Welding is one of the most important crafts for humans. Thanks to discoveries in this area, we can realize any, even the most daring ideas: from making swing gates to designing spaceships. There are many types of welding, including industrial, but among them it is manual arc welding that is most widespread. This is a simple and understandable technology that you can learn on your own.

The modern market offers different types of electrodes for manual arc welding, which are difficult for novice welders to understand. In this article we will tell you what types of electrodes there are for manual arc welding and how to choose them based on your tasks.

The essence of manual arc welding

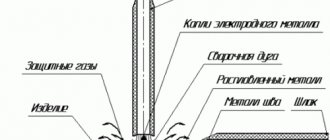

Before we talk about electrodes, let's understand what manual arc welding is. An arc is a flow of particles formed during the ionization of the anode and cathode. The ionization process itself is formed by the interaction of current and short circuit. At the same time, the welding process is also influenced by the composition of the electrode coating and oxygen obtained from the atmosphere. Together, these processes lead to heating of the arc and the release of a large amount of heat, sufficient to melt the edges of the parts being welded. The edges then cool, forming a strong and reliable seam.

The key element in this process is the electrode. Without it, it is impossible to ignite the arc and keep it burning. Welding can be done using one or more arc welding electrodes. There is no single classification of rods, since the types of electrodes for manual welding can be divided into many small categories: from purpose to materials of manufacture. By the way, the electrodes themselves for electric arc welding can be made not only from metal, and we will talk about this later.

Polarity and strength of welding current

Welding can be done with either alternating or direct current. For example, rutile electrodes can operate on both direct and alternating current, while consumables with a basic coating can only operate on direct current of reverse polarity.

When carrying out work using direct current, there are two connection options:

- When working on direct current of straight polarity, the workpiece to be welded is connected to the “+” terminal, and the electrode to the “–”.

- When using direct current of reverse polarity, the workpiece is connected to the “–” terminal, and the electrode holder to the “+”.

It should be taken into account that more heat is generated at the “+” contact. This means that it is better to weld massive parts using direct polarity, and thin sheet metal and high-alloy steels using reverse polarity. Using direct current of reverse polarity will avoid burning through thin parts and overheating of high-alloy steels.

Correctly selected amperage greatly facilitates the welding process and allows you to avoid defects during operation. There is an unspoken rule that 20-30 Amperes of current are added per millimeter of electrode diameter. The choice of current strength is also influenced by the spatial position of the weld, the number of layers of the weld and the thickness of the metal. As a rule, manufacturers indicate a range of recommended welding current values on the packaging with electrodes. Approximate current settings:

| Electrode diameter | 2 mm | 2.5 mm | 3 mm | 4 mm | 5 mm | 6 mm |

| Current strength | 40-64 A | 65-80 A | 70-130 A | 130-160 A | 180-210 A | 200-350 A |

There is no single correct setting. As a rule, the welder sets the amperage based on his own experience and feelings, as well as the equipment used. The main thing is that during the welding process, sufficient penetration depth and free control of the weld pool are ensured.

Brief classification of electrodes

As we wrote above, it is difficult to classify electrodes according to only one parameter. But basically, all rods are primarily divided by the type of material from which they are made, as well as by coating (or coating). Here is a brief classification of electrodes:

- Melting electrodes. They are made from metal, such as cast iron, aluminum, steel or copper. The material from which the electrode is made is selected in accordance with the metal that needs to be welded. Consumable electrodes are both anode and cathode. This is the most common type of rod at the moment.

- Non-consumable electrodes. Made from coal, graphite or tungsten. They are used in conjunction with welding wire, because such rods are not capable of forming a welding seam. When using carbon rods, use straight polarity instead of reverse polarity. Tungsten rods are indispensable for argon arc welding due to their high melting point, but are rarely used in manual arc welding.

- Electrodes without coating or coating. They are used in conjunction with flux, which is continuously supplied throughout the welding process. For manual arc welding, such rods are not used.

- Coated or coated electrodes. The most common electrodes on the market. The coating of electrodes for manual arc welding performs several functions at once: protects the metal from the negative effects of oxygen, ensures stable arc burning, and improves the quality of the welded joint. Such electrodes are used not only for manual arc welding, but also for semi-automatic and automatic ones.

