A meat grinder is one of the most basic and in-demand cooking tools. And despite the wide selection of household appliances today, even super-fashionable food processors or blenders have not been able to supplant this device.

And if literally 10-15 years ago every apartment had only a mechanical type of meat grinder, today almost every housewife has an improved electric model. How to properly assemble an electric meat grinder, and are there any nuances to the assembly process?

Types and features of designs

Thanks to the significant rise in the market of household appliances and modern appliances, the choice of meat grinders is quite wide, and allows everyone to choose the most suitable option for themselves in many respects. Theoretically, they can be divided into two types - electric and manual, that is, mechanical.

Thanks to the large number of attachments and knives, these devices are very multifunctional and convenient to use. With their help, you can not only twist minced meat, but also make many different dishes, for example, sausages or sausages, prepare freshly squeezed juice, vegetable puree, you can even make your own pasta (pasta).

Today, the electric type of meat grinder is very popular. Firstly, working with such a device does not require any physical effort. Secondly, it will take much less time to process food using such a device, because you just need to place the product in the meat receiver and press the start button. In just a few minutes, minced meat or any other product will be ready. And thirdly, unlike mechanical devices, this device has many different attachments.

However, there are also negative sides. And the first of them is the lack of control over the presence of bones in the meat. If manual meat grinders are not afraid of this problem, then in the case of their modern analogues, the device may simply deteriorate. The second disadvantage is that the entire cooking process is directly related to electrical power. Therefore, if the power is turned off or the motor in the device burns out, or some other part breaks down, then it will simply not be possible to prepare food using an electric meat grinder.

Unlike the manual type, when working with an electric meat grinder, it is possible to select the degree of minced meat grinding, thanks to different grinding speeds.

Types of meat grinders

Since meat grinders have been around for a very long time, there are many types of them. In addition, they tried to replace them with combines and blenders. And the manufacturers of meat grinders had to come up with as many interesting functions and “tricks” for them so that they would not lose their necessity. They are equipped with a huge number of knives and attachments, which give the devices incredible functionality and ease of use. With them you can turn meat into minced meat, make sausages and pasta. In addition, they can be used to prepare homemade sausage and even juices and purees. But in order not to get confused in the many types of these devices, we will consider two global and main types of these devices.

These are manual and electrical appliances. It is the latter that are now super popular among most people. In order to twist the meat with them, you do not need to exert much physical effort to stuff the sausage and twist it. Just press the “Start” button and watch the process of preparing minced meat. True, they also have a number of disadvantages. For example, if you missed a bone, the device will definitely be damaged because it will not be able to cope with it. Besides, if the lights in the house suddenly turn off, you won’t be able to make minced meat. And sometimes the motor in the devices burns out, and then you just need to buy a new one.

For many, mechanical Soviet models (knowing how to assemble them correctly is very important) are antiquities that it’s time to forget. However, they are incredibly reliable and durable.

This has been proven in practice. And it is almost impossible to break them. The only thing that can become faulty is the knives. But you can sharpen them yourself at home. And they will last for a very long time.

As a rule, their body material is cast iron, stainless steel or durable plastic. However, some can be made from aluminum. Cast iron devices are almost impossible to break. They are practically eternal. And many people love them and consider them much better than their electric counterparts. But they are very heavy. And they can be a little tricky to install. You may even have to ask a man for help every time you install and remove it. Although maybe this is better. But modern aluminum devices are much lighter. Here you no longer have to put in additional physical effort. At the same time, they can serve you just as long as steel or cast iron and do their job with the highest quality.

As for plastic models, they are lightweight and functional. But at the same time, they are very fragile, they must be handled with extreme care, and they must be avoided from falling or sharp blows.

Devices also differ in power

It is important to know how much meat you plan to process. For example, if the power of the device is 1000 W, then you can grind up to 1.3 kg of meat without fear that something will break

Each device has a power reserve, which will be needed if veins or cartilage get into pieces of meat. In this case, the device goes to maximum operation. This is very harmful for him. So try to avoid this.

Devices are also divided into household and professional. The latter have much greater power. They are needed so that the kitchens of restaurants and cafes can quickly process orders and prepare dishes. But the first ones are not so powerful, they are much smaller in size, but are ideal for use in the home. Moreover, you don’t need any huge power in everyday life; you won’t be doing too much work.

Also, some models are equipped with a reverse system. It allows the screw in the meat grinder to rotate in the opposite direction. This helps a lot if veins accidentally get into pieces of meat. The device slows down, and you can get them out.

What does an electric meat grinder consist of?

The design of this type of kitchen appliance consists of durable plastic. And if in the case of a manual one, the entire body consists of metal, then in this case there are only individual metal elements. A motor is built into this body, which performs the main function. By pressing the start button, the device is activated and begins to work.

