Welding machine and its capabilities

Connections of metal parts are considered the strongest and most reliable. Using welding, it is difficult to make seams unnoticed, so either additional finishing is required, or seams are made in places where aesthetics are not important. Metal products are connected under the influence of high temperatures. The electric arc used in modern devices melts. This electric welding method is most popular in the construction industry.

The optimal heating temperature is 7 thousand degrees. The electric arc works due to the current generated from the welding electrode to the electrode itself. When exposed to heat, the melt forms a weld pool. As a result, the electrode is connected to the metal. Due to the slag, a protective film is formed. As it cools, a seam will form.

Electrode grades suitable for manual arc welding

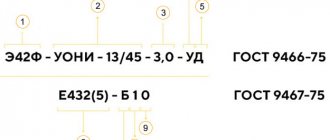

There are also types of electrodes for manual arc welding, divided by brand. The brand of electrode you use also depends on the metal you need to weld.

The following grades are used for welding low-alloy carbon steels:

- E42: grades ANO-6, ANO-17, VSC-4M.

- E42: UONI-13/45, UONI-13/45A.

- E46: ANO-4, ANO-34, OZS-6.

- E46A: UONI-13/55K, ANO-8.

- E50: VSC-4A, 550-U.

- E50A: ANO-27, ANO-TM, ITS-4S.

- E55: UONI-13/55U.

- E60: ANO-TM60, UONI-13/65.

For welding alloy steels (including high-strength):

- E70: ANP-1, ANP-2.

- E85: UONI-13/85, UONI-13/85U.

- E100: AN-KhN7, OZSh-1.

- E125: NII-3M, E150: NIAT-3.

For metal surfacing: OZN-400M/15G4S, EN-60M/E-70Kh3SMT, OZN-6/90Kh4G2S3R, UONI-13/N1-BK/E-09Kh31N8AM2, TsN-6L/E-08Kh17N8S6G, OZSh-8/11Kh31N11GSM3YuF.

For welding cast iron: OZCh-2/Cu, OZCh-3/Ni, OZCh-4/Ni.

For welding aluminum and its alloys: OZA-1/Al, OZANA-1/Al.

For welding copper and its alloys: ANTs/OZM-2/Cu, OZB-2M/CuSn.

For welding nickel and its alloys: OZL-32.

Types of Welding Machines

There are a large number of models of welding machines of different types on the market.

Of all their diversity:

- transformers;

- rectifiers;

- inverters;

- semi-automatic;

- machine guns;

- plasma;

In a home workshop, transformers are most often used because of their low cost, and inverters because of their simplicity and ease of use. The rest require either special working conditions, achievable only in production, or special training and long-term acquisition of skills.

Transformer

The design of such devices is extremely simple - it is a powerful step-down transformer, in the secondary winding of which a working electrical circuit is connected.

Transformer welding machine

Transformer advantages:

- unpretentiousness;

- survivability;

- simplicity;

- cheapness.

Flaws

- very large weight and dimensions;

- low arc stability;

- AC operation;

- causes voltage surges in the supply network.

Such a device requires skill and extensive experience from the welder. It is not suitable for teaching a novice welder how to weld correctly.

Inverters

The inverter device has a much more complex design. The inverter unit repeatedly converts the input mains voltage, bringing its parameters to the required ones. Due to the transformation of high frequency current, the dimensions and weight of the transformer are many times smaller.

Inverter

Inverter advantages:

- low weight and dimensions;

- stabilized voltage and current in the circuit;

- additional anti-stick and hot start functions;

- possibility of precise adjustment of current and arc parameters;

- does not cause voltage surges in the supply network.

The inverter also has disadvantages:

- high price;

- low frost resistance.

It’s best to start learning how to cook properly with an inverter. The stability of the arc parameters and additional functions that make starting easier and preventing “sticking” will allow the beginner to concentrate on the seam and quickly master the technology.

What types of electric welding exist?

- MMA. A simple and easy-to-use hand-held device that requires coated electrodes. Suitable for home use, inexpensive, but its use is impossible for a number of metal structures, only for stainless steel and ferrous metal.

