After installing a new barrel with a larger volume on the outdoor shower, the need arose to install some sort of “sensor” for the water level, so as not to constantly climb onto the roof of the shower, and besides, the new barrel is equipped with a lid that is fixed with a clamp, and you have to constantly remove it and I don’t really want to see how much water is left. So I installed this easy-to-make device.

Necessary materials:

- polystyrene foam (I found a piece like the one in the photo in a box from a gas stove; they are used to cover camphors during transportation); - small nut; - large nut; - long screw; - two pieces of plastic strip; - fishing line.

Manufacturing the sensor

First of all, we drill a through hole in the middle of the foam (this is done so that when we tighten the screw, the foam does not split), as well as on both plates.

Then we fasten the parts as shown in the photo:

We attach a fishing line to the screw and our “sensor” is almost ready.

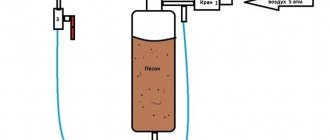

Now we take everything to the roof of the shower, drill a hole in the lid of the tank (the hole must be made such that the fishing line can pass through it freely).

Next, we lower the resulting float into the tank, pass the fishing line through the lid and now, where our water level is, we tie a small washer.

And this is the finished result.

The operating principle of our “sensor” is very simple. When the water in the tank runs out, our float drops to the bottom, and the washer on the outside rises to the top, therefore, we need to add water. And when the water is pouring, it is also very convenient to monitor. You can, of course, make markings on the tank and hang some kind of arrow instead of a washer, but this is a matter for everyone personally. If you have any questions, please ask!

Source: www.freeseller.ru

Selecting a water level sensor in the tank and container

To automate many production processes, it is necessary to monitor the water level in the tank; the measurement is carried out using a special sensor that gives a signal when the process medium reaches a certain level. It is impossible to do without level meters in everyday life; a striking example of this is the shut-off valve of a toilet cistern or an automatic system for shutting off a well pump. Let's look at the different types of level sensors, their design and operating principle. This information will be useful when choosing a device for a specific task or making a sensor yourself.

Rice. 2. Float sensor for pump control

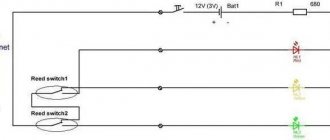

The design consists of a float with a magnet and two reed switches installed at control points. Let us briefly describe the principle of operation:

- The container is emptied to a critical minimum (A in Fig. 2), while the float drops to the level where reed switch 2 is located, it turns on the relay that supplies power to the pump pumping water from the well.

- The water reaches the maximum level, the float rises to the location of reed switch 1, it is triggered and the relay is turned off, accordingly, the pump motor stops working.

It’s quite easy to make such a reed switch yourself, and setting it up comes down to setting on-off levels.

Note that if you choose the right material for the float, the water level sensor will work even if there is a layer of foam in the tank.

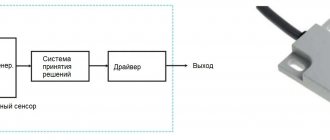

Ultrasonic

This type of meter can be used for both liquid and dry media and may have an analogue or discrete output. That is, the sensor can limit the filling upon reaching a certain point or monitor it continuously. The device includes an ultrasonic emitter, receiver and signal processing controller. The operating principle of the alarm is demonstrated in Figure 3.

Rice. 3. Operating principle of ultrasonic level sensor

The system works as follows:

- an ultrasonic pulse is emitted;

- the reflected signal is received;

- The duration of signal attenuation is analyzed. If the tank is full, it will be short (A Fig. 3), and as it becomes empty it will begin to increase (B Fig. 3).

The ultrasonic alarm is non-contact and wireless, so it can be used even in aggressive and explosive environments. After initial setup, such a sensor does not require any specialized maintenance, and the absence of moving parts significantly extends its service life.

Electrode

Electrode (conductometric) alarms allow you to monitor one or more levels of an electrically conductive medium (that is, they are not suitable for measuring the filling of a tank with distilled water). An example of using the device is shown in Figure 4.

Rice. 5. Capacitive level sensor

The operating principle of the alarm is the same as that of a capacitor: the capacitance is measured between the plates of the sensitive element. When it reaches the threshold value, a signal is sent to the controller. In some cases, a “dry contact” design is used, that is, the level gauge operates through the tank wall in isolation from the process medium.

These devices can operate over a wide temperature range, are not affected by electromagnetic fields, and can operate over a long distance. Such characteristics significantly expand the scope of application up to severe operating conditions.

