Yes, of course, there are many differences between copper and aluminum when used in electrical installations, such as conductivity, weight, and, one of the most important factors, cost. In the last century, aluminum was a more common metal for making electrical products such as fuses, busbars, circuit breakers, and was used for laying internal networks in residential and industrial buildings. Under the influence of modern trends, many designers have actively replaced aluminum with copper in their products, but recently trends have changed again, and they are moving from copper back to aluminum. The reason for this transition is the high cost of copper.

History of discovery

Copper is one of the first metals that humanity learned to mine and exploit; According to archaeologists, around the same time as copper, people began to use gold. The fact is that both of these metals occur in nature in their native form, and a piece of copper in order to be used as a tool or weapon simply had to be given the desired shape after heating. This happened, most likely, 6-7 thousand years ago. Gradually, people learned to smelt metal from ore, and slag, indicating the presence of copper metallurgy, was found during excavations of the ancient settlement of Çatalhöyük in Turkey. Initially, weapons and agricultural tools were made from pure metal, but over time, people discovered that when combined with tin, copper produced much stronger bronze.

The difference between aluminum and copper is that the date of its first production is clearly recorded in history. This happened in 1825 in Denmark and the “father” of aluminum was the chemist Hans Oersted. Aluminum does not occur in nature in its native form, but when interacting with oxygen it forms a stable compound, so its production was initially very expensive. The first aluminum was more expensive than gold, and in 1889 the British presented the great Russian chemist Dmitry Mendeleev with scales made of gold and aluminum as a sign of recognition of his services to humanity.

Flaws

There are quite a few disadvantages to this type of wire:

- Metal fluidity. Aluminum tends to stretch, this has a negative consequence in the case of screw connections of wires. Wire connections weaken over time, begin to heat up, oxidize and burn, until contact is completely lost.

- Aluminum fragility. During the process of aging and long service life, the wires will simply break, especially with frequent loads and overheating. This also needs to be taken into account when you re-terminate old strands - when unwinding and re-twisting them, there is a high risk that the core will break.

All of these shortcomings, to one degree or another, ultimately lead to the fragility of the entire power supply system and a short service life. When asked how long aluminum electrical wiring lasts, you will receive a comprehensive answer - as long as its insulation lasts. Depending on the conditions and installation method, the service life is 5-25 years.

Comparison

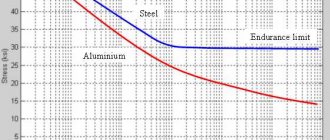

The electrical conductivity of copper is one and a half times higher than that of aluminum, but the density of aluminum is 3.3 times less than that of copper. There is no need to talk about the price - after the development of industrial technology for the production of aluminum, its cost has fallen very much and now it is significantly less than that of copper. These circumstances predetermined the use of aluminum for the production of multi-core wires and cables. Please note when you see high voltage power lines: all wires are made of aluminum. It’s cheaper this way and the load on the supports is much lower. Well, if the electrical conductivity is less, you have to put up with it.

Copper is also used to produce bronze. In ancient times, bladed weapons and tools were made from it until iron smelting was mastered. But later, guns were cast from bronze, and this continued for quite a long time, until the 19th century. The Tsar Cannon and the Tsar Bell were cast from bronze. In addition, due to its high corrosion resistance, copper has found application in the manufacture of pipes for transporting various liquids and gases, as well as in some other industries.

Aluminum is called the “winged metal”. This name speaks of the second large-scale area of its application (after electrical engineering). When aluminum (95.6%) and copper (4.4%) are combined, an alloy is obtained, which is called duralumin, or duralumin. Having a density close to that of aluminum, it has significantly higher strength characteristics, which is why it is widely used for aircraft production.

Useful tips

The wire connection must comply with safety regulations

The cable layout in the apartment consists of an upper and lower level. The lower one has sockets designed to power consumers, the power of which can reach 2 kW: washing machines, boilers, microwave ovens. In order not to expose the lines to the risk of overheating and burning, it is advisable to install a copper cable with the maximum cross-section of conductors allowed for household outlets.

The upper level is used to power doorbells, ceiling and wall lamps. These products consume a minimal amount of electricity, especially if they are equipped with modern LED lamps. You can run a thin and inexpensive aluminum cable on top, the power reserve of which is sufficient with a large reserve. With this solution, a separate issue arises of a safe way to join two incompatible metals.

