Among the many cutting methods, plasma cutting of metals is considered one of the most popular. The technology is supported by special equipment - numerically controlled plasma cutters.

They are widely used in many industries. Using this machine, elements of building metal structures, parts for various equipment, components of agricultural machinery, metal doors, shelving for retail establishments are accurately and efficiently produced; ventilation devices for industry, many other products.

Structure and operating principles

The CNC plasma machine is available in various models, which differ in the type of device, control circuit and material supply method. But they must have the following components:

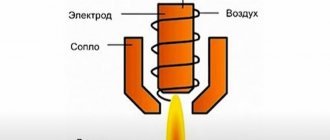

- plasmatron with a gas supply system;

- rotating surface of the work table to facilitate the installation of sheet metal;

- cutter movement mechanism and magnetic fastening system;

- control sensor for controlling the height of the torch above the workpiece surface;

- a profile rail and on both sides of it two toothed racks;

- CNC systems.

The plasma cutter has a simple operating principle. An air flow with a certain pressure entering the cutter, in contact with the electrode, acquires a temperature of up to a maximum of 30,000˚ C. The electrical conductivity of ionized air increases.

As a result, the metal melts from contact with a directed flow of hot air or a gas mixture (this is plasma), and the cut-off part is discarded due to pressure. This is how CNC plasma metal cutting processes work. Having processed the program set by the operator of the unit, the device, using plasma, cuts sheets of metal independently, and the participation of people in the process is minimal.

OCCUPATIONAL SAFETY REQUIREMENTS BEFORE STARTING WORK

2.1. Tidy up your clothes, button or tie up your sleeve cuffs. The canvas jacket should have no pockets and be worn untucked over the trousers. Pants must be worn over boots and cover them securely. 2.2. Check the serviceability of personal protective equipment and safety equipment (shields, dark glasses, mittens, etc.), the operation of local gas suction. 2.3. Inspect and tidy up the workplace, remove all unnecessary things from under your feet, put rubber mats and stands in place. 2.4. Check the serviceability of the equipment, electrical wiring, presence and serviceability of grounding. 2.5. Check the presence of water and its free passage through the water-cooled elements (plasma torch). 2.6. Check the serviceability of devices regulating the operation of the installation. 2.7. Check the condition of electrical wires and contacts. 2.8. Ensure free movement of the moving parts of the cutting machine from touching the hoses and cables connecting the machine to the power source. 2.9. Check the serviceability of hoses, cutters, pressure gauges, working surfaces of guides and leading elements of cutting machines. 2.10. Turn on the water and make sure it flows and drains from the cutter. 2.11. Open the air valves and adjust its flow, turn on the ventilation. 2.12. Set the cutting current specified by the technical process. 2.13. Turn on the power switch with the switch, and the switches on the control panel, as well as on the cutting machines, should be in the “off” position. 2.14. Place the plasma torch in its original position. 2.15. Set the speed controller for the mechanized movement of the cutter to the required speed of movement, depending on the thickness and material of the process. 2.16. Turn on the automatic control circuit switch and press the toggle switch to light the pilot arc. 2.17. Turn on the cutter stroke on the moving mechanism. When the pilot arc touches the metal being cut and the working arc is excited, it is necessary to turn off the pilot arc (automatically or by switching the toggle switch). 2.18. Report any noticed deficiencies, malfunctions in the equipment and any dangers that have arisen to the technician. 2.19. You can begin work only after all faults have been eliminated and the technician has given permission.

Operational advantages of the device

A CNC plasma metal cutting machine has some advantages:

- work operations for cutting metal sheets of complex configuration are performed with unique precision;

- The plasma cutter has low power consumption and does not require additional devices or financial costs. Production costs are reduced and profitability increases;

- The device has high performance CNC plasma cutting. Not a single device involved in cutting metals (except for a laser) is capable of achieving a similar speed as a plasma cutter. This determines its industrial use for the production of mass products;

- the device is convenient to use and easy to maintain;

- The device is capable of plasma cutting sheets of all metals, low-alloy and carbon steels, cast iron with a thickness of 0.5 to 150 mm, ensuring a clean cut. Additional processing of the ends of the cut blanks is not necessary;

- plasma cutters that operate without emitting gas or open flame are safe;

- There is a function for automatically determining the thickness of a metal sheet.

