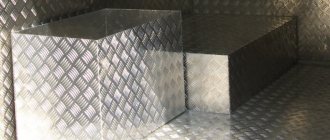

Corrugated steel sheet is a rolled product with corrugations on the surface of the sheet in the form of rhombic elements or lentil grains. For the manufacture of sheet products, steels St0, St1, St2 and St3 are most often used. The thickness of the product is 2.5-12 mm. The height of the corrugations is 10-30% of the sheet thickness, but not less than 0.5 mm.

The size of the sides of the rhombic elements is (25-30) x (60-70) mm. By agreement with the counterparty, the manufacturer can produce rolled products with a non-standard pattern. The distance between the lentil corrugations is 20, 25 or 30 mm. The length of the product is 1400-8000 mm, and the width is 600-2200 mm. The size change step is 60 mm.

| Table of main characteristics of corrugated sheet | |||

| Drawing | Sheet thickness, mm | Weight, kg | Standard |

| diamond knurling | from 2.5 to 12 | from 21.0 to 99.3 | GOST 8568-77 |

| lenticular corrugation | from 2.5 to 12 | from 20.1 to 96.8 | GOST 8568-77 |

Factories produce corrugated sheets of measured and unmeasured lengths. The sheets have normal and increased accuracy. Products can be produced in rolls. The marking of the corrugated sheet indicates the following characteristics:

- Type of corrugation.

- Steel grade.

- Dimensions.

- Accuracy class.

- Other parameters (type of flatness and nature of edge processing).

At the end of the marking, GOST is indicated, which defines the technical characteristics of rolled products. As an example, we can give the following symbol: Rhombus sheet V-K-2.0x1000x1500 St1 GOST 8568-77.

The indicated marking indicates a steel sheet with rhombic corrugations and a rolled edge. The length of the product is 1000 mm and the width is 1500 mm. The height of the corrugation is 2 mm. The rolled products are made of steel grade St1. The product parameters comply with GOST 8568-77 standards.

Application

The sheet is characterized by high strength and wear resistance. The steel alloy is resistant to corrosion and mechanical stress. To improve the technical properties of the product, galvanizing is used. Corrugated sheets are used as flooring in non-residential buildings. Sheets with lentil corrugations, made in accordance with GOST standards, are used for finishing building structures, ramps, stairs, paths and bridges. Steel products are used for lining refrigerators and freezers.

For finishing industrial premises, sheets with a thickness of at least 4 mm are used. Products used for exterior and interior decoration are thinner. The rolled products are stored in the cabins of freight and passenger elevators. The use of anti-slip corrugated sheets reduces the likelihood of industrial injuries and prevents accidents.

Hot-smoked corrugated steel sheet 5x1500x6000 lentils

Rolled metal → Products → Steel sheets → Hot-rolled corrugated sheets → Hot-rolled corrugated steel sheets 5x1500x6000 lentils

Pattern: lentils

Sheet base thickness, mm: 5.0 Sheet width, mm: 1500 Sheet length), mm: 6000 Corrugated base width, mm: 5.0 Weight of 1 sq. m., kg: 40.5 Square meters per ton: 24, 7 GOST: GOST 8568-77

Corrugated steel sheet is a rolled metal product made from carbon boiling, calm or semi-calm steel, on the surface of which there are lentil and rhombic convex patterns located at an angle to each other. Depending on the material, there are steel, aluminum and stainless steel corrugated sheets.

The main function of corrugated steel sheet is anti-slip. Corrugated steel sheets are used as flooring, wall coverings, stair treads, decking in industrial and subway applications. Used in agriculture and machine tool industry. Corrugated steel sheets are often used for finishing buildings.

Corrugated steel sheet is one of the most popular types of metal products. This product is especially popular in the oil and gas industry.

The corrugated steel sheet supplied meets all GOST requirements.

