Welding of thick metal is based on the multi-layer weld method, in which elements must be applied to the edges of the joints using special technological processes. There are several techniques for welding metal with thick walls, which provide for technological preparation of the edges and some subtleties when connecting products with a wall of 20 mm and above.

At the junction of the two parts, it is necessary to leave a gap where the electrode will pass.

Electroslag welding

Electroslag welding (ESW) allows you to weld metal parts up to 60 cm thick. The principle of ESW is that a slag mass is placed in the gap between the ends of two metal parts being welded. This mass is melted by an electric arc created between the electrode and the metal parts. After the slag has melted, the arc goes out, and a current flows through the slag mass, which, with correctly selected welding parameters, evenly heats the weld pool to high temperatures.

A filler material is added to the slag mass, which melts along with the slag and the edges of the parts being joined. Since the molten metal is heavier than the slag, it falls down the gap and solidifies there. The molten mass rises upward. This process results in welding of the vertical gap.

To prevent the melt from flowing out of the gap, special plates - sliders - are placed on both sides. They are cooled by water and gradually move upward.

Electroslag welding diagram

There are three methods for implementing EHS:

- A filler electrode , which is located in a horizontal plane, is continuously fed into the melt.

- Plate electrodes are used, which replace sliders . By bridging the gap, an effective melt is created, which allows you to join the gaps of parts without adding an additive.

- Combining the first two methods . In this case, plate and consumable electrodes are used.

Advantages and disadvantages of EHS

The main advantages of EHS:

- protection of the seam from exposure to the atmosphere with liquid slag;

- low sensitivity of the process to changes in the current value and even its short-term interruption;

- welding thick metal in one pass;

- ability to weld raw ends of parts;

- low power consumption and low cost of slags;

- high efficiency.

Disadvantages of EHS:

- it is possible to weld only vertical seams or seams at an acute angle to the vertical;

- when the process is interrupted, defects arise that cannot be corrected;

- the seam has a coarse-grained structure , which limits the use of the product at low temperatures (the seam becomes brittle);

- To organize an EHS you need to have a fairly large number of devices.

Equipment

To perform EHS operations, automatic or semi-automatic machines are used. The second type of equipment is rarely used, since it is quite difficult for a person to manually move heavy equipment vertically.

EHS machines usually include:

- Automatically moving welding machine with copper slides;

- power supply;

- Flux and wire feeders;

- control system.

Depending on the design, machines for EHS can be suspended or self-propelled (rail or trackless type).

Preparation for work. Edge processing

Welding work using a semi-automatic machine should be carried out only with clean workpieces. The surface should be free of rust, oil and dirt. Otherwise, pores will appear.

Proper cutting of edges is an important stage in preparing parts for welding. To ensure the formation of high-quality seams, chamfers should be removed in accordance with GOST 14771-76 - depending on the type of connection. If everything is done correctly, the connection will be strong. It is important to ensure that the metal is fused throughout its entire thickness.

Arc welding

Electric arc welding (EDGS) is a type of permanent connection of parts obtained by melting metal with an electric arc that occurs when voltage is applied to the electrode and metal from a current source. When the parts being connected are exposed to such an arc, a weld pool of molten metal is formed, after cooling and solidifying, a seam is formed that connects the parts.

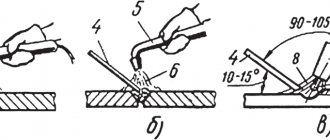

When welding products of large thickness (more than 20 mm) using EDGS, it is impossible to weld the entire thickness of the product. Therefore, in this case, multi-layer sutures are used. Before you start welding thick metal, you need to prepare its ends. Most often, the edges of the ends are ground off at a certain angle. A gap is left between the parts.

When making the first root (connecting) seam, a thin electrode 1-3 mm thick is used. Its use allows you to fix the parts and avoid burn-through.

Subsequent filling of the welding seam is carried out with an electrode of larger diameter. In this case, the layer must be laid over the uncooled previous layer. The thickness of the layer for sufficient heating should not be more than 4-5 mm.

EDGS classification

EDGS are of the following types:

- manual;

- semi-automatic;

- automatic.

With manual EDGS, the welder manually moves the electrode, resulting in the formation of a weld. In semi-automatic welding, the filler wire is fed automatically and the electrode is moved manually. In automatic welding, both the wire and the electrode move automatically.

Equipment

The most common is manual EDGS. When performing this type of welding, the following are used:

- welding machine;

- welder hand tool;

- welding aids.

The welding machine is, first of all, a power source for the electric arc.

Welding transformers, rectifiers (inverters) or generators are used as power sources for EDGS.

Approximate cost of inverter power sources on Yandex.market

The welding transformer is designed to lower the mains voltage to a lower arc voltage and provide the required current. Welding rectifiers consist of a step-down transformer and a semiconductor rectifier. They feed the arc with direct current. Generators provide power to the electric arc by converting mechanical energy into electrical energy.

In addition to the power source, the welding machine includes an electrode, an electrode holder and wires that connect the power source to the weld pool. The electrode is usually a filler material with a coating designed to protect the weld pool from the external atmosphere. Electrode holders are of screw or clamp type.

Approximate cost of electrode holders on Yandex.market

As equipment, the welder must use a protective mask that filters UV and IR radiation from the arc, a respirator and special clothing. In addition, a welder is required to have a hammer, chisel, and metal brush as hand tools.

