordingly, a short service life of 2–3 years. This material is only suitable for installing temporary fencing.

Meshes with zinc and PVC coating have high anti-corrosion properties, therefore they are more in demand. Mesh material is available in various shapes and mesh sizes.

Fence post made of corrugated pipe

The strength of the product is determined by the size of the cells. The smaller they are, the stronger the mesh. The standard hole size of the mesh material used to construct the fence is 40–50 mm.

How to choose a galvanized welded mesh fence

- The first thing you need to pay attention to is the wire thickness and dimensions. The larger the diameter of the rod and the smaller the mesh, the stiffer the structure of the galvanized fence will be. Such a fence will have a higher price, because more material is spent on the mesh;

- Choice of canvas sizes. Depending on the desired height of the fence, you can select a galvanized mesh from 0.5 to 2 m, the length of the mesh in a roll is from 15 to 33 m. Dimensions of the mesh fence section: height - 2 m, length - up to 2.5 m;

- The ends of the wire should have an even cut or bend. There should be no cracks or damage. A mesh produced in violation of technology is unlikely to last long;

- The cells must have the correct symmetrical shape, and the dimensions must correspond to the parameters declared by the manufacturer;

- Polymer-coated mesh should not have any damage to the protective layer; you should especially carefully inspect the bends if you purchase the mesh in a roll.

step-by-step instructions, photos and videos

When constructing a fence, it is not always possible to use materials that have a monolithic surface. This most often applies to situations where it is necessary to delineate adjacent garden plots in which various plants are grown. In this case, it is most advisable to build a fence from a welded mesh with your own hands. Such a structure will save the neighbor’s and your own territories from shading and will not interfere with the full development of plants, thereby causing discontent among people living in the neighborhood.

Material selection

First of all, you need to choose what type of material the welded mesh fence will be made from. There are four main options, which differ from each other in coating.

Uncoated mesh

It is usually sold in rolls and is cheap. Its use would be appropriate among bushes, since the surface of this fence will very quickly become covered with rust. Painting will be economically infeasible and labor-intensive. On the other hand, if there is dense vegetation at the border of the plots, and you need to protect yourself, mainly from migrating animals, then this option is quite acceptable.

Galvanized mesh

Perhaps the most practical material would be this kind of material. It is not much more expensive than the first one, and taking into account the total price of the entire structure, the difference will be about 10%. After all, the price of the structure includes pillars, hardware and components for concreting the supports.

Galvanized painted mesh

Its coating is applied according to the same principle as on corrugated sheeting. First, the product is galvanized, and the top is also painted. This is a very reliable coating. The only thing it is afraid of is abrasive effects. Rains and watering the garden lead to regular splashing of the soil-containing substance, which leads to the abrasion of the protective layer and subsequent corrosion. Therefore, it is recommended to attach such material slightly above the ground surface, and if it is necessary to seal the lower space, you can build a concrete or other base.

Polymer coated mesh

This type of protection is the most expensive, but also the most effective. It is resistant not only to temperature influences, but also to friction. In the most visible areas, it is worth using this option, since it has a beautiful appearance and will allow you to isolate the territory to the entire required height without additional costs.

In addition to the fact that the material differs in the type of coating, it can also differ in the method of execution, which can be:

- Welded flat mesh

- Welded mesh 3d for fence

The last name is produced by specialized enterprises, which, complete with this name, supply special poles and fastenings to create an aesthetic and reliable fence.

Preparation of tools and material for sampling

Once the welded mesh for the fence has been selected, you can begin preparatory work, one of the stages of which is equipping the work contractor with the necessary tools. This is an important stage, since the inability to carry out this or that operation will greatly slow down the construction, and the material prepared and laid out on the site will create interference. Therefore, it is best if all the necessary components have already been purchased and delivered to the construction site. Here's what you'll need:

Tools

Surely everyone assumes that you will definitely need basic tools, such as:

Digging tool

Any means for digging holes that are found on the farm will be suitable. The hole drill can be used either manual or electric. Of the shovels, the most convenient will be the “American” one, since it has a curved end, and this is very convenient when digging holes for posts.

