When calculating any electrical networks, such a concept as the cross-sectional area of the conductor is used. This property directly affects the safety and durability of the entire system, so it is important that the calculated cross-sectional area of the electrical conductor matches the actual one. This article will discuss methods for measuring the diameter of a conductor and its cross-section, as well as other options for determining the characteristics of a wire.

How to find out the cable cross-section by appearance

You can determine the cable cross-section without calculations. A factory-made cable must be marked: on its outer sheath the manufacturer, type of cable, number of cores and cross-sectional area of the current-carrying core are stamped with a certain step.

For example, if the cable has the designation VVG-ng-LS 3x2.5, this means that the cable has an outer sheath and core insulation made of non-flammable PVC with no release of hazardous gases during combustion, and also such a cable has 3 conductive cores with a cross-sectional area each conductor 2.5 mm2.

The marking does not always indicate the true value of the core area, since compliance with this parameter remains on the conscience of the manufacturers. This is due to the fact that most manufacturers do not adhere to GOST during production, but are guided by their own specifications when producing cable products, which leads to a free interpretation of cross-section calculation methods and is not properly regulated. Therefore, before using the cable for its intended purpose, it is best to check that its cross-section corresponds to that stated in the marking.

Wire diameter measurement

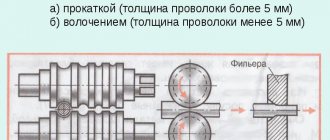

According to the standard, the diameter of the wire must correspond to the declared parameters, which are described in the marking. But the actual size may differ from the declared one by 10-15 percent. This is especially true for cables that are manufactured by small companies, but large manufacturers can also have problems. Before purchasing an electrical wire for transmitting large currents, it is recommended to measure the diameter of the conductor. For this purpose, various methods can be used, differing in error. Before performing measurements, it is necessary to remove insulation from the cable cores.

Measurements can be made directly in the store if the seller allows you to remove the insulation from a small section of the wire. Otherwise, you will have to purchase a small piece of cable and take measurements on it.

Micrometer

Maximum accuracy can be achieved using micrometers that have a mechanical and electronic circuit. On the shaft of the instrument there is a scale with a division value of 0.5 mm, and on the circle of the drum there are 50 marks with a division value of 0.01 mm. The characteristics are the same for all micrometer models.

When working with a mechanical device, the following sequence of actions should be followed:

- By rotating the drum, the gap between the screw and the heel is set close to the measured size.

- Use a ratchet to bring the screw closer to the surface of the part being measured. The eyeliner is performed by rotating the hand without effort until the ratchet operates.

- Calculate the transverse diameter of the part according to the readings on the scales located on the stem and drum. The diameter of the product is equal to the sum of the values on the rod and the drum.

Mechanical micrometer measurement

Working with an electronic micrometer does not require rotation of the units; it displays the diameter value on the liquid crystal screen. It is recommended to check the settings before using the device as electronic devices measure in millimeters and inches.

Vernier caliper

The device has reduced accuracy compared to a micrometer, which is quite sufficient for measuring a conductor. Vernier calipers are equipped with a flat scale (vernier), a circular dial or a digital display on a liquid crystal display.

To measure the transverse diameter, you must:

- Clamp the conductor to be measured between the jaws of the caliper.

- Calculate the value on the scale or view it on the display.

An example of calculating size on a vernier

Ruler

Measuring with a ruler gives a rough result. To perform measurements, it is recommended to use tool rulers, which have greater accuracy. Using wooden and plastic school products will give a very approximate diameter value.

To measure with a ruler you need:

- Remove insulation from a piece of wire up to 100 mm long.

- Wind the resulting piece tightly around a cylindrical object. The turns must be complete, that is, the beginning and end of the wire in the winding are directed in one direction.

- Measure the length of the resulting winding and divide by the number of turns.

Measuring the diameter with a ruler by the number of turns

In the example above there are 11 turns of wire which are about 7.5mm in length. By dividing the length by the number of turns, you can determine the approximate value of the diameter, which in this case is 0.68 mm.

On the websites of stores selling electrical wires, there are online calculators that allow you to calculate the cross-section based on the number of turns and the length of the resulting spiral.

Segment cable cross-section

When working with conductors, it is necessary to understand their designation. There are wires and cables that differ from each other in their internal structure and technical characteristics. However, many people often confuse these concepts.

A wire is a conductor that has in its design one wire or a group of wires woven together and a thin common insulating layer. A cable is a core or a group of cores that has both its own insulation and a common insulating layer (sheath).

Each type of conductor will have its own methods for determining cross sections, which are almost similar.

The amount of energy that a conductor transmits depends on a number of factors, the main one of which is the material of the current-carrying conductors. The following non-ferrous metals can be used as the core material of wires and cables:

- Aluminum. Cheap and lightweight conductors, which is their advantage. They are characterized by such negative qualities as low electrical conductivity, a tendency to mechanical damage, high transient electrical resistance of oxidized surfaces;

- Copper. The most popular conductors, which have a high cost compared to other options. However, they are characterized by low electrical and transition resistance at the contacts, fairly high elasticity and strength, and ease of soldering and welding;

- Aluminum copper. Cable products with aluminum cores coated with copper. They are characterized by slightly lower electrical conductivity than their copper counterparts. They are also characterized by lightness, average resistance and relative cheapness.

Various types of cables according to core material

Important! Some methods for determining the cross-section of cables and wires will depend specifically on the material of their conductor component, which directly affects the throughput power and current strength (method for determining the cross-section of conductors by power and current)

Aluminum cable with sector conductors

In such cases, it is necessary to resort to a table where the size (height, width) of the cable takes the corresponding value of the cross-sectional area. Initially, it is necessary to measure the height and width of the required segment with a ruler, after which the required parameter can be calculated by correlating the obtained data.

Table for calculating the area of an electric cable core sector

| Cable type | Sectional area of the segment, mm2 | ||||||||

| S | 35 | 50 | 70 | 95 | 120 | 150 | 185 | 240 | |

| Four-core segment | V | – | 7 | 8,2 | 9,6 | 10,8 | 12 | 13,2 | – |

| w | – | 10 | 12 | 14,1 | 16 | 18 | 18 | – | |

| Three-core segmental stranded, 6(10) | V | 6 | 7 | 9 | 10 | 11 | 12 | 13,2 | 15,2 |

| w | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | |

| Three-core segmental single-wire, 6(10) | V | 5,5 | 6,4 | 7,6 | 9 | 10,1 | 11,3 | 12,5 | 14,4 |

| w | 9,2 | 10,5 | 12,5 | 15 | 16,6 | 18,4 | 20,7 | 23,8 |

Dependence of current, power and core cross-section

When choosing a cable, you must be guided by several criteria:

- the strength of the electric current that the cable will pass;

- power consumed by energy sources;

- current load exerted on the cable.

Power

The most important parameter during electrical installation work (in particular, cable laying) is throughput. The maximum power of electricity transmitted through it depends on the cross-section of the conductor.

