The sandblasting machine is used for processing, cleaning from dirt and polishing products made of metal, wood, and concrete. The design of this device is not complicated, but it necessarily includes several main components.

A sandblasting nozzle is a hollow, threaded tube designed to deliver an abrasive mixture to a contaminated surface. If you wish, you can make a nozzle with your own hands, although the highest quality nozzles can only be purchased ready-made.

Design and characteristics

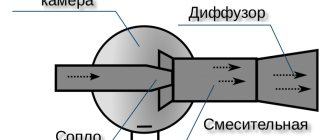

The purpose of the nozzle is to increase the speed of air flow with sand and form a treatment spot. The straight nozzle has the main elements:

- frame;

- thread for fastening to the nozzle holder;

- confuser;

- diffuser.

The housing protects a person from injury in the event of destruction of the internal nozzle. It is quickly erased by abrasive particles passing through it. At the same time, on the back of it there is a thread for a union nut or clamp, with which it is attached to the handle - the nozzle holder.

The confuser is a long conical hole in the insert that regulates the speed of the supplied mixture. Has standard holes with a diameter of 6–16 mm, with a pitch of 2 mm. The choice depends on the performance of the installation.

The diffuser is conical, short, expands at an angle of 7–15⁰. Thanks to it, turbulence is eliminated and the sand is evenly distributed over the working spot. The outlet of the nozzle can be round or oblong, depending on the size of the workpiece and its shape.

Between the confuser and the diffuser there is a section with a uniform cross-section. Having passed along the tapering cone of the nozzle, air and sand form a mixture of uniform composition.

Venturi nozzle

The complex design of the high-performance Venturi nozzle has an internal diameter with a stepped variable cross-section, consisting of a number of cylinders. The diameter of the inlet hole is almost 2 times larger than the outlet hole. This changes the nozzle parameters and increases the flow rate when operating in one mode. For example, an air-sand mixture comes out of a classic nozzle at approximately 320–350 km/h. When installing a Benturi nozzle, the speed of the outflow flow increases to 700 km/h.

The nozzle has a complex design. In addition to the standard elements, the tip is protected by a shockproof rubber shell. There is an aluminum bushing underneath for strength. Insert made of durable and abrasion-resistant tungsten carbide alloy.

It is impossible to make a Venturi design nozzle yourself. Inside it, the cross section changes stepwise. Each transition has a protrusion. Its integrity depends on a correctly selected radius, which is calculated depending on the difference in the diameters of the transition. Rounding is performed with an accuracy of 0.005 mm. Benturi type nozzles are manufactured using modern technologies on computer-controlled equipment.

Working with sandblasting with a Venturi nozzle

This is interesting: Rolling machine: types, making it yourself

Operating principles

The sandblasting nozzle is attached to a holder - the end of the hose, with a union nut or clamp. The air flow, passing through the container with sand, captures it and delivers it through the hose to the nozzle. Passing through the nozzle, the mixture is evened out in its composition and increases speed. Coming out of the diffuser, sand particles hit the surface of the part at high speed, knocking out particles of dirt and old finishes.

When installing Chinese nozzles, you need to pay attention to the diameter and method of attachment. They mostly have clamps on them. They are mainly suitable for equipment manufactured in the Middle Kingdom. On devices from other manufacturers, the nozzle is installed through an adapter.

The homemade device is short-lived. It can be used at pressures less than 6 atm. Ceramic inserts are made from candles by drilling out the electrode. Cast iron and steel are drilled. The surface of the hole is rough, sand slows down and at the same time wears out quickly.

In sandblasting equipment, in addition to sand, other abrasive elements are used: crushed glass, metal balls, ceramics.

A nozzle you make yourself will not last long. It will help out when repairing your own car or restoring furniture.

Advantages and disadvantages

Sandblasting equipment allows you to quickly clean the surface of various contaminants and outdated finishes:

- dirt;

- oil;

- scale;

- fat;

- dye;

- primer;

- putty.

It takes several times less time to prepare a part for further processing and painting than using detergents and solvents.

Sand is easy to obtain. If used continuously, it can be used several times. It must be sifted and calcined.

The air flow with sand and other abrasives penetrates narrow cracks and small holes. The cleaning speed does not depend on the complexity of the design.

