The argon arc welding process is absolutely not possible without the use of a Tig torch. A device that is simple in its structure plays a key role, hardly inferior in importance to the quality of the current source used. That is why it is recommended to pay maximum attention to the selection of accessories and components. We tried to answer all questions regarding the Tig gas burner, its structure and existing varieties. After carefully studying the information, you can easily select an accessory suitable for solving existing problems.

Air-cooled burners

Article: 072.264.123 Torch TIG TP 26VF (160,200AC/DC) 4m TBW2604-10 Argon-arc torch TIG TP 26VF (160,200AC/DC) with air cooling.

The connection is made through the OKS 35-50 with the gas supply hose removed. Connection via 2 PIN. The first meter of cable is made of leather. Price: RUR 8,101

Article: 072.098.122 TIG torch TP 9F (M12x1) 8m TBW0903-08

Air-cooled argon-arc torch TIG TP 9F (M12x1). The connection is made via a nut with M12×1 thread.

Price: RUB 10,280

Article: 072.094.122 TIG torch TP 9F (M12x1) 4m TBW0903-04

Air-cooled argon-arc torch TIG TP 9F (M12x1). The connection is made via a nut with M12×1 thread.

Price: RUR 5,898

Article: 072.098.120 TIG torch TP 9 (M12x1) 8m TBW0901-08

Air-cooled argon-arc torch TIG TP 9 (M12x1). The connection is made via a nut with M12×1 thread.

Price: RUB 10,291

Article: 072.094.120 TIG torch TP 9 (M12x1) 4m TBW0901-04

Air-cooled argon-arc torch TIG TP 9 (M12x1). The connection is made via a nut with M12×1 thread.

Price: RUB 5,979

Article: 072.098.121 TIG torch TP 9V (M12x1) 8m TBW0902-08

Air-cooled argon-arc torch TIG TP 9V (M12x1). The connection is made via a nut with M12×1 thread.

Price: RUR 7,457

Article: 072.094.121 TIG torch TP 9V (M12x1) 4m TBW0902-04

Air-cooled argon-arc torch TIG TP 9V (M12x1). The connection is made via a nut with M12×1 thread.

Price: RUR 4,601

Article: 072.268.124 TIG torch TP 26VF (160,200AC/DC) 8m TBW2608-11

Argon-arc torch TIG TP 26VF (160,200AC/DC) with air cooling. The connection is made through the OKS 35-50 with the gas supply hose removed. Connection via 2 PIN. The first meter of cable is made of leather.

Price: RUB 12,105

Article: 072.174.121 TIG torch TP 17V (M12×1) 4m TBW1704-04

Valve torch for argon arc welding TIG TP 17V (M12×1) with air cooling. It is possible to connect to MMA welding machines with the LIFT TIG function via OKS 16-25 or OKS 35-50.

Price: RUR 5,176

Article: 072.178.120 TIG torch TP 17F (M12×1) 8m TBW1708-03

Air-cooled argon-arc torch TIG TP 17F (M12×1). The connection is made via a nut with M12×1 thread. Connection via 2 PIN. Flexible torch head (FLEX). The first meter of cable is made of leather.

Price: RUB 10,494

Article: 072.174.122 TIG torch TP 17F (M12×1) 4m TBW1704-02

Air-cooled argon-arc torch TIG TP 17F (M12×1). The connection is made via a nut with M12×1 thread. Connection via 6 PIN is possible. Flexible torch head (FLEX). The first meter of cable is made of leather.

Price: RUR 6,519

Article: 072.174.120 TIG torch TP 17 (M12×1) 4m TBW1704-01

Argon-arc torch TIG TP 17 (M12×1) with air cooling. The connection is made via a M12×1 threaded nut and a 2 PIN connector. The first meter of cable is made of leather.

Price: RUR 6,448

Article: 072.268.122 TIG torch TP 26F (M12×1) 8m TBW2608-10

Argon-arc torch TIG TP 26F (M12×1) with air cooling. The connection is made via a nut with M12×1 thread. Connection via 6 PIN is possible. Flexible torch head (FLEX). The first meter of cable is made of leather.

Price: RUR 13,962

Article: 072.264.122 TIG torch TP 26F (M12×1) 4m TBW2604-09

Argon-arc torch TIG TP 26F (M12×1) with air cooling. The connection is made via a nut with M12×1 thread. Connection via 6 PIN is possible. Flexible torch head (FLEX). The first meter of cable is made of leather.

Price: RUR 8,490

Article: 072.268.121 TIG torch TP 26V (M12×1) 8m TBW2608-08

Valve torch for argon arc welding TIG TP 26V (M12×1) with air cooling. It is possible to connect to MMA welding machines with the LIFT TIG function via OKS 16-25 or OKS 35-50.