- TIG is a technology that opens up the possibility of working with a large number of substances. The peculiarity is in the electrode that is used to create the arc, as well as in a special atmosphere of inert protective gas to obtain an even seam. The advantage is the purity of action and the power of the equipment. The downside is that special training is required, since it is difficult to learn how to properly weld with this type of electric welding.

- MIG-MAG. This is a semi-automatic device. Instead of an electrode, welding wire is automatically fed. Its use is suitable for atmospheres with inert and active gases, with various metals. Modern equipment that can be used at home. The welded joint is smooth and neat, productivity and speed of work increases. But in a garage or workshop, the installation itself along with the cylinder will take up a lot of space.

- SPOT, also known as spot welding, is used in cases where careful soldering is required and appearance is important, for example, when body repairing cars in a car service center.

Arc welding

The heat source is an electric arc that occurs between the end of the electrode and the product being welded when welding current flows as a result of the closure of the external circuit of the electric welding machine. The resistance of the electric arc is greater than the resistance of the welding electrode and wires, therefore most of the thermal energy of the electric current is released into the plasma of the electric arc. This constant flow of thermal energy keeps the plasma (electric arc) from decaying.

The released heat (including due to thermal radiation from the plasma) heats the end of the electrode and melts the welded surfaces, which leads to the formation of a weld pool - a volume of liquid metal. During the process of cooling and crystallization of the weld pool, a welded joint is formed. The main types of electric arc welding are:

- manual arc welding

- non-consumable electrode welding

- consumable electrode welding

- submerged arc welding

- electroslag welding

Manual arc welding

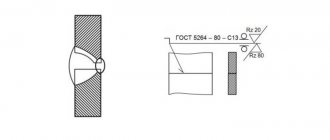

Manual arc welding with a consumable coated electrode is performed using a welding power source and welding electrodes. The electrode is supplied to the welding zone and moved along the joint by the welder himself. The power source can be either AC (transformer) or DC (rectifier). A welding electrode is a metal rod with a coating applied to it.

During the welding process, an electric arc burns between the workpiece and the electrode, melting them. The molten metal of the electrode and the product forms a weld pool, which, upon subsequent crystallization, forms the seam of the welded joint.

The substances that make up the coating either burn, forming a gas protection of the welding zone from the surrounding air, or melt and fall into the weld pool. Some molten coating substances interact with the metal of the weld pool, deoxidizing and/or alloying it, others form slag, which protects the weld pool from air, promotes the removal of non-metallic inclusions from the weld metal, the formation of a seam, etc.

Manual arc welding is designated by code 111 according to the GOST R ISO 4063-2010 standard; in Russian-language literature the designation RD is used, in English - SMAW (from the English shielded metal arc welding) or MMA (from the English manual metal arc welding).

Non-consumable electrode welding

Main article: Non-consumable electrode welding

Non-consumable electrode welding, in the English-language literature is known as gas tungsten arc welding (GTA welding, TGAW) or tungsten inert gas welding (TIG welding, TIGW), in the German-language literature - wolfram-inertgasschweißen (WIG).

The electrode is a rod made of graphite or tungsten, the melting point of which is higher than the temperature to which they are heated during welding. Welding is most often carried out in a shielding gas environment (argon, helium, nitrogen and their mixtures) to protect the seam and electrode from the influence of the atmosphere, as well as for stable arc burning. Welding can be carried out both without and with filler material. Metal rods, wire, and strips are used as filler material.

Gas shielded welding

Gas shielded arc welding is welding using an electric arc to melt metal and protecting the molten metal and electrode with special gases.

Applications of gas shielded welding

Widely used for the manufacture of products made of steel, non-ferrous metals and their alloys.

Advantages of gas shielded welding compared to other types of welding

- high performance,

- easily automated and mechanized,

- no need for electrode coatings or flux.

A metal wire of a certain brand is used as an electrode, to which current is supplied through a current-carrying mouthpiece. The electric arc melts the wire, and to ensure a constant arc length, the wire is fed automatically by the wire feeder.