There are practically no disadvantages to this equipment. But they are not used for cutting sheets of high-alloy steel with a thickness exceeding 10 cm, as well as titanium.

With proper regular maintenance, you can guarantee a long service life for the plasma cutter. You can learn about the specifics and frequency of its implementation from video materials.

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. To prevent fires, the following requirements must be observed: - do not block access and passages to fire-fighting equipment, fire extinguishers, hydrants; — store flammable and flammable substances in specially designated areas in compliance with fire safety measures; - smoke only in specially designated areas equipped with fire-fighting equipment and trash cans; — store used cleaning material in a metal box with a tight-fitting lid; - do not approach the hoses with open fire; — do not clean or wash work clothes with gasoline or other flammable liquids. 4.2. The work area must be provided with fire safety posters and inscriptions. 4.3. If a fire is detected, immediately notify the fire department by calling 101 and, before firefighters arrive, begin to extinguish the fire using available means. 4.4. If situations arise that can lead to breakdowns and accidents (for example, in case of breakdown of insulation in the circuit, leakage of the plasma torch and hoses, faulty water cooling of the plasma torch or interruption of water supply), it is necessary to stop work, turn off the power supply, remove people from the dangerous area and inform about the situation to the master. 4.5. If an accident occurs, immediately take measures to provide first aid to the victims using available means, call an ambulance by calling 103.

Features of the cutting process

When using plasma cutters, one must take into account their technical characteristics, the chemical composition of the mixtures used, the parameters of the products, and the peculiarities of their processing.

If the sheets have a small thickness (up to 1 cm), it will be enough to have the temperature of a low-power plasma arc. Workpieces with greater thickness can be cut, further stabilizing the arc. When the thickness exceeds 10 cm, plasma installations are needed that are able to form an arc with a more powerful effect.

The type of source matters a lot. For thin sheet steel up to 6 mm, a small current is sufficient. To process sheets twice as thick, you will need a source with a high current level. When the current source turns out to be weaker, sections of the cuts will have slag deposits.

OCCUPATIONAL SAFETY REQUIREMENTS AFTER WORK COMPLETION

5.1. At the end of the work, tidy up the workplace, clean tools and devices from dirt and put them in the designated storage area. 5.2. It is necessary to turn off the electrical power of the device, as well as the lighting and ventilation. 5.3. Burning materials must not be left in the workplace. 5.4. Clean overalls and shoes and put them in closets, wash your face and hands with warm water and soap. 5.5. When handing over a shift, inform the foreman and shift worker about installation malfunctions that were discovered during work.

We thank Tatyana Ivanovna for the instructions provided! =)

What's in the plasma cutter review?

Enterprises in various industries use:

- stationary models, among them there are portal machines; articulated; console type for cutting metal using plasma;

- mobile or portable for the same purpose (vertical plasma cutting), equipped with CNC systems.

Today it is not difficult to make a choice of a plasma machine - there are many manufacturers specializing in the manufacture of devices of this kind. The range is represented by domestic and foreign models. Let us name and briefly describe at least some of them:

- The PlasmaCut installation from the Russian company Unimash is aimed at being used in medium and small businesses. The Hypertherm plasma source is one of the most technologically advanced; it has a FOCUT mechanism that controls the torch height and powerful motors. It can be controlled remotely via USB and Ethernet from the rack on which the control panel is mounted.

- The IGNIS CNC plasma cutting machine (Russia) has several modifications - IGNIS 2500, 3000 and 6000 with different dimensions, power of the plasma source and load capacity. All of them are designed for use with a metal thickness of 28 mm, have a stable demand and are applicable in the technical equipment of small-scale workshops and enterprises.

- Powermax is considered a machine with unique properties, capable of performing plasma cutting of products of various types and shapes.

- PlasmaBox is an excellent machine from a series of multi-axis machines, it has four motors operating with different powers.

