In some cases, it becomes necessary to bend profile pipes into an arc shape. This will require special skills and some tools. Special devices will help you create a pipe bender for a profile pipe with your own hands. For such products you do not need to purchase expensive materials and equipment. Read more in the material below.

Homemade unit option

How to build a hydraulic pipe bender

The design of a hydraulic pipe bender with your own hands is presented in the video below.

Building a tool of this type will not be difficult if you have two 0.5 meter channels at your disposal. The base of such a device included the following elements:

- hydraulic cylinder;

- stops;

- supercharger.

In addition, you should also highlight:

- A jack that can withstand loads of up to 5 tons.

- There are 2-3 rollers.

- Channel - 3-4 mm.

- Thick plates.

The principle of using such a tool is that you need to install a profiled pipe into the shoe. Use a jack to set the required bending radius. When the jack is inflated, the rod rises, pressing on the roller. After establishing the bending angle, the pipe can be removed. This type of bending device is relevant when it is necessary to bend a pipe in one place, for example, when installing a heating system.

Design and principle of operation of an electric pipe bender

The main load when operating a pipe bender with an electric drive falls on the powerful engine. It is he who transfers the rotational load to the bending element. Various attachments are put on the rotor, the shape of which depends on the expected result.

In addition, the structure of the pipe bender includes the following parts:

- frame;

- clamping devices;

- fastenings;

- control panel.

If it's a cheaper option for regular users, it will usually have setup buttons and a control panel. On industrial machines of this type, displays are installed, with the help of which settings are made.

The main functions of the clamps are:

- reliable fixation of the workpiece;

- protecting the employee from possible injuries.

Fasteners also serve to hold the bent element in the position required for operation.

How to make a pipe bender with your own hands instructions

If you have an example or diagram of a pipe bender, then making the machine yourself will not be difficult. You must adhere to the appropriate sequence of actions. To make a pipe bender for a profile pipe, the following manipulations are performed:

- On the shaft you need to place gears, as well as bearings and rings. The production of shafts is entrusted to an experienced turner. If you plan to create all the parts yourself, then you will need three shafts, two of which are distributed on the lower base (a channel serves), and the third is suspended on springs.

- The corresponding holes are drilled in the rings, which are needed in order to cut the thread. This thread is needed to attach gears to the shafts.

- The shelf for securing the third roller is also made from a channel.

- All elements are distributed on the frame and combined by welding or bolted connections.

- The first step is to install the frame on which the corresponding structural elements are distributed.

- The shelf is welded perpendicularly to the base.

- A handle is attached to one of the shafts.

- Finally, to adjust the bending radius of the profile pipes, you need to install a hydraulic jack on the top shelf.

If you make a tool according to a template, then there will be no difficulties

To clarify some points, you should pay attention to the following factors:

- The pressure shaft located on the shelf must be additionally secured to it. It is also secured with dowels.

- The pressure roller is made by performing the following manipulations: a shaft is fixed to the shelf, as well as springs that are attached to pre-installed nuts. After making the shelf, it can be welded to the frame of the main device.

- To tension the chain, you need to use a magnetic corner. It will serve as a holder.

- The sprockets are fixed with dowels made from Grover.

- The drive handle is constructed from a steel tube.

- The jack is placed on a hanging shelf.

The design of the simplest homemade unit for bending profiled pipes is presented in the video below.

For profile pipe

Profile pipe is often used to assemble the frames of greenhouses, gazebos, gates and wickets, canopies and much more.

Therefore, the owner of a garage or summer cottage sooner or later faces the question of how to bend a corrugated pipe at home.

A pipe bender will come to the rescue.

However, ready-made solutions cost a lot of money. Therefore, the best option is to do it yourself.

To make such a device you will need the following tools:

- Angle grinder, in common parlance – grinder;

- Drill with a set of metal drills;

- Welding machine, best of all – a household electrode inverter;

- A set of keys or sockets.

Before starting work, you need to draw up a drawing of the future bending machine so that all the parts relate to each other.

