free forging

Website materials about free forging

Free forging: functional features Free forging can be manual or machine. In hand forging, only small forgings are made. This type of forging is used in small repair shops.

Machine forging is the main type of open forging in the field of mechanical engineering.

Open forging technology

To produce forgings of any shape and size, a previously developed technology is required. Thanks to forging, metal is deformed under pressure from a press or a blow from a hammer. Deformation can be plastic or elastic. Plastic differs from elastic in that the first remains under the influence of force, and the second disappears.

The technological process is to increase plasticity by increasing temperature. When the metal is heated, the resistance decreases, which helps to change the shape of the metal.

Basic Open Forging Operations

Basic forging operations: upsetting, piercing, broaching, bending, cutting, forge welding and twisting.

Due to the draft, the height of the workpiece decreases. This process helps to increase the cross-section. In this case, there can be complete (settlement of the entire workpiece) and incomplete settlement (settlement of only one place of the workpiece). Incomplete settlement is often called landing.

Broaching is used to increase the length of the workpiece by reducing its cross-section. The process occurs by compressing the workpiece with hammer blows from its middle to the edges.

Piercing is the operation performed to create a hole in a forging. To do this, the forging is heated, placed over the hole in the anvil and struck by a punch, which is installed on top.

Chopping allows you to divide the forging into parts. The workpiece is cut with a chisel, and then turned 180 degrees and chopped off.

Forge welding is used to hold metal parts together. Certain welding areas are heated to the desired temperature, and then welded in parts and with small blows with a sledgehammer.

Advantages and Disadvantages of Open Forging

The advantage of open forging is its versatility in terms of shapes, weights, and sizes of workpieces. There is also no need to purchase expensive technological equipment. This type of forging allows the use of relatively low-power machines with a concentrated expenditure of forging forces with strikers in a small volume of deformed metal.

Among the disadvantages, it is worth noting low productivity and low metal utilization. The ratio of the weight of the part to the weight of the forging on average reaches 0.65-0.6.

Open Hammer Forging Tool

The use of one or another tool depends on the chosen method of upsetting.

Main methods of precipitation:

- on universal flat strikers,

- on special sedimentary flat or spherical plates

- in rings

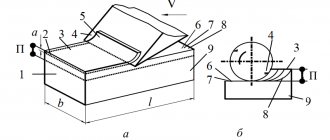

Dimensions of universal flat strikers (Fig. A.1.1)

Metal forging concept

In simple terms, forging is the processing of metal heated to forging temperature. The principle of the technology is based on the physical properties of any material that has a melting point. But before this threshold is reached, the structure of the substance will become softer.

Each metal has its own temperature, upon reaching which it becomes softer, and, therefore, more pliable for processing by forging.

However, there is also a metalworking technology where the workpiece is not heated, but forged cold. This technique allows you to obtain products that are no less durable; without heating, the workpiece is pressed and bent. The table shows the temperature limits at which a particular metal can be forged.