Therefore, it is extremely important to know the total power of the energy consumption sources that will be connected to the wire

Typically, manufacturers of household appliances, appliances and other electrical products indicate on the label and in the documentation accompanying them the maximum and average power consumption. For example, a washing machine can consume electricity ranging from tens of W/h during rinsing mode to 2.7 kW/h when heating water.

The average power of all electrical appliances and lighting devices in an apartment rarely exceeds 7500 W for a single-phase network. Accordingly, the cable cross-sections in the electrical wiring must be selected to this value.

On a note. It is recommended to round the cross-section towards higher power due to a possible increase in power consumption in the future. Typically, the next largest cross-sectional area from the calculated value is taken.

So, for a total power of 7.5 kW, it is necessary to use a copper cable with a core cross-section of 4 mm2, which is capable of transmitting about 8.3 kW. The cross-section of the conductor with an aluminum core in this case must be at least 6 mm2, passing a current power of 7.9 kW.

Marking labels for electrical appliances and household appliances indicating their rated power

Electric current

Often the power of electrical equipment and equipment may not be known to the owner due to the absence of this characteristic in the documentation or completely lost documents and labels. There is only one way out in such a situation - to calculate using the formula yourself.

P = U*I, where:

- P – power, measured in watts (W);

- I – electric current strength, measured in amperes (A);

- U is the applied electrical voltage, measured in volts (V).

When the strength of the electric current is unknown, it can be measured with control and measuring instruments: an ammeter, a multimeter, and a clamp meter.

Measuring current with clamp meters

After determining the power consumption and electric current, you can use the table below to find out the required cable cross-section.

Load

Calculation of the cross-section of cable products based on current load must be carried out to further protect them from overheating. When too much electric current passes through conductors for their cross-section, destruction and melting of the insulating layer can occur.

The maximum permissible long-term current load is the quantitative value of the electric current that can pass the cable for a long time without overheating. To determine this indicator, it is initially necessary to sum up the powers of all energy consumers. After this, calculate the load using the formulas:

- I = P∑*Ki/U (single-phase network),

- I = P∑*Kи/(√3*U) (three-phase network), where:

- P∑ – total power of energy consumers;

- Ki – coefficient equal to 0.75;

- U – electrical voltage in the network.

| Section of cable and wire products | Electrical voltage 220 V | Electrical voltage 380 V | ||

| Current strength, A | power, kWt | Current strength, A | power, kWt | |

| 2,5 | 27 | 5,9 | 25 | 16,5 |

| 4 | 38 | 8,3 | 30 | 19,8 |

| 6 | 50 | 11 | 40 | 26,4 |

| 10 | 70 | 15,4 | 50 | 33 |

| 16 | 90 | 19,8 | 75 | 49,5 |

| 25 | 115 | 25,3 | 90 | 59,4 |

| 35 | 140 | 30,8 | 115 | 75,9 |

| 50 | 175 | 38,5 | 145 | 95,7 |

| 70 | 215 | 47,3 | 180 | 118,8 |

| 95 | 260 | 57,2 | 220 | 145,2 |

| 120 | 300 | 66 | 260 | 171,6 |

Determining the cross-section of a cable product is a particularly important process in which miscalculations are unacceptable. You need to take into account all factors, parameters and rules, trusting only your calculations. The measurements taken must coincide with the tables described above - if they do not contain specific values, they can be found in the tables of many electrical engineering reference books.

How to determine whether the parameters match?

As a rule, extreme care on your part allows you to avoid such incidents during the purchase:

- A normal wire must have its marking, which provides the buyer with all the information about the model, operating features, and parameters. If you encounter questionable products, you may find that the product data is not presented in full or is completely missing.

- If the conductor is really good, he must be provided with quality certificates. The technical documentation indicates that it was not only manufactured in accordance with the ND, but also passed the appropriate tests.

- A good wire cannot cost a penny - since the price of materials is quite high, the cheapness should make you wonder if there is some kind of catch in this. If you wish, you can come to the store with a micrometer or caliper and perform a test to clear your doubts.

Determination of cross-section by diameter

After determining the diameter of the wire, you can begin to calculate the cross-sectional area in squares (mm2). For cables of the VVG type, consisting of three single-core conductors, calculation methods are used using a formula or a ready-made table of diameters and areas. The methods are also applicable to products with other markings.

According to the formula

The main method is to calculate using a formula of the form - S=(n/4)*D2, where π=3.14, and D is the measured diameter. For example, to calculate the area with a diameter of 1 mm, you will need to calculate the value: S=(3.14/4)*1²=0.785 mm2.

Online calculators are available on the Internet that allow you to calculate the area of a circle by diameter. Before purchasing a cable, it is recommended to calculate the values in advance, put them in a table and use it in the store.

The video from user Alexander Kvasha demonstrates checking the cross-section of wire cores.

According to the table with common diameters

To simplify the calculation, it is convenient to use a ready-made table.

The order of using numbers from the table:

- Select the type of wire that you intend to purchase, for example, VVG 3*4.

- Determine the diameter from the table - a section of 4 mm2 corresponds to a diameter of 2.26 mm.

- Check the actual wire diameter. If there is a match, the products can be purchased.

Below is a table of the ratio of cross-sections of the main types of copper wiring to diameters and current (at a voltage of 220 V).

| Wire core diameter, mm | Core cross-section, mm2 | Allowable current, A |

| 1,12 | 1 | 14 |

| 1,38 | 1,5 | 15 |

| 1,59 | 2,0 | 19 |

| 1,78 | 2,5 | 21 |

| 2,26 | 4,0 | 27 |

| 2,76 | 6,0 | 34 |

| 3,57 | 10,0 | 50 |

| 4,51 | 16,0 | 80 |

| 5,64 | 25,0 | 100 |

| 6,68 | 35,0 | 135 |

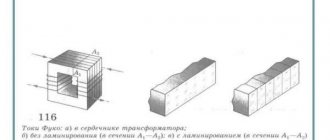

An additional criterion for matching the cross-section to the diameter is the weight of the wire. The method of determining diameter by weight is used when testing thin wire for winding transformers. The thickness of the product starts from 0.1 mm, and it is difficult to measure it with a micrometer.