The main elements of a home pipe bender are:

- Frame welded from a steel channel or I-beam with a thickness of at least 4 mm;

- Roller shafts;

- The videos themselves;

- Sprockets for connecting a chain drive;

- Drive chain from an old bicycle or timing gear;

- Screw lowering the pressure roller;

- The rotation handles for the pressure screw and shafts are a hollow steel tube or a solid rod;

- Various accessories: nuts, bolts, washers, grommets, cotter pins.

It’s worth mentioning right away that if you don’t have rollers and shafts in your arsenal, it’s not possible to make them yourself without a lathe. As a last resort, you can cut the existing metal rods to size and sand them down. Barrels with an internal hole can be used as rollers.

With central roller

The sequence of actions when assembling a homemade pipe bender with a central pressure roller will be as follows:

- Using a grinder, cut the channel or I-beam into pieces of the desired size. Tack them pointwise, and then, when the frame is ready, weld along the entire length. Afterwards, for aesthetic reasons, you can grind the seams with a grinding wheel.

- Provide either legs from scraps of the same channel, or mounting holes for bolts that will allow you to clamp the machine to the workbench.

- Drill holes for the shafts. Also, using a drill and grinder, make slits in the vertical part of the frame. The pressure roller shaft will move up and down in them. Insert the shafts with the rollers on into the holes made and secure them with cotter pins.

- The threaded connection between the pinch roller rod and the blind frame is made either using a lathe or using a tap. Remember that large diameter threads are very difficult to cut. Be sure to use drill or other cheap lubricant when cutting threads.

- Carefully grind off the outer part of the shafts on both sides so that the sprockets can be put on them. Put on the chain with a slight slack; if you make the grip too tight, additional force will be spent on overcoming the resistance.

- Attach a lever to one of the shafts - to secure it, use the same lock as for the sprockets. If you want to strengthen the lever on the shaft, drill a hole and cut the internal thread. After screwing the bolt in, the lever will lock, and by unscrewing the bolt, the lever can always be removed for transportation. By rotating the lever, you can pull the workpiece through the rollers. By tightening the clamping screw, you can change the radius of curvature of the bent pipe.

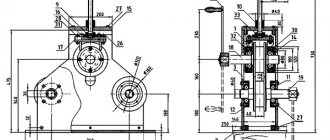

Drawings and dimensions of a homemade structure:

Making a simple template-type pipe bender

A simple rolling pipe bending machine can even be made from wood. Naturally, this will be a manual pipe bender, the design of which may not even include a pressure roller if it is used for thin-walled products. The template for such a device is made from a wooden board, the thickness of which should be such that it exceeds the diameter of the pipe itself.

Wooden template for a simple manual pipe bender

For ease of work, it makes sense to consider profiling the template from its end in order to avoid the pipe jumping off during bending. For these purposes, you can fold two boards, first sawing one edge at a time, thus creating a kind of gutter. A pre-drawn drawing will help avoid mistakes.

When using such a pipe bender, the template is attached to a reliable base, and a stop is attached to the left side of it (for right-handers). The pipe that needs to be bent to the required radius is placed between the template and the stop and carefully bent, making sure that it does not jump off the template.

Collapsible hook template

With the help of such a pipe bender, made from scrap materials, you can bend along a large bend radius. You can avoid making a wooden template and simplify the device by replacing it with metal hooks fixed to the base, located in a circle with the required bend radius. This device is convenient in that the dimensions of the bend can be changed at any time by placing the stop hooks around a circle with a different radius.

Armed with a manual winch, you can significantly expand the range of work performed due to a noticeable increase in traction force for bending pipes.

The winch will help expand the functionality of the simplest manual pipe bender

Useful tips for “pioneers”

For those who are encountering flexible profiles for the first time, it is recommended to take into account some features of the processing technology of this type of pipe. For example, experienced craftsmen never sacrifice the quality of the bend to save time.

It is wiser to do a few gentle presses with the adjusting screw and a few passes on the rollers rather than doing everything at once. This approach completely eliminates deformation of the profile pipe and significantly reduces the load on the drives (or on the master’s muscles).

