When doing plumbing work at home, everyone will come across the concept of “pipe thread”. Without an engineering/specialty education, it may not be possible to understand all the nuances of pipe connections on your own.

Running to the nearest plumbing store for help is no longer relevant these days; it’s much easier to type the relevant query into the search bar. Next, comprehensive information will be presented regarding pipe thread sizes + their classification by type.

Applications and features of inch threads for pipes

Pipe threads are used on pipes and other elements of the pipeline system: fittings, shut-off and control valves, flanges.

Standardized by international specifications. Products with threads are widely used on the following systems:

- where the use of welding is undesirable or impossible;

- where it is necessary to form a dismountable connection;

- which are not subject to pressure or temperature surges, etc.

Previously, each manufacturer applied its own thread, which corresponded to paired parts manufactured in the same production. The need for unification arose when a discrepancy between various parts with threads from different manufacturers was discovered and, as a result, it became impossible to sell or exchange threaded metal products.

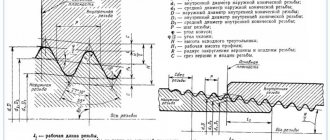

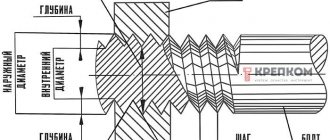

The thread differs in such parameters as

- profile angle (55°, 60°);

- shape of protrusions and depressions (sharp, flat, round);

- step (large, small);

- shape (conical, cylindrical);

- number of threads per inch.

In order to satisfy the needs of all industries, there are several types of threads. Moreover, the USA and Europe have their own standard pipe threads, which were created independently of each other. Despite some similarities in parameters, dimensions, and scope of application, threaded pipe fittings of different types cannot be used, since the only result of such a combination is damage to the products and poor quality of connections of pipeline elements.

NPT – National Pipe Taper – American tapered thread

| standard | ASME/ANSI B1.20.1 |

| form | conical |

| angle of inclination of the triangle (profile) | 60° |

| ridges and valleys | flat (blunt) |

| kinds | NPT, NPTF |

| other names* | MIP/FIP IPT FPT/MPT |

*May also refer to NPS (National Parallel) threads, which are not similar or equivalent to NPT pipes.

NPT pipe threads are common in various types of industries. Provides a strong and tight connection of pipeline fittings. For operation under high pressure conditions, installation with a gasket is required.

NPTF threads are regulated by ASME B1.20.3. The dimensions of the two types are almost the same (except for the diameter of the protrusions and recesses). NPTF pipes are in demand in systems transporting liquid substances. The NPTF thread is more airtight and does not require the use of sealing materials.

Standard Tapered NPT Thread Size Chart

| Nominal size | Diameter, mm | Threads per inch | Drilling diameter, mm | Pitch, mm |

| 1/16″ - 27 NPT | 7,87 | 27 | 6,0 | 0,0940 |

| 1/8″ - 27 NPT | 10,22 | 27 | 8,25 | 0,0940 |

| 1/4″ - 18 NPT | 13,58 | 18 | 10,7 | 1,411 |

| 3/8″ - 18 NPT | 17,016 | 18 | 14,1 | 1,411 |

| 1/2″ - 14 NPt | 21,211 | 14 | 17,4 | 1,814 |

| 3/4″ - 14 NPT | 26,566 | 14 | 22,6 | 1,814 |

| 1″ - 11 ½ NPT | 33,195 | 11,5 | 28,5 | 2,209 |

| 1 ¼" - 11 ½ NPT | 41,952 | 11,5 | 37,0 | 2,209 |

| 1 ½" - 11 ½ NPT | 48,021 | 11,5 | 43,5 | 2,209 |

| 2″ - 11 ½ NPT | 60,06 | 11,5 | 55,0 | 2,209 |

| 2 ½" - 8 NPT | 72,642 | 8 | 65,5 | 3,175 |

| 4″ - 8 NPT | 113,913 | 8 | 107,0 | 3,175 |

Correspondence table for various types and standards of threads

TABLE OF CORRESPONDENCE

| Thread type, designation | Application area | Regulatory and technical documents | Thread sketch | |

| Russian | Foreign | |||

| Metric M12; M20x2; M20x2 LH | general mechanical engineering | GOST 24705-2004 | ISO 724; DIN 13 (Germany); BS 3643 (England); ANSI/ASME B1.13M (USA); NF E 03-050 (France); JIS B 0205, JIS B 0207 (Japan) | |