A brief table of correspondence between vein diameters and weight is given below. Detailed data is available in stores specializing in the sale of electronic components.

| Diameter, mm | Section, mm2 | Weight, g/km |

| 0,1 | 0,0079 | 70 |

| 0,15 | 0,0177 | 158 |

| 0,2 | 0,0314 | 281 |

| 0,25 | 0,0491 | 438 |

| 0,3 | 0,0707 | 631 |

| 0,35 | 0,0962 | 859 |

| 0,4 | 0,1257 | 1,122 |

When calculating the wire diameter for fuses, the conductor material should be taken into account. A brief table of cable diameters from common types of material and current strength is given below.

| Break current, A | Copper | Aluminum | Nikelin | Iron | Tin | Lead |

| 0,5 | 0,03 | 0,04 | 0,05 | 0,06 | 0,11 | 0,13 |

| 1 | 0,05 | 0,07 | 0,08 | 0,12 | 0,18 | 0,21 |

| 5 | 0,16 | 0,19 | 0,25 | 0,35 | 0,53 | 0,60 |

| 10 | 0,25 | 0,31 | 0,39 | 0,55 | 0,85 | 0,95 |

| 15 | 0,32 | 0,40 | 0,52 | 0,72 | 1,12 | 1,25 |

| 25 | 0,46 | 0,56 | 0,73 | 1,00 | 1,56 | 1,75 |

| 50 | 0,73 | 0,89 | 1,15 | 1,60 | 2,45 | 2,78 |

| 100 | 1,15 | 1,42 | 1,82 | 2,55 | 3,90 | 4,40 |

| 200 | 1,84 | 2,25 | 2,89 | 4,05 | 6,20 | 7,00 |

| 300 | 2,40 | 2,95 | 3,78 | 5,30 | 8,20 | 9,20 |

For multi-core cable

The diameter of a multi-core cable is determined by the cross-sectional size of one conductor multiplied by their number. The main problem is measuring the diameter of a thin wire.

An example is a cable consisting of 25 cores with a diameter of 0.2 mm. According to the above formula, the cross-section is equal to: S=(3.14/4)*0.2²=0.0314 mm2. With 25 cores it will be: S=0.0314*25=0.8 mm2. Then, using the correspondence tables, it is determined whether it is suitable for transmitting the current of the required strength or not.

Another way to approximately calculate the current strength is to multiply the diameter of a multi-core cable by an adjustment factor of 0.91. The coefficient provides for a non-monolithic wire structure and air gaps between the turns. The outer diameter is measured with little effort, since the surface is easily deformed and the cross-section becomes oval.

When calculating the segment part of the cable, formulas or table values are used. The table shows the standard values for segment width and height.

| Sectional area, mm2 | 35 | 50 | 70 | 95 | 120 | 160 | 185 | 240 |

| Height/width for three-core monolithic cable, mm | 5,5/9,2 | 6,4/10,5 | 7,6/12,5 | 9/15 | 10,1/16,6 | 11,3/18,4 | 12,5/20,7 | 14,4/23,8 |

| Height/width for three-core cable made of thin cores, mm | 6/10 | 7/12 | 9/14 | 10/16 | 11/18 | 12/20 | 13,2/22 | 15,2/25 |

| Height/width for four-core monolithic cable, mm | No | 7/10 | 8,2/12 | 9,6/14,1 | 10,8/16 | 12/18 | 13,2/18 | No |

Three main ways to determine wire diameter

There are several methods, but each of them is based on determining the diameters of the core with subsequent calculations of the final results.

Method one. Using instruments. Today there are a number of instruments that help measure the diameter of a wire or wire strand. This is a micrometer and caliper, which come in both mechanical and electronic (see below).

This option is primarily suitable for professional electricians who are constantly installing electrical wiring. The most accurate results can be obtained using a caliper. This technique has the advantage that it is possible to measure the wire diameter even on a section of a working line, for example, in a socket.

After you have measured the diameter of the wire, you need to make calculations using the following formula:

It must be remembered that the number “Pi” is 3.14, so if we divide the number “Pi” by 4, we can simplify the formula and reduce the calculation to multiplying 0.785 by the diameter squared.

Method two. We use a ruler. If you decide not to spend money on a device, which is logical in this situation, then you can use a simple proven method for measuring the cross-section of a wire or wire?. You will need a simple pencil, ruler and wire. Strip the core of insulation, wind it tightly onto a pencil, and then use a ruler to measure the total length of the winding (as shown in the figure).

Then divide the length of the wound wire by the number of cores. The resulting value will be the diameter of the wire cross-section.

But the following must be taken into account:

- the more cores you wind on a pencil, the more accurate the result will be; the number of turns should be at least 15;

- press the coils tightly against each other so that there is no free space between them, this will significantly reduce the error;

- take measurements several times (change the measuring side, the direction of the ruler, etc.). Several results obtained will again help you avoid a large error.

Please note the disadvantages of this measurement method:

- You can only measure the cross-section of thin wires, since it will be difficult for you to wind a thick wire around a pencil.

- To begin with, you will need to purchase a small piece of the product before making the main purchase.

The formula discussed above is suitable for all measurements.

Method three. We use the table. In order not to carry out calculations using the formula, you can use a special table that indicates the diameter of the wire? (in millimeters) and conductor cross-section (in square millimeters). Ready-made tables will give you more accurate results and will significantly save your time, which you will not have to spend on calculations.

| Conductor diameter, mm | Conductor cross-section, mm² |

| 0.8 | 0.5 |

| 1 | 0.75 |

| 1.1 | 1 |

| 1.2 | 1.2 |

| 1.4 | 1.5 |

| 1.6 | 2 |

| 1.8 | 2.5 |

| 2 | 3 |

| 2.3 | 4 |

| 2.5 | 5 |

| 2.8 | 6 |

| 3.2 | 8 |

| 3.6 | 10 |

| 4.5 | 16 |

Section calculation

If there is a cable in front of you, the cross-section of which you do not know (there is no marking), then this indicator can be calculated independently using the formula for the area of a circle:

S=πd²/4=0.8d².

That is, you measure the diameter of the core with your own hands using a caliper and insert this indicator into the formula. If the marking on the wire remains, for example, VVG 3x1.5, then this means that you have a three-core wire with a cross-section of 1.5 mm².

But it is also necessary to take into account the fact that wires are different in terms of the material from which they are made. All electrical cables are based on either copper or aluminum. So, copper cables can withstand a higher current load than aluminum cables. In addition, they practically do not oxidize, so when you are faced with a choice, it is best to give preference to the copper option.

There is one more point that needs to be taken into account. This is the method of wiring a power supply circuit. That is, the electrical cable was laid in grooves and plastered, or the wiring was carried out in a corrugated hose, or open electrical wiring was made. What is the difference?

The thing is that internal wiring (hidden) creates conditions under which the wire ends up in a confined space. That is, when heated, it does not give off heat to the air that surrounds it. This means it overheats faster and more. And this, in turn, reduces the service life and creates conditions for rapid failure. That is, in such wiring it is necessary to use wires with a cross-section slightly larger than the nominal one.

Current Density

Gradually, understanding electrical wires, or more precisely, the choice of cable cross-section, we came to another equally important indicator - current density. What it is? Essentially, this is the same current strength, measured in amperes, that passes through a standard cross-section of an electrical wire equal to one millimeter squared

Let's just say that this is a relative value, so it can be used in the formula that determines the diameter of the wire:

d=1.1*√I/Ip, where Ip is the current density.

Now you can calculate the cross-section of the wire by substituting the value of “d” into the area formula. Ultimately we get that S=I/Ip.

But where then can I get the “Ip” readings? These are standard values, depending again on the material from which the wires are made and the type of wiring. The table below shows this relationship.

Area of a circle

| Material | Copper | Aluminum |

| Hidden wiring | 6 A/mm² | 4 |

| Open wiring | 10 | 6 |

As we said above, copper is preferable in this case.