Forging operations using open-die hammers

When free forging under hammers, the same forging operations are used as in hand forging, i.e. cutting, drawing, upsetting, bending, twisting, stitching and punching holes and finishing surfaces. The techniques of forging under hammers are somewhat different from the techniques used in hand forging. We will describe the basic working methods and rules for using forging tools when performing the main types of forging operations using open-die forging hammers. Chopping. Blacksmith axes are used to cut metal under hammers. Metal under hammers is usually cut hot. Metal cutting is carried out at a temperature not lower than 700°. Blanks are cut using hammers in various ways. First way. The heated workpiece 4 is placed on the lower striker 2, the cutting place is marked and the ax 3 is placed on it. Under the impact of the striker, the ax blade cuts into the metal and displaces it in the direction of less resistance, i.e., in the direction 5. The ax will move along line A —B. Having thus chopped the workpiece to the middle, turn it 180°, place the ax at a point opposite the cutting site, and cut off the remaining part with hammer blows. Part 5 of the workpiece will be cut off. With this cutting method, a burr 7 is obtained, which is then cut off using pads or a square. Second way. They chop with an ax and a square. Workpiece 1 is cut through almost all the way through; the blade of ax 2 is not brought slightly to the bottom striker 3 in order to avoid its damage. Then the workpiece is raised a little, square 4 is placed under the notched part; the ax is removed, and the workpiece is cut with a blow from the striker 5. Third way. The workpiece is placed on the striker 5 and cut through from two opposite sides with an ax 2, and a small isthmus is left between the cutting points. Then the ax is inserted with the butt into the cut, and with strikes of the striker 4 on the blade, a narrow isthmus of metal is cut through. The most common and safest method is the second. Burrs formed during cutting must be removed by cutting (notching) using squares and overlays. It is impossible to forge a workpiece with burrs, as this may lead to the formation of pressure in the future. Extraction (broaching). The hood is produced on strikers. With such drawing by the edges of the strikers 3 and 2, almost all of the displaced metal will be used to lengthen the workpiece 1. The same can be obtained if the drawing is done on narrow strikers or through a rolling 4, for which a special rolling (rolling) is placed between the upper striker and the metal, which In this case, it will act as a narrow striker, i.e., accelerate the metal along the length of the workpiece. The most productive hood is considered to be a hood with narrow strikers. In large forges there are hammers with narrow strikers for drawing and with wide strikers for smoothing, that is, leveling the surface of the workpiece after it has been drawn on narrow strikers. The drawing is carried out gradually along the length of the workpiece, usually starting from the middle. Short blanks are pulled from the end. When drawing an ingot, forging begins from the middle so that the defects located at the profit and bottom parts are turned into waste, i.e., into the cut off parts of the ingot - the profit and the pallet. After several blows on one side, the workpiece is turned 90°, that side is forged, then returned to its original position, etc. In this way, the workpiece can be pulled to the required length and to the required cross-section. But it is not always possible to extract the hood in this order. When forging under hammers, the workpiece is cooled from the lower striker faster than from the top, since the upper striker is in contact with the metal only during the impact, and the lower striker during the entire forging time. Uneven cooling of the workpiece (its bottom and top) can cause it to bend - the end of the workpiece will bend. Therefore, it is impossible to rotate the workpiece 90° without disturbing the balance. In this case, the workpiece is turned 180°, i.e., to the opposite side, and stretching is continued until the workpiece straightens; then the workpiece is turned 90 and struck with a hammer on the side. For complete drawing, it is necessary to heat the metal to forging temperature along the entire length of the workpiece. When forging large parts, complete drawing is done in parts; heating of the parts occurs alternately: first one end, and after drawing it out - the other, etc. When local exhaust is needed, local heating is given. You need to pull out the metal with quick and strong blows; in this case, the impacts penetrate deep into the metal; its grains are crushed throughout the entire cross-section. Weak impacts deform only the surface layers of the metal, and the inner layers will be stretched less. As a result, cracks in the metal will appear between the inner and outer layers. The hood is produced on flat cut-out and combined strikers (the upper striker is flat, the bottom is cut-out). Round products are drawn in cut-out dies at a higher speed than in flat ones, since in cut-out dies the metal flows less across the cross section than when forged in flat dies. The productivity of the hood in cut-out strikers is 20-30% higher than the productivity of the hood in flat strikers, while the productivity of the hood in combined strikers is greater than in flat strikers, but less than in cut-out strikers. Draft and disembarkation. Upsetting is an operation in which the cross-sectional area of the workpiece is increased by reducing its height. During upsetting, the metal is stretched, which causes great stress in it. Before upsetting, the workpiece must be heated to a high temperature over the entire cross-section and along the entire length. Upsetting is used in the following cases: 1) when it is necessary to mix up the fibers in the metal or give them a direction that would improve the quality of the product (for example, when forging gears); 2) when a workpiece of a given weight, but of insufficient cross-section, is forged; 3) when it is impossible to obtain the specified quantity from the existing workpiece. When upsetting, it is necessary to ensure that the length of the workpiece is no more than 2.5 times its diameter or the side of the square. If the length of the workpiece is more than 2.5 times the diameter, the workpiece may become distorted during the upsetting process, and it may even fly out from under the strikers. During upsetting, the entire workpiece is heated evenly, then it is placed vertically on the lower striker of the hammer, and under the blows of the upper striker on the end, its cross-section increases due to a decrease in height. During this operation, the workpiece must be constantly rotated around its vertical base. In order for the precipitation process to proceed more intensively, semicircular or oval rolling sheets are used. At the end of the upsetting, an iron strip 3-4 mm thick and 70-80 mm wide is used, after which the forging is ironed under flat strikers. The middle or end of a short workpiece is planted using rings. In order to facilitate the removal of the unplanted end from the ring, a slope of 6-7% is made along the inner diameter of the ring. But you can make a ring without a slope; in this case, the forging is released from the ring using pads and an extension ring. The middle of a short workpiece is also planted using rings. Before planting, the ends of the workpiece are pulled to the required size. Then one end of the workpiece is inserted into the lower ring 3, mounted on the striker 6, and the upper ring 4 is put on the other end. The hammer striker 5 strikes the workpiece 2 and the upper ring 4, and the middle part of the workpiece is landed. To upset the middle part, it is necessary that the walls of the internal hole in one ring have a slope of 6-7%, otherwise it will be very difficult to free the forging from the rings. Punching and sewing holes. Holes in thick blanks are punched under hammers, and this process occurs differently than in hand forging. Instead of a punch, piercing is used. Punching scheme. The workpiece 1 is placed on the lower hammer 2 without any pads or rings. Then piercing 3 is applied to the workpiece and the piercing is driven into the metal by hammer blows on the piercing. Since the workpiece lies tightly on the flat surface of the striker, the metal will flow from under the piercing to the sides, which will cause an increase in the size of the workpiece in diameter (as they say, the forging “gives out”), as well as its warping (bending upward). Then the workpiece is rotated 180°. On the reverse side of the workpiece, a slightly darkened outline will appear from the base of the stitching. The same piercing is installed in this place and driven into the workpiece with hammer blows. When punching a hole on the other side of the workpiece, the metal will be torn out from under the piercing. This torn out piece of metal 4 is called an "otter". To ensure that the piercing does not get stuck in the metal at the beginning of punching, after checking the correct installation and lightly hitting it with striker 6, it is lifted and coal dust is poured into the formed recess. With subsequent impacts, the coal burns, the resulting gases tend to push the piercing out of the hole in the workpiece and thereby facilitate its release from the hole after punching. Another way to release the stitching is using a ring. Place ring 5 on the workpiece in which the piercing is located and lightly strike it with a hammer. The workpiece is unbent and the stitching is released. After punching, a hole of irregular shape is obtained in the workpiece, since the piercing has the shape of a cone. The hole is therefore brought, or, as they say, calibrated, to the required size and shape using conical or barrel-shaped mandrels (gauges). Flexible. It is often necessary to bend the workpiece or part being forged at different angles. When forging under a hammer, the workpiece is clamped between the hammer strikers and, hitting the free end of the workpiece with a sledgehammer, it is bent. In this case, the outer layers of the metal are stretched and the inner layers are compressed. Before bending, local heating is performed, i.e., only the place where the workpiece will be bent is heated. In free forging, whenever possible, bending should be done using backing dies. Bending in backing dies requires much less time, and the dimensions of the forging are more accurate. Backing dies are used when it is necessary to forge a large number of identical products in order to justify the cost of making a backing die. Surface finishing. The forging surfaces are finished by ironing. The forging receives a smooth surface. Forgings are smoothed using smoothers, the design of which depends on the shape of the surface of the forgings. Flat forgings are sometimes smoothed with flat strikers by applying light blows. Ironing is carried out at the end of forging, when the scale has already been knocked down. If heating is necessary for ironing, the resulting scale is removed from the forging. Ironing is the final operation of the forging process, therefore it is combined with checking the dimensions of the forging according to a given drawing. If the forging has a complex and especially asymmetrical shape, then the test is carried out using a template, for which it is placed on the forging; at the same time, you can see how correctly the forging is made or in what places it needs to be corrected. Application of backing stamps. Recently, free forging under hammers and backing dies has become increasingly widespread. The use of backing dies does not require large expenditures, and therefore their production is economically justified when forging even small batches of parts. The main advantage of backing dies is that the flow of metal in them is limited by the walls of the die and the resulting forgings are close in accuracy to stamped ones. This makes it possible to sharply reduce the allowance for machining, which reduces metal consumption and the overall labor intensity of manufacturing the part. In addition, the working conditions of the blacksmith are facilitated, and labor productivity increases by 5-6 times.