To protect from the atmosphere, special gases are used, supplied from the welding torch along with the electrode wire. Special gases are divided into inert (argon, helium) and active (carbon dioxide, nitrogen, hydrogen). The use of a mixture of gases in some cases improves welding productivity and quality. If it is not possible to carry out semi-automatic welding in shielding gases, self-shielding wire (flux-cored) is also used. It should be noted that carbon dioxide is an active gas - at high temperatures it dissociates with the release of oxygen. The released oxygen oxidizes the metal. In this regard, it is necessary to introduce deoxidizing agents (such as manganese and silicon) into the welding wire. Another consequence of the influence of oxygen, also associated with oxidation, is a sharp decrease in surface tension, which leads, among other things, to more intense metal spattering than when welding in argon or helium.

International designation.

In English-language foreign literature it is referred to as gas metal arc welding (GMA welding, GMAW), in German-language literature - metallschutzgasschweißen (MSG). Welding in an atmosphere of inert gas (MIG) and in an atmosphere of active gas (metal active gas, MAG) are distinguished.

Submerged arc welding

In English-language foreign literature it is referred to as SAW. In this type of welding, the end of the electrode (in the form of a metal wire or rod) is fed under a layer of flux. Arc combustion occurs in a gas bubble located between the metal and the flux layer, which improves the protection of the metal from the harmful effects of the atmosphere and increases the depth of metal penetration.

Electroslag welding

The source of heat is the flux located between the products being welded, which is heated by an electric current passing through it. In this case, the heat generated by the flux melts the edges of the parts being welded and the filler wire. The method finds its application when welding vertical seams of thick-walled products.

Hyperbaric welding

Hyperbaric welding is a welding process at elevated pressures, usually carried out under water. Hyperbaric welding can take place in water or dry welding, that is, inside a specially built chamber in a dry environment. The applications of hyperbaric welding are varied - it is used to repair ships, offshore oil platforms and pipelines. Steel is the most common material for hyperbaric welding.

Orbital welding

Orbital welding is a type of friction welding or automatic arc welding (depending on whether the pipe is rotating or not). The name comes from the use of orbital welding - for welding joints of pipes, flanges, etc. It is used for welding steel pipes made of high-alloy steels or large-diameter aluminum alloys with a thick wall.

When the pipes being welded rotate coaxially, friction in the joints occurs when the axes of rotation are shifted parallel to each other. This type of welding uses friction to heat the joint. The combined action of forging pressure and heat leads to welding of the joints.

If the pipes do not rotate, then orbital welding uses welding heads that move along the joint and conduct arc welding with or without filler wire.

Gas flame welding

Acetylene-oxygen flame (temperature about 2621 °C at 2-3 mm from the core)

The source of heat is a gas flame formed by the combustion of a mixture of oxygen and combustible gas. Acetylene, MAF, propane, butane, blast gas, hydrogen, kerosene, gasoline, benzene and their mixtures can be used as flammable gas. The heat released during the combustion of a mixture of oxygen and combustible gas melts the surfaces being welded and the filler material to form a weld pool. The flame can be oxidizing, "neutral" or reducing (carburizing), this is controlled by the ratio of oxygen to combustible gas.

- A new type of fuel is used as a substitute for acetylene - liquefied gas MAF (methyl acetylene-allen fraction). MAF provides high welding speed and high quality of the weld, but requires the use of filler wire with a high content of manganese and silicon (SV08GS, SV08G2S). MAF is much safer than acetylene, 2-3 times cheaper and more convenient for transportation. Due to the high temperature of gas combustion in oxygen (2430 °C) and high heat release (20,800 kcal/m3), gas cutting using MAF is much more efficient than cutting using other gases, including acetylene.