- РВ 6000, РМ 3000, PS 2500 – units that cut workpieces of different lengths and thicknesses.

All of these high-performance machines use an AMN CNC control system. In some models for industrial use, the plasma torch is cooled forcibly under the influence of liquid, while others have natural air cooling.

It should also be said that the weak point of computer-controlled machines is their vulnerability to the effects of electromagnetic radiation. This makes CNC devices demanding in terms of the method of igniting the electric arc. The safest option is pneumatic ignition, sometimes referred to in the names of device models as PN. The main feature of pneumatic ignition is a movable electrode, which moves towards the nozzle at the right moment. By reducing the distance to initiate the arc, high-frequency pulses are not required and interference to the electronics is minimized. Today there are not many devices with pneumatic ignition on the market; for example, it is implemented in the Triton CUT 100 PN CNC plasma cutter.

Plasma cutting operator etc

Contact us!

Plasma cutting of metal, which has become a modern alternative to conventional gas cutting, is becoming increasingly in demand today. Productivity increases significantly and the workflow is simplified. However, to properly and effectively use a plasma torch, a specialist must have all the necessary skills.

Basic requirements for a plasma cutting operator

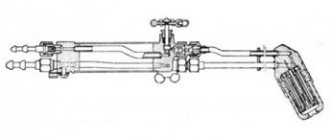

A metal cutting specialist cuts various metal structures using special equipment - a plasma torch, which produces a plasma arc or jet. Given the lack of qualified personnel, such specialists are required in various industries. Highly efficient processing of metal parts is important in construction work, industry, etc.

Therefore, to obtain the expected result, the following requirements are imposed on a professional:

• good health - nerves, vision, blood pressure should be normal; • patience and endurance - since you often have to work in cramped conditions or in an uncomfortable position; • professional skills; • knowledge of the device and its settings; • perseverance and hard work.

This is a creative and responsible job. The specialist must understand that the mistakes he makes can damage the product and harm those who will continue to work with it.

Professional knowledge and skills

The specialist must have sufficient technical knowledge, as well as knowledge of chemistry and physics. He needs to understand the properties of the metals being processed and methods of melting them, know the structure of the plasma torch and the features of working with it, and all the parameters of the working equipment. The operator must take into account the requirements for the quality of finished processed metal surfaces and know methods for eliminating defects.

A professional carver needs to master metal melting technologies, the properties of gases, and the operating features of equipment. Each ongoing process must be known and understandable to a specialist who must understand all the intricacies of processing various types of metals. Safety precautions are important.

The responsibilities of a plasma metal processing operator include:

• read drawings; • prepare parts for subsequent processing; • set up equipment, establish a suitable operating mode; • process metal products; • control the quality of treated surfaces; • prevent the occurrence of deformations.

The operator must be able to choose one or another cutting mode or method, depending on the properties and thickness of the metal. Only by correctly analyzing the actions performed will the operator predict the required costs of labor, time and materials.

Plasma torch maintenance skills

Plasma cutting equipment requires a professional approach. An experienced specialist in the quality of cutting, the sound of operation and the color of the arc can understand whether it is time to change the consumables of the plasma torch, in particular the electrode and nozzle. Nozzles and electrodes can withstand varying amounts of penetration, depending on the current, type of material and thickness. Untimely replacement of elements leads to failure of other consumable elements, or even the entire plasma torch.

The operator must be able to correctly configure equipment parameters and select consumables. The selection of consumables is made depending on the type of metal (stainless steel, brass or copper), its thickness, and the gas used for plasma formation. Failure to comply with these requirements provokes rapid unsuitability of consumables and a significant decrease in the quality of the cut.

A professional must have the skills to assemble the cutter so that all parts fit as tightly as possible. Only with tightly fitting parts is optimal contact and good circulation of air and cooling fluid created. Regular cleaning of equipment will prolong its operation.

