11/18/2021 Author: VT-METALL

From this material you will learn:

- Pros and cons of fusion welding

- 7 types of fusion welding

- 2 types of electrodes for fusion welding

- Fusion welding technology

- Fusion Welding Standards and Requirements

- Evaluation of the finished product

- 6 Common Fusion Welding Mistakes

Fusion welding has become widespread due to its ease of execution and high degree of reliability. This method is used both in the manufacture of household appliances and in the creation of space technology. The technology is so accessible that it is also used at home.

There are several methods of fusion welding, the choice depends on the task at hand. Read more about what stages this technology consists of and how the quality of execution is controlled in our material.

Pros and cons of fusion welding

What is fusion welding of metals? This is the process of connecting the components of a structure, during which melting of mating surfaces that are not compressed occurs. The power characteristics of the energy source used must ensure the process of melting the filler material and the edges of the parts.

You can ignite a high-temperature arc by performing three steps in sequence. First, you need to touch the workpiece with an electrode, which will cause a short circuit, leading to heating of its tip. After this, the electrode should be slightly removed from the part, but the stability of the arc should not decrease. This distance is determined empirically. Warming up the electrode tip is necessary for the stability of electron exo-emission, which also helps maintain a stable electric arc.

At the moment of melting of the electrode, its filler material is transferred to the weld pool, due to which the parts are connected. On some models of welding equipment used for welding parts using fireproof electrodes, the arc is ignited in a non-contact manner. Ignition is achieved using a special device called an oscillator.

At the same time, melting of various contaminants occurs with the metal, which leads to the formation of slag on the surface of the bath. The temperature of the top layer of the welded joint is higher than the molten metal, which leads to changes in the mechanical characteristics and structure of the weld after it cools. The advantages of electric fusion welding technology are the ability to join metals with dissimilar structures and versatility.

Electric welding equipment

Electric welding produces a permanent or hermetic connection. The welding process takes place in a heated state of the joined surfaces to the melting temperature or plastic state. Therefore, two types of welding are distinguished: arc - fusion welding and contact - plastic type of welding. In the first case, the thermal energy required for welding is released in an arc discharge in the immediate vicinity of the joint being welded; in the second case, thermal energy is released directly at the joint being welded due to the flow of electric current through the welded parts.

Arc welding is the most widespread. The main equipment for arc welding is power supplies (PS), electric drives for moving carts and feeding wire in automatic and semi-automatic machines, switching, protective and control equipment, devices for igniting and stabilizing the arc. For arc welding, power sources are used: direct current - electric machine converters, rectifiers and mobile welding units; AC - single- and three-phase transformers with low short-circuit resistance.

In an installation with an electric machine DC converter for multi-station manual arc welding (Fig. 10.4), BR ballast rheostats provide a wide range of welding current control (50-350 A). For example, the PSM-1000 converter is designed for simultaneous power supply of five posts with currents up to 200 A. The most widely used electric machine converters are PSO (single-post),

PSG (for welding in shielded gas). The power of the driven motors on these converters is 4-55 kW, supply voltage is 220/380 V.

Welding rectifiers use single- and three-phase full-wave bridge circuits. A three-phase bridge circuit is used more, which ensures good stability of the welding arc and uniform loading of the power network phases. Such rectifiers include VKS-300 (welding rectifier for 300 A), VD-101, VD-301 (rectifiers for manual arc welding for currents of 125 and 300 A), IPP-300, VS-400, IPP-500, as well as universal rectifiers VSU-300, VSU-500, VDU-504. The power of the rectifiers is in the range of 9–40 kV-A, the supply voltage is 220/380 V.

The main sources of alternating current are welding transformers of the TSD, STN, ST, TD, TSSh types (Fig. 10.5). Transformer power 9-165 kV-A, supply voltage 220/380 V.

For welding butt, fillet and overlap welds of vessels, tanks, pontoons with a diameter of 1 m or more, universal light welding tractors and self-propelled welding machines are used, moving directly over the product being welded during welding. Welding tractors TS-17M (Fig. 10.6), TS-26, UT-1250-3, UT-2000M-1, ADS-500, ADS-1000-2 have become widespread.

Contact welding is used along with arc welding. The main types of resistance electric welding are shown in Fig. 10.7, electrical diagram of the installation for resistance electric welding - in Fig. 10.8. the energy required for welding is released in an arc discharge in the immediate vicinity of the joint being welded; in the second case, thermal energy is released directly at the joint being welded due to the flow of electric current through the welded parts.

Arc welding is the most widespread. The main equipment for arc welding is power supplies (PS), electric drives for moving carts and feeding wire in automatic and semi-automatic machines, switching, protective and control equipment, devices for igniting and stabilizing the arc. For arc welding, power sources are used: direct current - electric machine converters, rectifiers and mobile welding units; AC - single- and three-phase transformers with low short-circuit resistance.