- The use of cyanogen for gas welding is of great interest due to its very high combustion temperature (4500 °C). An obstacle to the expanded use of cyanogen for welding and cutting is its increased toxicity. On the other hand, the efficiency of cyanogen is very high and comparable to an electric arc, and therefore cyanogen represents significant prospects for further progress in the development of gas-flame processing. The flame of cyanogen with oxygen emanating from a welding torch has a sharp outline, is very inert to the metal being processed, is short and has a purplish-violet hue. The metal being processed (steel) literally “flows”, and when using cyanogen, very high speeds of welding and cutting metal are permissible.

- Significant progress in the development of gas-flame processing using liquid fuels can be achieved by the use of acetylenedinitrile and its mixtures with hydrocarbons due to the highest combustion temperature (5000 °C). Acetylenedinitrile is prone to explosive decomposition when heated strongly, but is much more stable in mixtures with hydrocarbons. Currently, the production of acetylenedinitrile is very limited and its cost is high, but with the development of production, acetylenedinitrile can very significantly develop the areas of application of gas flame processing in all its fields of application.

Thermite welding

In most cases, thermite welding is classified as a thermal class. However, there are technological processes that belong to the thermomechanical class - for example, thermite-press welding. Thermite welding is the welding of parts with molten metal formed during a chemical reaction accompanied by high temperature (a large amount of heat). The main component of this type of welding is the thermite mixture.

Plasma welding

The source of heat is a plasma jet, that is, a compressed arc produced using a plasma torch. The plasma torch can be of direct action (the arc burns between the electrode and the base metal) and indirect action (the arc burns between the electrode and the plasma torch nozzle). The plasma jet is compressed and accelerated under the influence of electromagnetic forces, exerting both thermal and gas-dynamic effects on the welded product. In addition to welding itself, this method is often used for technological operations of surfacing, spraying and cutting.

The plasma cutting process is based on the use of a direct current air-plasma arc of direct polarity (electrode - cathode, metal being cut - anode). The essence of the process is local melting and blowing of molten metal to form a cutting cavity when the cutter moves relative to the metal being cut.

Electron beam welding

The source of heat is an electron beam obtained due to thermionic emission from the cathode of an electron gun. Welding is carried out in high vacuum (10−3 - 10−4 Pa) in vacuum chambers. The technology of electron beam welding in an atmosphere of normal pressure is also known, when the electron beam leaves the vacuum region immediately in front of the parts being welded.

Electron beam welding has significant advantages:

- A high concentration of heat input into the product, which is released not only on the surface of the product, but also at some depth in the volume of the base metal. By focusing the electron beam, it is possible to obtain a heating spot with a diameter of 0.0002 ... 5 mm, which makes it possible to weld metals with a thickness from tenths of a millimeter to 200 mm in one pass. As a result, it is possible to obtain seams in which the ratio of penetration depth to width is up to 20:1 or more. It becomes possible to weld refractory metals (tungsten, tantalum, etc.), ceramics, etc. Reducing the length of the heat-affected zone reduces the likelihood of recrystallization of the base metal in this zone.

- Low amount of heat input. As a rule, to obtain an equal penetration depth in electron beam welding, it is necessary to introduce 4-5 times less heat than in arc welding. As a result, product deformation is sharply reduced.

- Lack of saturation of molten and heated metal with gases. On the contrary, in a number of cases, degassing of the weld metal and an increase in its plastic properties are observed. As a result, high quality welded joints are achieved on chemically active metals and alloys, such as niobium, zirconium, titanium, molybdenum, etc. Good quality of electron beam welding is also achieved on low-carbon, corrosion-resistant steels, copper and copper, nickel, aluminum alloys .

Disadvantages of electron beam welding:

- Possibility of formation of non-fusion and cavities at the root of the weld on metals with high thermal conductivity and welds with a large depth-to-width ratio;

- It takes a long time to create a vacuum in the working chamber after loading products.

Laser welding

The heat source is a laser beam. All types of laser systems are used. The high concentration of energy, the high speed of laser welding compared to arc methods, and the insignificant thermal effect on the heat-affected zone due to high rates of heating and cooling of the metal significantly increase the resistance of most structural materials to the formation of hot and cold cracks. This ensures high quality welded joints from materials that are difficult to weld by other welding methods.