Skills in working with a plasma torch and knowledge of its features

Before starting work, the operator should check the pressure of the plasma gas and cooling liquid. If the parts of the device do not receive the necessary cooling, the service life of the plasma cutter will be reduced. The ability to maintain a constant level of gas pressure will provide the optimal arc for high-quality cutting. Beginners often have problems regulating pressure, as they set excessively high values, which damage the electrodes.

Read also: Which is softer, copper or brass?

The plasma torch operator must avoid such gross mistakes as punching when the height of the plasma torch is too low above the working surface. In this case, drops of molten metal reach the screens and nozzles, deteriorating the quality of cutting and destroying parts. If the plasma cutter touches a surface, the arc may retract and destroy the equipment. The problem of height can be solved by the use of special technological techniques by experienced specialists by changing and adjusting the height of the device.

The correct choice of equipment speed mode directly affects quality cutting. If the speed is lower than optimal, there will be sagging and unevenness on the cut holes, and hot metal will spatter. At excessively high speeds, the plasma arc bends backward, deforming the edges of the cut holes. Only a professional chooses the ideal cutting speed, and then the cut surface will be smooth.

It is the plasma cutting operator's responsibility to ensure that the arc does not deviate from the correct perpendicular. This can happen when the arc lags behind the plasma cutter.

Only a highly qualified operator of plasma cutting equipment will increase the profitability of metal cutting and increase the profit of his enterprise with impeccable results of his work. An experienced specialist with the necessary knowledge and experience will be able to reduce the company’s costs for the cutting process. This is achieved if a professional prevents premature wear and tear of equipment parts, and also carries out maintenance of the plasma cutter on time.

Manual plasma cutting and automated

Plasma cutting, as a method of cutting metals, is today gaining increasing popularity and widespread use among enterprises in the metalworking industry. Cutting is carried out both using portable portable devices and using automated equipment, when a plasma cutter (plasma torch) is installed on a CNC machine

10 common mistakes when cutting metal with plasma

Assembling the entire plasma cutting system can be a very difficult task. The task includes selecting the power source that generates the plasma flow, the CNC system, software, ventilation systems, and the cutting table and gantry system.

Gantry plasma cutting machines

Assembling the entire plasma cutting system can be a very difficult task. The task includes selecting the power source that generates the plasma flow, the CNC system, software, ventilation systems, and the cutting table and gantry system.

This topic has 18 replies, 3 voices, and was last updated by Plytarh 3 years ago.

Dear Colleagues! I can’t find a professional standard for a plasma cutter. Let's discuss what we can choose.

- This topic was modified 3 years, 1 month ago by Plytarh.

Attachments:

You probably need to start by defining the machine itself: A plasma machine is a device for processing the surface of a metal in different ways. The machines differ from each other in their internal structure, the method of placing the processed sheet, the main purpose, and also the method of control.

Equipment for CNC plasma cutting of metal is controlled using a computer program that automatically controls all the necessary parameters: angle of inclination of the cutter, output voltage power, etc. The design of such machines includes: Plasma cutter. Apparatus for supplying voltage and compressed air. Cutting system. A device for moving a cutter along a metal surface. Cutting process control system.

- This answer was modified 3 years, 1 month ago by Plytarh.

Attachments:

There is no such cutter in the General Classifier and ETKS. But on December 3, 2015, an order was issued approving the professional standard “Thermal metal cutter”

MINISTRY OF LABOR AND SOCIAL PROTECTION OF THE RUSSIAN FEDERATION

dated December 3, 2015 N 989н

On approval of the professional standard “Thermal metal cutting carver”

Hooray! found it! The professional standard for “Thermal Metal Cutting Cutter” has been published on the Ministry of Labor website. If you study it carefully, then in the descriptions of labor functions it is written: - Performing manual plasma separation cutting - Performing automatic plasma cutting That is, our plasma cutter is suitable for the Professional Standard “Thermal Cutting of Metals Cutter” . p.s. Profstandard itself is in the attached file. Using this professional standard, you can navigate the selection of personnel, writing job descriptions, drawing up PPE standards, and labor safety instructions.