Tools

0 votes

+

Vote for!

—

Vote against!

More and more people prefer country life to city apartments. Your farm requires a lot of work and maintenance. Very often there are times when you need to weld metal, for example, to repair a fence. And here, in order to save on calling welders, many try to master arc welding on their own. The article will discuss the choice of welding electrodes for various metals and alloys.

- Classification of welding electrodes

Types of welding machines

To understand which electrodes will be needed for a welding machine for certain jobs, you first need to understand the basic types of welding.

All welding machines are divided into two groups:

- household welders can work without interruption for a short time. They are designed for use from a regular network of 220 V with a frequency of 50 Hz, and the current rating is within 200 Amperes. These characteristics are sufficient to weld a fence, gate, reinforced frames or pipes. This means that they are optimal for the household;

- professional welders are more versatile and can work not only from 220 V, but also from 380 V. They can already produce a current of over 200 Amperes during operation. Externally, they are easy to distinguish from their household counterparts due to their larger dimensions. Therefore, for ease of work and movement, they are equipped with wheels. They are used on construction sites, installation of oil and gas pipelines and in other professional industries where reliable welding is required.

The operating principle of all welding machines, regardless of cost, is based on the use of direct or alternating current. This parameter depends on the quality of the resulting seam, the type of metal, etc.

Today, welders that work with a conventional electrode hold the lead in popularity. These are reliable devices that have been proven over the years and, thanks to their simple design, have high maintainability.

Transformer

- One of the first models of a welding machine with a primitive design. The meaning of its work is to convert high-voltage alternating current into lower voltage, resulting in welding.

- According to the adjustment method, they are divided into several main types: with standard magnetic dispersion, with increased and thyristor, equipped with an adjustment phase. Their main disadvantage is the inability to maintain a constant arc during welding. In addition, the quality of the weld is negatively affected by the presence of slag formations and gas emissions.

- Another disadvantage is their large size and weight. Sensitive to voltage surges with high power consumption. Working with it requires experience and dexterity, then you will be able to weld a high-quality seam. They are still used today, but only for rough work with cheap metals.

Rectifiers

- They are already more advanced than transformers; with their appearance, it was possible to eliminate the disadvantages of using alternating current. Their design is equipped with a block of semiconductor diodes, which allows you to convert alternating jumping current from the network into direct linear current. This device is convenient and easy to use even for a beginner, which makes it popular.

- All this made it possible to obtain seams of high quality and uniform depth throughout their entire continuation. When welding, a stable arc of high security is formed, which protects the metal from splashing of the melt.

Important: all types of electrodes are suitable for this welding machine.

- Another difference from the transformer is the ability to weld aluminum, low-alloy and stainless steel.

It turns out that straighteners are convenient for use at home and are suitable for working with a wide range of materials.

Inverter

- They appeared on the market relatively recently and immediately gained wide popularity. Today it is the most commonly used welding machine. Having low weight and compact dimensions, inverters have high power and functionality. Beginners choose them primarily because the system for setting operating modes is completely automated. For professionals, such a tool can significantly increase labor productivity.

- The first models of inverters are capable of operating only at a stable voltage, which can be guaranteed by an electric generator. Modern analogues already have a more modernized system. So, it contains a special rectifier that smoothes out the sinusoidal current from the network into direct current. Next, it is sent to the inverter unit, where, being converted back into an alternating one, it receives a higher frequency. After that, the voltage decreases in the transformer block and, passing through the power rectifier, a powerful direct current is obtained, creating a stable welding arc.

The main advantages of the inverter include:

- precise settings for different types of work;

- independent of power surges in the network;

- create high-quality welds;

- it is allowed to work even with thin-walled metals;

- a number of additional functions that are convenient to use: hot start, pulse welding, power stabilizer that prevents overheating of the device and an option to prevent electrode sticking.

Important: you can work with the inverter using electrodes of all types.

Semi-automatic

- You don't need electrodes to work with it; it works with gas. This allows you to significantly speed up the work, making the seam continuous and with deep penetration.

- Instead of electrodes, the semi-automatic machine uses wire and different types of gas, which are selected in accordance with the metal.