Let's look at one simple calculation example. Input data:

- The wire is copper.

- Open wiring.

- Cable load 2.2 kW.

First, we find the current strength in the electrical circuit: I=P/U=2200 W:220 V= 10 A.

Now we find the cross-section of the wire itself: S=I/Ip=10:10=1 mm², where the second number “10” is selected from the above table. Thus, you can independently calculate all cable cross-sections in each section of the electrical network at home. The main thing is to correctly calculate the power consumption on each loop. And this, as you know, is the total power of all household appliances and lighting bulbs. For example, if you are calculating a kitchen area, you will have to add up the power of all devices, and this is a refrigerator, microwave, coffee maker, electric kettle, hood, blender, and so on, plus lighting. This indicator is indicated on instrument tags and glass lamp housings.

In principle, you can assemble such a table of wire cross-sections for yourself, taking into account all the layouts described above. That is, if you know the power consumption on all electrical circuits, then you can divide the cables into sections depending on their cross-section.

Power of some household electrical appliances

- Firstly, it will simplify installation. That is, you will never get confused where which cable should be laid.

- Secondly, it will be possible to calculate the costs associated with the purchase of wiring, and thereby determine the repair budget.

- Thirdly, the table will help in the future. If the power consumption does not change over the years, then you will not need to do all the calculations again. It is enough to get a table and remember what cross-section the cable is and where it was laid.

Selection of conductor cross-section by power and length

The length of the conductor determines the voltage supplied to the end point.

A situation may arise when the voltage at the point of consumption is insufficient to operate electrical appliances. In household electrical communications, these losses are neglected and a cable is used ten to fifteen centimeters longer than necessary. This surplus is spent on switching. When connected to a distribution board, the reserve is increased, taking into account the need to connect circuit breakers.

Cable laid in a closed waySource kadetbrand.ru

When laying long lines, one should take into account the inevitable voltage drop. Everyone has their own resistance, which is influenced by three main factors:

- Length measured in meters. As this indicator increases, losses increase.

- Cross section, measured in square millimeters. If this parameter is increased, the voltage drop decreases.

- The resistance of the conductor material, the value of which is taken from the reference data. They show the reference resistance of a wire with a cross-section of one millimeter and a length of one meter.

The product of resistance and current numerically represents the voltage drop. This value should not exceed five percent. If it exceeds this figure, then it is necessary to take a conductor with a larger cross-section.

More information on how to calculate cable cross-section in the video:

Section calculation using formulas

The selection algorithm is as follows:

The conductor area along the length and maximum power is calculated using the formula:

Source infopedia.su

Where:

P – power;

U – voltage;

cosф – coefficient.

For household electrical networks, the coefficient value is equal to one. For industrial communications, it is calculated as the ratio of active power to total power.

- The PUE table contains the current cross section.

- Wiring resistance is calculated:

Source textarchive.ru

Where:

ρ – resistance;

l – length;

S – cross-sectional area.

At the same time, do not forget that the current moves in both directions and in fact the resistance is equal to:

Source textarchive.ru

The voltage drop corresponds to the relationship:

Source moypatent.ru

In percentage terms, the voltage drop is as follows:

Source tex.stackovernet.com

If the result exceeds five percent, then the nearest cross section with a larger value is searched in the directory.

Such calculations are rarely performed by generic electricity consumers. There are specialized specialists and a lot of reference material for this. Moreover, there are many online calculators on the Internet, with the help of which all calculations can be made in a couple of clicks.

Visually calculate the cable cross-section using the formulas in the video:

Different ways: how to determine the wire cross-section

A conductor is often referred to by two different words – wire and cable. This mixture is very inconvenient. In everyday life, these concepts are often confused, although there are some significant differences in the operation of these devices. In order to correctly determine and correctly find out the cross-sectional area, it is necessary to understand the differences between these conductors and understand a more or less accurate definition.

A conductor consists of a group of cores that are enclosed in separate insulation or in common insulation. The cores come in different types, usually woven or solid, depending on the wire model. Their diameter is measured both with a regular ruler and with a special device - a caliper. As a rule, conductors are made of various non-ferrous metals.

Typically the materials are as follows:

- Copper;

- Aluminum;

- Aluminum copper – (this is an alloy of aluminum and copper specially developed by scientists).

All these materials are distinguished by a relatively low price, low electrical resistance, fairly high electrical conductivity, ease of welding and installation

Another important characteristic is the minimal weight of the metal wire. The methods for finding the cross-sectional area of the above conductors are almost the same, and measuring it is not difficult at all

Calculation of the cross-section of electrical wiring according to the power of connected electrical appliances

To select the cross-section of cable wire cores when laying electrical wiring in an apartment or house, you need to analyze the fleet of existing electrical household appliances from the point of view of their simultaneous use. The table provides a list of popular household electrical appliances indicating the current consumption depending on the power.

You can find out the power consumption of your models yourself from the labels on the products themselves or data sheets; often the parameters are indicated on the packaging. If the current consumed by an electrical appliance is not known, it can be measured using an ammeter.

Typically, the power consumption of electrical appliances is indicated on the housing in watts (W or VA) or kilowatts (kW or kVA). 1 kW=1000 W.

Table of power/current consumption of household electrical appliances

| electrical appliance | Power consumption, W | Current strength, A |

| Washing machine | 2000 – 2500 | 9,0 – 11,4 |

| Jacuzzi | 2000 – 2500 | 9,0 – 11,4 |

| Electric floor heating | 800 – 1400 | 3,6 – 6,4 |

| Stationary electric stove | 4500 – 8500 | 20,5 – 38,6 |

| microwave | 900 – 1300 | 4,1 – 5,9 |

| Dishwasher | 2000 – 2500 | 9,0 – 11,4 |

| Freezers, refrigerators | 140 – 300 | 0,6 – 1,4 |

| Electric meat grinder | 1100 – 1200 | 5,0 – 5,5 |

| Electric kettle | 1850 – 2000 | 8,4 – 9,0 |

| Electric coffee maker | 630 – 1200 | 3,0 – 5,5 |

| Juicer | 240 – 360 | 1,1 – 1,6 |

| Toaster | 640 – 1100 | 2,9 – 5,0 |

| Mixer | 250 – 400 | 1,1 – 1,8 |

| Hairdryer | 400 – 1600 | 1,8 – 7,3 |

| Iron | 900 –1700 | 4,1 – 7,7 |

| Vacuum cleaner | 680 – 1400 | 3,1 – 6,4 |

| Fan | 250 – 400 | 1,0 – 1,8 |

| TV | 125 – 180 | 0,6 – 0,8 |

| Radio equipment | 70 – 100 | 0,3 – 0,5 |

| Lighting devices | 20 – 100 | 0,1 – 0,4 |

Current is also consumed by the refrigerator, lighting fixtures, radiotelephone, chargers, and TV in standby mode. But in total this power is no more than 100 W and can be ignored in calculations.