Read also: Nozzles for gas stoves for natural gas

Attachments:

This picture explains a lot. Well, it’s clear that a person is looking at cutting without the mandatory PPE - glasses. Minus 100 thousand for the employer. Either put on glasses or demand that a fence be installed. The inscriptions on the machine are still in English. Didn't translate. This is still a violation of GOST.

We entered the WTO, created professional standards, but there are still no Russian machines or their cost is too high. So, in order to understand how to work on a machine, a plasma cutter needs to speak Deutsche or speak English.

Or the solution is to invite a third-party specialist, as many Russian companies do. For example, 5 Uzbeks work on a plasma cutter and once a week a Russian programmer operator comes and sets up the machine. And no one cares that these 5 Uzbeks in a week of working on a plasma cutter reduce their eyes to the point of cataracts.

Modern machines in the midst of complete lack of culture.

- This answer was modified 3 years, 1 month ago by AlexGovor.

The inscriptions on the machine are still in English. Didn't translate. This is still a violation of GOST.

But you can talk about this in more detail. What is GOST?

We entered the WTO, created professional standards, but there are still no Russian machines

best remark! but it’s easier to sit in offices and slap professional standards... than to create/or work on machines.

Or the solution is to invite a third-party specialist, as many Russian companies do. For example, 5 Uzbeks work on a plasma cutter and once a week a Russian programmer operator comes and sets up the machine

or a foreign service engineer arrives for crazy money.

But you can talk about this in more detail. What is GOST?

GOST R 12.4.026-2001 System of occupational safety standards. Signal colors, safety signs and signal markings. Purpose and rules of use. General technical requirements and characteristics. Test methods

6.6.1 The text of explanatory notes must be in Russian.

Let's select a list of personal protective equipment for a plasma cutter (PPE) in the PPE topic. There is no such profession in the norms.

Let's select a list of personal protective equipment for a plasma cutter (PPE) in the PPE topic. There is no such profession in the norms.

What field of activity?

Order of the Ministry of Health and Social Development of the Russian Federation dated December 14, 2010 N 1104n “On approval of the Standard Standards for the free issuance of special clothing, special footwear and other personal protective equipment to workers of mechanical engineering and metalworking industries engaged in work with harmful and (or) dangerous working conditions , as well as work performed in special temperature conditions or associated with pollution"

163.Operator of automatic and semi-automatic lines

Somehow you spend a lot of time making norms and cards. To avoid duplication of paperwork, all you need to do is make a form of personal PPE cards and approve them by order as norms. Then, if the norms change, just make a new card and put it in the order. This unifies the work.

- This answer was modified 3 years, 1 month ago by AlexGovor.

What field of activity?

Plasma cutting of metal.

163.Operator of automatic and semi-automatic lines

This does not fit.

Somehow you spend a lot of time making norms and cards.

The workplace has not yet been introduced, only the machine has been purchased. At this stage I am preparing documents.

it fits perfectly.

My options: 1) Order No. 1104, paragraph 475 (pipe and blank cutter); 2) No. 997 (cross-cutting professions) p. 29 (Slotter; sharpener; gear cutter; plastic foundry worker; sander; adjuster of all types; operator of computer-controlled machines; presser of electrical products; presser of scrap and waste metal; metal cutter on shears and presses; carver on saws, hacksaws and lathes; driller; machine operator of woodworking machines; general machine operator; sawing machine operator; planer; turner; rotary turner; boring lathe; milling operator; grinder; sawmill; engraver); 3) No. 652 (FOR WORKERS OF MINING AND METALLURGICAL INDUSTRY AND METALLURGICAL PRODUCTIONS OF OTHER INDUSTRIES) item 1949 (Metal cutter on shears and presses; cold metal cutter; cutter of paper, cardboard and cellulose). Of the professions related to plasma cutting, there is only an equipment adjuster.

Yes, even though PPE for a plumber can be issued to an employee, the main thing is that he is familiar with and protected from harmful and dangerous factors by PPE of the second class of protection. According to the first class of protection according to the Code of the Russian Federation, there are no fines, so at least let him walk around in a T-shirt, but with GLASSES and a HAT.