Sandblasting machines have a simple design. It is enough to connect the compressor and a container with sand with hoses.

Disadvantages include operating equipment under high pressure. If a hose ruptures or enters the work area, a person may be seriously injured.

The attachments wear out quickly. A metal nozzle made of abrasion-resistant steel is enough for 1 – 2 hours of operation.

How to choose for a pistol?

When choosing, you need to understand that the cheapest parts are the most short-lived. As a result, replacing such nozzles will cost more than buying a high-quality one right away. This is especially true in cases where large volumes need to be processed.

Channel type

The simplest design is a nozzle, which has a cylindrical hole with the same diameter along its entire length. To improve aerodynamic characteristics, these elements are often made of 2 conical sections:

- Input confuser. It increases the flow force of the incoming sand-air mixture.

- Output diffuser. Thanks to it, the surface area being processed increases. At the same time, the flow energy decreases.

The most efficient nozzles are those with a Venturi profile. The hole in them has 3 connected sections with different geometries. Each of them has its own functions:

- At the inlet there is a confuser expansion with an angle of up to 20 degrees (this is less than that of a conventional nozzle).

- Cylindrical part. The length is about 15%.

- Diffuser part with an angle of up to 15 degrees. The length depends on the size of the nozzle itself.

To reduce resistance, the transitions between individual parts are made with radius rounding.

There are also other types:

- Double Venturi. Adds atmospheric air to the flow. The inlet often has a larger cross-section than a standard Venturi. Double allows you to increase the area of the treated surface. This nozzle is used on large planes.

- Venturi channel with wide outlet. The jet imprint at maximum force is wider than that of a simple Venturi. But such nozzles are rarely used.

- Venturi with square section. Such nozzles are the most productive, but they are rarely used, as they are quite expensive due to the complexity of manufacturing.

Material of internal wear-resistant insert

For household purposes, nozzles made of ceramic or cast iron are suitable. But it should be understood that they wear out quickly, which increases the consumption of abrasive material. It is not recommended to use such elements for large jobs. Tungsten carbide and boron carbide nozzles have a very long service life. They can also be used with almost any abrasive. The exception is aluminum oxide and carborundum.

Containment design and build quality

The shell is required to secure the wear sleeve. It is this that protects the nozzle from impacts. Shells come in the following types:

- Polyurethane. Lightweight and resistant to abrasives, but due to insufficient rigidity it wears out quickly.

- Metal. Typically made of steel or aluminum. Reliably secures the bushing, but it has low resistance to abrasive materials.

- Combined. Polyurethane and aluminum are used. This is the most durable shell.

Build quality is also important. There are nozzles where the threaded part is pressed into the body. They often spoil quickly. If you create a pressure of 8 bar, then such a part may even cause injury or damage to the device. It is necessary that the nozzle be machined from a solid piece.

Peculiarities

A sandblasting machine is a long-time and successfully used device that is used to clean surfaces from dirt. Its main purpose is to create a powerful supply of abrasive mixture. The simplest nozzle holder can be made with your own hands at home, but modern designs not only form a torch (a directed jet of air and sand), but also prepare it, use it economically, and impart the characteristics necessary for a specific surface.

Such devices can be used in a variety of situations - from cleaning the walls of houses to removing rust from a metal surface, and even for engraving on a glass surface. Hence the variety of models, simple, but made in different sizes. The need to work with a certain material and create the proper pressure dictates the requirements for the dimensions of the apparatus and its components. One of them is a sandblasting nozzle.

The importance of this detail is difficult to overestimate, since it is it that increases the flow rate of the mixture from the unit and forms a torch . It is selected according to its intended purpose and performance characteristics, as well as the nozzle holder, which is sometimes considered by craftsmen to be part of the functional bell.

Despite the similarity of the design (consists of a body, threads for reliable fastening, confuser and diffuser), it is divided into different types according to:

- the material of the case (its strength and service life depend on this) and the method of fixation to the handle - a nut or clamp;

- the diameter of the holes in the confuser (selected according to the sandblasting performance indicator);

- diffuser expansion angle;

- the shape of the outlet (round or oval, determined by the shape and size of the object being cleaned).