A made template for the required bend radius of the pipe. Similar templates are also made for profile pipes

It is recommended to work with rollers of a configuration that matches the pipe profile. So, if there is a correspondence between the size of the roller width and the cross-sectional size of the profile, the bend will be accurate and neat. In addition, the master will not have to periodically correct the pipe, which moves from the center of the support roller to its outer boundary.

Before starting the bending operation of a profile pipe, it is advisable to make a template according to a given bend radius. If it is impossible to make a template for some reason, you can limit yourself to calculating the distance obtained between two control points after bending the pipe. Knowing the calculated figures, the workpiece can be bent with a pipe bender without periodic control measurements, thus reducing work time.

How to make different types of pipe benders

The principle of operation of pipe benders is different - you can influence a section of pipe in different ways. For example, a spring-type device will help deform polymer pipes due to pressure. Segmental devices will stretch them, giving them curvature.

The method of making a template pipe bender is accessible even to a beginner. To do this, you need to accurately draw a part of a circle of the required diameter (or other type of curvature). This hemisphere or other curve is drawn on a wooden blank, as in the photo of a homemade template-type pipe bender.

The resulting part must be fixed on a stable base along the plane (wall, table).

After the template stop is ready, you need to figure out how to use a pipe bender of this type. This is clear from the drawing - the pipe is secured between the template and the thrust beam.

By exposing the opposite end to a heated aluminum or thin steel billet, the desired bend is obtained. If it is necessary to obtain segments of different curvature, several suitable templates are made.

Designs of homemade devices

The simplest option available to most novice craftsmen is bending pipes according to a pre-made template. This method is used when it is necessary to obtain a large number of blanks of the same type.

Bending a pipe using a wooden template is the easiest way to solve the problem

As a template, you can use a structure made of wooden boards. The thickness of the wood is chosen based on the diameter of the pipes being bent - the board should have a margin of 2-3 cm. To prevent the metal profile from sliding off the template during work, the ends are processed with a slight slope.

The structure is attached to the floor or other surface in any way, installing a stop for the pipe nearby. Having inserted the profile into the gap between the template and the thrust element, smoothly and carefully press on its other end, pressing the pipe against the template. To ease the pressing force, you can use a lever of a suitable size or install a winch.

A winch can facilitate the process of bending pipes using a template

In a similar way, you can bend a metal profile of small diameter. If it is necessary to change the configuration of a pipe larger than 1 inch, then the template is made from sections of powerful fittings. To do this, holes are made in the concrete slab along the required trajectory, into which guides are inserted in the form of pins from sections of pipes, fittings, etc. The bending is performed by securing the edge of the metal profile by welding.

The advantage of this method is its cheapness and simplicity, however, the accuracy of the resulting blanks and the quality of their processing leave much to be desired. In addition, the template will have to be made every time you need to obtain a bend of a different radius.

Factory-made snail pipe bender

To produce a large number of similar workpieces with a small radius of curvature, you can use a snail pipe bender. This unit consists of two pulleys (wheels) of different diameters, mounted on shafts. Having fixed the end of the pipe on the impeller, use a roller of a smaller diameter (drive wheel) to press the workpiece, simultaneously rolling it along the workpiece. As a result, the pipe bends around the surface of the large pulley, repeating its shape. The only drawback of this method is the impossibility of obtaining large radius curves.

The most versatile and practical are homemade rolling pipe benders (bending machines), in which you can set any angle of deformation of rolled metal. The simplest design of a rolling unit is a base with drive shafts fixed at a certain distance from each other. Pressure on the pipe is carried out by a movable roller, and it is drawn through the rotation of the drive shafts. Screw devices, jacks, winches and electric motors are used as power drives for such devices. The rolling machine is the most difficult to replicate at home, as it requires turning and welding. However, there are many variations of its design made by amateurs, which indicates the high popularity of this solution. With the help of such a device, bending of any configuration is obtained, and the process itself is often automated. The only thing such a device cannot cope with is obtaining a minimum radius of curvature of a metal profile over a small segment.

Types of pipe bending mechanisms

Devices that allow you to bend a steel pipe to a certain radius are divided according to the following characteristics:

- Mobility. Pipe benders can be stationary or portable.