In an installation with an electric machine DC converter for multi-station manual arc welding (Fig. 10.4), BR ballast rheostats provide a wide range of welding current control (50-350 A). For example, the PSM-1000 converter is designed for simultaneous power supply of five posts with currents up to 200 A. The most widely used electric machine converters are the PSO (single-post) and PSG (for shielded gas welding) types. The power of the driven motors on these converters is 4-55 kW, supply voltage is 220/380 V.

Welding rectifiers use single- and three-phase full-wave bridge rectification circuits. A three-phase bridge circuit is used more, which ensures good stability of the welding arc and uniform loading of the power network phases. Such rectifiers include VKS-300 (welding rectifier for 300 A), VD-101, VD-301 (rectifiers for manual arc welding for currents of 125 and 300 A), IPP-300, VS-400, IPP-500, as well as universal rectifiers VSU-300, VSU-500, VDU-504. The power of the rectifiers is in the range of 9–40 kV-A, the supply voltage is 220/380 V.

The main sources of alternating current are welding transformers of the TSD, STN, ST, TD, TSSh types (Fig. 10.5). Transformer power 9-165 kV-A, supply voltage 220/380 V.

For welding butt, fillet and overlap welds of vessels, tanks, pontoons with a diameter of 1 m or more, universal light welding tractors and self-propelled welding machines are used, moving directly over the product being welded during welding. Welding tractors TS-17M (Fig. 10.6), TS-26, UT-1250-3, UT-2000M-1, ADS-500, ADS-1000-2 have become widespread.

Contact welding is used along with arc welding. The main types of resistance electric welding are shown in Fig. 10.7, electrical diagram of the installation for resistance electric welding - in Fig. 10.8.

The most common are AC butt welding machines with a supply voltage of 380 V and a power of 10-1000 kVA. Single-spot welding machines with a supply voltage of 380 V and a power of 10-200 kV-A or more are widely used. Among the welding machines, the most widely used machines are those with single-phase alternating current transformers of the MSh type with electric motors for rotating the rollers for moving the parts being welded. The power of the machines is 50-500 kV-A, voltage 380 V.

Welding power sources must provide the ability to easily and smoothly regulate the amount of welding current and must respond quickly to changes in current and voltage in the welding arc.

Fusion welding technology

With any fusion welding technology, the process of joining parts must consist of the following steps:

- Preparatory work. The edges of the workpieces are cleaned from corrosion and grease residues, after which the edges are cut off taking into account the thickness of the part.

- The parts are installed and fixed in the required position.

- The arc is ignited (any method can be used). Sometimes the workpieces are heated using another method.

- A weld is formed, after cooling, the joint must be cleaned of slag inclusions.

Sv6.ru – portal about welding

In practice, welding is divided into special classes according to the type of energy used.

Class 1 – thermal. A type of welding in which the parts to be joined in the work area melt when exposed to thermal energy. Such processes occur during arc, gas, electroslag, electron beam, plasma, and laser welding. Class 2 – thermomechanical. A type of welding using pressure combined with thermal energy. This is electric resistance welding, diffusion welding, gas press welding. For example, electric resistance welding uses pressure and electrical heating. In this case, the current passes in the contact zone of the parts, a powerful short-term pulse heats the metal to a state of local melting and welding occurs under pressure. Diffusion welding is characterized by the mutual diffusion of atoms of the contacting parts under prolonged exposure to high temperatures and slight plastic deformation.

3rd class – mechanical. Type of welding using mechanical forces and pressure (cold welding, explosive, ultrasonic welding).

www.sv6.ru

Fusion Welding Standards and Requirements

The following documents have been developed to regulate the processes of fusion welding of metals:

- GOST 30242-97 (description and methods for eliminating defects);

- GOST R 55143-2012 (welding parameters);

- GOST R ISO 5817-2009 (requirements for seam quality);

- GOST 11969-79 (basic terms and designations).

The requirements for welding seams depend on the purpose of the structure. But in any case, the strength and hardness of the joint should be approximately the same as that of solid products.

Welding classification | Metal welding

The classification of welding according to GOST 19521 - 74 provides for three classes of welding: thermal, thermomechanical and mechanical.

Thermal class

The thermal class combines types of welding carried out by local melting of metal. The thermal class includes arc, gas, thermite, electroslag, electron beam, plasma beam, laser and other types of welding.

Figure - Thermal class of welding

Thermomechanical class

The thermomechanical class combines types of welding carried out by pressure (mechanical energy) using general or local thermal energy.

This class includes furnace (forging, rolling, extrusion - these types of welding involve general heating of the parts being welded), contact, thermite-press, induction-press, gas-press, diffusion and arc-press (these types of welding are performed with local heating of the parts being welded).

Each type of welding of the thermomechanical class is performed according to the pressure welding scheme without melting or with melting of the metal of the edges of the parts.