Laser welding is performed in air or in shielding gases: argon, CO2. A vacuum, as with electron beam welding, is not needed, so large structures can be welded with a laser beam. The laser beam is easily controlled and adjusted, with the help of mirror optical systems it is easily transported and directed to places that are otherwise difficult to reach. Unlike the electron beam and electric arc, it is not affected by magnetic fields, which ensures stable formation of the seam. Due to the high concentration of energy (in a spot with a diameter of 0.1 mm or less) in the laser welding process, the volume of the weld pool is small, the width of the heat-affected zone is small, and high heating and cooling rates. This ensures high technological strength of welded joints and small deformations of welded structures.

Types and methods

Electric arc welding has several varieties. Each of them has some distinctive features that affect the quality and type of welded joint. The following types of electric arc welding are distinguished:

- Manual electric arc welding. During it, only human manual power is used without mechanisms;

- Mechanized type. During the process, mechanization is used to feed wire into the welding area, and part of the work is done by manual force;

- Automatic type. Welding is carried out automatically. Special equipment independently feeds the arc, regulates its length and movement.

The technological process of electric arc welding is also divided into methods:

- In a bun . During welding, several electrodes are bundled together, their ends are welded and installed in a holder. A larger range of currents is used and you can independently increase performance indicators.

- Welding with a lying electrode . During this process, laying can be done with a length of 50 to 120 cm with coating in a cut joint or corner. A copper bar with a longitudinal groove is placed on it. After this, the workpiece and electrode are connected to a current source. The carbon rod ignites an arc that goes under the bar area. It moves along the joint, melts the working element and welds the edge. The result is a welded joint.

- Welding with an inclined electrode . This method is carried out to improve productivity. During this process, the electrode is fixed in a clamp with a holder, which moves under its weight along the stand. At the moment the arc is ignited, the electrode melts and the holder falls down.

Forward and reverse polarity

Melting of the metal for welding occurs under the influence of an arc. It, as noted above, is formed between the surface of the product and the electrode, since they are connected to opposite terminals of the device.

There are two main options for welding, differing from each other in the order of connection and called direct and reverse polarity.

In the first case, the rod is connected to the minus, and the part to the plus. In this case, an increased flow of heat occurs into the metal. As a result, a deep and narrow melting zone is formed.

Direct and reverse polarity.

With reverse polarity, the electrode is connected to the positive, and the product to the negative. In this case, the melting zone is wide and shallow.

The choice of polarity is entirely determined by the product you are working with. Welding can be performed with two types of polarity. When choosing, you should take into account the fact that the element connected to the positive is subject to greater heating.

For example, it is difficult to weld thin metal products due to possible overheating and burning. In this case, the part is connected to the minus. Currents are also selected according to the diameter of the electrode and the thickness of the metal. This data is taken from a special table.

Types of electrodes by purpose

Depending on the metal being welded, the operating mode of the welding machine and electrodes are selected. Different metals require different electrodes, this is called purpose. The purpose is indicated by one letter on the packaging and on the rod itself.

Electrodes marked “U” are used for welding low-alloy and carbon steels. The letter “L” denotes rods used for welding alloyed structural steels, and for high-alloy steels the designation “B” is used. The letter “T” denotes rods for heat-resistant metals, and the letter “H” denotes rods for surfacing.

What is the basis for the reliability of welding: the basics of welding work

Strength is due to plastic deformation, which occurs at the molecular level, because the molecules mutually penetrate into the bodies being welded. This is achieved by heating metals using a welding arc. The classic production method to date is electric arc, when an electron and current are used. But now technologies using laser and ultrasonic radiation are becoming more and more relevant. They actually leave no seam behind. The devices mainly operate on the basis of an inverter, that is, a device that creates alternating voltage.

Purchasing consumables

In addition to equipment, it is necessary to purchase consumables. The main thing is the welder’s mask, which protects his face from possible damage. An attractive option is the “Chameleon”.