If you turn on all the electrical appliances in the house at the same time, you will need to select a wire cross-section capable of passing a current of 160 A. You will need a finger-thick wire! But such a case is unlikely. It’s hard to imagine that someone is capable of grinding meat, ironing, vacuuming and drying hair at the same time.

Calculation example. You got up in the morning, turned on the electric kettle, microwave, toaster and coffee maker. The current consumption will accordingly be:

7 A + 8 A + 3 A + 4 A = 22 A

Taking into account the switched on lighting, refrigerator and, in addition, for example, a TV, the current consumption can reach 25 A.

Selecting a wire cross-section for connecting electrical appliances to a three-phase 380 V network

When operating electrical appliances, for example, an electric motor, connected to a three-phase network, the consumed current no longer flows through two wires, but through three and, therefore, the amount of current flowing in each individual wire is somewhat less. This allows you to use a smaller cross-section wire to connect electrical appliances to a three-phase network.

To connect electrical appliances to a three-phase network with a voltage of 380 V, for example an electric motor, the wire cross-section for each phase is taken 1.75 times less than for connecting to a single-phase network of 220 V

Attention, when choosing a wire cross-section for connecting an electric motor based on power, you should take into account that the nameplate of the electric motor indicates the maximum mechanical power that the motor can create on the shaft, and not the electrical power consumed

For example, you need to connect an electric motor that consumes power from a 2.0 kW network. The total current consumption of an electric motor of such power in three phases is 5.2 A. According to the table, it turns out that a wire with a cross-section of 1.0 mm2 is needed, taking into account the above 1.0 / 1.75 = 0.5 mm2. Therefore, to connect a 2.0 kW electric motor to a three-phase 380 V network, you will need a three-core copper cable with a cross-section of each core of 0.5 mm2.

It is much easier to choose the wire cross-section for connecting a three-phase motor based on the current consumption, which is always indicated on the nameplate. For example, the current consumption of a 0.25 kW motor for each phase at a supply voltage of 220 V (the motor windings are connected in a delta configuration) is 1.2 A, and at a voltage of 380 V (the motor windings are connected in a star configuration) it is only 0.7 A.

Taking the current strength indicated on the nameplate, according to the table for selecting the wire cross-section for apartment electrical wiring, we select a wire with a cross-section of 0.35 mm2 when connecting the electric motor windings in a “triangle” pattern or 0.15 mm2 when connecting in a “star” pattern.

How to determine

There are several ways to determine this value of an electrical wire. There are formulas that can be used to calculate a parameter or tables that contain all the values of common standard conductors. Knowing one parameter, for example, the diameter of the core, its current-carrying capacity, you can also find out the cross-section. Other methods of determination are:

- according to the formula through the diameter - S=π*R², where R is ½ the diameter (d), and π=3.14;

- measuring instrument - micrometer;

- using a caliper;

- when using a pencil or pen;

- ruler based on diameter.

A micrometer, as well as a caliper, helps to determine the most accurate diameter, and then, based on it, calculate the cross-section using the formula: S= d*d*d/4, the result will be in mm². Using tools, conductive elements of a circular cross-section are measured, but they are quite expensive and therefore it is not practical to buy them for one time.

To determine using a pen or pencil (a marker, felt-tip pen, etc. are suitable), first cut off the insulation. Then the core is tightly wound around the writing instrument along its entire length. Then measure the length of the winding with a ruler and divide it by the number of turns to find out the diameter. The more turns are made, the more accurate the calculation. When the diameter has become known, the cross-section is calculated using a special formula.

You can calculate this parameter using only a ruler, but the core must be thick enough. The diameter is determined with thread or thin paper - for greater accuracy. A strip is torn from the sheet and folded on one side. The paper is then wrapped around the core until it touches the strip. At the joint, bend it again and apply it to a ruler for measurement. The same applies to thread. The diameter is calculated using the formula: d=l/2π, where l is the length of the paper or thread. Then they use the standard calculation - S=π*R² to determine R, d (diameter) divided by 2.

We measure the cross-section of wires depending on the diameter

The cross-section of a cable or other types of conductors is determined in several ways. The main thing is to take care of preliminary measurements. To do this, it is recommended to remove the top layer of insulation.

About measuring instruments, description of the process

Calipers and micrometers are the main tools that help in measurements. Most often, preference is given to devices of the mechanical group. But it is also permissible to choose electronic analogues. Their main difference is digital special screens.

Electronic caliper

Vernier calipers are among the tools found in every household. Therefore, it is often chosen when measuring the diameter of wires and cables. This also applies to cases where the network continues to operate - for example, inside an outlet or panel device.

The following formula helps determine the cross-section based on the diameter:

S = (3.14/4)*D2.

D is a letter indicating the diameter of the wire.

If there is more than one core in the structure, then measurements are carried out for each of the component elements separately. After this, the results obtained are added to each other.

Then everything can be calculated using the following formula:

Stotal= S1+ S2+…

Stotal is an indication of the total cross-sectional area.

S1, S2 and so on are the cross sections defined for each of the cores.

It is recommended to measure the parameter at least three times to ensure accurate results. The conductor is turned in different directions every time. The result is an average value that is as close as possible to reality.

A regular ruler can be used if a caliper or micrometer is not at hand. The following manipulations are expected to be performed:

- Complete cleaning of the insulation layer near the core.

- Winding the turns around the pencil, as tightly as possible to each other. The minimum number of such components is 15-17 pieces.

- The winding is measured by its overall length.

- The final value is divided by the number of turns.

The accuracy of the measurement is questionable if the turns do not fit evenly on the pencil, leaving gaps of certain sizes. To ensure higher accuracy, it is recommended to measure the product from different sides. It is difficult to wind thick strands onto regular pencils. It is still better to use calipers.

The cross-sectional area of the wire is calculated using the formula described earlier. This is done after completing the main measurements. You can rely on special tables.

The micrometer is recommended to be used in cases where the composition contains ultra-thin conductors. Otherwise, there is a high probability of mechanical damage.

Table of correspondence of wire diameters and their cross-sectional area

Conditions for working with a table of cable cross-sections by diameter

The cable cross-section tables differ in some characteristics from the wire data, but the main characteristics and concepts are still the same - diameter and area. The calculation and its principle are not particularly different. In addition, the cable cross-section table invariably contains the following characteristics, for example, power, current, resistance of a particular material (copper or aluminum).

It should also be remembered that over time, the load can increase significantly for various reasons independent (including) from the owner of the apartment. In order not to create a fire hazard in your own apartment, it is advisable to select wires together with a qualified installation specialist, and to install these wires/cables and connections together with them.

Of course, the data provided in this table is adequate to reality only if certain conditions are met:

- The air temperature is slightly less than or equal to, for example, +30 ᵒC (it is clear that the temperature is different for each table, usually additional conditions are specified).

- The network voltage is 220 V.

- The wire is three-core, with general insulation.

- Separate grounding.

- Laying in a closed space - in the air or in a box.

There are also other conditions that it is advisable not to neglect in order to avoid dangerous and difficult situations associated with equipment failure or a threat to the safety (life and health) of people.