Price: RUB 11,493

Article: 072.264.121 TIG torch TP 26V (M12×1) 4m TBW2604-07

Valve torch for argon arc welding TIG TP 26V (M12×1) with air cooling. It is possible to connect to MMA welding machines with the LIFT TIG function via OKS 16-25 or OKS 35-50.

Price: RUR 6,903

Article: 072.268.160 TIG torch TP 26 (M16x1.5; 2pin) 8m TBW2608-06

Argon-arc torch TIG TP 26 (M16x1.5; 2pin) air-cooled. The connection is made through a nut with M16x1.5 thread. Connection via 2 PIN. The first meter of cable is made of leather.

Price: RUB 14,104

Article: 072.264.160 TIG torch TP 26 (M16x1.5; 2pin) 4m TBW2604-05

Argon-arc torch TIG TP 26 (M16x1.5; 2pin) air-cooled. The connection is made through a nut with M16x1.5 thread. Connection via 2 PIN. The first meter of cable is made of leather.

Price: RUR 8,150

Article: 072.268.100 TIG torch TP 26 (160,200AC/DC) 8m TBW2608-04

Argon-arc torch TIG TP 26 (160,200AC/DC) with air cooling. The connection is made through the OKS 35-50 with the gas supply hose removed. Connection via 2 PIN. The first meter of cable is made of leather.

Price: RUB 13,701

Article: 072.264.100 TIG torch TP 26 (160,200AC/DC) 4m TBW2604-03

Argon-arc torch TIG TP 26 (160,200AC/DC) with air cooling. The connection is made through the OKS 35-50 with the gas supply hose removed. Connection via 2 PIN. The first meter of cable is made of leather.

Price: RUR 8,668

Article: 072.268.120 TIG torch TP 26 (M12x1) 8m TBW2608-02

Argon-arc torch TIG TP 26 (M12x1) with air cooling. The connection is made via a nut with M12x1 thread. Connection via 2 PIN. The first meter of cable is made of leather.

Price: RUB 13,702

Article: 072.264.120 TIG torch TP 26 (M12×1) 4m TBW2604-01

Argon-arc torch TIG TP 26 (M12×1) with air cooling. The connection is made via a nut with M12×1 thread. Connection via 2 PIN. The first meter of cable is made of leather.

Price: RUR 8,350

Water-cooled torches are presented in the series: TIG TP 18, TIG TP 20 and TIG TP 25. Torch cable length: 4 and 8 meters.

general information

A torch for welding using argon must be of high quality and reliable, since it will have to work at elevated temperatures. It should also have a low mass for high current loads. It is desirable that the burner head rotates 180 degrees. This way it can be directed in the desired direction, protecting the handle from thermal overheating.

Torches for argon welding are distinguished by the fact that they are designed for welding using non-consumable rods in a shielding gas environment. This torch can be used when working with titanium, steels, nickel alloys, copper and aluminum.

Water-cooled burners

Article: 072.258.120 TIG torch TP 25 (M12x1, 1/4G, 3/8G, 2PIN) 8m TBW2501-08

Argon-arc torch TIG TP 25 (M12x1, 1/4G, 3/8G, 2PIN) with water cooling. The connection is made via a nut with M12×1 thread. Connection via 2 PIN. Two hoses for water cooling.

Price: RUB 11,328

Article: 072.254.120 TIG torch TP 25 (M12x1, 1/4G, 3/8G, 2PIN) 4m TBW2501-04

Argon-arc torch TIG TP 25 (M12x1, 1/4G, 3/8G, 2PIN) with water cooling. The connection is made via a nut with M12×1 thread. Connection via 2 PIN. Two hoses for water cooling.

Price: RUB 9,505

Article: 072.208.100 TIG torch TP 20 (OKS 35-50, w/r, 2PIN) 8m TBW2002-08

Argon-arc torch TIG TP 20 (OKS 35-50, non-ferrous, 2PIN) with water cooling. The connection is made through OKS 35-50. Connection via 2 PIN. Two hoses for water cooling.

Price: 12,400 rub.

Article: 072.204.100 TIG torch TP 20 (OKS 35-50, w/r, 2PIN) 4m TBW2002-04

Argon-arc torch TIG TP 20 (OKS 35-50, non-ferrous, 2PIN) with water cooling. The connection is made through OKS 35-50. Connection via 2 PIN. Two hoses for water cooling.

Price: RUR 8,278

Article: 072.208.120 TIG torch TP 20 (M12x1, 1/4G, 3/8G, 2PIN) 8m TBW2001-08

Argon arc torch TIG TP 20 (M12x1, 1/4G, 3/8G, 2PIN) with water cooling. The connection is made via M12x1. Connection via 2 PIN. Two hoses for water cooling.