The lighting is adjusted automatically, which makes it unnecessary to remove the mask during short breaks in work in order to evaluate the result of work or replace a burnt electrode. The light filter reacts by darkening to changes in the brightness of the electric arc.

In addition to the mask, you need to take care of protecting the body, hands and head by purchasing or selecting a suit, mittens and a hat. Sturdy shoes must be worn. Nothing should be left unprotected.

You will need a hammer to knock down the scale. An ordinary hammer is of little use for this, since it weighs a lot and is inconvenient for beating off slag in hard-to-reach places. A slag hammer is a very useful tool for doing DIY welding work. With its help, you can easily clean the boiled layer before applying the next one on top of it.

To securely fix the parts to be welded, you may need a vice or clamps. A metal brush will help get rid of rust before you begin the actual process.

It is necessary to ensure that there is a container of water near the welding site in case of fire.

Tools and protective equipment

Uniforms and personal protective equipment include:

- welder's mask with a built-in light filter to protect the eyes from bright light and ultraviolet radiation from the arc;

- split-leaf gloves—gaiters to protect hands from splashes of hot metal;

- thick clothing made of non-flammable fabric;

- cap under the mask;

- durable shoes.

- a respirator to protect the respiratory system from generated gases and dust, especially when working with non-ferrous metals.

Tools, materials and equipment you will need:

- Angle grinder (grinder) for cutting workpieces and cleaning seams;

- A set of hand tools - hammers, chisels, pliers, etc.;

- Metal brush for cleaning workpieces;

- Clamps and clamps for connecting workpieces;

- Electrodes.

And finally, the inverter with the included cables and holder.

Video: how to choose a welding inverter

Which electrodes to use

To learn how to weld with electric welding, you need to choose the right consumables. Let's pay attention to the electrical conductor. It can be in the form of wire for semi-automatic machines and is made like sticks with a metal core and winding. For beginners, we recommend taking the second one, they are easier to control. The optimal cross-section diameter is 3 mm. Less will be needed for welding thin-sheet products, more for industrial purposes and powerful equipment.

Step-by-step instructions for beginners

Start by preparing your work area. There should be no flammable or combustible substances nearby. The floor in the room can be concrete or earthen. It is best to weld structures outdoors or in a well-ventilated, large space. There should be fire extinguishing equipment and a first aid kit nearby. Now let's move on to the stages of learning how to learn how to weld with a welding machine.

External inspection of equipment

An external inspection of the welding inverter is carried out by the welder himself before the start of each work shift. During this procedure, the condition of the insulating sheaths of the welding and supply cables is first checked and, if necessary, they are replaced or repaired. Next, the electrode holder and the ground cable clamp are checked, as well as the condition of the plugs and sockets for connecting to the welding inverter. The next step is to inspect the welding control panel for the integrity of toggle switches, switches, buttons and indicators. In addition, the overall dust content of the device is determined and, if necessary, it is cleaned.

Machine modes and welding parameters

Experienced welders know how to weld thin metal by testing a variety of machine settings. As a result, optimal parameters were derived that are well suited for this type of work. Here are the main settings:

| Metal thickness, mm | Current strength, A | Electrode diameter, mm |

| 0.5 | 10 | 1 |

| 1 | 25-35 | 1.6 |

| 1.5 | 45-55 | 2 |

| 2 | 65 | 2 |

| 2.5 | 75 | 3 |

It is important to set the welding current lower than when working with thick plates. This will help avoid burns and leaks. Inverters that allow cooking with alternating voltage but at high frequencies, as well as direct current devices, have proven themselves to be excellent in this area.

If the unit settings allow you to set the starting voltage level, then you should take advantage of this and set a lower value (by about 20%) than the operating current. This will prevent the area from being scorched when starting to ignite the arc and will help to start welding immediately at the joint. If the starting current is not regulated, then you can ignite the electrode on a thick surface and then transfer it to the joint.

Welding thin metal involves working at low currents. To do this, the inverter settings must support the operating values of the ammeter at 10-30 A.

If the minimum adjustable value is higher than these parameters, then it is possible to reduce the current strength with additional resistance in the circuit. For this, a high-carbon steel spring is used, placed between the product and the ground cable.