The height of the corrugation of the steel sheet varies depending on the thickness of the product. In this case, the thickness of the finished product does not take into account the height of the corrugations. The configuration and location of the riffles is determined by the manufacturer. The height of the sheet corrugations ranges from 0.2-0.3 thickness, but not less than 0.5 mm.

Corrugated steel sheets are supplied in the form of rolls or sheets.

Corrugated steel sheets are produced with normal or increased precision. The length of the sheets can be measured (all products are the same length), unmeasured (sheets of different lengths) and multiple measured (minimum sheet length).

offers a wide selection of corrugated steel sheets.

| Name | Price | Availability |

| Corrugated hot-rolled steel sheet 5x1500x6000 lentils | specify | In stock |

Dimensions, weight and number of meters per ton of hot-rolled corrugated steel sheet

| Name | Sheet base thickness, mm | Width of ribbed base, mm | Weight 1m. sq., kg | Square meters per ton |

| Hot-smoked corrugated steel sheet 2.5x1250x2500 rhombus | 2,5 | 5,0 | 21,0 | 47,6 |

| Hot-smoked corrugated steel sheet 2.5x1250x2500 lentils | 2,5 | 3,6 | 20,1 | 49,8 |

| Hot-smoked corrugated steel sheet 3x1250x2500 rhombus | 3,0 | 5,0 | 25,1 | 39,8 |

| Hot-smoked corrugated steel sheet 3x1250x2500 lentils | 3,0 | 4,0 | 24,2 | 41,3 |

| Hot-smoked corrugated steel sheet 3x1500x6000 rhombus | 3,0 | 5,0 | 25,1 | 39,8 |

| Hot-smoked corrugated steel sheet 3x1500x6000 lentils | 3,0 | 4,0 | 24,2 | 41,3 |

| Hot-smoked corrugated steel sheet 4x1500x6000 rhombus | 4,0 | 5,0 | 33,5 | 29,9 |

| Hot-smoked corrugated steel sheet 4x1500x6000 lentils | 4,0 | 4,0 | 32,2 | 31,1 |

| Hot-smoked corrugated steel sheet 5x1500x6000 rhombus | 5,0 | 5,0 | 41,8 | 23,9 |

| Hot-smoked corrugated steel sheet 5x1500x6000 lentils | 5,0 | 5,0 | 40,5 | 24,7 |

| Hot-smoked corrugated steel sheet 6x1500x6000 rhombus | 6,0 | 5,0 | 50,0 | 20,0 |

| Hot-smoked corrugated steel sheet 6x1500x6000 lentils | 6,0 | 5,0 | 48,5 | 20,6 |

| Hot-smoked corrugated steel sheet 8x1500x6000 rhombus | 8,0 | 5,0 | 66,6 | 15,0 |

| Hot-smoked corrugated steel sheet 8x1500x6000 lentils | 8,0 | 6,0 | 64,9 | 15,4 |

Corrugated sheet weight

Weight 1 sq. meters of rental is determined according to a special table. When calculating the weight of a steel sheet, its dimensions, the height of the corrugations and the density of the metal are taken into account. In addition, the radius of curvature, the length and width of the base of the corrugated elements are taken into account. Weight calculations are made separately for sheets with different types of corrugations.

| Diamond Pattern Corrugated Steel Sheet Weight Chart | ||

| Sheet base thickness, mm | Width of ribbed base, mm | Weight 1 m2, kg |

| 2,5 | 5,0 | 21,0 |

| 3,0 | 5,0 | 25,1 |

| 4,0 | 5,0 | 33,5 |

| 5,0 | 5,0 | 41,8 |

| 6,0 | 5,0 | 50,0 |

| 8,0 | 5,0 | 66,0 |

| 10,0 | 5,0 | 83,0 |

| 12,0 | 5,0 | 99,3 |

| Weight table for 1 m2 lenticular corrugated steel sheet | ||

| Sheet base thickness, mm | Width of ribbed base, mm | Weight 1 m2, kg |

| 2,5 | 3,6 | 20,1 |

| 3,0 | 4,0 | 24,2 |

| 4,0 | 4,0 | 32,2 |

| 5,0 | 5,0 | 40,5 |

| 6,0 | 5,0 | 48,5 |

| 8,0 | 6,0 | 64,9 |

| 10,0 | 6,0 | 80,9 |

| 12,0 | 6,0 | 96,8 |

Types, location and sizes of riffles

Rifles have several types:

- lentils - in the form of stylized lentils;

- rhombic - in the form of rhombuses.