Container for mixing the solution

- Concrete mixer (if available)

- Trough with hoe or shovel (optional)

Tools for installing mesh

- Welding machine (if fasteners will be used with it)

- Drill

- Screwdriver

- Screwdriver

- Bulgarian

- A piece of reinforcement or thin pipe for stretching the mesh

Materials

Let's figure out what materials will be needed to install a welded mesh fence and decide on their choice.

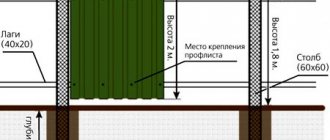

Pillars

It is best to use round or profile pipes with a diameter of 40-150 mm as pillars. The use of concrete or wooden supports is acceptable. In the latter case, it would be better to carry out protective treatment of the wood.

Cross bars

To create additional rigidity for the mesh covering, you can use thick wire threaded through the mesh. Also, spans can be attached to pipes or fittings attached between the pillars in the upper and lower parts. You don’t have to do this if the supports are often installed and the mesh has sufficient rigidity.

Wire can be used up to 5 mm. It is recommended to use fittings or pipes for rigid fastening from 10 mm.

Fasteners

To attach the mesh you can use:

- Bolt hooks (best option)

- Self-tapping screws

- Metal plates

- U-shaped clamps

- Brackets with bolts and nuts

Materials for concreting supports

- Water

- Cement

- Sand

- Rubble stone, slag or crushed stone

Fence installation

Like any other type of fencing, a metal fence made of welded mesh should be started in stages.

Site marking

With this procedure, it is necessary to take into account, first of all, the distance between future supports. It depends on their height, the thickness of the selected material, and the parameters of the material that will cover the spans.

The recommended distance in such cases is usually 2-3 meters. A more frequent arrangement of racks will entail additional consumption of material for them; a larger distance will require the use of transverse stiffeners, which will have to save the mesh from sagging. When marking, it is necessary to take into account the dimensions of rolls or finished sections of mesh, as well as the dimensions of the entire area. All these values must be compared and the distance between the supports must be planned so that the joints of the fence covering fall on the surface of the posts.

Installation of pillars

To do this, you need to dig or drill holes in the marking areas. The depth can be in the range of 0.7-1.2 meters. This depends on the size of the posts and the density of the soil. It is also worth considering the landscape of the earth's surface. On slopes, the depth of the holes needs to be greater. This is not only necessary because in such places the soil tends to slide, but also because streams of water flow along inclined surfaces when it rains. This leads to softening of the soil and a decrease in its ability to hold objects fixed in it.

After the pits are ready, prepared supports are installed in them and concreted. In this case, it is necessary to strengthen the installed racks with wedges in order to avoid tilting during the process of pouring and drying concrete.

Mesh installation

Installation is best done no less than 7-10 days after concreting the supports. It is during this time that the cement composition will gain the required installation strength. Although many craftsmen install the mesh the very next day, this is not the best option

If transverse pipes will be involved in the fastening, then you need to immediately weld them or attach them with self-tapping screws. It is better if these stiffeners are placed between the sides of the racks that face each other. With a carefully selected size of the jumpers, they will act as spacers and protect the supports from coming together under the influence of the tension of the mesh.

When used against sagging wire, it is threaded after hanging the mesh, but before tensioning.

The diagram below shows various options for attaching welded mesh with clamps

The mesh covering of the fence can be attached in several ways:

- Welding

- Using clamps

- By hanging on hooks

- Self-tapping screws and pressure plates

It is important that when attaching the mesh, it is tensioned in a timely manner. If the installation is carried out using hooks or self-tapping screws with plates, then first you just need to hang the material on them, and then tighten it evenly.

When welding fastening, the mesh must be tensioned immediately until final fastening. The material must be tensioned using a vertical pipe or fittings threaded through it, as discussed above. At least two people must participate in this process. One produces tension, while the other attaches the mesh to the post. The use of a vertical rigid rod is due to the need to produce uniform tension over the entire height, which will be very difficult to do by hand.

Now all that remains is to decide on the method of attaching the mesh and begin installation

Final actions

After hanging the mesh covering, you need to check the level of all racks, paint the fastening joints (if necessary), pillars, transverse pipes or tensioned wires.