Installing an additional ballast that reduces the current to the required level will also help.

If the device settings support the pulse mode, then you can use this. Especially thin steel is welded with an intermittent arc. The pulsed current will automatically break the arc, allowing the metal to cool.

How to connect the electrode

Insert it into the holder; it should not wobble. Then connect the two welding cables. They have different markings (plus and minus). A positive charge is applied to the part (using a clamp), and a negative charge to the electrical conductor. This polarity increases the heating of the metal.

In the article we told you how to learn how to weld from scratch yourself.

Use of protective equipment

When carrying out welding work, the greatest danger is the possibility of electric shock, burns from flying drops of molten metal and light exposure to the retina of the eye from the radiation of an electric arc. In addition, mechanical injuries and gases released during the welding process may enter the respiratory tract. Therefore, any novice welder who decides to master a welding inverter, in addition to the machine itself, is required to purchase a set of personal protective equipment, as well as carefully study the safety rules when performing welding work. The standard set of welder protective equipment includes a mask and spark-resistant gloves, as well as overalls and shoes made of non-flammable and non-melting materials. In addition, during welding with an inverter, a special respirator may be required, and the cleaning of workpieces and seams must be done using safety glasses.

Start of welding: light the arc

An electric arc is created independently when polarly charged elements come into contact in two ways:

- by striking - draw a strip along the joint;

- tapping - tap 2-3 times on a place where the mark is not important.

If a spark does not form immediately, you need to cut off the excess winding. We can continue to work.

Incline

Tilt the electrode in your direction at an angle in the range of 30-60 degrees. This ensures good heating of the slag bath. But in some cases this is not necessary, then they use the “backward angle” method, that is, away from themselves, then the seam stretches behind the tip of the protective coating.

How to learn to use welding and determine the speed of movement

You cannot tightly attach an electrical conductor to a metal structure; there should be 2-3 mm between them, this distance is necessary to form a slag bath. How quickly to perform manipulations depends on the voltage and degree of heating; usually this is an individual indicator; it can be determined by the degree of heating and heating upon contact.

Current setting

Correct selection of the current value of the welding inverter is the key to the quality of the weld. In order to select a value corresponding to the thickness of the metal and the diameter of the electrode, it is best for a novice welder to use the corresponding table from the inverter passport. After this, you need to turn on the device’s power switch, and then, by turning the regulator, set the required current value. For some devices, the scale of its values is marked on the front panel of the inverter along the arc of rotation of the regulator, for others it is displayed on a digital indicator (see photo below).

In any case, this will be an approximate value, so it is quite possible that the current strength for good penetration will have to be adjusted during the process of making test welds.

How to weld parts correctly

Before starting the process, you need to create temporary fastenings - ties, rivets. They will allow you not to pull the structure to one side so that it does not deform. Then the seam will be smooth, and the shape will be the way it was intended. Only after this can you begin to take active action.

Current selection

It always depends on the type of metal connections and the electrode. If the voltage in the home network is not enough for the required strength, you can go through two layers or work more slowly to achieve the optimal temperature. Table of correspondence:

| Electrode diameter, mm | Metal thickness, mm | Welding current, A |

| 1,6 | 1-2 | 25-50 |

| 2 | 2-3 | 40-80 |

| 2,5 | 2-3 | 60-100 |

| 3 | 3-4 | 80-160 |

| 4 | 4-6 | 120-200 |

| 5 | 6-8 | 180-250 |

| 5-6 | 10-24 | 220-320 |

| 6-8 | 30-60 | 300-400 |

Making various seams

Depending on their location, the seams can be vertical, horizontal, ceiling, or inclined.

Making a seam:

- prepare the plates;

- turn on the inverter, set the current;

- make a small gap between the plates, create weld pools;

- make a welding connection;

- beat off the slag.

Each seam is made using this algorithm, but in the photo you can see visual differences in the process.