| Trapezoidal Tr 40×7; Tr 40×7 LH | Lead screws in general mechanical engineering | GOST 24737-81 | ISO 2904; DIN103 (Germany); BS 5346 (England); NF E 03-618 (France); JIS B 0216 (Japan) | |

| Pipe cylindrical 55° G 1 ½ | used in cylindrical threaded connections | GOST 6357-81 | ISO 228/1; DIN ISO 228, DIN 259 (Germany) BS 2779 (England); ANSI/ASME B1.20.1, ANSI B 20.3 (USA) NF E 03-005 (France); JIS B 0202 (Japan) | |

| Pipe Taper Thread (55°) or British Pipe Taper Thread BSPT Rc 1 ½; Rp 1 ½; R 1 ½ | in gas water supply and sewer fittings. For greater tightness, use conn. internal cylindrical with external conical thread | GOST 6211-81 | ISO 7/1 DIN 2999, DIN 3858 (Germany) BS 21 (England); ANSI/ASME B1.20.1, ANSI B 20.3 (USA) NF E 03-004 (France); JIS B 0203 (Japan) | |

| Unified thread (ISO thread) ¼-20UNC-2A; 0.250-20UNC-2A; 10-32UNF-2B; 0.190-32UNF-2B | general mechanical engineering application, common in the USA | — | ISO 725; BS 1580 (England); ANSI/ACME B 1.1 (USA) | |

| Metric thread with MJ profile MJ 6×1 | in the aviation and space industry | — | ISO 5855; DIN ISO 5855 (Germany); BS 6293 (England) | |

| Unified (inch) external thread with standardized root radius UNR, UNRC, UNRF and UNREF | — | — | ANSI B 1.1 (USA) | — |

| Unified (inch) thread with increased root radius UNJ, UNJC, UNJF and UNJEF | used in the aviation and space industries | — | ISO 3161; BS 4084 (England); ANSI B 1.1 (USA) | |

| Unified (inch) thread with special diameters, pitches and make-up lengths UNS | — | — | ANSI B 1.1 (USA) | — |

| Whitworth Straight Thread ¼-20 BSW or BSF, BSP | in gas, water and sewer fittings. | industry standards, for example, OST NKTP 1260 | DIN 49301, DIN 477, DIN 4668 (Germany); BS 84:1956 (England) | |

| Trapezoidal thread 1 ¾-4 ACME-2G | Lead screws in general mechanical engineering | — | BS 1104 (England); ANSI B 1.5 (USA); JS B 0222 (Japan) | |

| Trapezoidal thread with reduced profile height 0.500-20 STUB ACME | Lead screws in general mechanical engineering | — | ANSI B 1.8 (USA) | |

| Thrust thread (metric Buttress) S 48×8 | general mechanical engineering | GOST 10177-82 | DIN 513 (Germany) | |

| Armored pipe thread Pg 21 | used in electrical engineering | — | DIN 40430 | |

| Thrust inch (American Buttress) 2.5-8 BUTT | casing pipes in mining | — | ANSI B 1.9 (USA) | |

| Buttress thread (API Battress) | casing pipes used in the oil and gas industry | — | API spec. 5B (USA) | |

| 60° Inch Pipe Thread K3/8″ 3/8-18 NPT | fittings and connections for machines and machines | GOST 6111-52 | ANSI/ASME B 1.20.1 (USA) | |

| 60° Inch Pipe Thread 1/8-27 NPTF | sealed thread of fuel lines | — | ANSI B 1.20.3 (USA) | — |

| Round thread RD | food industry and fire extinguishing systems | — | DIN 405 (Germany) | |

| Locking thread according to API Z-117 4 ½ Reg | rotating drilling tool (rods, bits, etc.) | GOST 28487-90 | API Specification 7 (USA) | |

| Locking thread API RD 8 TPI | tubing, casing and drill pipes | — | API Specification 5B (USA) | |

Notes:

1. UNC, UNF, UNEF

– threads with appropriate pitch for different diameters:

UNC

– coarse pitch;

UNF

– small step;

UNEF

is a particularly small step;

UN

– threads with one pitch value for different diameters. 2. Threads with a taper of 1:16 are similar in profile to OTTM and OTTG threads (GOST 632-80). Threads are not interchangeable. However, under certain conditions for choosing a tool, it is possible to process external threads in accordance with GOST 632-80. 3. API RD 8 TPI thread (pitch 3.175) is interchangeable with tubing threads according to GOST 631-75, GOST 632-80 and GOST 633-80.