REVIEW QUESTIONS 1. What types of strikers are used on hammers during open forging? 2. Tell us about the basic blacksmith tool. 3. What devices are used for placing blanks into the furnace, dispensing blanks and feeding them to the hammer? 4. Tell us about the devices for transporting workpieces. 5. What tool is used to cut metal? 6. What cutting methods do you know? 7. What is the hood used for? 8. Why does the workpiece bend during drawing and how can this deficiency be corrected? 9. Where should you start forging when drawing an ingot? 10. Why is drawing on cut-out strikers more productive than on flat strikers? 11. For what purposes and in what cases is workpiece upsetting used? 12. How should the metal be heated when the workpiece is completely upset? 13. What conditions must the workpiece meet (in terms of size) so that it does not bend during upsetting? 14. What forging tools should be used to carry out the upsetting more intensively? 15. How to land the end of the workpiece? 16. How is the middle of the workpiece planted? 17. How is the end of a long workpiece that cannot be landed under the hammer strikes carried out? 18. How is the end of a short workpiece planted in rings? 19. How is the middle of a short workpiece planted in rings? 20. What is the difference between punching and piercing? 21. How do you make a hole? 22. What is the height of the otter when punching, when making holes? 23. In what cases is firmware used? Punching? 24. How is a workpiece bent under a hammer? 25. How is the surface of the forging finished? 26. Tell us about the use of backing dies.