Depending on the design of the connection, the seams can be butt, tee or overlap. You can learn how to make seams experimentally, using detailed photo instructions as a guide. Welding will become beautiful over time. The main thing is to start and try to work with hardware.

Principle of electric arc welding

There are several principles in electric arc welding technology - short circuit and breakdown. It is the last indicator that deserves special attention.

In this case, the basis is the breakdown of the dielectric, which occurs when the interatomic space is filled with particles with an electric charge. Ions create positive charges, and electrons create negative charges. In some situations, breakdown is possible for any dielectric. But as for electric arc welding of metals, during it a breakdown of the air space between the electrode and the mass is used.

During welding, a current charge is created on the electrode with a low voltage, but with high strength - approximately 80-200 A. A huge density is also observed - several thousand A / m2.

At the moment the electrode touches the mass, namely another material with high electrical conductivity when welding metal structures, a short circuit may occur, which creates an electric field with high power. This is where the breakdown occurs.

Common mistakes made by newbies

Arc welding diagram.

Beginner welders tend to make mistakes due to ignorance of the basics regarding the use of welding equipment. For example, beginners may not know how to choose the correct polarity for welding with an inverter, which will lead to poor-quality joint formation or even burning of the part.

The following main errors can be identified:

- neglect of safety precautions;

- incorrect choice of welding machine;

- use of low-quality or unprepared electrodes;

- work without trial seams.

For beginners, it is worth separately noting one feature if you cook Resanta by welding. This equipment is very popular, but it has short connection cables, which can create inconvenience in operation.

Selection of electrodes depending on the type of seam

It is also advisable to select electrodes for manual arc welding according to the type of seam with which you are going to weld metal. In addition to the standard horizontal, vertical, inclined and angled seams, there are also oblique, butt, beveled and many others. This is more useful for experienced welders, but novice welders should also know this information. Now let's talk about what types of electrodes there are for manual arc welding.

conclusions

The task of initial training is completed. We talked about the basic fundamentals and technologies of welding with an inverter for home craftsmen. Let us repeat, everyone has the opportunity to make beautiful, even and high-quality seams. They are obtained only with regular practice and several kilograms of electrodes burned.

Tips for novice welders:

- Before welding, do not forget to use protective equipment. Very important! Do not weld without a mask, leggings and special clothing - a welding suit, the material of which will not be burned by sparks and splashes of hot metal, otherwise you can damage your eyes or get burned in open areas of your body.

- Store electrodes in a dry place. Do not cook with damp electrodes or electrodes with chipped coating. You can dry the electrodes in an electric oven or in a household oven.

- The more you practice and use metal and electrodes, the better your welds will be. Starting with welding a fence made of corrugated sheets, over time, you will move on to more complex work. Welding of arches, greenhouses, sliding and swing gates, gates, canopies over the house, homemade tools and devices that are used in the home workshop.

- Welding is especially useful when building a house if you plan to work with metal structures and use a pipe profile, fittings, angle, channel, etc.

Sources

- https://uniform-met.ru/articles/kak-pravilno-varit-svarkoy-sovety-ekspertov-pravila/

- https://stankiexpert.ru/spravochnik/svarka/kak-pravilno-varit.html

- https://www.rocta.ru/info/kak-nauchitsya-pravilno-varit-svarkoj-ehlektrosvarkoj-v-domashnih-usloviyah/

- https://ru.wikipedia.org/wiki/%D0%A1%D0%B2%D0%B0%D1%80%D0%BA%D0%B0

- https://tutsvarka.ru/vidy/svarka-invertorom-dlya-nachinayushhih

- https://osvarka.com/obuchenie-svarke/kak-pravilno-varit-svarkoy

- https://WikiMetall.ru/metalloobrabotka/svarka-invertorom-dlya-nachinayushhih.html

- https://master-azov.ru/metally/kak-varit-metall-raznoj-tolshchiny.html

- https://stroy-podskazka.ru/svarka/kak-varit/

- https://www.forumhouse.ru/journal/themes/28-pravilnaya-svarka-likbez-dlya-chajnikov-i-sekrety-masterstva