The density of riffles per unit area can be different.

For rhombic sheets, convex diamonds can be oriented either along or across, if you focus on the diagonal of the workpiece.

The thickness of the sheet is considered equal to the thickness of its base. The height of the convex grooves can be from 0.1 to 0.3 the height of the base, but the minimum height of the grooves is 0.5 mm in any case.

The diagonals of the rhombus with rhombic corrugation change in the ranges of 25-30 mm to 60-70 mm. This is required by GOST, which regulates this type of flat steel. However, consumers can order the production of corrugated products according to individual requirements - this is permitted, and such orders are accepted for execution.

There are also standard requirements for lentil corrugation. Thus, the distance between convex riffles can be 20; 25 or 30 mm. The width varies in the range of 60-220 cm, and the length - 140-800 cm in increments of 5 cm. Products with other parameters are manufactured only on individual orders.

Permissible deviations in the dimensions and flatness of sheets and rolls are established by GOST 19903.

The weight of sheets of the same size, but with different types of corrugation will be different.

Methods for producing corrugated sheets

Corrugated products are created using the method of hot deformation and cold pressing. In the first case, the steel billet is heated to the required temperature and passed through rollers, one of which has a stencil. Raised bumps are printed on only one side of the sheet. On the other hand, the surface remains smooth.

When using the second method, special presses are used. After processing the workpiece, the corrugations are visible on both sides of the product. On the working surface the image is raised, and on the reverse surface it is depressed.

Finished products are cut on all sides. In accordance with GOST standards, there should be no delamination on the edges of corrugated sheets. Jagged edges are allowed on the rolled edges. They should not extend the sheet beyond the established width dimensions. The presence of traces of mechanical damage on the surface of the products is not allowed. To control technical parameters, one roll or two sheets are selected from the batch

Other characteristics and features of the material

Steel sheets, supplemented with lenticular or rhombic corrugation, in accordance with GOST 380-2005, are made from carbon steel grades St0-St3. In this case, the following condition is required: the height of the corrugation must be from 0.1 to 0.3 of the total thickness of the base (at least 0.5 mm). In some cases, it is convenient to use a material in which this parameter reaches 1 mm.

It is worth paying attention to the following:

- The size of the diamonds should be 25–30 x 60 x 70 mm. The location method can be any: it is determined by the manufacturer in accordance with his wishes.

- Lentil corrugation is performed in increments of 20 to 30 mm.

Sheets of this type are in most cases sold in batches whose weight does not exceed 70 tons. It is important that packaging and labeling of products must be carried out in accordance with GOST 7566-94. A material certificate is issued for the entire batch of corrugated sheets.

| Weight of 1 square meter corrugated steel sheet | |

| Lentil corrugated sheet GOST 8568-77 steel st3sp/ps5 | Weight 1 m2 |

| Lentil leaf 2.0 | 16.34 kg |

| Lentil leaf 2.5 | 20.41 kg |

| Lentil leaf 3.0 | 24.5 kg |

| Lentil leaf 4.0 | 32.2 kg |

| Lentil leaf 5.0 | 40.5 kg |

| Lentil leaf 6.0 | 48.5 kg |

| Lentil leaf 8.0 | 64.9 kg |

| Lentil leaf 10 | 80.9 kg |

| Lentil leaf 12 | 96.8 kg |

Hot-rolled and cold-rolled steel sheets

Dimensions and weight of the sheet (GOST 19903-90 and 19904-90) based on a specific gravity of 7.85 g/cm3