Related documents:

GOST 3469-91 - Microscopes. Lens thread. Dimensions GOST 4608-81 - Metric thread. Interference fits GOST 5359-77 - Ocular threads for optical instruments. Profile and dimensions GOST 6042-83 - Edison round thread. Profiles, dimensions and maximum dimensions GOST 6111-52 - Conical inch thread with a profile angle of 60 degrees GOST 6211-81 - Conical pipe thread GOST 6357-81 - Cylindrical pipe thread GOST 8762-75 - Round thread with a diameter of 40 mm for gas masks and calibers for her. Main dimensions GOST 9000-81 - Metric thread for diameters less than 1 mm. Tolerances GOST 9484-81 - Trapezoidal thread. Profiles GOST 9562-81 - Single-start trapezoidal thread. Tolerances GOST 9909-81 - Tapered thread of valves and cylinders for gases GOST 10177-82 - Persistent thread. Profile and main dimensions GOST 11708-82 - Thread. Terms and definitions GOST 11709-81 - Metric thread for parts made of plastic GOST 13535-87 - Reinforced thrust thread 45 degrees GOST 13536-68 - Round thread for sanitary fittings. Profile, main dimensions, tolerances GOST 16093-2004 - Metric thread. Tolerances. Clearance fits GOST 16967-81 - Metric threads for instrument making. Diameters and pitches GOST 24737-81 - Single-start trapezoidal thread. Main dimensions GOST 24739-81 - Multi-start trapezoidal thread GOST 25096-82 - Persistent thread. Tolerances GOST 25229-82 - Metric conical thread GOST 28487-90 - Conical locking thread for drill string elements. Profile. Dimensions. Tolerances

BSP – British Standard Pipe – British pipe thread

| Options | BSPP | BSPT |

| standard | DIN ISO 228, DIN 259 | ISO 7, BS EN 10226-1 |

| form | cylindrical | conical |

| angle of inclination of the triangle (profile) | 55° | 55° |

| ridges and valleys | rounded | rounded |

| other names | G | R/Rp |

BSP pipe thread is also called Whitworth thread after its creator. Joseph Whitworth suggested sticking to the following parameters:

- profile angle – 55°;

- protrusions and depressions should be round;

- One of the main values is TPI (threads per inch).

BSPP British Straight Pipe Thread Sizes

| Nominal diameter | Diameter, mm | Threads per inch | Drilling diameter, mm | Pitch, mm |

| G 1/16″ | 7,722 | 28 | 6,561 | 0,907 |

| G 1/8″ | 9,728 | 28 | 8,565 | 0,907 |

| G 1/4″ | 13,157 | 19 | 11,445 | 1,337 |

| G 3/8″ | 16,662 | 19 | 14,950 | 1,337 |

| G 1/2″ | 20,955 | 14 | 18,633 | 1,814 |

| G 5/8″ | 22,911 | 14 | 20,587 | 1,814 |

| G 3/4″ | 26,441 | 14 | 24,120 | 1,814 |

| G 7/8″ | 30,201 | 14 | 27,877 | 1,814 |

| G 1″ | 33,249 | 11 | 30,292 | 2,309 |

| G 1 1/8″ | 37,897 | 11 | 34,939 | 2,309 |

| G 1 1/4″ | 41,910 | 11 | 38,953 | 2,309 |

| G 1 3/8″ | 44,323 | 11 | 41,365 | 2,309 |

| G 1 1/2″ | 47,803 | 11 | 44,846 | 2,309 |

| G 1 5/8″ | 52,883 | 11 | 49,926 | 2,309 |

| G 1 3/4″ | 53,746 | 11 | 50,788 | 2,309 |

| G 1 7/8″ | 56,998 | 11 | 54,041 | 2,309 |

| G 2″ | 59,614 | 11 | 56,657 | 2,309 |

| G 2 1/4″ | 65,710 | 11 | 63,392 | 2,309 |

| G 2 1/2″ | 75,184 | 11 | 72,227 | 2,309 |

| G 2 3/4″ | 81,534 | 11 | 79,216 | 2,309 |

| G 3″ | 87,884 | 11 | 84,927 | 2,309 |

| G 3 1/2″ | 100,330 | 11 | 98,012 | 2,309 |

| G 4″ | 113,030 | 11 | 110,073 | 2,309 |

| G 4 1/2″ | 125,730 | 11 | 123,412 | 2,309 |

| G 5″ | 138,430 | 11 | 135,473 | 2,309 |

| G 5 1/2″ | 151,130 | 11 | 148,812 | 2,309 |

| G 6″ | 163,830 | 11 | 160,873 | 2,309 |

To improve the tightness of the joint, BSPP threaded pipes should be installed with a gasket. Some fittings come with rings or other types of seals.