This type of alarm device can truly be called universal, since it can work with any process environment, including aggressive and explosive ones, and pressure and temperature will not affect the readings. An example of how the device works is shown in the figure below.

Level measurement with radar sensor

The device emits radio waves in a narrow range (several gigahertz), the receiver catches the reflected signal and, based on its delay time, determines how full the container is. The measuring sensor is not affected by pressure, temperature or the nature of the process fluid. Dustiness also does not affect the readings, which cannot be said about laser alarms. It is also necessary to note the high accuracy of devices of this type; their error is no more than one millimeter.

The role of alarms in drainage pumps

A drainage pump with a float switch is widely used both in industry and in everyday life. Its scope of use is cleaning wells, removing dirty liquid, etc. In a drainage pump, the float is equipped with the function of turning the drive on and off automatically. The switch is lowered into the wastewater via an extended cable along with a pipe for collecting liquid. The vertical type drain pump kit includes a vertical float switch with the function of pumping liquid out of a confined space. Such a drainage pump can, for example, drain inactive pipelines.

How to choose?

The choice of a water level sensor in a tank depends on many factors, the main ones:

- Composition of the liquid. Depending on the content of foreign impurities in the water, the density and electrical conductivity of the solution may change, which is likely to affect the readings.

- The volume of the tank and the material from which it is made.

- The functional purpose of the container is to accumulate liquid.

- The need to control the minimum and maximum level, or monitoring of the current state is required.

- Admissibility of integration into an automated control system.

- Switching capabilities of the device.

This is not a complete list for selecting measuring instruments of this type. Naturally, for domestic use it is possible to significantly reduce the selection criteria, limiting them to the volume of the tank, the type of operation and the control circuit. A significant reduction in requirements makes it possible to independently manufacture such a device.

Operation of the filling mechanism in the tank

Float valve for toilet

To begin with, you will need the most detailed familiarization with the design features and operating principle of such tanks.

This makes it possible to carry out sufficient repair work at a professional level with your own hands without outside help.

This ensures significant savings in the family budget.

As one of the main structural elements of the flush tank, a special button is used, interaction with which allows you to direct the flow of water into the container of the plumbing fixture, so that everything is flushed under pressure into the drainage system.

Filling is carried out in various ways:

- Water supply from below.

- Side feed device. During operation, quite a lot of noise occurs.

Upon superficial inspection, the mechanism of the tank seems quite simple. Visually, only the float device and part of the drain mechanism are determined.

In reality, the design of all components cannot be called so simple. The float valve circuit includes the following components:

- The housing on which the membrane is installed. This device is responsible for filling the container with water.

- A float connected to the membrane itself by several levers.

Making a water level sensor in a tank with your own hands

Let's say there is a task to automate the operation of a submersible pump for water supply to a dacha. As a rule, water flows into a storage tank, therefore, we need to make sure that the pump automatically turns off when it is filled. It is not at all necessary to buy a laser or radar level indicator for this purpose; in fact, you don’t need to purchase any. A simple problem requires a simple solution, it is shown in Figure 8.

Water pump control circuit

To solve the problem, you will need a magnetic starter with a 220-volt coil and two reed switches: a minimum level for closing, a maximum level for opening. The pump connection diagram is simple and, importantly, safe. The principle of operation was described above, but let’s repeat it:

- As the water collects, the float with the magnet gradually rises until it reaches the maximum level reed switch.

- The magnetic field opens the reed switch, turning off the starter coil, which leads to de-energization of the engine.

- As the water flows, the float drops until it reaches the minimum mark opposite the lower reed switch, its contacts close, and voltage is supplied to the starter coil, which supplies voltage to the pump. Such a water level sensor in a tank can work for decades, unlike an electronic control system.

Source: www.asutpp.ru

Reed switch device

The main actuator element of the reed switch is the reed switch. The device is a small glass cylinder filled with an inert gas or with air evacuated. Gas or vacuum prevents the formation of sparks and oxidation of the contact group. Inside the flask there are closed contacts made of a ferromagnetic alloy of rectangular cross-section (permalloy wire) coated with gold or silver. When exposed to a magnetic flux, the contacts of the reed switch are magnetized and repel each other - the circuit through which the electric current flows opens.

Rice. 6 Float vertical water level sensors

A similar pump control circuit, placed in the control cabinet, can be used when monitoring the level in a tank with liquid, if the reed switches are swapped, that is, SV2 will be at the top and turn off the pump, and SV1 in the depths of the water tank will turn it on.