How to choose electrodes for welding

The quality of the seam is affected not only by the welding machine, but also by the correctly selected electrodes. Today, the market offers a wide range of electrodes for inverter welding. They are distinguished from each other not only by the coating material, but also by the diameter and a number of other characteristics that will be discussed in this article.

Classification of welding electrodes

Electrodes are usually divided into two main groups: consumable and non-consumable. The former are made of wire with a special outer coating that provides a stable welding arc. They also help protect the metal being processed from gas emissions and slag splashes. To work with stainless steel or copper, they are made from special alloys. But for argon welding it is recommended to use non-consumable electrodes.

A more detailed classification of electrodes is as follows:

- carrying out repairs or surfacing;

- welding carbon or low-alloy steel;

- welding of copper or any copper alloys;

- welding of cast iron and cast iron alloys;

- welding of aluminum and aluminum alloys;

- working with metals that are difficult to weld;

- welding of high-alloy steel;

- welding of alloys with heat-resistant properties.

How to choose electrodes based on the type of coating of the electrode rod wire:

- main electrodes. This type is represented by the most popular model UONI 13/155. With its help, high-quality welds are achieved, characterized by mechanical strength and resistance to the formation of crystallization cracks. Basic electrodes are suitable for creating critical seams on structures that are intended to be used in harsh conditions. But they also have their drawbacks: an incorrectly set arc during operation, or a wet coating can lead to the formation of a porous structure. In addition, you can only work with them on a constant reverse current;

- rutile coated electrodes . The most popular type of electrode of this group is MP-3. They are designed for welding low-carbon metal. Their advantage lies in a stable welding arc not only on direct, but also on alternating current. Regardless of the spatial location of the work, the seam is of high quality with an almost complete absence of splashes. It is allowed to cook rusty or stained metal.

Welding electrode diameters

As mentioned above, the electrodes have different diameters. This parameter is important and has the greatest impact on the welding process.

- The point is that with a larger electrode diameter, it will be possible to weld a larger thickness of metal, but at the same time it will be necessary to add more current.

- The most commonly used size is 2.5 mm, this is quite enough for home work, as it allows you to weld metal up to 4 mm thick.

- In fact, there is a huge selection of diameters, but, as a rule, only the most popular ones are on sale - from 1.5 mm to 6.0 mm. The step between sizes is 0.5 or 1 mm. If you need to purchase an electrode of a larger diameter, it will not be difficult to order it in the store.

Advice: the thickness of the metal is not always the only criterion when choosing an electrode. Experienced welders know that its properties are also important. Unfortunately, this can only be learned through experience, since there are no clear instructions on this matter. Or try to find out this information on specialized forums or blogs.

Having decided on the choice of electrode thickness, you need to understand how to select the correct current for it, because these two parameters are directly interrelated. So, if the welding current is too strong, the metal will simply burn through, and if the welding current is too low, it will not be possible to form an arc. These recommendations are given by the manufacturer on the box with the electrodes.

How to choose welding electrodes taking into account the operating mode and characteristics of the metal

- First of all, the choice depends on the type of current that will be used to perform the work. In most cases, inverters create direct current, and when welding, the electrode can be connected in two ways: with direct polarity, the electrode is connected to the “minus”, and the metal being welded to the “plus”; with reverse polarity, the connection is changed to the opposite.

- In the first case, the heat generation will be higher, which is especially good for thick-walled steel or large parts, but this is not always advisable. For example, reverse polarity is selected when welding thin sheet metal, which reduces the risk of burn-through. And when working with high-alloy steel, it reduces overheating.

The three pillars on which the principle of welding with electrodes rests are the diameter of the product, the thickness of the metal being welded and the current strength. As already written above, the thicker the metal, the larger the electrode diameter will be required. But there is one nuance here. When operating as an inverter, the thickness of the electrode will affect the operating current density, reducing it. This leads to instability and oscillation of the arc, which in turn will affect the quality of the seam - it will become wider and the penetration will be less deep. It’s good if the manufacturer of the welding machine indicated all the necessary parameters of the welding current; if there is no such data, then you can rely on average indicators:

- an electrode with a diameter of 2 mm will require a current of 50-60 A;

- for an electrode measuring 2.5 mm, this figure will be 60-90 A;

- a product measuring 3 mm is cooked with a current of 80 -140 A;

- if the electrode diameter is 4 mm, then the current should be in the range of 130-160 A;

- with a diameter of 5 mm, you will need a professional welder that produces a current of 200 A;

- a 6 mm electrode is welded with a current of at least 220-240 A.