Standard Tapered BSPT Thread Dimensions in mm

| Nominal diameter | Diameter, mm | Threads per inch | Drilling diameter, mm | Pitch, mm |

| R 1/16″ | 7,723 | 28 | 6,561 | 0,907 |

| R 1/8″ | 9,728 | 28 | 8,566 | 0,907 |

| R 1/4″ | 13,157 | 19 | 11,445 | 1,337 |

| R 3/8″ | 16,662 | 19 | 14,950 | 1,337 |

| R 1/2″ | 20,955 | 14 | 18,631 | 1,814 |

| R 3/4″ | 26,441 | 14 | 24,117 | 1,814 |

| R 1″ | 33,249 | 11 | 30,291 | 2,309 |

| R 1 1/4″ | 41,910 | 11 | 38,952 | 2,309 |

| R 1 1/2″ | 47,803 | 11 | 44,845 | 2,309 |

| R 2″ | 59,614 | 11 | 56,656 | 2,309 |

| R 2 1/2″ | 75,184 | 11 | 72,226 | 2,309 |

| R 3″ | 87,884 | 11 | 84,926 | 2,309 |

| R 4″ | 113,030 | 11 | 110,072 | 2,309 |

| R 5″ | 138,430 | 11 | 135,472 | 2,309 |

| R 6″ | 163,830 | 11 | 160,872 | 2,309 |

BSPT tapered threads are self-sealing and are used for connections with increased tightness requirements. BSPT male thread pipes can be used in conjunction with BSPT and BSPP fittings and pipes.

Thread R, pipe tapered

Compatible with BSPT threads

Pipe conical thread used in conical threaded connections, as well as in connections with external conical threads and internal cylindrical threads in accordance with GOST 6357-81. Based on BSW (British Standard Whitworth) threads and compatible with BSPT (British Standard Pipe Tapered Thread).

- GOST 6211-81 - Basic standards of interchangeability. Conical pipe thread.

- ISO R7

- DIN 2999

- BS 21

- JIS B 0203

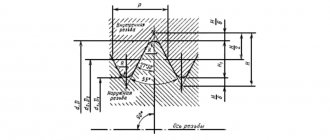

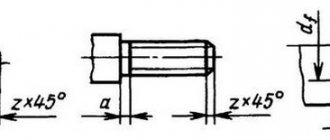

Thread parameters

Inch thread with a taper of 1:16 (taper angle 3°34'48″). The profile angle at the apex is 55°. Symbol: letter R for external threads and Rc for internal threads (GOST 6211-81 - Basic standards of interchangeability. Conical pipe threads), numerical value of the nominal thread diameter in inches (inch), letters LH for left-hand threads. For example, a thread with a nominal diameter of 1 1/4″ is designated as: R 1 1/4″. For more information about threads, thread pitch and other parameters, see Wikipedia.org.

Comparison table of pipe thread types

| Options | NPT | BSPP | BSPT |

| form | conical | cylindrical | conical |

| profile angle | 60° | 55° | 55° |

| thread angle | 1°47’ | 0° | 1°47’ |

In the catalog of the European Metallurgical Company you can buy pipes and fittings with NPT-F, NPT-M, BSP threads made of carbon and stainless steel. To order metal products according to international standards EN, ASTM, ANSI, DIN, ISO, etc., you can leave a request on the website or contact our operators online.

Thread G, cylindrical pipe

Compatible with BSP threads

Pipe cylindrical thread used in cylindrical threaded connections, as well as in connections of internal cylindrical threads with external conical threads in accordance with GOST 6211-81. Based on BSW (British Standard Whitworth) thread and compatible with BSP (British standard pipe thread).

- GOST 6357-81 - Basic standards of interchangeability. Cylindrical pipe thread.

- ISO R228

- EN 10226

- DIN 259

- BS 2779

- JIS B 0202

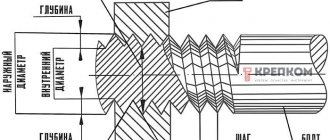

Thread parameters

Inch thread with a profile angle at the tip of 55°. Cuts on pipes up to 6″ size, pipes over 6″ are welded. Symbol according to GOST 6357-81: letter G, numerical value of the nominal diameter of the pipe in inches (inch). For more information about threads, thread pitch and other parameters, see Wikipedia.org.