Another difference is the absence of a handle. There is simply no need for it here, since the machine performs the main function independently, from the operation of the engine. Almost all models have a removable meat receiver, which must be attached to the main body before starting work.

The kit usually includes a special pusher for the food being processed, with which it is convenient to move the food towards the knife. At the end of the screw there is a corrugated plastic rod that provides fixation. And thanks to the convexities on the knife, more gentle and high-quality chopping of meat occurs. This is one of the differences between the new model and the old one.

What is the working principle of the mechanism

A manual cast iron meat grinder is a common household item found in every kitchen, where a woman is used to preparing all kinds of dishes herself.

When disassembled, the manual meat grinder consists of six parts that must be correctly assembled into a single whole so that it can be used to obtain minced meat.

All parts except the handle and the clamping nut, necessary for firmly fastening the mesh, are inserted one by one into the round hole of the all-metal body.

We also recommend our article How to choose the right electric meat grinder for your home?

There are three holes in the body, by looking at which you can answer the question of how to assemble a manual meat grinder.

- A meat receiver where products that require processing are loaded.

- The rear large exit of the auger shaft is intended for a handle that will rotate it. To ensure that it sits firmly, manufacturers can equip the meat grinder with a special nut. Some housewives remove it because it interferes with their work. Therefore, it is sometimes missing on old meat grinders.

- The front outlet is for the thin end of the shaft on which the knife and mesh are attached.

At the bottom of the housing is equipped with a special device, with the help of which the unit is tightly attached to the kitchen table for work.

What is included in the set of kitchen unit parts:

- The screw shaft is a large spiral necessary for delivering processed products to the knife.

- A knife in the form of a disk or a four-wing propeller, properly positioned, is capable of grinding many products.

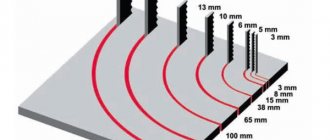

- The grate is a flat disc with a large number of holes, which determines how well the final product is crushed.

- A clamping nut that is screwed on top and secures the grid and knife to the shaft.

- Handle attached on the opposite side. It can be freely installed on the outgoing end of the screw shaft or attached to it with a special screw.

Having dealt with all the details, you can learn how to assemble a manual meat grinder.

Read also our article Useful kitchen appliances.

How to properly assemble an electric meat grinder?

If you have already encountered assembling a manual meat grinder, then assembling an electric product will not bring any difficulties. As a rule, the assembly process is described precisely and in detail in the instructions for a particular model, and depending on different manufacturers, some nuances may vary slightly.

Algorithm for assembling an electric meat grinder:

- The first step is to connect the gearbox housing to the metal housing of the auger. The end of the auger must be immersed in the plastic groove of the gearbox. Afterwards, you need to smoothly scroll it counterclockwise until you hear a characteristic click. If the parts are not connected tightly, the motor simply will not be able to turn the auger during operation.

- When inserting the auger, pay special attention to ensure that the protrusion clearly aligns with the hole on the body. Otherwise, the screw shaft simply may not work.

- It is necessary to put a blade and a grid on the other end of the auger, paying attention to the coincidence of the protrusions and holes. At this stage, it is important to place the knife blade on the correct side.

- Secure all parts with a clamping nut, as if using a manual meat grinder.

- Install the loading bowl, after which you can begin working directly with the device.

According to the principle of operation, a manual and electric meat grinder are almost identical. And if you have experience in mechanical assembly, then the modern version of this technique will not cause problems at all.

Operating principle of a manual meat grinder

One of the main elements and functional parts of the meat grinder is the screw shaft; it moves pieces of meat to special knives, which are fixed at the end of the shaft on special attachments. Thus, slowly but surely the raw material reaches the grinding and forming mesh. It comes in different shapes and hole sizes so that you can choose the desired consistency of the future minced meat.

All elements of a manual meat grinder are standard; they may differ only in the set of additional accessories

When purchasing a manual meat grinder, pay attention to the quality of the material from which the body and main parts are made. Even in a plastic meat grinder, knives and grids must be metal

Otherwise, such a meat grinder can simply be handed over to a toy store.

Even in a plastic meat grinder, the knives and grids must be metal. Otherwise, such a meat grinder can simply be handed over to a toy store.

Unlike older models, some modern variations are equipped with siphons for squeezing juices or are used instead of a grater. Most of these devices, of course, are produced for electric drive, but you can also find manual and mechanical models.

How to disassemble and clean a meat grinder?

After each use, it is important to completely disassemble and clean the household appliance to avoid food drying out and the proliferation of bacteria and pathogenic microorganisms. This can lead not only to a number of diseases, but also to the unsuitability of equipment. Washing the assembled device is not permitted!