Mechanical class

The mechanical class of welding combines types of welding performed by pressure (mechanical energy). This class includes cold, friction, ultrasonic, explosion and magnetic pulse welding.

www.svarkametallov.ru

Evaluation of the finished product

When welding structures that are not included in the critical category, the quality of the weld can be checked only by visual inspection. For critical structures, the following quality control methods are used:

- radiation;

- capillary;

- magnetic;

- ultrasonic flaw detection.

The requirements for welding seams depend on the purpose of the product. But there is a mandatory condition: the hardness and strength of the welded joint should not be lower than that of the metal workpiece itself.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

Before proceeding with visual inspection, it is necessary to clean the seam from scale and slag formed during fusion welding of metal. The width of the welded joint along the entire length should be the same, and the surface should have a fine-scale structure. The presence of narrowings, omissions and sagging is unacceptable. If, after welding, cracks and pores are found on the surface of the metal, then such a weld must be rejected.

Which fusion welding method to use depends on the task at hand. If such work is often carried out outdoors, it will be more convenient to use a gas burner with cylinders or a portable arc apparatus. In cases where welding work is carried out at one place, the best option would be a semi-automatic one, and in case of mass production, an automatic welding unit.

Manual arc welding with consumable electrode

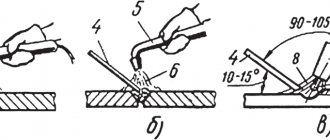

Manual welding is performed with a consumable metal electrode according to the Slavyanov method (Fig. 10.3).

Manual electric arc welding is universal and widespread, as it can be performed in any spatial position. It is often used for installation in hard-to-reach places where mechanized welding methods cannot be used. A lower depth of penetration of the base metal and lower productivity of manual welding due to the reduced strength of the applied current, as well as less stability of the manual process (compared to automatic submerged arc welding) are the disadvantages of manual welding.

Why should you contact us?

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

- non-ferrous metals;

- cast iron;

- stainless steel.

When completing an order, our specialists use all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

In order to bring the workpiece closer to the sketch submitted by the customer, our specialists use universal equipment designed for jewelry sharpening of tools for particularly complex operations. In our production workshops, metal becomes a plastic material from which any workpiece can be made.

catalogue of articles

Types of mechanical welding class

| The mechanical class of welding combines types of welding performed by pressure (mechanical energy). The essence of pressure welding is the plastic deformation of the edges of the parts being welded under the influence of load: the pressure of a blast wave, a sledgehammer, etc. Welding can be performed both cold and heated. Due to plastic deformation, the process of establishing interatomic bonds between the connected parts occurs. As a result, a welded joint is formed. This class includes: cold welding, friction welding, ultrasonic, explosion, etc. |

| Fig.91 - detonator; 2 - explosive; 3, 4 — plates; 5 - base. | Explosion welding is based on the impact of directed short-term ultra-high pressures of explosion energy on the parts being welded. The plate to be welded is installed on the base (Fig. 9). The second plate to be welded is placed above the first at some distance. An explosive charge is placed on the second plate in a layer of equal thickness. The charge is exploded using a detonator. Under the influence of a blast wave, the upper plate hits the lower plate at high speed and is welded to it, forming a monolithic joint. The welded joint is the result of diffusion. Explosion welding is used in the manufacture of bimetal blanks, in cladding (coating) the surface of structural steels with metals and alloys with special physical and chemical properties, as well as in welding parts made of dissimilar metals and alloys. Explosion welding is the fastest welding. |

| Fig. 101, 2 - parts to be welded; R - strength. | Friction welding is performed in the solid state under the influence of heat generated by friction of the rotating surfaces of the parts being welded, followed by their compression (Fig. 10). A strong welded joint is formed as a result of the formation of metallic bonds between the contacting surfaces of the parts being welded. The formation of these bonds is prevented by various inclusions and films covering metal surfaces. They are destroyed by friction and due to significant plastic deformation of the rubbing parts. surfaces are removed from the zone in the radial direction. Friction welding is used to weld cutting tools (drills, cutters, reamers), various round-section parts made of steel, cast iron, non-ferrous metals and alloys, dissimilar metals. |

| Fig. 111 - parts to be connected; 2 - sledgehammer. | Cold welding of metals (forging). The essence of this type of welding is that when high pressure is applied to the elements being connected, plastic deformation occurs at their contact point, which contributes to the emergence of interatomic adhesive forces and leads to the formation of metal bonds. Welding is performed with a sledgehammer (hammer) without heating (Fig. 11). The surfaces to be welded are first cleaned of contaminants: degreased, treated with a rotating wire brush, or scraped. Connections are made in the form of individual points or a continuous seam. Cold welding is used to weld ductile metals: copper, aluminum and its alloys, lead, tin, cadmium, titanium. |

forging, explosion welding, cold welding, friction welding, welding

www.sibelektrod.ru