Recommendations and conclusions

With proper preparation, a sectional fence made of welded mesh can be built by any home craftsman with minimal training. There are several recommendations that will help you get the best results:

- It is important at all stages to monitor the level of the installed posts and not to apply excessive force when tensioning the mesh.

- Before painting, any metal surfaces should be thoroughly cleaned with sandpaper, degreased with a solvent and primed. This will ensure the durability of the paint and save you from additional costs in the future.

- If it is planned to make a concrete plinth under the main fence, then it must be done together with concreting the pillars.

- When working with cutting and welding mechanisms, you should not forget about your own safety measures and use protective equipment and clothing.

Photos of welded fences

We have selected interesting photographs of welded mesh fences. Please note that the installation and assembly of this type of fence is quite simple and inexpensive. Therefore, this type of fence is more suitable for summer cottages

Installation video

This short video shows the complete welded mesh fence installation process. In this video, the 3D mesh is attached using a hook bolt. Please note, as mentioned above, that there are quite a lot of options for attaching the mesh and you just have to choose it

myfencing.ru

Features of installing a fence made of galvanized mesh

There are two ways to install galvanized mesh:

- Tension of the fabric between the pillars;

- Installation of sections.

The first option is cheaper and easier to do yourself. But the second option is considered more aesthetically pleasing and stronger.

If you do not purchase ready-made welded spans, you will have to make the sections yourself from angles or profiles.

Fence posts can be either wooden or metal. Of course, if you build thoroughly, you should use steel supports with a cross-section from 6 to 12 cm.

Installation of chain-link mesh on a section with a wooden frame

This method involves knocking down a section of a wooden frame from timber for a chain-link fence. The dimensions must be such as to ensure reliable attachment to the posts.

- If metal supports are used, the frame is attached to them using bolts. To do this, plates with eyes are pre-welded at the top and bottom of the fence supports.

- When installing wooden posts, the frame can be nailed directly or secured with wood screws.

- Hooks or regular construction nails are placed around the perimeter of the wooden frame. How to attach the chain-link to the posts - the decision is yours. When using the last fastener option, you do not need to drive it in completely.

- A broach is installed between the hooks (or nails) and secured by bending the nails.

- A chain-link mesh is attached to the broach (tension method).

After installing sections of chain-link fence, protective treatment of the wooden frame should be carried out. It is impregnated with antiseptics, covered with primer, and then painted with varnish or decorative paint.

Installation of pillars

- Perimeter marking. To ensure that the fence is level, the cord is pulled and the location of the posts is determined. The supports must be located at even intervals of at least 2.5 m.

- Installation of fence posts. Holes 120–150 cm deep are prepared for the pillars, the bottom of the wells is filled with crushed stone and sand 10–15 cm thick.

Each layer is moistened with water and compacted. The pole is installed in the hole, checked for verticality and supported. - Mixing mortar and concreting pillars. Concrete is poured into the well and carefully compacted with a crowbar or reinforcing rod. You can start installing sections and stretching the mesh no earlier than in a week, then the composition will be strong enough.

Return to contents

Installation process

All work must be performed in strict sequence, carefully taking measurements. The most important thing is to be extremely careful at each stage, otherwise you will have to repeat certain steps.

To ensure that you are completely satisfied with the result, we offer a detailed action plan.

The first step is marking

This step is extremely important, since it will give us an understanding of the amount of materials required to complete the entire project. The first step is to install pre-prepared pegs at the corners of the perimeter of the future fence. The main point when performing this step is compliance with the standards for the distance between products. Maintain a distance of 2.5 - 3 meters. In the future, pillars will be installed in place of these pegs.

Next, between these pegs, you need to stretch the cord. This way we can determine the dimensions of the mesh:

- the length of the cord is responsible for the length of the fence;

- The width of the fence is determined by the required height.

The second step is to install the pillars

After we have decided on the markings and the amount of required materials at the first stage, we can proceed directly to the installation of the pillars. Key points for completing this stage:

- It is necessary to dig holes with a depth of 1 meter.

- Their base must be covered with crushed stone, sand, and then compacted.