It is simply impossible to completely clean a mechanical meat grinder when assembled, and in the case of an electric one, a short circuit and fire may occur.

Algorithm for disassembling an electric meat grinder:

- In the case of a removable meat receiver, the first step is to get rid of this particular part by pulling it out of the neck.

- Next, you need to turn the clamping nut, carefully holding all the contents.

- Take out the grate and knife blade.

- Remove the auger from the body of the electric meat grinder.

After disassembling the device, you must thoroughly rinse all parts with detergent and running water, and the grille can be cleaned with a match or toothpick. After washing the parts, it is recommended to place them on a napkin or spreader, leaving them to dry completely.

The electric meat grinder and all its parts must be stored in a dry place. Otherwise, fungus and rust may form, which will render the device unusable.

It is not recommended to wash knives with hot water, as this reduces their sharpness, rendering the device inoperable. And the body of the meat grinder, into which the motor is built, can be simply wiped with a damp cloth or cloth. It is forbidden to lower the housing under running water, as this will render the meat grinder unusable and may subsequently cause a fire, electric shock or short circuit.

Operating rules

To ensure that the meat grinder lasts as long as possible, pay close attention to the features of its operation and the preparation of products before placing them in the tray.

- Prepare the meat thoroughly before grinding. Cut the fillet into small pieces and remove bones and veins.

- Make sure that the knife is always sharp. If you follow this rule, the device will quickly grind various products.

- To ensure that products pass smoothly inside the device, lubricate all components with sunflower oil.

- Always disassemble and wash all components after using the meat grinder.

- Store the meat grinder unassembled.

On the Internet you can find recommendations for cleaning the assembled meat grinder using lump sugar. In reality, such a process will not bring a guaranteed result. The device will still have to be disassembled and washed in the usual way.

Installation of additional components

Most modern meat grinders come with additional knives, grates with various holes and attachments for preparing sausages or kebbe. If it is necessary to use them, the order of assembling the meat grinder may vary, which is also usually specified in detail in the instructions for the device from the manufacturer.

In this case, you should adhere to the following algorithm for assembling an electric meat grinder:

- installation in the middle of the auger body;

- attaching a ring with the largest holes to the auger (their number may vary depending on the meat grinder model and manufacturer);

- installation of a double-sided knife;

- installation of a grille with medium-sized holes;

- fastening the remaining knife;

- installation of the last grate;

- securing the clamp nut.

In the case of preparing sausages, instead of knives and grates, you will need to attach a special attachment to the auger, which is secured with a clamping nut. And for the purpose of making cookies or pasta, you can use metal or plastic shaped rings.

Often, such household appliances include a nozzle for juice and pasta. Usually they are already assembled and you just need to attach them to the main body of the meat grinder.

When assembling an electric meat grinder, it is better to follow the factory instructions from the manufacturer. If a household appliance malfunctions, it is recommended to contact a service center for diagnostics and repair if necessary.

Step-by-step assembly algorithm

How to assemble a mechanical meat grinder? To do everything correctly, you need to follow the operating instructions that come with each product. If it is missing, then we will tell you a step-by-step assembly method.

- The main shaft or auger must be inserted into the housing, with the handle attachment point coming out from the opposite side, and the remaining parts are installed at the thinner end.

- Installing the knife is the most important task; one side of it is flat and polished to a shine, so this part must face the grate in order to slide along it while working. Many users are confused about which side the cutting tool should be placed on - as a result, the device is assembled incorrectly.

- When installing the disk version, the cutting edge also always faces the grille. It is this moment that is of great importance - it all depends on how to install the knife correctly so that the meat grinder chops the food and does not crush it.

- Now it’s time to install the grille correctly - it has a special groove that must be inserted into the protrusion on the main body. The grid should fit snugly against the cutting tool.

- The final step is to tighten the clamping device, which securely fixes all the parts inside the case.

- Now you can install and secure the handle to rotate the mechanism. The meat grinder is assembled - you can attach it to the edge of the table and prepare minced meat.

We described in detail how to correctly assemble a manual meat grinder yourself; the main task is to correctly install the knife and grid, otherwise the product will not work. How to properly position the product for work is shown in the photo below.

Basic rules of use

How to use a household electric meat grinder so that it serves its owner for a long time without expensive repairs and replacement of important elements? There are several simple rules, the observance of which guarantees long-term and safe operation of the device:

- When preparing products for processing, carefully remove the tendons, free them from bones and hard-to-grind parts that can cause failure of the knives and power drive;

- Cut the meat into pieces that can easily fit into the neck of the meat receiver;

- Always keep your knives sharp. A sharp cutting tool will provide higher productivity in the production of minced meat, pates, etc.;

- After use, you should immediately disassemble the grinding mechanism, thoroughly rinse and dry all its elements, and then place it in storage;

The grinding mechanism must be washed immediately - Before assembling the device, lubricate the surface of the grid adjacent to the knives and the auger shaft with oil. This will reduce friction and ensure better passage of the product through the mechanism;

- Do not overheat the device. Household models are not designed for long-term continuous operation in intensive mode;

- For safety reasons, use the standard pusher to push food toward the auger. The length of the pusher corresponds to the depth of the meat receiver, which avoids jamming of the auger and failure of the power part of the device.