Section and installation method

Another factor that influences the choice of conductor cross-section is the method of laying the lines. There are two of them:

- open;

- closed.

In the first method, the wiring is placed in a special box or corrugated pipe and is located on the wall surface. The second option involves embedding the cable inside the decoration or main body of the walls.

Here the thermal conductivity of the environment plays a major role. In the ground, heat is removed from the cable better than in air. Therefore, with the closed method, wires with a smaller cross-section are taken than with the open method. The table below shows how the laying method affects the cross-section of the conductor.

Laying method and conductor cross-section Source m-strana.ru

Determining the size of the cable cross-section

Cables can be either single-core or multi-core. In the second case, it is best to determine the diameter of each individual core. Also, the core can be single-wire or consist of many wires. Regardless of the type of cable, you can determine its cross-section by diameter.

However, do not forget that “it’s also written on the fence” and it is best to carry out all the necessary measurements yourself when choosing a wire. Fortunately, carrying them out is not that difficult. Determining the actual wire diameter is possible using available tools. Such tools include a micrometer and a caliper.

Micrometer measurement

The most accurate method for measuring diameter is using a micrometer. For such a measurement, you need to take a conductor and move the measuring screw to it until the characteristic ratcheting sound appears. The exact diameter value consists of two values: on the micrometer rod and on the drum.

Measuring with a caliper

You can also measure the cable diameter using a common tool such as a caliper. To do this, you need to clamp the wire to be measured between the jaws of the meter and read the exact value from a special scale.

Measuring with a ruler

The least accurate type of measurement is using a simple ruler. However, in this case, accuracy can be achieved by measuring a large number of turns. The procedure for measuring with a ruler:

- A conductor is wound around a certain rod over a certain distance.

- The length of the wrapped section of the rod is measured with a ruler.

- The resulting value is divided by the number of turns.

This method still has a certain accuracy due to the reduction in error.

Next, you can determine the cable cross-section by diameter. This can be done using the formula:

S = π*D2/4

where D is the measured diameter of the wire.

On this topic:

BACK FORWARD 1 of 2

The skill of independently calculating the conductor cross-section will help you avoid all sorts of problems in the future, as well as deception on the part of the product supplier.

Tables and norms

Another very common method for determining the wire cross-section by diameter is the use of standardized tables that list all the most common and widely used cable cross-sections.

The procedure for selecting the wire cross-section according to the table:

- First you need to decide on the type of cable.

- Next, we find the diameter we need in the table.

- We determine the appropriate section.

- If necessary, we independently check the indicators using the methods described above and make a decision on purchase.

Table of wire cross-sections by diameter.

| Wire core diameter, mm | Core cross-section, mm2 |

| 1,12 | 1 |

| 1,38 | 1,5 |

| 1,59 | 2,0 |

| 1,78 | 2,5 |

| 2,26 | 4,0 |

| 2,76 | 6,0 |

| 3,57 | 10,0 |

| 4,51 | 16,0 |

| 5,64 | 25,0 |

| 6,68 | 35,0 |

The table relating wire cross-section and diameter shows that the formula described above is very fair. The cross-section values given in the proposed table are calculated precisely from it with certain permissible roundings.

So, we already know how to independently find out the wire cross-section. All that remains is to put the acquired knowledge to good use.

When purchasing a cable, you can ask the seller to strip a small section of the wire in order to carry out all the necessary manipulations to measure the product. However, practice shows that not many sellers take such a step. Then the only solution is to first purchase a small section of cable needed for measurements. But after all doubts have disappeared, you can purchase as much wire as you need. Still, the not most joyful fact is that truly attentive buyers often choose a cable with a larger cross-section. After all, in reality they turn out to be somewhat smaller than the formal sizes.

Features of self-calculation

Independent calculation of the longitudinal section is performed on a core without an insulating coating. A piece of insulation can be moved or removed on a piece purchased specifically for testing. First you need to determine the diameter and find the cross section using it. Several methods are used for the work.

Using a caliper

The method is justified if the parameters of a truncated or defective cable are measured. For example, VVG may be designated as 3x2.5, but in fact be 3x21. Calculations are made as follows:

- The insulating coating is removed from the conductor.

- The diameter is measured with a caliper. You will need to place the wire between the legs of the instrument and look at the scale markings. The integer value is on top, the decimal value is on the bottom.

- Based on the formula for finding the area of a circle S = π (D/2)2 or its simplified version S = 0.8 D², the cross section is determined.

- The diameter is 1.78 mm. Substituting the value into the expression and rounding the result to hundredths, we get 2.79 mm2.

For domestic purposes, you will need conductors with a cross section of 0.75; 1.5; 2.5 and 4 mm2.

Using a ruler and pencil

Calculating PS using a ruler and pencil

If you don't have a special meter, you can use a pencil and ruler. Operations are performed with the test image:

- An area of 5-10 cm is cleared of the insulating layer.

- The resulting wire is wound around a pencil. Full turns are laid tightly, there should be no space between them, the “tails” are directed up or down.

- Ultimately, a certain number of turns should be obtained; they need to be counted.

- The winding is applied to the ruler so that the zero division coincides with the first winding.

- The length of the segment is measured and divided by the number of turns. The resulting value is the diameter.

- For example, it turned out 11 turns, which occupy 7.5 mm. When dividing 7.5 by 11, 0.68 mm is the cable diameter. The cross section can be found using the formula.

The accuracy of the calculations is determined by the density and length of the winding.

Table of correspondence between wire diameter and cross-sectional area

If it is not possible to test the diameter or make a calculation when purchasing, you can use a table. The data can be photographed, printed or transcribed, and then used to find the standard or popular core size.

| Cable diameter, mm | Conductor cross-section, mm2 |

| 0,8 | 0,5 |

| 0,98 | 0,75 |

| 1,13 | 1 |

| 1,38 | 1,5 |

| 1,6 | 2 |

| 1,78 | 2,5 |

| 2,26 | 4 |

| 2,76 | 6 |

| 3,57 | 10 |

When purchasing an electrical cable, you will need to look at the parameters on the label. For example, VVNG 2x4 is used. The number of cores is the value after “x”. That is, the product consists of two elements with a cross section of 4 mm2. Based on the table, you can check the accuracy of the information.

Most often, the cable diameter is smaller than stated on the package. The user has two options - use a different one or choose a cable with a larger cross-sectional area in diameter. Having chosen the second one, you will need to check the insulation. If it is not solid, thin, or varies in thickness, choose products from another manufacturer.

Formula: how to determine cable cross-section

The concept of cross-sectional area, or, in common parlance, cable thickness is an interesting thing. It is determined by a device called a caliper. First, using this device, you need to calculate the diameter of the conductor (of course, previously cleared of insulation).

Then you should find the cable area using the formula S = π (D/2)2, in this formula:

- S is the cross-sectional area of a stranded or solid conductor, which is expressed in mm2.

- π = 3.14 (the banal, well-known number Pi).

- D is the diameter of the electrically conductive cable core, expressed in mm.