Read also: How to restore a rubber seal

I found more suitable PPE for the plasma cutter. Appendix to the Order of the Ministry of Health and Social Development of Russia dated December 14, 2010 N 1104n Mechanical engineering and metalworking. p. 116 Gas cutter Standards: 1 Mandatory: 1.1 A suit with fire retardant impregnation or a welder's suit 1.2 Leather boots with a protective toe cap or leather boots with a protective toe cap 1.3 Canvas mittens or welder's gauntlets 1.4 Knee pads 1.5 Goggles or a protective shield 1.6 A protective helmet 1.7 A balaclava helmet 1.8 Anti-aerosol personal respiratory protection equipment (RPE) 1.9 Signal vest, 2nd class of protection

| Category : Personnel records management | |

| Replies: 10 |

You can add a topic to your favorites list and subscribe to email notifications.

| #1[481390] September 12, 2022, 10:52 |

| Colleagues, good afternoon! I ask for help from experienced colleagues who have encountered this issue. We bought a new machine with program-controlled plasma cutting for production, and we are looking for a worker to use it. Now I’m drawing up a job description and can’t figure out what to correctly name this position. I searched and found only the professional standard Thermal metal cutter. From this, it seems to me that the position of Automatic Plasma Cutting Operator is suitable for our employee. Now I’m trying to find PPE standards for this position and standards for cleaning agents and disinfectants. I would be very grateful for your help! And I also wanted to clarify what the working conditions are for this profession? We have two more CNC machines, a plate bender and a guillotine, which employ two employees - is it possible to transfer them all to the position of CNC Machine Operator? Or should there be a separate position for a plasma cutter? I will be very grateful to everyone for your help! The question is urgent, but I can’t figure it out ((((((( |

| #2[481394] September 13, 2022, 8:59 am |

| machine with program controlled plasma cutting. Now I’m drawing up a job description and can’t figure out what to correctly name this position. I searched and found only the professional standard Thermal metal cutter. From this, it seems to me that the position of Automatic Plasma Cutting Operator is suitable for our employee. Professional standard “Thermal metal cutting carver”. And it says: The main goal of the type of professional activity: Performing thermal cutting of metals in the production (manufacturing, reconstruction, installation, repair and disposal) of structures for various purposes Group of occupations: 7212 Welders and gas cutters The main thing is to go through lists 1 and 2 (I didn’t do this, sorry, I don’t have time). If a profession is on these lists, it means early retirement, additional leave and other goodies. I googled and found these documents: ETKS issue 2 part 1 section “Welding work”. It has a “laser operator”. See functionality. SP 4053-85. Sanitary rules for the installation and operation of equipment for plasma processing of materials were APPROVED by the Deputy Chief State Sanitary Doctor of the USSR A.I. Zaichenko No. 4053-85 December 13, 1985 (the document is still valid). Sanitary rules apply to all types of plasma installations that generate low-temperature plasma (UPU, UMP, UPR, UPN, APR-401, 403, “Crystal”, “Zenit”, “Plasma-4”, UMPO, etc.) intended for work manually, in semi-automatic, automatic modes, including with numerical control. The rules establish a list of measures to limit the influence of harmful production factors associated with plasma technology, and regulate hygienic requirements for the design and installation of installations, technology, materials, organization of workplaces, and ventilation. The rules are mandatory for all enterprises and organizations designing, manufacturing and operating technological plasma installations for spraying, cutting, surfacing, plasma mechanical processing (PMP), plasma chemical technology, plasma metallurgy, and welding. The requirements of the Rules must be taken into account when developing regulatory and technical documents (GOSTs, OSTs, TUs, instructions, methods, etc.) regulating the design, technological and operational requirements for plasma installations. there are two more computer-controlled machines, a sheet bending and a guillotine |

Let's say a word about pipe cutters

Pipe cutting machines, which can be classified as portal machines, are also very popular. For example, Autom-3 with a plasma cutter is used for cutting pipes. Its speed is several times higher than that of a gas cutter. The most in demand are plasma cutting machines designed for cutting steel pipes with a wall thickness of 38-40 mm. They are able to cut the pipe quickly enough, and its sections will have smooth edges.