Standing apart from the simple lineup is the Venturi nozzle . It cannot be done at home, since this will not allow for a stepwise change in the cross-section.

An important difference that deserves close attention when choosing is the material of manufacture. Knowing some features, you can choose a nozzle that is suitable for achieving your goal and will last a longer time.

Design features of a nozzle for a sandblasting machine

The main parameters of the nozzle installed on the sandblasting machine are:

- diameter and type of hole;

- length;

- manufacturing material.

Abrasive blasting nozzles of various configurations

The diameter of the hole in the nozzle, which is fixed on the sandblasting machine using a special nozzle holder, is selected depending on the performance the device should have. The performance of any sandblasting machine - both serial and home-made - depends on the power of the jet or the volume of air that the nozzle is able to pass per unit time.

The power of the jet generated by the nozzle is directly proportional to the volume of air that passes through it per unit time. Accordingly, in order to increase the power of the sandblasting machine, it is necessary to make a hole of a larger diameter in its nozzle. For example, you can estimate the power of nozzles whose holes have different diameters. If a nozzle whose diameter corresponds to 6 mm (1/4 inch) has a power equal to 100%, then products with holes of larger diameters will differ in the following value of this parameter:

- 8 mm (5/16 inch) – 157%;

- 9.5 mm (3/8 inch) – 220%;

- 11 mm (7/16 inch) – 320%;

- 12.5 mm (1/2 inch) – 400%.

To better understand the power of a nozzle with a particular internal hole diameter, you can take into account that products with a diameter of 6 mm (1/4 inch) are capable of providing an average jet power of 30 m3/hour.

The table allows you to roughly estimate the effect of nozzle diameter and air pressure on productivity and abrasive consumption

If you are not going to make a nozzle for a sandblasting machine with your own hands, then you should keep in mind that mass-produced products have standard hole diameters of 6, 8, 10 and 12 mm.

The choice of a nozzle parameter such as its length is influenced by the degree of contamination of the surface being cleaned. For sandblasting surfaces that have minor contamination, shorter nozzles (7–8 cm) are selected. If it is necessary to treat a surface on which there are complex contaminants, the length of the nozzle must be significant (up to 23 cm). Shorter nozzles, installed in a standard nozzle holder, are also used in cases where hard-to-reach areas need to be treated.

Nozzles, the diameter of which does not change along their entire length, make it possible to ensure an exit speed of the abrasive material of 320 km/h, while the pressure of the mixture of air and abrasive coming from such a nozzle is 6 atm. Nozzles with a Venturi channel form a jet of an abrasive mixture, the speed of which can reach up to 720 km/h. It is clear that nozzles with internal holes of this type increase the efficiency of sandblasting.

It is obvious that the flow area of the VENTURI type nozzle is significantly larger than that of a conventional straight line

The use of nozzles with Venturi-type internal holes allows enterprises and specialized companies not only to increase their productivity, but also to significantly improve the quality of the processing performed. What is important is that the use of products with such channels does not require the purchase of special abrasives and does not lead to an increase in compressed air consumption.

If nozzles with holes of the usual type for sandblasting machines can be made with your own hands (although this is difficult), then it is almost impossible to make products with a Venturi channel at home without special equipment.

Design of a sandblasting nozzle with a Venturi channel: d - internal diameter; D—inlet diameter; T - connecting thread; L—nozzle length

To make nozzles, including with your own hands, various materials can be used, the choice of which determines the durability of the product. Thus, depending on the material used, nozzles for sandblasting machines have the following durability:

- ceramic products that are made at home from ordinary spark plugs - 1–2 hours;

- cast iron nozzles – 6–8 hours;

- products for the production of which tungsten carbide was used – 300 hours;

- nozzles made of boron carbide - 750–1000 hours.

If steel shot, rather than sand, is used as an abrasive material in a sandblasting machine, then the durability of any type of nozzle increases by 2–2.5 times.

Manufacturers

Experts recommend nozzles from the following companies:

- Contracor - Russia;

- CLEMCO - Germany;

- VMZ - Velikoluksky Mechanical Plant.

German products are known for their reliable performance and long service life. Nozzles from CLEMCO are considered the best. The company produces mainly ceramic and tungsten carbide inserts.