- Type of drive. Depending on this feature, manual, electric, hydraulic and electro-hydraulic devices are distinguished.

- Method of influence. The tubular product is bent under the influence of rolling, winding, rolling and rod.

Before you make a pipe bender at home, you need to understand how the device affects the workpiece and become familiar with each process separately.

Run-in

This method involves performing the following actions: one end of the tubular product is pressed against a stationary template and the pipe is rolled around it using pressure rollers.

Winding

This type of device has a movable template. A pipe is directly wound onto it, which passes between the template and a special stop located at the beginning of the bend.

Crossbow type pipe bender

This device is equipped with two fixed rollers and a template mounted on a movable rod. When the rod presses in the middle of a certain section, the pipe bends.

Rolling

The design is made on the basis of two support rollers and one central roller. This three-roller mechanism helps to obtain the required radius when bending as a result of pressing the central roller on the pipe, the position of which determines the bending radius. This makes it possible to call this type of pipe bender universal, since all other types bend the pipe according to a specific pattern.

A pipe bender operating on the winding principle is quite difficult to make at home, so industrial enterprises produce such mechanisms. When using a crossbow pipe bender, it is worth remembering that the impact of the rod on the pipe product can cause the material to rupture. Consequently, these mechanisms are not suitable for bending products with thinner walls. The rolling device has no significant disadvantages; it is used in the factory production of bends.

The design of a machine for bending home-made tubular products can be varied. Select the desired device according to the required bending radius

In addition, it is worth studying the recommendations for choosing a device, and also taking into account the main parameters of the pipes used: diametrical cross-section and wall thickness.

How to bend a profile pipe without a machine

There are two ways to make an arc from a profile pipe without a profile bender - using welding and a template. Let's start with welding.

Get an arc by welding

The profile pipe is cut with a grinder on one side. They are made every 15-30 cm, depending on the required radius, cross-section and wall thickness. The cuts should not touch one side - the one that will be on the outside.

Result of bending by welding

The spare part prepared in this way is bent, giving the desired bend. For reliability, the edges of the arc can be fixed by welding a rod to them. Then welding is carried out along all the cuts, welding them. And the last stage is grinding the weld spots and treating them with anti-corrosion compounds.

Using a template

Thin-walled profiled pipes can be bent by hand using templates. If you need a special shape, it can be cut out of a piece of thick plywood or chipboard and secured to the table using clamps. On the workbench where we will bend the pipes, make about 8-10 holes. The template is placed near these holes.

The process of obtaining an arc from a profile pipe using a template

The holes are repeated at one end of the pipe; with their help, the pipe is attached to the workbench. Now the free end of the pipe begins to be pulled smoothly, forming a bend that follows the shape. You need to pull smoothly, without jerking.

The template can also be made on the ground. Pipes-pegs are driven into the ground (at least half a meter deep). They form the required arc. For emphasis, two additional stakes are driven in, which are located to the side of the arc. The distance you need to step aside is slightly greater than the width of the pipe.

Pattern on the ground

Having inserted the pipe, it is pulled towards the arc. Great efforts are required, the work is hard. This can only be achieved with a thin-walled, seamless pipe. The suture has too much resistance in the seam area. It is very difficult to overcome it manually.

Device of manual edge benders

Edge benders, although somewhat similar in appearance to sheet benders, have a fundamental difference - the height of the shelf usually does not exceed 5...20% of their length. A lower value corresponds to flanging the inner edge. When bending there is no such limitation, which predetermines noticeable design changes in the compared devices.

The first of them concerns the length of the flanging working area - for manual edge benders it can be small, since the height of the bead and the radius of curvature do not change. Accordingly, portable manual edge benders are produced, moving which along a pre-marked flanging line, we obtain the required profile.

If the edge formation zone is large, the process should be performed simultaneously. In such cases, an edge bender is more similar to a sheet bender, differing, in fact, only in the way the workpiece is pressed.

Let's consider the first version of the device. Portable manual edge bender for gradual bead shaping includes:

- Two handles, and one of them or both can be movable.

- Lever reinforcement system to create the required flanging force.