Level sensors can be used in everyday life to automate the process when filling large containers with water using electric water pumps. The easiest types of reed switches to install and operate are those produced by industry in the form of vertical floats on rods and horizontal structures.

Video text

A float valve for water tanks is one of the main elements of the water supply system if you want to use a storage tank.

A float valve for water tanks can be purchased at a low price here: https://clck.ru/FUkaV

If you want to share this video with your friends, send them this link:

In this video: 00:50 float valve for water tanks: application 02:10 float valve: types 03:10 level float valve: advantages 03:20 float valve for a container or tank: material 03:40 float valve for a container: valve selection 04:45 float valve for a tank: where is it profitable to buy

The float valve is installed in the tank and works on a simple principle: as soon as the tank is filled with water, the level float valve will close and water will stop flowing into the tank, which guarantees no overflow. As soon as you start using water and its level drops, the float valve for the container or tank will open and water will begin to flow into the container again, replenishing it.

The most common float valve for a container with a counterweight - a ball. This tank float valve is a simple mechanical shut-off device that works the same way as a water float valve, for example, used in a toilet.

The tank water level float valve also consists of a mechanical valve and a light ball that floats on the surface of the water. When the water level drops, the ball drops with it, the water level float valve opens and lets water through. As soon as the tank is filled, the float shut-off valve is closed by the same ball, which at that moment floats up - and the supply of liquid to the tank stops.

The plastic float valve is made of structural plastic - which makes it inexpensive and very wear-resistant. Also, the plastic float valve is protected from corrosion and does not change the taste of the water.

The float valve for the tank can be produced in different connecting sizes. The most common is the 1" inlet float valve. This size mechanical water level float valve combines high performance (tank filling speed) with a relatively low price.

An automatic mechanical float valve of other sizes is less common and is used only in cases where its use is justified, for example, by the manufacturing process.

Float valve for storage tank made of stainless steel - used mainly in food production, as well as float valve for water tank made of brass. They are both quite expensive. But - in some cases, another mechanical float valve simply cannot be used (for example, in distilleries, all shut-off valves are made of stainless steel).

A mechanical float valve for water is a very simple and inexpensive device, which is used mainly if a water supply system in which the water is under pressure is connected to the tank (for example, a centralized water supply system).

An automatic float valve works best in combination with a plastic tank and a pumping station - in this case, you get a full-fledged pressure increase system if, for example, the pressure in the pipe is not very high. And here the float valve for the barrel plays a very important role.

Because if the float valve for the water supply fails, the water will fill the barrel and begin to pour into the room, which cannot be allowed.

Source: www.youtube.com

Operating principle of a float valve

In tanks made using old technologies, a toilet float valve with a bottom supply is installed. The main purpose of such a device is to ensure the optimal filling level of the tank.

The main disadvantage of such devices is the increased likelihood of failure. In addition, splashes are formed, as well as some other undesirable phenomena.

As the float is filled, it changes position. This ensures that the water supply process stops if its level reaches a certain level.

The main operating principle of float valve technology is as follows. When the float rises, the rod with the curved edge moves.

After this, the thrust exerts an influence on the lever, which presses on the valve, which is pressed against the seat with a special gasket. Water completely stops flowing into the container.

When draining occurs, the reverse function is performed. The volume of water decreases and the float lowers. The lever pressure on the piston stops, water flows back into the empty container.

Water level float switch for pump control

When the need arises to control the fluid level, many do this work manually, but this is extremely ineffective, takes a lot of time and effort, and the consequences of oversight can be very expensive: for example, a flooded apartment or a burnt out pump. This can be easily avoided by using float water level sensors. These are devices that are simple in design and operating principle and are affordable.

At home, sensors of this type allow you to automate processes such as:

- monitoring the liquid level in the supply tank;

- pumping groundwater from the cellar;

- turning off the pump when the level in the well falls below the permissible level, and some others.

Inexpensive industrial devices

There are also inexpensive models of liquid level control sensors, which can be purchased in stores for about 2 thousand rubles

Various modifications of ARS

Such float sensors are usually used in reservoirs. The measuring head in devices of this type is small, which makes the device compact. The load capacity, according to the operating instructions, can reach 1 ampere. The wire entry into the devices is sealed. The body is made of plastic. The operating differential is 45 degrees. The maximum pressure for correct operation of devices is 3 bar. The cost is about 2 thousand rubles, depending on the modification.