Sandblasting nozzles from the Russian company Contracor are not inferior to them in quality. The main products are boron carbide, tungsten and ceramic inserts are available.

VSW produces conventional nozzles at a budget price. Hobbyists can purchase a variety of attachments - metal, ceramic and cast iron for one-time repairs.

The essence of sandblasting

Sandblasting involves exposing various surfaces to an abrasive material. Sand, shot, silicon carbide, small glass beads, etc. are used as the latter.

Sandblasting is a mechanical action on the surface of small solid particles

Before processing begins, the abrasive is placed in a sealed hopper. Air coming from a separate compressor is supplied through the main hose of the device under high pressure. Passing by the opening of the intake hose, the air flow creates a vacuum in it, which facilitates the suction of abrasive into the main hose. The air, already mixed with abrasive, is supplied to the gun, the main element of which is a sandblasting nozzle, through which the abrasive mixture is supplied to the surface being treated.

Layout of the sandblasting area

As mentioned above, various types of abrasives can be used to perform sandblasting. The choice here depends on the type of surface that needs to be cleaned. Thus, treatment using sand is effective in cases where it is necessary to remove a layer of old paint from a concrete surface, clean brick walls from cement residues, and prepare metal parts for further painting. Abrasives such as plastic or wheat starch are successfully used in the shipbuilding, automotive and aircraft manufacturing industries, with their help they effectively remove old coatings from composite materials.

This is interesting: Check valve for water: principle of operation, design and varieties

Choosing the right nozzle: compressor installation parameters

An important factor for obtaining high productivity of the cleaning process is the accurate selection of the required nozzle diameter for the compressor used.

For this, the following parameters are defined:

- pressure of the compressor used (bar);

- total capacity of the compressor unit (m3/min).

Quite often, technical indicators cannot be achieved due to wear of the internal screw pair of the compressor equipment used. According to the parameters, the compressor should provide approximately 50% more of a certain volume of air flow than required by the new nozzle being used.

Thanks to the existing performance reserve, the high efficiency of the cleaning performed is maintained in the event of partial wear of the installed nozzle. To prevent this phenomenon, the element is replaced when the diameter increases by approximately 30%, despite the sufficient thickness of the walls of the stakes.

For example, an increase in the diameter of the working nozzle from 8 to 11 mm has a significant impact on the performance of the cleaning performed. In this case, the inlet neck of the structure must be the same as the inner diameter of the hose through which the abrasive and air flow are supplied. If the combination of parameters is incorrect, wear points appear, pressure drops and severe turbulence occurs inside.

Overview of species

Types of functional devices can be divided into:

- pressure (designed for a large area that needs to be treated);

- injection (ideal for non-industrial work).

In turn, injection systems are divided into:

- suction;

- vacuum (the abrasive does not remain on the surface, but is sucked back by the vacuum);

- pneumatic – optimal for carrying out work over a large area.

The nozzle for a sandblasting machine can be:

- different diameters (both outlet and in the holes on the nozzle);

- round or oval cross-section;

- made of different materials - ceramic, steel and cast iron, boron carbide, fluorine (up to 1 thousand hours of operation) or tungsten.

In the description, you should definitely look at the performance of the compressor (this is one of the factors in the correct selection of the tip).

The Venturi nozzle stands separately, it has a complex design and is not cheap, but if the direct-flow nozzle gives an abrasive flow rate of no more than 340 km, it provides an indicator almost twice as high. When creating it, the principle of the Laval nozzle was taken into account, which in many cases determines the optimization of operation and regulation of the direction of the emitted jet.

How to do it yourself?

Craftsmen with imagination and skillful hands often make sandblasting attachments on their own, and this has an undoubted practical meaning. Buying a nozzle for a small rusty spot on a car or making it yourself from scrap materials - the only difference is wasting money or time. There are many videos on special websites in which home-grown craftsmen proudly demonstrate a homemade simple device made of steel or cast iron, a car spark plug. They use gas cylinders as a receiver and show improved models of a ready-made pistol, which is somehow unsatisfactory to use.

Let's look at how you can make sandblasting attachments yourself.

For production you will need:

- an ordinary plastic bottle, the volume of which is no more than 1 liter;

- a gun for blowing and another for inflating tires;

- the camera will need a valve.