- Working jaws with a profile that matches the dimensions of the edge. Typically, the manufacturer equips a manual edge bender with a set of several jaws and the most commonly found in practice edge height and radius of curvature during the transition from the edge to the main plane.

- Adjustable travel stop: most often this is a removable slotted screw equipped with a thrust thread.

For ease of use, the handles are rubberized, which prevents the operator’s hand from slipping while applying force.

The second version of a portable manual edge bender is a roller bender, where the sliding friction of the jaws on the workpiece is replaced by rolling friction when the working rollers rotate. In this case, the shaping force is significantly reduced, but the tool turns out to be less universal, since there is only one pair of rollers, and it is not possible to change the edge formation parameters except by replacing a pair of rollers, which is quite labor-intensive. In addition, roller edge benders in most cases fail to perform internal flanging along small radii.

The main disadvantage of manual portable edge benders is their low accuracy: when moving the tool along the uneven line of the future edge, an error gradually accumulates, which at the end of the operation can reach a millimeter or more. This is unacceptable during auto body repair, so the quality of bead formation is determined only by the experience of the performer.

Design features of profile benders

As we said earlier, bending machines can differ in what pipes they are intended for: round or profile. The latter, among other things, also allow you to work with other rolled metal: strips and corners.

If pipe benders use rollers with grooves, then conventional shafts can be used in the design of profile bending machines: two support shafts and one pressure shaft. The radius of curvature during the transition must be adjusted manually.

Some even use bicycle bushings as shafts, but they will not withstand heavy loads. Therefore, it is better to rely on round steel timber.

Rollers made from bearings are also often used. You can read how to make a budget profile pipe bender with your own hands in our article.

Pipe bending machines are mostly table-top designs, while profile benders can be either table-top or floor-mounted. The latter are used when it is necessary to bend arcs and half-arcs from long profile pipes.

Do-it-yourself manual edge bender

Let us dwell on the option of designing and manufacturing a manual edge bender with simultaneous production of an internal or external contour along the entire length of a pre-marked workpiece. The general view of the device is shown in the figure. Such a manual edge bender can be used not only in car repair shops, but also in roofing work, the manufacture of tin ventilation ducts and other spatial products made of sheet metal.

The dimensions of a homemade manual edge bender are determined depending on the largest dimensions of the workpiece for which flanging is performed. For example, for large products, it is more expedient to build a table from wood or multi-layer plywood, on which to mount the edge bender; in other cases, the structure is welded from channels and sheet metal.

The design of the manual edge bender is designed for sequential execution of two transitions:

- clamping the workpiece using a clamp and lower clamp;

- flanging along a given contour by turning the handle with the punch located on it.

It is usually recommended to make a welded version of such an assembly, but this is impractical: the parameters of the flanging curve may change, and it is no longer possible to change the punch. Therefore, taking into account the small forces arising during deformation, it is better to produce a collapsible punch, which is a collection of individual modules, characterized by their radius of curvature and edge height.

The fastening of such punches to the beam is carried out using bolts (of course, all seats must be designed and made with the highest possible accuracy).

The edge formation itself is performed after the workpiece is securely fixed between the upper and lower clamps (the latter ensures smooth clamping due to the spring mounted on the rod in the upper plane). The combination of the two halves of the flanging die is carried out by moving the support bracket along the mating surface of the stops, which act as guide elements of the manual edge bender.

By changing the configuration of the punch modules, you can perform flanging not only at a straight line, but also at any other angle - up to 110...120º (to do this, you just need to provide a small bevel on the limiter, which is visible in the figure).

Pipe benders with pressure roller

A more complex design is a manual pipe bender, which uses a pressure roller. To make such a device, you can use both wood and metal.

For pipes made of soft materials (for example, copper), wood rollers are the best option, since they do not cause metal deformation. It’s not at all difficult to make such videos at home if you use photos or drawings of similar devices, which are posted in large numbers on the Internet. The manufacturing material can be thick boards or several layers of plywood.

Drawing of a pipe bender with a pressure roller

A homemade pipe bender of a similar design, which is based on rollers - movable (pressing) and stationary - allows you to bend round pipes that even have a significant diameter.