Conversion to other units of measurement or to the SI system is optional. You can also write this formula in abbreviated form: S = 0.8 D² (the area is equal to the product of 0.8 and the square of the diameter). In this case, 0.8 D² is a rounded factor. In fact, calculating the cross-sectional area and the ratio of different parameters of the conductor is not at all difficult.

By the way, it is very convenient to measure the cross-sectional area with a micrometer or use a calculator.

Of course, it will not give an exact number, like 16mm2, but it will make the calculations much easier. Watching a video about this is quite boring, but it can be quite useful, especially if you decide to do home renovations yourself (this is not a very good idea, but your apartment is your rules).

Cross-sectional area as an electrical quantity

The conductivity of the wire depends on the cross-section.

As an example of the cross-section, you can consider cutting the product at an angle of 90 degrees relative to the transverse axis. The outline of the resulting figure is determined by the configuration of the object. The cable looks like a small pipe, so when cut it will come out in the form of two circles of a certain thickness. When a round metal rod is cut transversely, the shape of a circle is obtained.

In electrical engineering, the PS area will mean the rectangular cross-section of the conductor in relation to its longitudinal part. The cross-section of the cores will always be round. The parameter is measured in mm2.

Novice electricians may confuse the diameter and cross-section of elements. To determine what cross-sectional area the core has, you need to take into account its round shape and use the formula:

S = πxR2, where:

- S – area of the circle;

- π – constant value 3.14;

- R is the radius of the circle.

If the area indicator is known, it is easy to find the resistivity of the manufacturing material and the length of the wire. Next, the current resistance is calculated.

For convenience of calculations, the initial formula is transformed:

- The radius is ½ the diameter.

- To calculate area, π is multiplied by D (diameter) divided by 4, or 0.8 multiplied by 2 diameters.

When calculating, use the diameter indicator, since its incorrect selection can cause overheating and ignition of the cable.

How to calculate the cross-section of a copper wire and determine the load on the cable

| Max. power, kWt | Max. load current, A | Wire cross-section, mm2 | Circuit breaker current, A |

| 4.5 | 4-6 | ||

| 9.1 | 1.5 | ||

| 13.6 | 2.5 | ||

| 18.2 | 2.5 | ||

| 22.7 | |||

| 27.3 | |||

| 31.8 | |||

| 36.4 | |||

| 40.9 | |||

| 45.5 | |||

| 50.0 | |||

| 54.5 | |||

| 59.1 | |||

| 63.6 | |||

| 68.2 | |||

| 72.7 | |||

| 77.3 |

This table shows the data for the following case.

— Single phase, voltage 220 V

— Ambient temperature 30 C

— Laying in the air or in a box (in a closed space)

— Three-core wire, in general insulation (cable)

— The most common TN-S system with a separate ground wire is used

— The consumer reaching maximum power is an extreme but possible case. In this case, the maximum current can operate for a long time without negative consequences.

If the ambient temperature is at least 20 C higher, or if there are several cables in the bundle, it is recommended to select a larger cross-section.

It is also important to know what kind of wire you are buying. Some manufacturers underestimate the cross-section of the cable cores to save money and time

There are a number of companies making such wires (I will not list them).

But there are also those who make high-quality, but expensive wires

This is worth paying maximum attention to

In the process of determining the cross-section of the wire by diameter, it is necessary to pay attention to the metal of the core. Copper or aluminum conductor is characterized by a bright, rich color

If the color is in doubt, then we can conclude that the quality is low. Most likely, the manufacturer simply saved on metal by using a metal alloy for manufacturing.

The alloy is dangerous for installation work, because the rated load and current conductivity are lower compared to the original product.

- To accurately determine the cross-sections of the wires, look at the cores. With normal thickness of products, a situation is possible where a decrease in the size of the core is compensated by an increase in the insulation layer.

- Experts advise purchasing a wire with a larger cross-section. It is worth considering that the power reserve cannot damage the quality and performance of the electrical wiring.

- The calculation changes if we are talking about a cable, since it consists of several wires. To obtain the most accurate indicators, you need to determine the diameter of each wire, then sum the resulting values.

There are different ways to determine the cross-section of a wire by diameter. Experienced electricians can determine this value in a matter of minutes. Beginners are advised to choose the method that is closest and clearest to you.

Pivot table

There are tables that allow you to determine the required cross-section using several parameters at once - current, power, conductor material, and so on. They are more convenient to use and one of them is located below. It indicates the cross-section of the wire in terms of current and power, and also takes into account the installation method.

Wire cross-section by current and power - table for copper and aluminum conductorsSource tvz2.ru

Perhaps the article came out a little boring and full of technical terms. However, the information contained in it should not be neglected. Since the reliability and safety of the functioning of the home electrical network depends on how correctly the wiring was chosen.

Device recommendations

The wiring device, among other things, requires design skills, which not everyone who wants to do it has. It is not enough to just have good electrical installation skills. Some people confuse design with drawing up documentation according to some rules. These are completely different things. A good project can be written out on pieces of paper from a notebook.

First of all, draw a plan of your premises and mark future sockets and lamps. Find out the power of all your consumers: irons, lamps, heating devices, etc. Then enter the power of the loads most frequently consumed in different rooms. This will allow you to choose the best cable options.

You will be surprised how many opportunities there are and what reserves there are for saving money. Once you have selected your wires, count the length of each line you draw. Put everything together, and then you will get exactly what you need, and as much as you need.

Each line must be protected by its own circuit breaker (circuit breaker), designed for a current corresponding to the permissible power of the line (the sum of the consumer powers). Label the machines located in the panel, for example: “kitchen”, “living room”, etc.

It is advisable to have a separate line for all lighting, then you can easily repair the socket in the evening without using matches. It is the sockets that are most often overloaded. Provide outlets with enough power - you don't know in advance what you'll have to plug into them.

In damp rooms, use only double-insulated cables! Use modern sockets (“Euro”) and cables with grounding conductors and connect the grounding correctly. Bend single-core wires, especially copper ones, smoothly, leaving a radius of several centimeters. This will prevent them from breaking. In cable trays and channels, the wires should lie straight, but freely; in no case should they be pulled like a string.

There should be a few extra centimeters in sockets and switches. When laying, you need to make sure that there are no sharp corners anywhere that could cut the insulation. It is necessary to tighten the terminals tightly when connecting, and for stranded wires this procedure should be repeated; they have a tendency for the cores to shrink, as a result of which the connection may become loose.

Copper wires and aluminum wires are not “friendly” with each other for electrochemical reasons; they cannot be connected directly. To do this, you can use special terminal blocks or galvanized washers. The joints must always be dry.

Phase conductors should be white (or brown), and neutrals should always be blue. Grounding is yellow-green in color. These are generally accepted color rules and commercial cables, as a rule, have internal insulation in exactly these colors. Compliance with colors increases the safety of operation and repair.

We bring to your attention an interesting and educational video on how to correctly calculate the cable cross-section by power and length:

The choice of wire cross-section is the main element of a power supply project of any scale, from a room to large networks. The current that can be taken into the load and power will depend on this. Choosing the right wires also ensures electrical and fire safety and keeps your project budget-friendly.