| Thickness (size), mm | Sheet weight, kg |

| 0.5 (1250x2500) | 12,26 |

| 0.55 (1250x2500) | 13,5 |

| 0.6 (1250x2500) | 14,71 |

| 0.7 (1250x2500) | 17,81 |

| 0.8 (1250x2500) | 19,62 |

| 0.9 (1250x2500) | 22,06 |

| 1 (1250x2500) | 24,53 |

| 1.2 (1250x2500) | 29,43 |

| 1.4 (1250x2500) | 34,34 |

| 1.5 (1250x2500) | 36,78 |

| 1.7 (1250x2500) | 41,69 |

| 1.8 (1250x2500) | 44,16 |

| 1.9 (1250x2500) | 46,60 |

| 2 (1250x2500) | 49,06 |

| 2.5 (1250x2500) | 61,31 |

| 3.0 (1250x2500) | 73,59 |

| 3.5 (1250x2500) | 85,84 |

| 4 (1500x6000) | 282,6 |

| 5 (1500x6000) | 353,25 |

| 6 (1500x6000) | 423,9 |

| 7 (1500x6000) | 494,55 |

| 8 (1500x6000) | 565,2 |

| 9 (1500x6000) | 635,85 |

| 10 (1500x6000) | 706,5 |

| 12 (1500x6000) | 847,8 |

| 14 (1500x6000) | 989,1 |

| 16 (1500x6000) | 1130,4 |

| 18 (1500x6000) | 1271,7 |

| 20 (1500x6000) | 1413 |

| 22 (1500x6000) | 1554,3 |

| 25 (1500x6000) | 1769,4 |

| 30 (1500x6000) | 2119,5 |

| 40 (1500x6000) | 2826 |

| 50 (1500x6000) | 3532,5 |

| 60 (1500x6000) | 4239 |

Characteristics of corrugated sheet

Steel sheets with rhombic and lentil corrugation (GOST 8568-77) Steel corrugated sheet GOST 8568-77 with one-sided rhombic and lentil corrugation for general purpose. Corrugated steel is produced in sheets and rolls with one-sided rhombic or lenticular corrugation. The height of the corrugations on the sheets should be 0.2 - 0.3 of the thickness of the base of the sheet, but not less than 0.5 mm. Sheets with rhombic corrugation are made with diamond diagonals (25-30) x (60-70) mm. The configuration of the corrugations and the location of the large diagonals of the diamond along or across the sheet are set by the manufacturer. Pzhya with lentil corrugation are made with a distance between corrugations of 20, 25 m 30 mm. Sheet metal with lentil corrugation A-1-PV-StZsp2-6x600x6000 TV 14-2-818-88 with a rolled edge, one-sided corrugation is made of carbon steel with a chemical composition in accordance with GOST 380. The height of the reefs on the strip is 1.5 mm at a distance of 40 mm from the side edge. Sheets are manufactured in widths from 600 to 2200 mm and lengths from 1400 to 8000 mm with a gradation of 50 mm. By agreement between the manufacturer and the consumer, it is possible to produce sheets of other sizes. Depending on the purpose, sheets are manufactured:

- measured length;

- multiple measured length;

- measured length with a remainder of no more than 10% of the batch weight;

- a multiple of the measured length, amounting to no more than 10% of the mass of the batch;

- of unmeasured length.

The remainder is considered to be sheets of length within the unmeasured range that remain when cutting into dimensional and multiples of dimensional.

You can also buy corrugated sheets from our catalog.