An electric meat grinder is a simple and useful device that can significantly simplify the process of preparing minced meat and diversify your diet with original homemade delicacies and dough products.

Watch a video on how to properly mince meat

Device Features

Today the market offers two options for devices for rolling meat:

- electric meat grinders;

- manual models.

The general design of such a device is quite simple, and its main function is the processing of meat products to a homogeneous soft mass.

Electrical and mechanical devices are found in every kitchen.

The principle of operation of a mechanical meat grinder and differences from the electric model

The diagram of a manually driven device is clear even to a child

Before you figure out the differences between an electric and manual meat grinder and how to properly assemble the meat grinder immediately before use, you should first pay attention to some points

It is important to understand the operating principle and have an idea of the appearance of the parts, and only then will it not be difficult to assemble an electric meat grinder or its manual equivalent

It is important to understand the operating principle and have an idea of the appearance of the parts, and only then will it not be difficult to assemble an electric meat grinder or its manual equivalent. What does a manual meat grinder consist of:

What does a manual meat grinder consist of:

| Image | Manual meat grinder parts |

| Metal body Usually this is a whole cast container with a meat receiver in the form of a wide tube extending upward. | |

| Spiral Shaft This screw shaft serves as a pushing device to feed the meat to the chopping knives. | |

| Knife Can be in the form of a cross-shaped or disk-shaped part with sharp edges and a hole in the middle. | |

| Disc-shaped grille with holes. Some meat grinders may have several such grates, and the diameter of the holes in them allows you to adjust the degree of minced meat grinding. | |

| Clamping cover in the form of a wide nut It allows you to tightly press the shaft, insert knife and grid, avoiding play. | |

| Pen It is put on the part of the auger shaft protruding from the housing and secured with a special clamp. It is the movement of the handle that ensures the rotation of the spiral inside the body and this is how the meat is minced. | |

| Clamp It allows you to secure the device to the work surface. |

The main difference between an electric device and a manual one is how the screw shaft is driven. Unlike its mechanical counterpart, an electric meat grinder has a special electric motor installed, which rotates the shaft. It is enough to turn on the device and press the button, placing meat in the receiver in a timely manner.

The manual unit is attached to the working surface using a special clamp

Step-by-step assembly of a hand-held device

Assembling a manual meat grinder may seem complicated, but after the first time this procedure will take a matter of seconds and seem elementary.

How to properly and quickly assemble a manual meat grinder? The table describes each action in detail, and the photos attached to each step will allow you to clearly navigate and perform all the steps correctly:

| Image | Instructions |

| Step 1 The spiral (screw shaft) is installed inside the housing so that it is completely inside. The shaft part for attaching the handle should easily fit into the special hole in the housing. | |

| Step 2 Now it's time to install the knife and grill. The blades should be installed on the shaft so that the flat surface of the knife faces the grate. This will be the answer to the question of how to properly place a knife in a meat grinder. | |

| Step 3 When the blade has taken its rightful place, the grate is placed nearby. All that remains is to secure the mechanism with a screw-on cap in the form of a large nut. | |

| Step 4 The handle is attached and screwed on the opposite side of the meat grinder. | |

| Step 5 There is nothing complicated about the question of how to install a meat grinder on a work surface. It is enough to secure the unit on a flat and durable table using a special screw. By making rotating movements of the screw, we set in motion the clamp, which firmly fixes the meat grinder. |

Assortment of goods in the “Spare parts for everyone” store

We supply only original spare parts for meat grinders, which are of high quality and wear resistance. The product catalog is constantly updated with new components, which increases the opportunity to choose the right part specifically for your equipment.

Spare parts in our catalog are compatible with brands such as: Bork, Bosch, Braun, Cameron, Kenwood, Elenberg, Panasonic, Philips, Polaris, Rolsen, Scarlett, Tefal, Vitek, Moulinex, Redmond, Saturn, Siemens, Zelmer and others. If you have not found a part of your brand, contact our manager - he will help you choose the right model.

If your meat grinder is broken, but you don’t know which part is broken and how to replace it, contact the manager using the feedback form on the right side of the website. Our consultant will study your problem and offer a detailed algorithm of actions to check the functionality of the main working units. You can also call a technician from our store to carry out a comprehensive diagnostics of the device.