Often, before purchasing cable products, there is a need to independently measure its cross-section in order to avoid deception on the part of manufacturers, who, due to savings and setting a competitive price, may slightly underestimate this parameter.

Variety of cable products and wires

It is also necessary to know how the cable cross-section is determined, for example, when adding a new energy-consuming point in rooms with old electrical wiring that does not have any technical information. Accordingly, the question of how to find out the cross-section of conductors always remains relevant.

About choosing a cable brand for home wiring

Making apartment electrical wiring from aluminum wires at first glance seems cheaper, but operating costs due to low reliability of contacts over time will be many times higher than the costs of electrical wiring made from copper.

It is recommended to make wiring exclusively from copper wires! Aluminum wires are indispensable when laying overhead electrical wiring, as they are light and cheap and, when properly connected, serve reliably for a long time.

Which wire is better to use when installing electrical wiring, single-core or stranded? From the point of view of the ability to conduct current per unit of cross-section and installation, single-core is better. So for home wiring you only need to use solid wire.

Stranded allows multiple bends, and the thinner the conductors in it, the more flexible and durable it is. Therefore, stranded wire is used to connect non-stationary electrical appliances to the electrical network, such as an electric hair dryer, an electric razor, an electric iron and all the others.

After deciding on the cross-section of the wire, the question arises about the brand of cable for electrical wiring. The choice here is not great and is represented by only a few brands of cables: PUNP, VVGng and NYM.

PUNP cable since 1990, in accordance with the decision of Glavgosenergonadzor “On the ban on the use of wires such as APVN, PPBN, PEN, PUNP, etc., produced according to TU 16-505. 610-74 instead of APV, APPV, PV and PPV wires according to GOST 6323-79*" is prohibited for use.

Cable VVG and VVGng - copper wires in double polyvinyl chloride insulation, flat shape. Designed for operation at ambient temperatures from −50°С to +50°С, for wiring inside buildings, outdoors, in the ground when laid in tubes. Service life up to 30 years.

The letters “ng” in the brand designation indicate the non-flammability of the wire insulation. Two-, three- and four-core wires are available with core cross-sections from 1.5 to 35.0 mm2. If in the cable designation there is a letter A (AVVG) before VVG, then the conductors in the wire are aluminum.

The NYM cable (its Russian analogue is the VVG cable) with round copper cores with non-flammable insulation, complies with the German standard VDE 0250. Technical characteristics and scope of application are almost the same as the VVG cable. Two-, three- and four-core wires are available with core cross-sections from 1.5 to 4.0 mm2.

As you can see, the choice for laying electrical wiring is not large and is determined depending on what shape the cable is more suitable for installation, round or flat. A round-shaped cable is more convenient to lay through walls, especially if the connection is made from the street into the room. You will need to drill a hole slightly larger than the diameter of the cable, and with a larger wall thickness this becomes relevant. For internal wiring, it is more convenient to use a VVG flat cable.

Table of wire sections and diameters

Sometimes, instead of fiddling with wires with a ruler, it is much easier to use ready-made tables. One of them will be given below with some abbreviation. In such a table, the left column will indicate the specific diameter of the wire strands, and the right column will indicate the cross-section of the conductor in square millimeters.

Section definition:

- 0.8 mm2 – 0.5;

- 1 mm2 – 0.75;

- 1.1 mm2 – 1;

- 2.28 mm2 – 6;

- 3.2 mm2 – 8;

- 4 mm2 – 8.3.

The table above is far from complete. In total there are about 10-12 lines in it, and each of its meanings can easily be found in a store. The most accurate information on each specific type of wires and cables will be provided upon request by a sales consultant in a household appliances or electrical goods store.

The following characteristics may also be useful. For example, the table may also indicate whether the wire is laid open, how many wires are in one connection and what exactly they are, for example, 2, 3, 4 single-core or 1 two-wire, 1 three-wire.

These points are also very important, which is why, when planning to install a wire and calculate its cross-sectional area, such details should still be clarified and measured for the sake of peace of mind and comfort. An error threatens the failure of all electronics (TVs, desktop computers, refrigerators, electricity and even washing machines), as well as a fire hazard in your own home. That is why, when choosing any wires or cables at home, a thrifty owner must be an extremely attentive, demanding and careful buyer.

What does cross section mean?

Before revealing the basic concept, you need to decipher the meaning of the term and understand how a wire differs from a cable. A wire is a conductor that is used to connect several sections of an electrical circuit. May have one or many current-conducting conductor elements. They, in turn, can be bare, insulated, single-core or multi-core.

Conductor cut area

The former are used in overhead electrical transmission lines. The latter are used in electrical devices, panels or cabinets. In everyday life, they are located inside electrical wiring.

For your information! Insulated and single-core conductors are used everywhere, and stranded conductors are used where bends with a small radius are needed.

What is a cross section

A cross section is a figure that is formed from a conductive section by a directional plane. The area obtained from a perpendicular cut of any type of wire is indicated in square millimeters. This is an important parameter for calculating the electrical network.

Section according to GOST or TU

A large assortment of electrical products helps to quickly solve problems associated with electrical installation work. The quality of these products plays a very important role and all products must comply with GOST requirements.

Often, manufacturers, wanting to save money, find loopholes to deviate from GOST requirements and themselves develop technical production conditions (TU) taking into account the permitted errors.

As a result, the market is oversaturated with low-quality and cheap goods that need to be double-checked before purchasing.

If the cables available in retail outlets of a suitable price do not correspond to the declared characteristics, the only thing that can be done is to purchase a wire with a reserve cross-section. Power reserve will never negatively affect the quality of electrical wiring

It would also be useful to pay attention to products from manufacturers who value their name - although they are more expensive, they are a guarantee of quality, and wiring replacement is not done so often that you can save on it

Cable selection according to PUE and GOST tables

When purchasing a wire, it is recommended to look at the GOST standard or the technical specifications according to which the product is manufactured. GOST requirements are higher than similar parameters of technical specifications, so you should prefer products made according to the standard.

Tables from the rules for electrical installations (PUE) represent the dependence of the strength of the current transmitted through the conductor on the cross-section of the conductor and the method of installation in the main pipe. The permissible current decreases as the individual cores increase in size or as multi-core cable insulation is used. The phenomenon is associated with a separate clause in the PUE, which stipulates the parameters of the maximum permissible heating of the wires. The main pipe is understood as a box, including a plastic one or when laying wiring in a bundle on a cable tray.

Loading …

The parameters in the tables are indicated taking into account the operating temperature of the core of 65 ° C and only phase wires (zero buses are not taken into account). If a standard three-core cable for supplying single-phase current is laid in a room pipe, then its parameters are taken into account in the data column for one two-core wire. Below is information for cables made from different materials. Please note that the tables are used to select wires. In the case of determining the type of cables, other data is used, which is also available in the PUE.

The second way to select a cable is the tables of the GOST 16442-80 standard, which exist in two versions - for copper and. In this information, the choice is made depending on the type of laying and the number of cores in the cables.