Examples of symbols:

Hot rolled sheet of steel grade St3sp in accordance with GOST 380-88 with one-sided rhombic corrugation size 3.0x1000x2000 mm, normal thickness accuracy, improved flatness with a rolled edge: Rhombus sheet V-K-PU-3.0x1000x2000 St3sp GOST 8568-77 The same , with lentil one-sided corrugation: Lentil sheet V-K-PU-3.0x1000x2000 St3sp GOST 8568-77 Rolled hot-rolled steel grade St3sp in accordance with GOST 380-88 with one-sided rhombic corrugation size 3.0x1000 mm, high precision, with rolled edge: Roll rhombus A-K-3.0x1000 St3sp GOST 8568-77. The same, with lentil one-sided corrugation: Lentil roll A-K-3.0x1000 St3sp GOST 8568-77. Thickness and weight of 1m2 corrugated sheet (GOST 8568-77)

| Sheet base thickness S, mm | Width of ribbed base b, mm | Weight 1m2, kg |

| diamond knurling | ||

| 2,5 | 5,0 | 21,0 |

| 3,0 | 5,0 | 25,1 |

| 4,0 | 5,0 | 33,5 |

| 5,0 | 5,0 | 41,8 |

| 6,0 | 5,0 | 50,0 |

| 8,0 | 5,0 | 66,0 |

| 10,0 | 5,0 | 83,0 |

| 12,0 | 5,0 | 99,3 |

| lenticular corrugation | ||

| 2,5 | 3,6 | 20,1 |

| 3,0 | 4,0 | 24,2 |

| 4,0 | 4,0 | 32,2 |

| 5,0 | 5,0 | 40,5 |

| 6,0 | 5,0 | 48,5 |

| 8,0 | 6,0 | 64,9 |

| 10,0 | 6,0 | 80,9 |

| 12,0 | 6,0 | 96,8 |

Calculation of the weight of galvanized sheet with polymer coating

- Iron density - 7.85 t/m3

- Zinc density - 7.13 t/m3

- Polymer coating density - 1.5 t/m3

- Thickness of polymer coating - 0.035mm

- The thickness of the cold-rolled substrate for class 1 zinc coating is 0.05 mm less than the thickness of the finished product, class 2 - by 0.03 mm

| Zinc coating class | Thickness of zinc coating, mm |

| 1 | 0,0381 |

| 2 | 0,0216 |

| Z100 | 0,0208 |

| Z140 | 0,0212 |

| Z180 | 0,026 |

| Z200 | 0,0297 |

| Z275 | 0,0405 |

| Z350 | 0,0529 |

The mass of 1 m2 is calculated using the formula: M=t*l*h*? , where t-width, l-length, h-thickness, ?-density.

An example of calculating the mass of 1 m2 of galvanized rolled steel with a polymer coating 0.5 mm thick, class 2 zinc coating: m=0.47 x 1 x 1 x 7.85+0.0216 x 1 x 1 x 7.13+0.035 x 1 x 1 x 1.5=3.89kg

Explanation: the thickness of the cold-rolled substrate in mm is multiplied by the sheet area (1x1m) and the density of iron (7.85 t/m3) - the mass of the rolled material is obtained. The mass of the galvanized coating is added - the thickness of the galvanized layer with coating class 2 (from the table) is multiplied by the area and density of zinc (7.13 t/m3). Next, the mass of the polymer coating is added, which is calculated as thickness (0.035 mm) multiplied by area multiplied by density (1.5 t/m3).

How much does one sheet of corrugated aluminum sheet quintet weigh?

| Weight of 1 sheet of aluminum corrugated paper | sheet weight |

| Weight of corrugated aluminum sheet quintet 1.5x1200x3000 | 13,6 |

| Weight of corrugated aluminum sheet quintet 1.5x1500x3000 | 19,8 |

| Weight of corrugated aluminum sheet quintet 2x1200x3000 | 20,6 |

| Weight of corrugated aluminum sheet quintet 2x1500x3000 | 25,2 |

| Weight of corrugated aluminum sheet quintet 3x1200x3000 | 30,3 |

| Weight of corrugated aluminum sheet quintet 3x1500x3000 | 37,3 |

| Weight of corrugated aluminum sheet quintet 4x1200x3000 | 39,6 |

| Weight of corrugated aluminum sheet quintet 4x1500x3000 | 47 |

| Weight of corrugated aluminum sheet quintet 5x1500x3000 | 66,7 |