The manufacturing process is shown in the video.

If you have a drawing, you can even assemble a sandblasting machine by purchasing its components separately in specialized stores. However, specialists in such work are confident that purchased products have higher functionality and performance . And if we are talking about a large volume of work, it is better to purchase a factory nozzle with good characteristics - shock resistance and long service life.

Accessories for a homemade sandblasting installation

To assemble a sandblasting machine with your own hands, as mentioned above, you need to prepare all the components of such a device. Some of them can be found in your garage or home workshop, and some can be purchased at any construction market. One of the important elements of a sandblasting installation is the container from which the abrasive will be supplied to the system. To make such a container, an old gas cylinder is suitable, which is made of high-quality metal and can withstand even significant mechanical loads (from a gas cylinder, by the way, you can also make a receiver for a compressor, if the latter is not equipped with one).

You can use a lid from an old fire extinguisher for the filling hole.

In order to fill a container for abrasive material, it is necessary to weld a piece of pipe to a metal container, in the upper part of which, for ease of filling, a special neck is fixed, used as a funnel. When making a sandblasting machine on your own, special attention should be paid to the choice of compressor. High-quality and reliable compressor units, which can be suitable for completing such a device, are quite expensive, so if you want to save money on their purchase, you can make a compressor yourself, using inexpensive components. In particular, to manufacture a mini-compressor, the power of which will be quite sufficient for sandblasting at home, you can use ready-made compressor heads from the pneumatic brake drive of ZIL (130-157) and MAZ cars. Such heads must be equipped with a receiver (it can be made from an old gas cylinder), a drive electric motor, and a frame on which all structural elements will be attached.

Homemade compressor based on the brake compressor from the ZIL-130 car

To equip a homemade sandblasting unit, the assembly process of which is well demonstrated by numerous videos on the Internet, you will also need: ✔ ball valves, which should be highly reliable and durable (which is why it is better to choose such products from trusted manufacturers); ✔ reinforced rubber hose (at least 14 mm in diameter), capable of withstanding high pressure and constant exposure to abrasive material; ✔ a gas hose through which compressed air will be supplied, not yet mixed with abrasive material (the diameter of such a hose must be at least 10 mm); ✔ fittings, which will be used to connect hoses to system elements, as well as collet-type clamps; ✔ FUM tape, which is needed to ensure the tightness of the connection of all structural elements of a homemade sandblasting installation operating under high pressure.

A complete set of parts for assembling the system: from squeegees to the dehumidifier

How to make a budget sandblasting nozzle with your own hands

If the sandblasting nozzle has become unusable, you can make a replacement yourself. True, the continuous service life of such a product will be short, but the cost of consumables will not hit the budget. The base for the nozzle can be a ceramic spark plug or an old ceramic resistor with an internal diameter of 2–4 mm.

The procedure for working with a resistor is as follows:

- Tear off the caps and legs with pliers or saw off with a grinder.

- take an M14 metal bolt, cut off the top, drill a through hole with a No. 5 drill.

- deepen the hole with a No. 8 drill approximately 1.4 cm.

- Weld a wide M5 washer onto the M14 clamping nut on top, and use a No. 8 drill to make a cone from the inside, pressing the future nozzle.

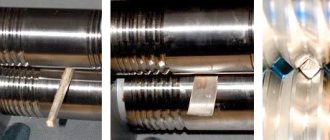

To create a nozzle from a spark plug, you need to proceed as follows:

- Using pliers, pull the contact rod out of the spark plug, after heating it with a gas burner.

- grind off the rolled edge of the spark plug body on a machine.

- knock out the ceramic insulator.

- Use a sharpener to cut the edges of the nut and remove it.

- Use a diamond wheel to cut off part of the ceramic insulator where the central electrode is located.

- attach an adapter with a clamping nut purchased or pre-machined from a bolt to the rod.

There are a variety of sandblasting nozzles on sale, and the service life and performance of the most modern products will be many times higher than that of homemade ones. If you regularly use sandblasting, it makes sense to purchase a high-quality ready-made part, but for a one-time job, if you have the necessary equipment and skills, you can make the nozzle yourself.