Everyone who has seen this photo admires the courage of the builders and the skill of the unknown photographer. But few people pay attention to perhaps the most important detail of the plot. Without her, most likely, there would have been neither a photo nor such a construction project. We are talking about a beam on which workers sit. This is an element of the supporting structure of the skyscraper, which today is part of Rockefeller Center. The total height of the building is 259 meters.

Such tall buildings in the United States and around the world appeared due to the fact that at the beginning of the twentieth century, rolled metal began to be actively used in construction. And metal structures became the load-bearing elements of skyscrapers instead of bricks. And they were assembled, among other things, from beams - one of the main types of large-grade shaped metal products.

Shaped metal products are one of the types of long products. But it has its own characteristics and areas of application.

What is the difference between shaped rolled products and simple shaped profiles? There is a very simple answer. If the tangent to any point of the contour of the rolled section does not intersect any part of it, then it is a regular long rolled product. But in shaped steel, due to its complex shape, such tangents intersect its cross section.

In turn, shaped steel also has two main classifications.

According to the form they are distinguished:

- angular;

- T-bar;

- beam;

- trough (for example, Larsen tongue);

- zeta (Z-profiles);

- special purpose profiles, etc.

For industrial purposes:

- general purpose profiles (equal and unequal angles, I-beams/I-beams, channels);

- profiles for special purposes (rails, tongues, special profiles, strip bulbs, etc.).

Characteristics of shaped metal products

Angle, I-beam and channel belong to the same group of rolled metal not only because of the cross-section characterized by intersecting longitudinal strips. They also have other unifying characteristics:

- workpiece material - structural, low-alloy or carbon steel;

- production method - hot rolled, cold rolled, bending or welded;

- The purpose of the product is to accept and redistribute constant and variable external load.

The material for future shaped rolled products is selected depending on the requirements for the final metal product. Thus, for buildings located in harsh climates or structures that will be subject to large mechanical loads, profiles made of low-alloy steel are chosen. And for structures erected in places with an aggressive environment, rolled carbon galvanized steel is most often used.

The shaped profile, which is obtained after processing, is a ready-to-use product, in contrast to long and flat rolled metal, which is an intermediate blank for other types of metal products.

Features of the production of shaped steel

All rolled steel is produced from semi-finished products: sheets and coils are made from slabs, pipes are made from round billets, and long products are made from blooms and square billets.

If you delve deeper into the technology for the production of shaped rolled products, you can find an interesting feature: at some metallurgical enterprises in the world there are continuous casting machines (CCMs), which immediately produce a workpiece of a complex multifaceted shape - the so-called beam billet or “dog bone” (the semi-finished product in cross-section resembles this dog treats). From this form it is clear what kind of products will be made from it at rolling mills - wide-flange I-beams. This allows you to significantly reduce energy and time costs for the production of rolled metal.

Other types of shaped steel are produced from blooms and squares of various sections. From steel smelting shops, semi-finished products are sent to rolling shops. There it is heated and compression begins to give it the desired shape.

For example, at the AZOVSTAL iron and steel plant, deformation begins on the two-roll reversible stand 1000.

The processed semi-finished product, in which the shape of the future product can already be guessed, is sent for further rolling to the three-stand rolling mill “800”, which consists of two “trio” stands and a finishing “duo” stand. The final molded products are cut into lengths, cooled, straightened and sent for final finishing and acceptance.

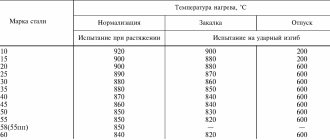

The most common steel grades used in the production of shaped steel are S235JR, S355J2, S420M, St3sp, St5ps, 09G2S, 10KhSND and 15KhSND. They are determined in accordance with the requirements for structures in which such metal products are used. For example, low-alloy steel grades provide high strength and stable operation at both high and low temperatures.

Features that allow you to distinguish between types of shaped profiles

In addition to appearance, each type of rolled metal is also distinguished by its application features.

- An I-beam is most often used as a load-bearing element of light structures that must withstand large variable loads - bridges, overpasses, mines.

- A steel channel acts as an effective support element in structures that must be resistant to compression and tensile loads, for example, in roof frames. It is used in the construction of structures with numerous connecting elements. It ensures a reliable connection of parts and distributes the resulting load, transferring it to the base of the structure.

- Steel angle is a universal shaped metal product, most often used in the creation of small-sized objects that are subject to dynamic loads - railway transport, trams, cars.

Purpose

Long rolled steel is practically not used in its “raw” form without processing, but is used for production or processing. It is used to make products of complex shapes, with bent and welded elements, stamp small parts, bend them and otherwise process them on machines. It turns out that in almost all cases this is a useful product sold at a low price.

The profile (another name for shaped metal) is intended, first of all, for creating frames of various kinds, since it is very durable due to the presence of stiffeners. It is also well suited for metal structures and reinforcement, and large sizes are used to strengthen critical objects, such as bridges.

Minimizing the cost of purchasing rolled metal products

The solution to the same construction problem is possible using different types of rolled metal. This is especially true for structures that do not have high requirements. In our catalog you can find a large assortment of shaped metal products of different price categories, which will help not only minimize costs, but also save time. Another way to minimize costs is to purchase rolled metal of unmeasured length, which has a low cost, and independently cut it into elements of the required length. This method is especially good for those who have a tool capable of performing this task. However, the best way to save money is considered to be one in which you do not have to regularly spend additional money on repairs to the constructed facility. To do this, you just need to purchase high-quality materials once, the construction of which will have a long service life.