Price: RUB 11,379

Article: 072.204.120 TIG torch TP 20 (M12x1, 1/4G, 3/8G, 2PIN) 4m TBW2001-04

Argon arc torch TIG TP 20 (M12x1, 1/4G, 3/8G, 2PIN) with water cooling. The connection is made via M12x1. Connection via 2 PIN. Two hoses for water cooling.

Price: RUR 7,565

Article: 072.188.100 TIG torch TP 18 (250,315AC/DC) 8m water cooling TBW1808-02

Argon-arc torch TIG TP 18 (250,315AC/DC) with water cooling. The connection is made through the OKS 35-50 with the gas supply hose removed. Connection via 2 PIN. Two hoses for water cooling. The first meter of cable is made of leather.

Price: RUB 14,079

Article: 072.184.100 TIG torch TP 18 (250,315AC/DC) 4m water cooling TBW1804-01

Argon-arc torch TIG TP 18 (250,315AC/DC) with water cooling. The connection is made through the OKS 35-50 with the gas supply hose removed. Connection via 2 PIN. Two hoses for water cooling. The first meter of cable is made of leather.

Price: RUR 8,805

Accessories for argon welding torch

The design of any tig burner is quite simple. To work with accessories of this type, it is necessary to equip them with a number of accessories that ensure the fixation of the tungsten electrode, as well as the correct supply of gas to the welding site. These accessories include:

- Classic ceramic nozzle or nozzle with gas lens. In the second option, gas flows through the grate. This flow provides a higher level of protection.

- Collet holder.

- Collet.

- Cap. Can be elongated, long or short.

The dimensions of the first three accessories are selected based on the diameter of the tungsten electrode used. It is extremely important that the accessories fit well with the consumables, otherwise the result of the work performed will not please you.

Today, ordering a torch for TIG welding is not at all a problem. A large assortment of accessories is already waiting for you in the catalog of our online store. We offer burners and accessories for them at excellent prices and with fast delivery. You can also order any consumables of excellent quality from us. Call us, we will be happy to help!

Adapters

Article: 072.700.002 Adapter M12x1–M16x1.5 DAB1216

The adapter M12x1–M16x1.5 is designed for transition from one thread to another. Used to connect TIG argon arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

Article: 072.700.001 Adapter M12x1–3/8 DAB1238

The M12x1–3/8 adapter is designed to change from one thread to another. Used to connect TIG argon arc torches to welding machines. The adapter is made of brass.

Price: 1,007 rub.

Article: 070.100.052 Adapter M14x1–M12x1 DAB1412

The adapter M14x1–M12x1 is designed for transition from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,014

Article: 070.100.114 Adapter M14x1–1/4 DAB1414-1

The M14x1–1/4 adapter is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: 1,024 rub.

Article: 070.100.043 Adapter M12x1–M10x1 DAB1210-1

The adapter M12x1–M10x1 is designed for transition from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: 983 RUR

Article: 070.100.042 Adapter M12x1–M10x1 (internal) DAB1210

The adapter M12x1–M10x1 (internal) is designed for transition from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: 922 RUR

Article: 070.100.041 Adapter M12x1-1/4 DAB1214

The M12x1–1/4 adapter is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

Article: 070.100.032 Adapter 3/8–M12x1 DAB3812

The adapter 3/8–M12x1 is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

Article: 070.100.031 Adapter 3/8G–OKS (water) DAB3800

Adapter 3/8G–OKS (water) is intended for transition from one thread to another. Used to connect water-cooled TIG arc torches to welding machines. The adapter is made of brass.

Price: RUR 1,047

Article: 070.100.022 Adapter 3/8–1/8 DAB3818

The 3/8–1/8 adapter is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

Article: 070.100.021 Adapter 3/8–1/4 DAB3814

The 3/8–1/4 adapter is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

Article: 070.100.012 Adapter 1/8–M12x1 DAB1812

The 1/8–M12x1 adapter is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

Article: 070.100.011 Adapter 1/8–3/8 DAB1838

The 1/8–3/8 adapter is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

Article: 070.100.002 Adapter 1/4–M14x1 DAB1414

The 1/4–M14x1 adapter is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

Article: 070.100.001 Adapter 1/4–3/8 DAB1438

The 1/4–3/8 adapter is designed to change from one thread to another. Used to connect TIG hot-arc torches to welding machines. The adapter is made of brass.

Price: RUB 1,018

To connect valve torches to manual arc welding (MMA) machines, you can use OKS cable lugs with quick release.

Welding power sources

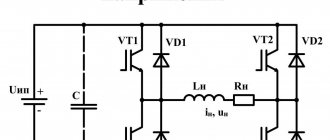

Figure 2. Installation diagram for argon arc welding.