“Crystal” container filling control devices

These float type sensors can be used in harsh environments. Very compact. The measuring head is 2.3 centimeters in diameter. The maximum pressure for correct operation reaches 3.3 bar. The wire input is made in the form of a plastic seal. The devices are equipped with a spark protection barrier. Can work in hot environments. The price is slightly higher than 2 thousand rubles, depending on the modification.

Burkle devices

These devices are designed for contaminated environments, but can also be used in clean ponds and clean water tanks. The maximum pressure for correct operation is 4.1 bar. The maximum possible load is 1A. It is possible to work in environments heated to 170 degrees, in liquids with a density of up to 3 kg per square meter. cm. The average price of the device is 2,200 rubles and depends on minor modifications made by the manufacturer.

Fine Tek and Wilo sensors

These float type devices can be used in harsh environments. They are used for drainage purposes and can also be installed in wells. The sensors can withstand loads up to 2 amperes. The measuring heads are compact and measure 2.5 cm. The wire inputs are made in a specialized seal. The cases are made of heat-resistant plastic. The devices are equipped with fuel probes, which allows their use in flammable environments. The price ranges from 2 thousand to 2500 rubles and also depends on the modification.

Wilo float-type devices are the cheapest, but are not functionally designed for aggressive environments and can only be used in clean water. The sensors have small measuring heads and are compact in appearance. The maximum temperature of use is 140 degrees. The operating differential is only 30 degrees. The maximum operating pressure does not exceed 2 bar. The price of such sensors fluctuates around 1900 rubles.

Equipment classification

Float sensors can independently monitor the liquid level or send a signal to the control circuit. According to this principle, they can be divided into two large groups: mechanical and electrical.

Mechanical devices

Mechanical valves include a wide variety of float valves for the water level in the tank. The principle of their operation is that the float is connected to a lever; when the liquid level changes, the float moves this lever up or down , and it, in turn, acts on the valve, which shuts off (opens) the water supply. Such valves can be seen in toilet flush tanks. They are very convenient to use where you need to constantly add water from the central water supply system.

Mechanical sensors have a number of advantages:

- simplicity of design;

- compactness;

- safety;

- autonomy - do not require any sources of electricity;

- reliability;

- cheapness;

- ease of installation and configuration.

But these sensors have one significant drawback: they can control only one (upper) level, which depends on the installation location, and regulate it, if possible, then within very small limits. On sale, such a valve may be called a “float valve for containers.”

Electrical sensors

An electric liquid level sensor (float) differs from a mechanical one in that it itself does not shut off the water. The float, moving when the amount of liquid changes, affects the electrical contacts that are included in the control circuit. Based on these signals, the automatic control system makes a decision on the need for certain actions. In the simplest case, such a sensor has a float. This float acts on the contact through which the pump is turned on.

Reed switches are most often used as contacts. A reed switch is a sealed glass bulb with contacts inside. Switching of these contacts occurs under the influence of a magnetic field. Reed switches are miniature in size and can be easily placed inside a thin tube made of non-magnetic material (plastic, aluminum). A float with a magnet moves freely along the tube under the influence of liquid, and when it approaches, the contacts are activated. This entire system is installed vertically in the tank . By changing the position of the reed switch inside the tube, you can adjust the moment the automation operates.

If you need to monitor the upper level in the tank, then the sensor is installed at the top. As soon as the level drops below the set level, the contact closes and the pump turns on. The water will begin to increase, and when the water level reaches the upper limit, the float will return to its original state and the pump will turn off. However, in practice such a scheme cannot be used. The fact is that the sensor is triggered by the slightest change in the level, after which the pump turns on, the level rises, and the pump turns off. If the water flow from the tank is less than the supply, a situation arises when the pump constantly turns on and off, and it quickly overheats and fails.

Therefore, water level sensors for pump control work differently. There are at least two contacts in the container. One is responsible for the upper level; it turns off the pump. The second determines the position of the lower level, upon reaching which the pump turns on. Thus, the number of starts is significantly reduced, which ensures reliable operation of the entire system. If the level difference is small, then it is convenient to use a tube with two reed switches inside and one float that connects them. If the difference is more than a meter, two separate sensors are used, installed at the required heights.

Despite their more complex design and the need for a control circuit, electric float sensors allow fully automated liquid level control.

If you connect light bulbs through such sensors , they can be used to visually monitor the amount of liquid in the tank.