Brands of imported welding electrodes

Foreign electrodes are quite widely represented on the Russian market. They have their own markings, which are easy to understand. The most popular brand we have is called ESAB. It labels its electrodes with alphanumeric values. OK always comes first, followed by 4 digits.

Below we will explain which electrodes to choose:

- OK 46.00. This is an electrode with a rutile coating, an analogue of the Russian MP-3. Will create a seam with high performance on alternating or direct current. Suitable for welding carbon and low alloy metals.

- OK 48.00. Capable of operating exclusively on direct current, while creating reliable seams. This makes it popular when working with critical structures.

- OK 53.70. Ideal for welding pipes, these electrodes are classified as specialized types.

- OK 61.30 and OK 63.20. They cook stainless steel.

- OK 68.81. Recommended for welding difficult-to-weld metals;

- OK 92.60. Designed for cast iron alloys or when connecting cast iron with another metal;

- OK 96.20. Required for working with aluminum.

General tips on how to choose the right electrodes

Summarizing the above, you can clearly formulate for yourself the main criteria for choosing electrodes for operating an inverter.

- The choice depends on the type of metal, its thickness and properties. If you need to make a critical seam, it is better to choose products from well-known manufacturers who have been confirming the quality of their electrodes for years.

- When working with carbon steel, the surface must be absolutely clean. If there are traces of rust or dirt that cannot be cleaned, then you need to choose products with rutile coating.

- When welding work at critical sites, basic electrodes are the best choice.

Types of electrodes by purpose

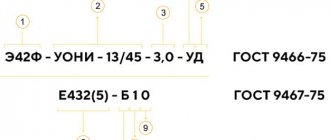

Depending on the metal being welded, the operating mode of the welding machine and electrodes are selected. Different metals require different electrodes, this is called purpose. The purpose is indicated by one letter on the packaging and on the rod itself.

Electrodes marked “U” are used for welding low-alloy and carbon steels. The letter “L” denotes rods used for welding alloyed structural steels, and for high-alloy steels the designation “B” is used. The letter “T” denotes rods for heat-resistant metals, and the letter “H” denotes rods for surfacing.

Types of coatings for electrodes

Along with the material of manufacture and purpose, the type of electrode coating is also selected. The choice of coating also depends on the metal being welded. The coating (or coating) performs a protective function. When the electrode melts, the coating releases protective substances and slag, which improves the quality of the seam and produces reliable and durable welded joints. Manufacturers use the following types of electrode coatings:

- Acid coating. Marked with the letter “A” on the packaging and the electrode itself. Used for highly targeted applications, such as bottom welds. Can be used with both AC and DC current.

- Rutile coating. Marked with the letter "P". One of the most popular coatings among both beginners and professionals. Compared to other coatings, it is almost non-toxic and provides good quality seams. When burned, it forms slag with protective properties. The composition can be varied, but the base is always titanium dioxide or simply rutile. Hence the name.

- Cellulose coating. Marked with the letter "C". Suitable for making any welded joints, ensures good quality of the seam, but at the same time contributes to strong metal spattering. We recommend using cellulose-coated electrodes when welding pipelines, since the disadvantages are not critical in such work.

- Basic coating. Denoted by the letter "B". The most popular type of coating along with rutile. Simulates gas welding due to the release of carbon dioxide when the arc burns. We recommend using base coated rods only in combination with direct current and reverse polarity. If you use alternating current, the weld will be of poor quality and additional measures will be required to improve the strength of the seam.

- Other types of coatings. Marked with the letter "P". The composition contains alloying substances. Thanks to this, the quality of the seam improves. In general, other types of coatings are used the least often.

- Special types of coatings. They are designated by the letter “C” or the inscription “special” on the packaging. They are used for complex welding under water, since they contain liquid glass and resin-containing substances.