- After this, you can proceed to installing the pillars.

- When there is already a post in the hole, we fill it with earth and compact it thoroughly.

When these steps are completed, everything will be ready for further installation of the grid itself. They serve as the basis and this stage can easily be called the most labor-intensive. Let's move on.

The final stage is tensioning and fixing the fence

To avoid sagging, it is necessary to install the roll where the corner post is located, the edge is securely fixed. To achieve the most reliable fastening, you can use hooks that are welded to the pole.

Important - we strongly do not recommend fastening using wire, as this will put the entire fence at risk. As an alternative, you can also use clamps, nails, staples

Next, the fence is unwound and secured in a similar way. If the mesh is not galvanized, it is recommended to raise it from the ground by 5-10 cm. The final touch is to protect the entire fence from corrosion processes - special paint is applied for this.

Useful tips

When starting installation, you should take into account several tips from professional builders. This will help install the fence faster and better.

- When installing supports for welded mesh, do not choose wooden posts. Under the weight of the metal mesh, the fence may become deformed.

- If the choice is made in favor of a rolled chain-link, it should be deployed in advance (1-2 days before installation). In this case, the product will have time to rest, and there will be fewer errors in the work.

- It is better to carry out excavation work in the off-season (autumn or spring). At this time of year, the ground is more loose, so making holes will not be difficult.

- Experienced installers advise preparing a cement mortar designed for 1 hole. This will prevent the total mass from solidifying and will reduce the cost of constructing the fence.

Advantages and disadvantages

Sectional fences made of welded mesh are in high demand among consumers, which is explained by the large number of advantages of such products:

- Reliability. Such a fence protects the territory from animals and third parties entering the territory.

- Strength. When making the mesh, thick rods are used that can withstand great mechanical stress.

- Possibility of free penetration of sunlight. Even with a high fence, the area will not be in the shade. This characteristic of fencing is especially important for garden plots and vegetable gardens.

- Easy to install. The installation of the fence can be completed even without the involvement of builders and installers.

- Low cost. Unlike products made of polycarbonate, wood and some other materials, metal fences made of welded mesh are characterized by affordability.

- Insensitive to weather conditions. The steel rods are treated with an anti-corrosion layer, so the fence does not rust from rain and snow. In addition, when there is wind, there is no sail effect.

- Easy to care for. Unlike a wooden fence, welded mesh does not require annual painting and is durable.

- Relatively light weight of the finished structure. Thanks to this feature, there is no need to prepare a reinforced base.

Connecting clips for 3D mesh Gitter

| The connecting clip for the 3D Gitter mesh is made of stainless steel. | Universal connecting clip for 3D mesh Gitter | ||||

| Size | Price /piece | Size | Price /piece | ||

| 20x18x11x1.5 | 27.00 rub. | 10x14x13x1.5 | 25.00 rub. | ||

What affects the cost

If you decide to purchase fasteners for fences, you will be interested to know what the prices for such products generally consist of. The type of elements, the material used to produce them, and the manufacturer’s fame and reputation are of key importance. In order not to make a mistake, you should buy fasteners made from profiled metal pipes, the production of which was made using exclusively high-strength carbon steel with anti-corrosion characteristics.

As for the types of fasteners, there are really many of them:

- bolts and x-brackets;

- log holders;

- rivets;

- self-tapping screws;

- logs secured by screws or welding.

The cost of fasteners is influenced by the absence/presence of powder coating. Some types of elements are treated with hot zinc, for example, x-brackets made of solid metal sheets. Additional processing increases the prices of fittings and accessories. However, it also gives them additional strength, better performance and protective characteristics and beauty.

Application area

Installation of a fence made of welded mesh is often ordered for summer cottages and vegetable gardens, but such fencing has many more applications.

- Territory of public institutions. The list of such places includes kindergartens, schools, and parks.

- Sports grounds. Metal mesh is resistant to mechanical damage, so it is indispensable in areas for sports activities.

- Industrial enterprises and facilities. With the help of such a fence, you can block the entrance to the territory of gas stations, transformer substations, railway stations, electric and gas stations.

- Parking lots for vehicles.

- Fencing for forestry and agricultural land.