Conductive paste

To avoid problems with contacts after installation, you can use one of the following devices:

- Clamp. The product consists of 3 steel plates. The cores are inserted between them, after which the plates are tightened with bolts.

- Bolt with 2 iron washers. The ends of the cores are twisted into rings and placed on the axle, and washers are installed between different materials. Tightening the nut ensures reliable contact.

- Spring switch. Its terminals are treated with a special anti-corrosion lubricant. The cores are inserted into the grooves and secured with spring levers.

- Pads. They are a steel strip with contacts pressed into a plastic case. The ends of the cable are inserted into the holes where they are tightened with bolts. The products can be used to connect 2-10 pairs of wires.

How to distinguish copper from other metals

For most of us, knowledge about copper and its properties is limited to a school chemistry course, which is quite enough at the everyday level. However, sometimes there is a need to reliably determine whether a material is a pure element, an alloy, or even a composite material. The opinion that this information is needed only by those who are engaged in the acceptance or delivery of scrap metal is erroneous: for example, on amateur radio forums, topics are often raised about how to distinguish copper in wires from copper-plated aluminum.

Briefly about element No. 29

Pure copper (Cu) is a golden-pink metal with high ductility, thermal and electrical conductivity. Chemical inertness in an ordinary non-aggressive environment is ensured by a thin oxide film, which gives the metal an intense reddish tint.

The main difference between copper and other metals is color.

. In fact, there are not so many colored metals: only gold, cesium and osmium are similar in appearance, and all elements included in the group of non-ferrous metals (iron, tin, lead, aluminum, zinc, magnesium and nickel) have a gray color with varying intensity of shine.

An absolute guarantee of the chemical composition of any material can be obtained only through spectral analysis. The equipment for carrying it out is very expensive, and even many expert laboratories can only dream of it. However, there are many ways to distinguish copper at home.

with a high degree of probability.

Determination by color

So, we have before us a piece of unknown material that needs to be identified as copper. The emphasis on the term “material” rather than “metal” was made specifically, since recently many composites have appeared that are very similar to metals in appearance and tactile sensations.

First of all, we consider color. It is advisable to do this in daylight or “warm” LED lighting (under “cool” LEDs, the reddish tint changes to yellow-green). It is ideal if there is a copper plate or wire for comparison - in this case, errors in color perception are practically eliminated.

Important: old copper products can be covered with an oxidized layer (a greenish-blue loose coating): in this case, the color of the metal must be looked at in a cut or saw cut.

Determination by magnet

Color matching is a reliable but not sufficient method of identification. The second step of independent experiments will be a test with a magnet. Chemically pure copper is classified as diamagnetic - i.e. to substances that do not respond to magnetic influence. If the material under study is attracted to a magnet, then it is an alloy in which the content of the main substance is no more than 50%. However, even if the sample did not react to the magnet, it is too early to rejoice, since often an aluminum base is hidden under the copper coating, which is also not magnetic (this can be eliminated by filing or cutting).

How to distinguish between copper and its alloys?

Copper alloys are widely used in industry. Over many years of research, it has been possible to obtain many materials with unique properties: high ductility, electrical conductivity, chemical resistance, strength (all depends on alloying additives). The most common are bronze (with the addition of tin, aluminum, silicon, manganese, lead and beryllium), brass (with the addition of 10-45% zinc), as well as copper-nickel alloys (nickel silver, cupronickel, copel, manganin).

Only bronze and brass are difficult to identify, since copper-nickel alloys differ significantly in color due to their low copper content.

Copper or brass?

Brass can contain from 10 to 45% zinc, a silver-gray metal. Naturally, the more zinc, the paler the alloy. However, high-copper brasses, in which the amount of additives does not exceed 10%, differ little in color from the copper sample. In this case, you can only trust your feelings: brass is much harder and more difficult to bend (for greater reliability, a comparison with a reference sample is advisable). You can try to remove the shavings: copper shavings will have a curl shape, brass shavings will be straight, needle-shaped. When the samples are placed in a solution of hydrochloric acid, no reaction with copper is observed, and a white coating of zinc chloride forms on the surface of the brass.

Copper or bronze?