As you can see, electrodes are selected based on specific tasks. For manual arc welding, rutile-coated rods are most often used because they are universal.

Basic coating

It is known that it contains calcium salts - carbonate and fluoride. Its advantage is considered to be a low hydrogen content. Typical representatives of electrodes with basic coating are UONI products. Their coating ensures a high-quality seam, both in appearance and in technical indicators: ductility, strength, impact strength.

The electrodes do not form crystalline cracks inside the seam, therefore they are recommended by specialists for critical welding operations and for products operated in harsh climatic conditions. They can be used when welding in any position except vertical.

Selecting the electrode diameter

Most novice welders classify welding rods by diameter, which is correct. After all, the diameter of the electrode directly depends on the thickness of the part. And even if you choose a rod with the right coating and from the right material, but the size is wrong, you will not get a quality seam.

The diameter of the electrode is indicated in millimeters on the packaging or on the rod itself. In this case, the length of the electrode also depends on the diameter. For welding at home, arc welding electrodes with a diameter of 2 to 4 mm are usually used. This is a universal size suitable for most welding jobs. Thicker electrodes are used in factories or private workshops.

Popular and best domestic electrodes for welding

ATTENTION! The following information is based on publicly available data at the time of this writing. For greater objectivity, we will make our own rating of welding electrodes, which is given below. We invite you to add your voice.

As a result of marketing research of the welding materials market, the most popular brands in recent years are:

- Resanta.

- SpetsElektrod (Moscow).

- “LEZ”.

The expert rating is as follows:

- KOMZ.

- ESAB-Tyumen.

- “Penzaelectrode”.

- “LEZ”.

- "SEZ".

[ads-pc-4][ads-mob-4]

Selection of electrodes depending on the type of seam

It is also advisable to select electrodes for manual arc welding according to the type of seam with which you are going to weld metal. In addition to the standard horizontal, vertical, inclined and angled seams, there are also oblique, butt, beveled and many others. This is more useful for experienced welders, but novice welders should also know this information. Now let's talk about what types of electrodes there are for manual arc welding.

Electrode grades suitable for manual arc welding

There are also types of electrodes for manual arc welding, divided by brand. The brand of electrode you use also depends on the metal you need to weld.

The following grades are used for welding low-alloy carbon steels:

- E42: grades ANO-6, ANO-17, VSC-4M.

- E42: UONI-13/45, UONI-13/45A.

- E46: ANO-4, ANO-34, OZS-6.

- E46A: UONI-13/55K, ANO-8.

- E50: VSC-4A, 550-U.

- E50A: ANO-27, ANO-TM, ITS-4S.

- E55: UONI-13/55U.

- E60: ANO-TM60, UONI-13/65.

For welding alloy steels (including high-strength):

- E70: ANP-1, ANP-2.

- E85: UONI-13/85, UONI-13/85U.

- E100: AN-KhN7, OZSh-1.

- E125: NII-3M, E150: NIAT-3.

For metal surfacing: OZN-400M/15G4S, EN-60M/E-70Kh3SMT, OZN-6/90Kh4G2S3R, UONI-13/N1-BK/E-09Kh31N8AM2, TsN-6L/E-08Kh17N8S6G, OZSh-8/11Kh31N11GSM3YuF.

For welding cast iron: OZCh-2/Cu, OZCh-3/Ni, OZCh-4/Ni.

For welding aluminum and its alloys: OZA-1/Al, OZANA-1/Al.

For welding copper and its alloys: ANTs/OZM-2/Cu, OZB-2M/CuSn.

For welding nickel and its alloys: OZL-32.

How to choose quality electrodes

Like any welding equipment, electrodes are subject to GOST standards, which regulate their quality. Thus, according to regulations, rods must be made of high-quality materials purchased from certified suppliers.

The coating of electrodes for manual arc welding should not have significant defects; small cracks and dents are allowed due to poor transportation. When melting, the electrode coating should not crumble or melt unevenly, and should also splash within the normal range for each specific type of coating.

The rods must be strong and resistant to mechanical stress. The seam should be of high quality, without cracks or pores. Knowing these features, you can easily choose high-quality electrodes and be confident in the result.