In order to understand that such a device is simple in design and use, just look at its photo or drawing. Depending on what loads are expected for a pipe bender of this type, the base for it is made of metal or durable plywood. The U-shaped holder on which the central and pressure rollers will be placed is made of metal.

Relative to the axis of the central roller, securely fixed to the base, such a holder must be able to rotate. On the reverse side of the central roller, a handle is attached to the holder, which is a lever, so the force created directly depends on its length. This lever pipe bender allows you to perform operations with different bending radii of pipes.

Many people wonder whether it is possible to make a winding-type pipe bender with your own hands. Naturally, it is first advisable to study a drawing or photo of such a device, which does not have a stop on the base. The design of this type of pipe bender is based on two pulleys, a frame with a lever and a pressure roller, and a reliable base. Bending using such a device is carried out due to the fact that the pipe, placed in the groove of a stationary pulley and clamped with a clamp, is wrapped around a template using a lever and a movable roller.

Pipe bender for soft pipes with two different bend radii

For small and soft products (aluminum or copper), a homemade pipe bender is suitable, allowing bending with two different radii. Photos of such a device are easy to find on the Internet. This pipe bender uses one pressure roller and the template is made with two radii at the same time on one plate. Naturally, for each bending option, the pipe bender handle must be reinstalled, for which two holes are provided on its base.

Conclusions and useful video on the topic

From the video you can find out what a homemade pipe bender looks like on a bed.

You have to work with profile-shaped pipes quite often in the context of running a household or country house. Therefore, the presence of a tool called a pipe bender in a home workshop is welcome.

As the practice of self-taught craftsmen shows, this instrument is not difficult to make yourself. And having made such a design, it is easy to master and periodically use.

Please write comments in the block below. Tell us about how you bent a profile pipe with your own hands. Share interesting technological details, ask questions, post photos related to the topic of the article.

How to assemble ET yourself

If you wish, you can assemble an electric pipe bender with your own hands; you just need to perform a series of sequential steps.

At the initial stage, it is worth deciding what frame the device will have. This structure can be assembled from rectangular profile pipes with a wall thickness of 3 mm.

At the end of the profile, 3 cm from the end, make a hole with a cross-section equal to the dimensions of the axis.

The next step in assembling an electric pipe bender with your own hands includes several steps:

- A control lever with a movable wheel driving the belt is mounted on the frame.

- Install a stationary wheel.

- Secure the falling shaft. A pulley with a belt drive from the engine is placed at the end of the shaft.

- At the second end of the frame there is a star for the drive gear.

- The second shaft is attached last.

Next, you can begin trimming the profile. The degree of trimming of this part will depend on the desired bending angle, taking into account a margin of 5 cm. Any excess can be cut off with a hacksaw.

The axle on which the wheel and lever will be installed is easy to make yourself:

- you will need two steel plates with a width equal to the diameter of the axle and a thickness of 5 mm;

- By putting the steel pipe and these two plates together, you need to weld the structure.

Now you can begin assembling the entire mechanism.

This can be done in several steps:

- The finished frame from the profile must be securely fixed in a vice.

- Now we install the axle into the holes made in advance.

- We connect the axle with the handle and the wheel.

- Tighten the wheel securely with the bolt.

- At the end we mount the clamp with a pin.

Since the actuation of the pipe bender, which was assembled by hand, was intended to be connected to the electrical network, the last thing that needs to be done is to connect the electric drive to the machine. This device will cause the shaft to rotate.

Thus, we can say that electric pipe benders are distinguished by their efficiency and versatility. In addition, the ability to quickly complete work makes them indispensable in industrial enterprises and when performing work at a professional level.

Manual lever pipe bender

If you do not need such a complex device, but only need to bend a small round steel pipe, then you can make a simple lever mechanism. It is designed for bending pipes with thin walls.

Watch the video for manufacturing instructions.

We also decided to try to assemble this pipe bender with our own hands. We will need: a shaft with a round profile, a pressure roller, a metal sheet of 8 for the frame, studs, nuts.