A simple float sensor for a garden watering barrel

Authorization on the site

A simple float sensor that allows you to monitor the moment a garden watering barrel is completely filled (to the very top) with water.

Greetings to all do-it-yourselfers, as well as summer residents and gardeners!

Now, at the end of summer, we are in a drought again and therefore we have to water the garden almost every day. At the same time, we water from three two-hundred-liter barrels standing in our garden. We first pour tap water into these barrels, and after it heats up, using watering cans and watering cans, we water the plants with it, both in greenhouses and in open ground. Many of our neighbors who have vegetable gardens do the same.

And here recently, I somehow got into a conversation with one of our neighbors - an elderly woman. By the way, she also uses a two-hundred-liter barrel to water her small garden. And this granny, among other things, complained to me about one problem. The problem is that when she fills a watering barrel with a hose, she can’t keep track of when the barrel is filled to the top with water.

The fact is that her barrel stands next to the house and the tap itself, which shuts off the water, is located on an inch steel water pipe leaving the house. A rubber hose is attached to the end of this pipe. So, when she puts the hose in the barrel and opens the tap, she herself sits on a chair next to the wall of the house where the tap is located (literally 2-2.5 meters from the barrel) and monitors the filling of the barrel.

But she can’t see clearly when the barrel is filled to the top with water, as a result of which the water often unnoticeably overflows over the edge and quite a lot of it can leak out until the grandmother finally understands that the barrel is filled to the top and will shut off the water.

This grandmother neighbor asked me to come up with something so that she could clearly see when the barrel was filled to the top with water, so that she could turn off the water in time.

After listening to her, I immediately realized that this problem could be solved by a simple float, which rises along with the surface of the water in the barrel when it is filled with water. When the barrel is filled to the top, this float will float to the surface and will rise above the barrel, which will signal that the barrel is filled to the top. The main thing is that this float is clearly visible from the outside.

This is perhaps the easiest way to solve this problem, and such a float sensor can be made in just a few minutes.

Homemade float switch

If you have the time and desire, then you can make a simple float water level sensor with your own hands, and the costs for it will be minimal.

Mechanical system

In order to simplify the design as much as possible, we will use a ball valve (faucet) as a locking device. The smallest valves (half-inch or smaller) work well. This type of faucet has a handle that closes it. To convert it into a sensor, you need to extend this handle with a strip of metal. The strip is attached to the handle through holes drilled in it with the appropriate screws. The cross-section of this lever should be minimal, but it should not bend under the influence of the float. Its length is about 50 cm. The float is attached to the end of this lever.

use a two-liter plastic soda as a float The bottle is half filled with water.

You can check the operation of the system without installing it in the tank. To do this, install the faucet vertically and place the lever with the float in a horizontal position. If everything is done correctly, then under the influence of the mass of water in the bottles, the lever will begin to move down and take a vertical position, and the valve handle will turn with it. Now submerge the device in water. The bottle should float up and turn the valve handle.

Since valves vary in size and the amount of force required to switch them, the system may need to be adjusted. If the float cannot turn the valve, you can increase the length of the lever or take a larger bottle .

We mount the sensor in the container at the required level in a horizontal position, while in the vertical position of the float the valve should be open, and in the horizontal position it should be closed.

Electric type sensor

To make a sensor of this type yourself, in addition to the usual tools, you will need:

- Half-inch plastic pipe for soldering water pipes. The length of the pipe is arbitrary and depends on the size of your tank.

- Three-core copper wire with a wire cross-section of 0.5 mm2. The length of the wire is equal to the length of the tube plus the distance to the control unit to which the sensor will be connected.

- Polystyrene foam block 5*5*8 cm.

- Magnet. It’s good if it’s a ring one, for example, from an old speaker. Its internal diameter should be 4-6 mm larger than the outer diameter of the tube.

- Two reed switches. One is with a normally closed contact, the other is with a normally open contact.

- Soldering iron, solder and rosin.

The manufacturing sequence is as follows:

- We make a float from polystyrene foam. To do this, round the corners to make a cylinder. We drill a hole along the length 3 mm larger than the outer diameter of the pipe. We attach a magnet to one of the ends of the cylinder. You can attach it with epoxy glue or tighten it with threads. Make sure the magnet does not drown the float.

- We pick up the phone. We heat one of the ends and crush it so that a thickening is formed. This will prevent water from entering the pipe and at the same time will serve as a limiter for the lower position of the float.