Like brass, bronze is much stronger, which is explained by the presence of harder metals in the alloy. The most reliable test will be a “tooth test” - there is unlikely to be a trace of pressure left on the surface of the bronze.

You can also experiment with a hot saline solution (200 g of table salt per 1 liter of water). After 10-15 minutes, a copper sample will acquire a more intense shade than a bronze one.

Copper or aluminum wire - which is better?

The most common types of cable for electrical wiring (apartments and industrial premises) are aluminum and copper wires. It should be noted that they are sold nearby on the shelves of our stores. YES, sometimes we can find copper and sometimes aluminum in wiring. So what is the difference and which is better between these two materials? Today I invite you to think about this...

If you studied physics, then of course you know that copper cable has the best electrical conductive properties. Also, this type, unlike aluminum, has an increased service life (aluminum is up to 20 years, but copper is already from 30 and above).

So if you are laying electrical networks in an apartment, then it is preferable to choose copper. And now in detail for each type.

Aluminum cable

Pros:

The big advantage is that the cost of this option is about half cheaper than its opponent (and sometimes even more). That is why all old houses (“STALINKI” and “KHRUSHCHEVKI”) have just such wiring. You know guys, this is probably the only plus, there are many more minuses.

Minuses:

This type of wire can withstand smaller loads compared to its competitor - remember, every millimeter of cross-section can withstand only 1 kW of power.

As I wrote above, the service life of an aluminum cable is only 20 years, so it is not recommended to install it in the wall, otherwise, after this period has expired, you will need to pick at the walls.

Another disadvantage (for me personally) is the inconvenience of installation. Such wires (as a rule) are single-core rigid, so if you use a cross-section of 3.5 mm, connecting them to sockets is quite problematic.

Copper cable

Pros:

This type can withstand high loads - 1 millimeter of cross-section can withstand 2 kW of load, which is twice as much as that of the enemy.

The service life is much longer; according to electricians, they can last 50 years.

There are plenty of types and designs of such wires, these include single-core and multi-core versions, having a practically non-melting braid (NYM cable), etc. Installation of a multi-core cable is much easier, it can be easily connected to a standard outlet, and it bends perfectly.

Minuses:

It's just the price. Technological wires (those with many cores and high-tech braiding) can cost up to two times more than a competitor.

A short comparison video - you can see the price and flexibility.

Useful tips

1) If you design the wiring yourself, then definitely choose copper. After all, with a smaller cross-section, it can withstand a fairly high voltage. That is, it will take up exactly half as much space. So a simple example - if I connected my hob with aluminum (let me remind you that its power is about 7.5 kW), then I would need a core cross-section of about 8 mm, and there are three of them in the cable, and even a braid - that is, the thickness would be about 4 – 5 cm, not a weak wiring! But copper can withstand a cross-section of 4 mm (total diameter about 2 cm), which is also quite a lot, but tolerable.

2) When designing sockets, the first thing you need to remember is that the wire must have three cores (grounding is required). Make the distance between them 2 meters, and the distance from the floor 30 cm, this is the EUROPEAN STANDARD. For lighting, you can use a two-wire version, since the load is minimal and there is practically no need for grounding.

3) Do not hang all electrical equipment on one wiring, the load will be very large! You need to make a branch, preferably for each room. The kitchen is especially worth highlighting. For the main cores for rooms, I advise you to take a cross-section from 4 mm, for the kitchen from 6 mm.

4) We bought an old apartment, it’s more than 20 years old, look at the wiring. Most likely, there is aluminum and it needs to be changed because after such a period it loses its elasticity and simply crumbles. This is often the cause of fires. “YES”, such a replacement will cost a pretty penny, but the game is worth the candle, because it’s your safety.

This is the choice, I think - now you will buy the right copper wire, aluminum is too difficult to install, and also short-lived.

I’ll finish here, read our construction blog.

remo-blog.ru

For those familiar with electrical engineering

Very often, copper cores from electrical cables are sold as scrap non-ferrous metals, and there are often cases when copper-coated aluminum is used in the production of electrical products. This material has a significantly lower density, but due to its irregular geometric shape, determining the volume to calculate the density is quite difficult. In this case, copper can be determined by electrical resistance (of course, if you have the appropriate instruments - a voltmeter, ammeter, rheostat). We measure the cross-section and length of the core, take instrument readings, and Ohm’s law will help you. Resistivity is a fairly accurate characteristic by which any metal can be identified with a high degree of reliability.