content .. 91 92 ..

Rolling out

Rollers (Fig. P.1.3 1–5 and 34) are made from steel 40–50. Short handles of small size rollers are made by pulling the ends. Long handles (sometimes up to 2.5 m) are used with inserts made of steel 10–20. A deep hole for the handle is stitched with a punch. Then, using a semicircular chisel around the hole, retreating from its edge by 10–20 mm, a shallow groove is pressed in. The handle, with its pre-thickened end, is inserted into the hole prepared in this way and caulked on all sides using a punch by striking the inner edge of the indicated groove. Another method of attaching handles is also used. In this case, a groove is cut into the specially thickened end of the flat-laid rolling sheet with a depth up to the axis of the rolling sheet and a length of approximately 1.0–1.5 times the thickness of the rolling sheet. Then place the end of the handle flat into the groove and hammer it to the bottom of the groove. After this, forging the thickened end of the rolling to the required size, forge the end of the handle in it.

A rolling sheet, for example, oval (Fig. P.1.3, .3) or shaped (Fig. P.1.3, 5), is placed on the workpiece to be upset so that it covers only part of the upper end surface of the workpiece, and then the upper face presses the rolling sheet into workpiece After this, the rolling sheet is moved and the next pressure is applied, thus subjecting the end surface to processing in parts over several pressures. This process of processing the upsetting workpiece is called distillation. The force transmitted by the upper striker is distributed over a smaller area and is sufficient to upset the entire workpiece in parts. In addition, pressing the rolling material causes an intense flow of metal to the sides of it. Using this, it is possible to significantly reduce the resulting barrel shape during upsetting and, if necessary, obtain a thickened part directly at the end of the workpiece.

Rice. P.1.3. The main tool for machine forging: Rolling sheets: 1 – round; 2 – semicircular; 3 – oval; 4 – rectangular; 5 – shaped; 6 – crimping for round profile; 7 – crimping for a square profile; 8 – cut-out strikers; 9 – inserts of cut-out strikers; 10 – conical mandrel; 11 – cylindrical mandrel; 12 – bracket; 13 – goats; 14 – straight clamping of a round profile; 15 – the same complex profile; 16 and 17 – shaped clamps, stitching; 18 – cylindrical; 19 – conical; 20 – wedge-shaped; 21 – hollow; 22 – cylindrical extension; 23 – hollow extension; 24 – ring; 25 and 26 – barrel-shaped, conical calibration mandrel; 27 – bending stamp; 28 – straight fork; 29 – bent fork, axes; 30 – double-sided; 31 – one-sided; 32 – corner; 33 – shaped; 34 – square

Types of forging

There are main types of metal forging:

- Free.