If you need to cut pipes with a diameter from 100 to 315 mm made of stainless steel or low-carbon steel (with a thickness of up to 2 mm), which will be used in the installation of industrial ventilation systems, the TV-30 pipe cutter is the most effective. It is capable of operating in manual or automatic mode, having a CNC system. Plasma equipment of this type can be used from a network with a voltage of 380 V, with a compressed air pressure above 0.6 MPa.

A Vanad Miron CNC pipe cutter will achieve high precision. Technological operations for cutting pipes are performed automatically; a temperature of +5 – + 40˚С and exhaust ventilation are required.

A pipe cutting machine is capable of performing some preparatory actions when preparing the surface: cleaning welds, chamfering and cutting edges. It has the ability to cut, in addition to round, square or rectangular pipes.

I use a portable pipe cutting machine when performing work in hard-to-reach places in the case of small-scale orders. For example, Titan PIPR 15-5 plasma machines have a single-phase inverter that performs air plasma cutting; a contact arc ignition method is used here.

DIY making

Making a frame with your own hands

Many small workshops and private entrepreneurs are interested in program-controlled plasma cutters. Purchased models cost a lot of money, which is why they are inaccessible to many buyers. You may be thinking about assembling a homemade CNC cutter. Design drawings with a work table and guides can be found on the Internet. However, the biggest difficulties will arise with assembling the plasma torch and connecting the automated system. To complete the task, you need to understand programming and be able to correctly set the parts.

What if you make a plasma machine yourself?

There are many useful things you can do with a CNC plasma cutting machine for metal. Small workshops producing metal doors are interested in it. But the cost of this equipment (especially imported versions) is not cheap, so some home craftsmen try to assemble it themselves from parts of square pipes.

It is important to know that a unit, simple in design, cannot be made without knowledge and skills. It is especially difficult to assemble the plasmatron itself. But the components of the device and the CNC for controlling the machine can be purchased separately in specialized online stores.

Although options for electromagnetic and photoelectronic control systems are possible, it is CNC plasma machines that can provide the most accurate and fastest work. A home craftsman interested in the equipment will also have to assemble a gas supply system and achieve high positioning accuracy in order to fully take advantage of the capabilities of this device, as provided for by its technical characteristics.

Varieties

CNC plasma cutters are classified according to different factors. If we talk about design, we can distinguish two groups:

- Mobile compact models that have special wheels for moving around the workshop.

- Stationary machines. Large-sized with a lot of weight.

Based on the method of placement of rolled products, there are two types of installations:

- Machines with a portal that allow you to securely secure workpieces and make more accurate cuts.

- Console machines that do not have a desktop. Do not apply to industrial installations.

The equipment is divided according to the permissible number of metal sheets to be cut and the type of workpieces processed. Some models are designed for cutting sheet material, others for separating pipes.

Stationary CNC Plasma Cutter

Processing program

Products are created on the basis of sketches, the role of which is transferred to three-dimensional mathematical models. The participation of a plasma cutter is organized at later stages. This name is given to an exact copy of the structure, which is recreated in virtual space.

In some ways, 3D models are similar to assembly drawings. These models are created based on “flat” two-dimensional models. For example, which are the part drawings. It is their construction that becomes the main function for special CAD programs. The AutoCad function package is a typical representative of such solutions, involving processing using plasma cutting.

Such solutions can be described as automatic design systems. In industry and design bureaus, this tool has long become an indispensable assistant. The entire cycle that makes up the process of developing documents for designers is made easier and simplified thanks to packages of similar software solutions. This also applies to creating sketches for parts using plasma cutting, modeling technology in a three-dimensional plane, and developing parts for assembly.

Bottom line

A master working with a CNC machine for plasma cutting of metal structures and products must undergo mandatory instruction regarding the safe use of this equipment and receive permission to work with it.

The location where this type of work is planned must be inspected by a fire inspector. Repeated inspections are carried out at certain intervals to confirm compliance with the requirements for the safe use of the unit.