Someone can make this device by eye, but it is better to prepare a drawing of a pipe bender or find a suitable option on the Internet. We decided to work according to the drawing.

Drawing of a lever pipe bender

Lever fork drawing

Let's start making:

- We make blanks for the fork. The size of the fork depends on the distance between the wheels, or more precisely on the seat of the pipe, it should be equal to its diameter plus 1–2 mm. Cut it out of a metal sheet and grind it:

- frame and cover for the shaft;

- support for the frame and a small stand for the lid;

- two rectangular plates, along the edges of which we make holes for the studs.

Cutting the blanks

We make holes in the cover and frame for attaching the shaft.

Making holes Finished blanks

We fix the stop in a vice, weld the frame to its middle, and the stand for the lid to the top, grind the seams.

We weld the parts

We thread the pin into the hole of the station, put on the shaft and cover it with a lid made of metal sheet. We tighten the nuts on both sides.

Installing the shaft

We fasten the cover to the stand with bolts.

Fastening the lid

We screw two rectangular blanks onto the nuts on both sides.

We assemble rectangular blanks

On top, between these plates, we place a roller, which we secure with a pin and nuts.

Installing the roller

We weld two plates of the fork, placing a channel blank between them.

We weld the fork

We screw the handle from a piece of metal profile.

Connecting the handle

Well, the lever pipe bender is ready, it turns out that almost any home craftsman can make it himself.

Types of electric pipe benders

The operating mechanism of electric pipe benders may differ. Let's look at some types of such products.

Winding machines

. In this case, a special shaft is installed on the device, which is rolled along a pipe fixed in the machine, thereby creating a bend of the desired configuration.

Roll-in pipe benders

. Such devices have paired rollers. The mechanism of action of such equipment is called mandrelless. The peculiarity of such pipe benders is the limited bending angle of the products, which coincides with the diameter of the fixed shaft. Typically, equipment of this type comes with a set of various rollers designed to increase the capabilities of the device.

Products with a rolling mechanism

. These pipe benders have three rhythmically operating rollers. Equipment of this type is often used in the manufacture of decorative jewelry from profile pipes.

With squeezing principle of action

. This is the most common type of product, shaped like a crossbow. In this case, the pipe is fixed on both sides, and the bending is done by extrusion. The bend configuration depends on the type of nozzle. However, working on such equipment takes a lot of time.

Stationary pipe benders

For stationary equipment, a separate space is required, since they are large in weight and size. These ET models have a strong, large frame that supports a fairly powerful engine.

Such devices can work with pipe products of all types and sizes. In particular, they can process profiled steel pipes with thin walls, products with a large cross-section and thick walls, used in high-pressure water mains.

Compared to stationary devices, handheld ETs have more limited capabilities, although they can still be very useful for their purposes.

Stationary pipe bender step by step instructions

If you plan to make your own greenhouse from steel pipes, then you will need to acquire not just an ordinary pipe bender, but a reliable product. After all, with this approach you will need to bend more than a dozen profile pipes. To make the greenhouse design neat and beautiful, you need to use a stationary pipe bender.

Before you start making a greenhouse, you need to make sure that you have the appropriate tool for bending profile products. The following elements will be needed to construct a stationary pipe bender:

- rod at 25;

- 6 bearings;

- channel.

You will also need a welding machine, which will be used to connect all the components. Step-by-step instructions for making a stationary pipe bender are as follows:

- Bearings are welded to the base (channel), which are connected to each other by a shaft in the form of a steel pipe of the appropriate diameter.

- To prevent the shaft from being located too close to the base, the bearings should be welded onto 5 cm pieces of rectangular pipe.

- In order to deliberately produce a unit with which the bending radius could be adjusted, the base must be made of two channels connected to each other by curtains, as can be seen in the photo above.

- Two shafts with bearings are located at the same height, and the third (central) is welded using a rectangular tube 15-20 cm higher.

- An additional tube needs to be welded to the upper shaft, to which the handle will be attached. This shaft will be driven by muscular force.

- The handle is welded to the upper shaft, after which the resulting product can be checked for functionality.