- Machine.

- Stamping.

Free forging means that the workpieces are not limited to any shape. Or the material will be fixed on one side on the anvil. This technological technique also includes hand forging of metal, when the product is shaped using a sledgehammer or hammer. Open forging is used both for the production of individual products and simply to improve the quality of the material.

When forging the surface of the workpiece, the properties of the metal improve. Large crystals of the material are crushed, the structure becomes more fine-grained and homogeneous. In addition, during forging, the internal shells are welded, strengthening the body of the workpiece.

Machine forging is a more modern processing option. This technology is used in mass, heavy industry. In this case, mechanized hammers (weighing from 40 kilograms to 5 tons), forging machines or presses are used. The weight of blanks and final forgings can sometimes reach several tens of tons.

VIEW Induction heater on AliExpress →

Stamping. This technological technique made it possible to make mass production. When making products, the metal is limited by stamps and, when deformed, receives the desired shape.

Stamping is used in mass production where it is important to obtain a large number of products. Open forging is typically used in small-scale and one-off production.

Equipment and tools

The centuries-long development of this type of metalworking has led to the emergence of a huge number of tools and devices.

But hot forging of metal retained the same technological line as thousands of years ago: heating, fastening, deformation, hardening. When making forged products by hand, they use almost the same sets of tools and equipment that craftsmen have used since the inception of this technology. The list is as follows.

- Blacksmith hearth → VIEW on AliExpress

- Anvil → VIEW on AliExpress

- Ticks.

- Hammer → VIEW on AliExpress

A forge or forge is used to heat the material to the desired temperature. There are many different types of this equipment.

- Stationary and portable.

- Closed and open hearths.

- Fuel or electric.

- Liquid, gas or solid fuel.

- With side air supply nozzles or central lance.

Anvils are massive metal tables where the workpiece is actually formed. They consist of a base, a horn and a casing with holes for bending. There are several varieties of this forging device, but a steel support with a weight of 30 kilograms or more is required.

In hand forging, the craftsman uses pliers to handle the workpiece during the work process.

Hammers, the main tool used in blacksmithing, can have different weights to work with workpieces of different sizes.

Strikers

To prevent them from biting the metal of the workpiece, the edges of the working surfaces of the strikers must be rounded to sufficiently large radii.

Strikers for hammers are usually made forged from steels 50 and 60 or from die steels such as 5ХНТ, 5ХНМ, etc., strikers and plates for presses are cast or forged from steel 35 or 50.

Due to the impact nature of the hammers, the strikers are secured to the dovetail with a wedge and a key, the top striker is directly in the hammer head, the bottom striker is attached to the hammer head or to a transition pad. Due to the fact that the shanks of forging strikers are usually made narrow, the strikers rest not on them, but on the shoulders. The strikers are attached to the movable cross member and the press table with bolts or also on a dovetail. The dimensions of the striker attachment points are indicated in the characteristics of the forging equipment. Moreover, in hammers the inclination of the side faces of the dovetails is usually 5 or 7°.

As noted, billet settlement at h0/d0 > 2.5 is accompanied by longitudinal bending. For a cylindrical workpiece, the direction of longitudinal bending is predetermined by the presence of curvature of its axis before upsetting, the non-parallelism of its bases, the non-parallelism of the strikers, and sometimes the uneven heating of the workpiece. The value of the maximum permissible ratio h0/d0 for settlement under unfavorable conditions is reduced to 2. The limited number of possible longitudinal bending planes for a workpiece with square (only two) and rectangular (only one) cross sections can increase the maximum permissible ratio of the height of the workpiece to its thickness.

A slight longitudinal bend can be corrected by upsetting, in which the upper striker covers only part of the workpiece (Fig. A.1.2).

With a more significant longitudinal bending, a gradual upsetting should be carried out, alternating it with straightening by crimping between flat strikers, for which the workpiece is turned over each time and laid flat on the lower striker.

As the cross-sectional area of the workpiece being upset increases, upsetting becomes increasingly difficult. In this case, the force developed by the forging equipment may be insufficient for upsetting 59 by simultaneous compression of the entire end surface of the workpiece. In such cases, upsetting is performed using rolling pins.