Choosing a CNC plasma cutter for home production

What criteria should you pay the most attention to when choosing before purchasing an inexpensive plasma cutter for home production of sheet metal products? Before making a purchasing decision you must:

- Indicate to the manufacturer the type and thickness of metal that the tool will be able to cut.

- Find out whether it is possible to work with a plasma cutter in the cold (for most models, in cold weather it is necessary to place the device and the compressor in a warm room).

- Determine the type of cutting - plasma arc or plasma jet cutting:

Also important technical parameters and characteristics of the device:

Plasma torch cutting speed under CNC control

This parameter determines the performance of the plasma cutter. The cutting speed depends on the type and thickness of the material relative to the specific voltage of the plasma electric arc. Naturally, the higher the cutting speed, the more efficient the cutter will be.

Maximum cutting current

The amperage of a plasma cutter is a key indicator of its power, efficiency, and the maximum thickness of materials it can cut. This figure for plasma cutters varies from 5 to 160 A. Modern plasma cutters allow you to smoothly adjust the current strength over a wide range.

Duty cycle

This is another extremely important parameter of the device that determines the pace of work. The duty cycle determines how quickly the torch will overheat and how soon it will need to take a break to cool down the temperature of the operating components. The duty cycle is determined by a percentage of 10 minutes of the time the device can operate and the time within which it must stop operating.

Exploitation

It is possible to obtain the desired result only by taking into account the features of the technology for cutting metal with plasma, observing the operating rules of the equipment:

- Check how securely the workpiece is secured to the workbench.

- Use safety glasses and special headphones to block low frequencies for the operator.

- Work only in a well-ventilated area.

- Check the integrity of the surface of the metal sheet before cutting.

- The operator must be able to configure the program and set algorithms.

- Lubricate moving parts with oil in a timely manner. Clean work surfaces from metal shavings that appear during work.

- Do not touch the workpiece until the plasma torch is turned off.

Failure to follow operating instructions can lead to serious injuries and defective workpieces.

Plasma cutting of metal parts on CNC machines has gained popularity at large enterprises and in private workshops. This is due to the fact that automated equipment allows work to be carried out more accurately, without human effort. This improves productivity.

Features of working with equipment

The typical strategy by which CNC milling machines are used when creating products can be described as follows:

- The stage dedicated to creating a sketch or drawing.

- Previous work becomes the basis for developing models in three dimensions.

- Setting a route when using the software. The three-dimensional model now becomes the basis on which this very route is created.

- Then they proceed to export the control program using a special format. The main thing is that the format is understandable to the laser machine model itself.

- Loading the control program into the device memory. After which the processing program is launched.

First stage

At the first stage, it is impossible to do without a thorough study of the design documentation. It is expected to use drawings for small components and assembly units, a large amount of materials when developing detailed drawings. On the drawings, specialists will indicate types, sections, sections, and put down the required dimensions. Using plasma cutting makes it easier to achieve the desired result.

Several years ago, production conditions required the creation of technological maps for the construction of future products. They were intended to effectively organize the work of specialists with manual milling machines. But, when automatic equipment appeared, it is no longer necessary to create such maps.

Detailed drawings in most cases support the electronic format from the very beginning and are created with its active use. Two-dimensional sketches, among other things, can be easily made by digitizing a paper drawing. Created in the program, such a picture will speed up the processing process.

Second phase

During the second stage, parts are created in a three-dimensional plane. This task is also carried out using a CAD environment. Thanks to this, visualization of the frame of parts, assemblies for assembly, and the entire product is available. An additional option is to perform calculations based on stiffness and strength.

The three-dimensional model, which has become the basis, is a mathematical copy of the product as it should be in finished form. To bring the project to life, all that remains is to produce a part that has the required characteristics. Using plasma cutting allows you to achieve results faster.

Third stage

It is to obtain the desired result that the third stage is used. It involves developing a route for future processing using plasma equipment. This work relates to the technological part of the process. It ultimately affects several parameters:

- The quality with which the products are produced.

- Cost level.

- Processing speed.