Advantages

From the very beginning, it should be noted that aluminum wiring is not the most reliable and high-quality and cannot boast of any outstanding merits compared to other types. But, nevertheless, it is precisely this type of electrical wiring that is installed in most old houses and apartments (Khrushchev). So, let’s start with the advantages of this type:

- lightness (aluminum has less weight compared to other metals that are used in electricity as conductors);

- resistance to corrosion (metal when exposed to air instantly oxidizes, forming a film that protects the rest of the wire from further corrosion).

According to chapter 7.1. PUE, clause 7.1.34. Electrical wiring must be carried out using cables with copper conductors. Aluminum cables and wires with core cross-section from 2.5 sq. mm can be used when connecting individual electrical appliances that belong to engineering electrical equipment or when connecting powerful electrical equipment with an aluminum cable with a core cross-section of 16 sq. mm.

In accordance with the above, today aluminum in electrical wiring is used most often in power cables of large cross-section (tens and hundreds of sq. mm.), where the weight and cost of the material are very important factors. The savings in this case can be very significant - aluminum is a cheap metal, and the amount of material used will still allow you to spend less compared to other types of wires. A true example of this is the enormous popularity of SIP wires, the cores of which are made of aluminum. For aerial cable laying, this conductor is one of the most suitable. Moreover, according to the PUE chapter 2.1. clause 2.1.14 and chapter 7.1. clause 7.1.131, the cross-section of the aluminum cable for branching through the air must be at least 16 square meters. mm.

However, aluminum wiring has not been used in new buildings for a long time, and there are reasons for this.

Copper or Aluminum: Which is Best for Wiring?

Nowadays, the vast majority of electricians use copper wiring instead of aluminum. But why? Why is copper better than aluminum? The answer is in our article.

In the USSR, all wiring was aluminum, but in modern new buildings you will no longer see such wiring. But why is copper better than aluminum? Which wiring is better for your home: copper or aluminum? We tell you why the material of the wires changed so quickly and irrevocably.

Copper or aluminum wire - which is better?

Previously, they installed one socket at a time.

Nowadays they even install 5 or more sockets in one place. This is due to the huge number of electrical appliances in a modern home. In this case, the sockets are connected with a cable, which is quite difficult to do with aluminum wire. Modern chandeliers also have copper lead-in ends, and they cannot be connected to aluminum.

Thirdly, aluminum is prone to oxidation. A film of high resistance appears on its surface. As a result, the contacts heat up and possibly burn out. Over time, aluminum becomes very brittle. Sometimes, after disassembling an old electrical box for repairs and taking out the wires, you can see how they simply crumble in your hands.

Moreover, although aluminum wiring laid in the USSR has been in service for 30 years, modern aluminum is no longer the same as it used to be. Today's aluminum wire can be broken during installation, especially Chinese wire. It’s hard to even imagine what will happen to him in ten years.

The superiority of aluminum over copper for power lines

But aluminum is not retired at all: overhead power lines are still made of this metal. So it also has advantages? Certainly!

Weight

Weight is largely determined based on the density of the metal. The higher the density, the heavier the conductor. The density of copper is 8900 kg/m3, and that of aluminum is 2700 kg/m3. That is, with an equal volume, a copper wire will weigh 3.3 times more than aluminum. For home wiring this is not critical, since the wire lies in the grooves, but for overhead power lines this is an important indicator. That is why aluminum wire is used for overhead power lines.

Features of connecting wires on the street

When installing a cable line along the street, all connection elements are exposed to external negative factors, such as snow, icing, rain, etc. Therefore, to perform such work, only a hermetically sealed structure that is resistant to ultraviolet rays and low temperatures is required. When making connections on a pole, roof or other open place, piercing clamps are most often used. You may be interested in learning in more detail how to connect SIP with copper cable on the street, because... in this case, the connection of aluminum and copper occurs in the open air.

In rooms, when laying a cable in a wall under plaster, the cable is laid in one piece in the groove, and any connection of even homogeneous metals is undesirable. All connections in a socket or junction box are made in any of the ways described above, suitable for each individual situation.