When installing a profile tube of any size, you should adjust the radius of the final bend. This can be done using a jack located under the base on which one of the shafts is fixed. Having adjusted the required bending radius, the handle rotates. The result is high-quality curved tubes. The advantage of a pipe bender is the ability to bend materials of any size and diameter.

Among the disadvantages, we can only note the possibility of operation in one place

It is important to understand that such a device can be used for any need. To manufacture such a device, an investment of no more than 500 rubles will be required.

You only need to buy 6 bearings, and all the other elements can be found in every craftsman’s household.

Main structural components

When planning to make a manual pipe bender, you must immediately decide whether it will be portable or stationary, as well as the diameter (section type) and bending radius of the pipes. If the master is going to “roll” a series of pipes with the same cross-section and radius, you can make the simplest possible mechanism in which all the parts are fixed and cannot be replaced. If a certain variety is still expected, it is better to provide for possible changes in elements and changes in the bending radius.

Below are examples of simple manual pipe benders based on welded elements and parts from decommissioned equipment.

This model provides only one position for the side rollers and their only profile is with a guide groove. For synchronization, the rolls are connected by a chain, the bending force is transmitted through a screw mechanism.

In this design, the rollers can be moved (the photo shows the places for attaching the rollers on the frame of the device). To compensate for the change in distance and to maintain the tension of the synchronizing chain, an additional gear is used in the middle. It can be moved up and down by tensioning the chain.

The photo above shows two models of pipe benders that are very similar in design. On the left is a portable model with a manual lever-type drive, on the right is a stationary model (on a raised bed), equipped with an electric drive. A conventional asynchronous drive with a reduction gearbox is used as an electric drive.

Another model where a diamond-shaped jack is used as a drive - it creates constant pressure on the central roller of a rolling (roll) pipe bender.

As can be seen from the photographs, all presented models are specifically roller models - that is, to bend a profile pipe, two stationary support rollers and one movable one are used, which creates pressure to obtain the bend.

It makes sense to consider three more device schemes: break-in, winding and crossbow.

rolling ) fixed on an axis and a pressure shoe (5), which is driven by a screw pair (3-4). In this case, a movable roller (6) with a lever (7), mounted on the same lever as the roller (9), when rotated, allows the fixed pipe to be bent according to a template, which is played by a rotating roller.

The mechanism itself is quite compact and lightweight, and considerable effort is required, so either a very heavy plate (at least 50 mm thick) or a workbench frame is used as a base.

A winding (winding) pipe bender has a very similar principle of operation, the difference is in the place where the pipe is secured. It is fixed on a rotary roller (essentially a template for bending) so that with further rotation of the part the pipe is “wound” onto the guide groove. Thanks to this feature, the roller has a cut on one side - this is necessary for accurate and convenient pipe fastening. In this case, the force is applied to the roller axis. Mobile stop rollers allow you to work with pipes of different diameters, but the type of section - round, square, rectangular - can only be changed by changing the main roller.

A variant of a winding pipe bender - an angular dial is added to the main structure to accurately determine the bending angle.

Crossbow pipe bender step by step design instructions

The crossbow bender got its name because it resembles the shape of a hand crossbow. The cost of crossbow devices is about 10 thousand rubles. To save on the purchase of such a unit, it is recommended to make it yourself.

The photo shows two options for crossbow devices for bending pipes. The first option is a factory design, and the second is a homemade machine. The difference between these two machines is significant, since the factory version is made of steel measuring no more than 2 mm, while for the homemade one, metal 3-4 mm thick was used. This means that the homemade unit was made not just to have it, but for everyday use.

Feeling the difference, every master will want to acquire a crossbow pipe bender, making it himself. The disadvantage of this version of the pipe bender is the fact that it allows you to bend the corrugated pipe at only one point. This is due to the fact that the device is equipped with a fixed shoe. This option is used for round pipes when you need to obtain a certain bending radius in one place.

To construct such a device, you need a channel and a hydraulic jack. A special shelf is made for the jack in which it is installed. In the upper working part, two rollers made of steel pipe are mounted between two channels. The distance between the rollers and the heel of the jack must be the same in order to be able to obtain even and neat bends.