Conventional welding machines with alternating or direct voltage output can be used as a source of welding current. To weld aluminum parts, you must use alternating current. In all other cases, direct current with straight polarity is preferable. You can also use inverter welding machines and other modern devices that provide the necessary power. Trade organizations offer a large range of complete kits and various devices for welding in a protective environment from various manufacturers. Burners are available for sale with a current regulator and a display showing its value. But the cost of such devices can only be covered by a serious enterprise with a stable volume of work. For a home workshop and small and periodic work, it is much cheaper to make a set of equipment yourself, upgrading and expanding it over time.

OKS cable lugs with quick release

Article: 072.700.202 Cable lug OKS 35-50 with quick release (TIG TP) PVS3550

Adapter for connecting a TIG torch to argon-arc metal welding machines. Suitable for KG cable with a cross-section of 35 or 50 mm. Connects to a 35-50 panel socket.

Price: RUB 1,286

Article: 072.700.201 Cable lug OKS 16-25 with quick release (TIG TP) PVS1625

Adapter for connecting a TIG torch to argon-arc metal welding machines. Suitable for KG cable with a cross-section of 16 or 25 mm. Connects to a 16-25 panel socket.

Price: 717 RUR

Setting up a tig machine from A to Z

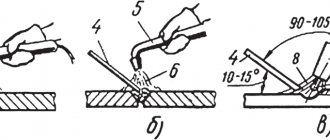

Almost all metals are welded with straight polarity (minus on the electrode). The only exception is welding of aluminum and its alloys. A striking example of an alloy can be copper alloys with a significant aluminum content. The use of alternating current is mandatory for them.

So, let's set up FUBAG INTIG 200 DC Pulse:

- On the control panel we set the welding method - TIG.

- Set the gas pre-purge to 0.5 seconds.

- We set the ignition current - 25% of the operating current (A).

- We fix the rise time to the operating current - 0.2-1.0 seconds.

- Set the welding current (A) (see table below)

- We set the time until the crater filling current (decay in seconds)

- Select the value of the crater filling current in amperes

- The last parameter will be the gas purging time after welding (sec)

The parameters that relate to crater welding are selected depending on the thickness of the metal.

This table provides general recommendations for selecting welding current for the most commonly used metals and thicknesses. This will help you get your bearings as you prepare to get started.

Table. Setting up an argon arc apparatus depending on the type of metal and thickness

| Type of metal | Metal thickness, mm | Type of current | Current ¸A |

| Steel alloys | 1,0 | DC | 20 — 30 |

| 1,5 | DC | 40 — 60 | |

| 2,0 | DC | 70 -90 | |

| 3,0 | DC | 100 — 120 | |

| 4, 0 | DC | 120 — 140 | |

| Aluminum | 1-2 | A.C. | 20 — 60 |

| 4-6 | A.C. | 120-180 | |

| 6-10 | A.C. | 220-230 | |

| 11-15 | A.C. | 280-360 |

Why is monitoring current strength more important than other parameters? During TIG welding, you can burn through the workpiece by setting too high a current. A low value will not allow the metal to melt, which will negate all attempts to weld the part.

Air or water cooled burner?

It all depends on the maximum currents at which you are going to work. If you plan to weld thick metals or make long welds without tearing, then we recommend that you choose a 26 series torch . If you need a torch for short-term work at low currents, look at the 17 series torch.

If you have serious production and you need to work without interruption, no matter what currents, low or high, the 18 series water-cooled torch We strongly recommend that you do not use this burner without a water connection. It's the water cooling that makes it special. The cross-section of the power cable is cooled by water, and not by air from the environment, which is what allows the burner to operate for a long time without interruptions for cooling.

What is a tig welding torch and why is it needed?

Today, argon arc welding is quite popular.

It is used everywhere, because with the help of this technology you can easily join workpieces from almost any metal, including “problematic” aluminum. It is noteworthy that the resulting seams practically do not require additional processing, there is no slag or scale on them, and this greatly simplifies the life of a specialist. During the work, welders use not only filler rods, but also special tungsten electrodes, which are practically not straightened. It is for their fixation that an argon arc torch is needed. It is highly recommended that it be relatively lightweight, have a swivel head, and withstand the load level stated by the manufacturers.

Criteria for selecting welding equipment

If the goal of your choice is a high-quality torch for argon welding, then you need to pay attention to convenience and ease of operation. The work must be safe and the welding flame must be stable.

You also need to pay attention to cooling. Air cooling is sufficient for low power welding since much of the heat remains in the air.

And the protective gas supplied through the body cools the handle and tip. This cooling method is very convenient and does not require large expenses. In addition, no additional cooling source is required.

Liquid cooled welding requires higher power. This requires the use of an additional cooling unit. You need to know that pure water cannot be used as a cooling liquid, as it can freeze very quickly.