Setting up the device and gas equipment

Semi-automatic welding machines from different manufacturers are designed differently. There are at least two or three regulators on the front panel:

- setting the wire feed speed – the rotation speed of the electric motor that moves the wire is adjusted;

- change in current strength - the parameter affects the melting rate of the additive in the weld pool;

- inductance adjustment - the change concerns the current characteristics. At minimum values, the depth of metal penetration is less and the seam is more convex. For welding thick workpieces, it is recommended to increase it to medium or even higher.

Tip: you can set up the device by ear. During welding, the melting of the wire occurs very smoothly, the semi-automatic machine produces an even rustling sound.

After connecting the reducer to a carbon dioxide cylinder, you need to set the outlet pressure. For indoor work, 1-1.5 kg/sq.m. is sufficient. cm. If a flow meter is installed on the gearbox, then it should be set to 10-12 liters per minute.

Welds

When welding thick-walled parts, pores or cracks may occur. To prevent them during welding, the following methods are used:

- "slide";

- block;

- cascade.

In the first case, layer No. 1 is first formed at the joint area of 200-300 mm. After cleaning it from scale, layer No. 2 is welded onto it, which is 2 times longer than the first. Next, they retreat 200-300 mm from the beginning of layer No. 2 and weld layer No. 3. In this way, fill the entire welding seam with seams on both sides of layer No. 1.

When welding metal with a thickness of 20 mm or more, the cascade method is used. In essence, this method is a variation of the “slide” method. In this case, the entire seam is divided into sections of 20 cm. First, the lowest section of 20 cm is boiled. Then a second layer 40 cm long is placed on top of the first layer. A third layer 60 cm long is placed on top of the second layer. Layers are laid in this way until the seam is filled above site No. 1. After this, short seams are welded in both directions from section No. 1. Thanks to this, the welding zone will be heated all the time, and cracks will not form there.

With the block method, the seam is first welded in separate sections (blocks), and the spaces between them are welded until the entire seam is welded.

Possible difficulties

Problems that arise when restoring parts:

- The damage affects the threaded holes intended for mounting the sensors. After repairing the fracture, it is necessary to drill the channel and restore the thread, but mechanical stress can destroy the seams. In this case, you will have to refuse to install the sensor or purchase a new unit.

- The crack runs through the cooling jacket or the engine oil supply passages. When carrying out welding work, complete or partial overlap of sections occurs. Such repairs lead to accelerated engine failure (due to local overheating or oil starvation).

- The resulting weld is not airtight, so a layer of epoxy resin must be applied. Before treatment, clean the surfaces from carbon deposits and degrease (for example, with paint solvents). After polymerization, epoxy resin does not allow liquid to pass through, but cannot withstand vibration loads and temperatures above +120°C. After welding with a ferrocopper electrode, the seam is treated with a 10% ammonium chloride solution for sealing. The reaction products fill the pores and reduce the risk of liquid leakage.

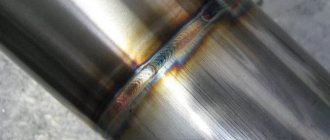

Features of welding pipes with thick walls

Pipes with thick walls are used in various areas of the national economy and industry. For example, the Turkish Stream pipeline uses pipes with a wall thickness of 39 mm, while high-pressure pipelines can use pipes with a wall thickness of up to 52 mm.

If the thickness of the pipe walls exceeds 20 mm, then welding of such pipes can be carried out using layers of increased thickness. This method allows you to increase the strength of the connection by 10-15%. In this case, welding of such pipes must be carried out simultaneously with 2 welding machines - one of them applies a regular layer, and the second - a thick layer.

As experience has shown, there are already results on welding joints with an increased layer thickness, in which joints of 45 mm were welded in 3 passes with a thickness of one layer of 15 mm. In this case, the joint had two types of edge bevels, one of which was Y-shaped, and the other was two-stage.

MULTILAYER MULTIPASS DOUBLE SIDED

more often - for corner and tee

I - III - order of application of layers; 1 - 8 - sequence of suturing

To heat the metal evenly along its entire length, seams are applied:

- double layer

- city committee

- cascade

- transverse

- blocks

- slide

With the double layer method, the second layer is applied over the uncooled first layer after removing the welding slag in the opposite direction at a length of 200-400 mm

Recommendations on how to weld metal correctly

To weld metal correctly, it is not enough just to learn how to make seams. The welder must also be a materials scientist - know a lot about the properties of the materials being welded, their interaction with each other and with high temperatures.

The technology includes many operations before and after the actual seam is completed.

Before starting the main operation, the parts to be welded must be thoroughly cleaned of mechanical impurities, old paint, rust and must be degreased. It is also necessary to correctly position them relative to each other and fix them in this position.

When connecting thin-walled structures or simply long seams, the parts are clamped to each other at several equally spaced points to avoid thermal deformation.

The future welder must know and anticipate in advance:

- potential problems;

- types of defects

and think about how to avoid them.

Start with the three simplest types of connections

- Butt. The edges of the parts to be joined are in the same plane with a small gap between them, and this gap is filled with suture material.

- Overlapping. The parts are arranged with some edge overlap.

- Tavrovy. One plate is welded end-to-end in the middle of the other, usually at a right angle.

Three main types of connection

In general, a welder's job is half welding and half planning and preparation. Learning to cook properly means learning to plan and prepare.

How to cook properly

To understand how to cook properly, a small amount of theory should be supplemented with a large amount of practice. It’s best to start learning by welding scraps of corners, fittings, and metal plates. Only after you “feel the seam” with your own hands can you begin to connect more or less important structures.

Arc Welding Process

There are several types of devices; in order to learn how to cook correctly, it is best to start with an inverter. It allows you to smoothly regulate and maintain a stable operating current, is slightly independent of the level and stability of the voltage in the supply network, and does not create voltage surges in this network.