Name

Long products are often called simple rolled steel or simple ferrous rolled metal. To avoid confusion, it is better not to use this unofficial name. In the same way, the shaped version also has a “nickname”; it is often called “curly”, however, it is better not to use this name.

The reason is that the classification of the assortment occurs according to the cross-section of the rolled product. The varietal version has the simplest possible cross-sectional shape - a line (steel sheet), a rectangle, a circle, a square, a hexagon. In other words, any tangent drawn to the contour line must not intersect with the section plane itself. In the shaped version, some figure appears in the cross-section in which such a rule does not work (for example, imagine the cross-section of an I-beam or channel).

Sections and shaped metal products must be selected according to their intended purpose.

Service

Our advantages

- Discounts on products up to 35%, on delivery - up to 10%

- Payment in cash and non-cash means

- 100% deferred payment up to 30 days

- Products in stock and for individual order

- Processing orders from 1 business day

Delivery terms

- Shipment on the day of payment

- Own vehicle fleet with vehicles with a carrying capacity from 1.5 to 30 tons

- Express delivery throughout the CIS

- Cooperation with SDEK and Business Lines

Service

- Packaging of goods according to GOST or customer requirements

- Free storage service in covered warehouses “BVB-Alliance”

- Cutting and bending metal to size

- Manufacturing of metal structures of any complexity

About Us

- 14 years in the rolled metal

- Representative offices in major cities and neighboring countries

- Member of the Russian Union of Suppliers of Metal Products (RSPM) since 2018

- We work according to Russian and foreign standards GOST, TU, ASTM, EN, DIN

offers shaped rolled steel for sale in Moscow, the products are certified according to GOST, and undergo strict production control at all stages of production. We guarantee product compliance with Russian and European quality standards. You can find out all the necessary information on delivery times, delivery conditions and product prices by calling. You can also contact us by e-mail:

Application

Shaped rolled steel is used in the construction of ships and cars, the production of parts for instrumentation and mechanical engineering, and motor vehicles. In the construction industry, shaped metal products are used to strengthen load-bearing elements and structures when carrying out installation and repair work.

You can also find out prices for stainless steel channels from us.

We are ready to manufacture products of any complexity in our workshops!

Deliveries in Moscow

will supply shaped rolled steel from a warehouse in Moscow to any locality in the Russian Federation and to the CIS countries. You can find out all the necessary information on delivery times, delivery conditions and product prices by calling +7(499)490-20-31. You can also contact us by e-mail: Call! We will advise!

Characteristics

Quality standard: GOST 535 – 2005.

Shaped products can be general purpose and special purpose.

Rolled elements for special purposes: railway rails for railway transport and tram rails, special profiles for energy, shipbuilding, oil refining, mechanical engineering, etc. The main elements of shaped rolled metal for general purposes: angle steel profile, steel channel and steel I-beam.

According to the method of surface treatment, shaped rolled products are distinguished for use without further processing.

Production methods: hot rolling, heat treatment.

Raw materials: ordinary quality carbon steel, high-quality carbon steel, low-alloy steel.

Long products - features, advantages and scope of use

The main feature is the correct geometric shape of the section. This group of rolled metal products includes:

- Circle.

The hot-rolled variety has a diameter from 5.0 to 270.0 mm, larger sizes are made to order. It is used in construction, mechanical engineering, for the production of fasteners, as a workpiece for cold processing. To improve the accuracy of parameters and surface quality, they are subjected to cold deformation.

The diameter of cold-rolled and drawn circles ranges from 3.0 to 100.0 mm, they are used without treatment and subjected to heat treatment, used in mechanical engineering, in the production of household appliances, and industrial equipment.

- Square.

Produced by hot rolling, side sizes range from 8.0 to 200.0 mm. Fasteners are made from the square and subjected to cold deformation. Calibrated products are characterized by precise dimensions and high-quality surface; side parameters range from 3.0 to 100.0 mm. Scope of application: automotive industry, equipment production, interior design.

- Hexagon.

Has a hexagonal cross section. Its size is equal to the diameter of the inscribed circle, the range is from 8.0 to 103.0 mm. Bolts, nuts and other fasteners are made from hexagons.

- Band.

In cross section it has the shape of a rectangle. It is made from different grades of steel and is used for the production of a variety of products - springs, decor, cutting tools. Width varies from 10.0 to 200.0 mm, thickness - from 4.0 to 80.0 mm.

The general advantageous characteristics of high-quality metal products are:

- Widely used in the form of blanks for forged and other products;

- resistance to corrosion;

- malleability to processing - cutting, forging, bending.

Surface

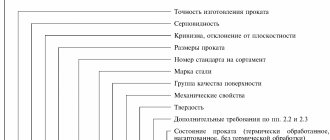

Since long rolled metal products are used as blanks, they can have different quality of the finished surface, intended for additional processing or ready-made. This factor can be found out from the labeling.

3GP says that products can be cut and processed in a cold way. 2GP signals the necessary hot and pressure treatment. Finally, 1GP indicates a surface that has already been treated, which can no longer be touched. The shaped profile is produced only with the latest surface treatment option, since it is essentially a ready-made product of complex shape that does not need to be further modified.