- We put the float on the pipe with the magnet facing up and move it to the lower position. The float with the magnet must move freely along the pipe.

- Let's take the wire. Align its end with the lower end of the tube. We put the first mark in the place where the magnet is located. The lower level reed switch will be located here. The second label should correspond to the top one. Apply the same mark to the pipe. This will simplify installation and configuration of the system.

- We take a reed switch with a normally open contact and solder it to the wire at the lower level. To do this, we strip the insulation on the central core and on one of the side cores.

- A reed switch with a normally closed contact is installed at the upper level. We solder it to the central core (it is common to both reed switches) and to the remaining free one.

- At the lower end of the wire, the wires must be insulated from each other. On the other side, mark which wire is connected to what.

- We insert the wire with the reed switches into the pipe until it stops, and fix its upper end with sealant.

- We attach the finished sensor vertically inside the container, taking into account the mark of the upper position of the float. The tube has some buoyancy. To prevent it from floating up and becoming deformed, load its lower end.

Difficulty with the shut-off valve

If malfunctions of the shut-off valve occur, everyone can cope with them without much difficulty on their own. The most common cause of such malfunctions may be the membrane, as well as special water-conducting devices that can become clogged from time to time.

Most often, the cause of such malfunctions may be the membrane, as well as water-conducting mechanisms, which tend to become clogged periodically.

To resolve such problems, simply disassemble the float device. A removable cap is provided for this.

After this, the membrane is removed, cleaned and installed in its proper place. The cap must be screwed back on.

In most examples, membranes often fail, so when replacing it, you need to select sufficiently high-quality products that are guaranteed to last as long as possible. If it is difficult to purchase such a device, there is always the possibility of making a new element with your own hands in accordance with the specifications of the instructions.

An old faulty part can be used as a suitable template. It needs to be leaned as tightly as possible against thin, hard rubber. After which the required shape is cut out in accordance with the design features of the existing sample.

Purpose and principle of operation

When water, oil or fuel mixture is consumed, the float lowers , with a downward thrust, and the lever stops pressing on the piston. This in turn leads to the stop cap. Under water pressure, the piston moves back and liquid flows into the reservoir until the pressure is restored.

Using the device, the following goals are achieved:

- Maintaining a given water level between the upper and lower limits.

- Maintaining a constant specified volume of liquid in the container.

The modern models produced are high-quality and silent, regardless of the scope of application - at home or for professional needs .

Valve modifications are different:

- designs with flexible adjustment of the required level;

- models for foam surfaces;

- devices for containers with stirring;

- steel.

The latter type is necessary when working with increased hygiene conditions or in aggressive environments. At the same time, it is undemanding to control, operates stably, is easy to clean and has a well-thought-out design with different connection methods.

There are two main types of products:

A mechanical water valve is often used in everyday life, for example, it is a float in a toilet flush tank.

The second type performs the functions of a signaling device and is used to turn on or off electric pumps when the level of the liquid medium changes. It is optimal to use it for frequent consumption in a small container. A float valve for water tanks can be used in conjunction with a solenoid valve to keep running automatically and prevent it from idling without water.

Features of choosing a device

The design of the float provides for different installation methods:

- Inside in container

- Outside on the container

- Inside the pipeline.

In this case, the valves can close or open when or other liquid medium in the container decreases

The choice of valve is determined by three parameters:

- pressure drop;

- flow based on maximum level;

- ambient temperature.

Possible mechanism malfunctions

Despite the simplicity of the device, breakdowns of individual components of the mechanism are possible. Evidence of a malfunction is that:

- Liquid stops flowing into the tank.

- The liquid flows, but it does not stop, which leads to overflow.

- Liquid flows, but extremely slowly.

All these signals indicate that the membrane has failed or the water inlet valve is clogged.

It is also possible that the seal of the amendment itself is broken, and water is poured inside, preventing it from floating to the surface. In this case, repairing the mechanism does not make sense and the entire structure must be replaced.

Float maintenance and repair

Subject to the operating rules, the float to turn on the pump will work for a long time and properly.

If the element is used in conditions of working with clean water, then it does not require special maintenance. If the float is used when working with dirty water and a large amount of solid fractions, then it, like the entire system, must be washed under running clean water. This must be done at least once a month. This will prevent the part from sticking to the pressure pipe or pump. If water gets inside the float, its contacts burn, or the integrity of the cable insulation is damaged, all faulty elements must be replaced, since they cannot be repaired. If the electronic float itself is completely out of order, then it must be changed at special service centers.