This problem often arises when the hex bolt is torn off and it is not possible to unscrew it with a wrench. The causes of this problem may be the sticking effect, displacement of the parts being fastened, over-tightening when installing hex hardware, as well as the use of inappropriately sized keys.

- 1 How to unscrew a hexagon: preparation

- 2 How to unscrew a broken hex bolt

- 3 How to unscrew an internal hexagon with torn edges

- 4 How to unscrew a hexagon without a key

How to unscrew a hexagon: preparation

Whatever the reasons for the situation when the bolt stops unscrewing, the following steps should be taken before plumbing:

- Before unscrewing the hexagon, to reduce the coefficient of friction, it is necessary to open the bolted fasteners with lubricant such as WD-40, kerosene or brake fluid. You can start unscrewing the bolt 30-60 minutes after application.

- A stuck bolt can be gently tapped with a hammer so as not to further disturb the thread.

- If the location of the fastener allows, you can heat it with a gas burner so that the metal becomes more pliable and rust and dirt turn into ash.

How to unscrew a broken hex bolt

To unscrew a protruding hex or star bolt, you can use the following methods:

Removing the valve body

If the valve body is damaged (wear, corrosion or manufacturing defects), it will have to be removed. They do it this way.

- Unscrew the nut of the flexible line going from the water fitting to the mixer.

- Loosen and unscrew the nut securing the faucet to the sink or countertop.

- If the nut cannot be unscrewed or you cannot get to it with a wrench, you can use a flat screwdriver to unscrew the fastening stud. For this purpose it is equipped with a slot.

- After removing the mixer body, you need to remove the gaskets from the sink and clean the mounting area from dirt and mineral deposits.

If the flexible hose has already worked for several years, it is better to replace it at the same time.

How to unscrew nuts

It is not recommended to use a Torx with a hole in the center; the sprocket can break off.

If all else fails

The methods described here will help you unscrew the nut even in the most difficult situations. However, although rare, it happens that they do not help. In this case, you can resort to more drastic methods that will irreversibly destroy the connection.

If you have a grinder, you can saw off the bolt along with the nut. This must be done carefully, as otherwise there is a risk that the part that was attached will be damaged. The disadvantage of this method is that you will have to somehow remove the remaining part of the bolt, which in some cases can be a difficult task.

Another way to solve the problem in a similar way is to use a drill. This requires drilling a screw. If you do not act accurately, you can damage the hole.

Unscrewing a nut using a hammer and chisel Source 7vaz.ru

How to unscrew an internal hexagon with torn edges

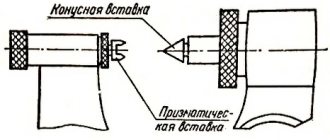

To unscrew a bolted connection with a through hole, you can use a file. With its help, the hexagonal hardware is bored to the next size and unscrewed with a wrench.

The second way is to use Torx. They can punch out new splines and reuse the hex hardware, but subsequently it can only be unscrewed with a Torx sprocket.

In addition, before unscrewing the torn hexagon, you can saw through the internal axis of the hexagonal fastener for a screwdriver and unscrew it. With this method, it is not always convenient to get to the fastener; sometimes its location does not allow the use of a screwdriver.

Causes of thread failure

Troubles with fasteners usually occur due to poor quality maintenance of products. Screws often do not have an anti-corrosion coating, and over time their surface rusts and the thread flow is disrupted. As a result, unscrewing with a regular screwdriver becomes difficult.

Bolt with damaged threads

Thread problems can cause:

- sticking – violation of the integrity of fasteners under the influence of high temperatures;

- low quality of the product itself - in this case, deformation can occur already during screwing in the bolt;

- natural wear - occurs when used for too long or excessively high loads;

- using unsuitable tools for screwing and unscrewing.

How to unscrew a hex without a key

Other ways to unscrew a bolt without a hexagon are as follows:

When purchasing a set of tools in a case, many buyers paid attention to the strange heads with rounded edges and the Super Lock inscription on the price tag.

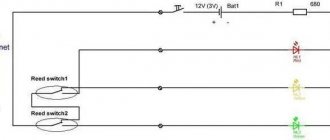

Super Lock socket technology has different names among manufacturers: NON SLIP, SURFACE DRIV, BOLT GRIP, SL sockets, sockets with reverse spiral grooves. The appearance of the heads is shown in the figure below.

Tip 1: How to unscrew the hub nut

Super Lock heads, or Super Lock, are fundamentally different from other profiles and have several secrets in their operation.

Socket heads with a Super Lock profile are fundamentally different from hex sockets in the location where the fastener is captured. While the hex head profile applies maximum force to the corners, Super Lock heads load the edges of the fastener.

Super Lock sockets have the following advantages:

Professionals have noticed that Super Lock socket heads allow maximum force to be applied to fasteners and minimize the risk of deformation or breakage. And with fasteners whose edge corners have already been torn off, the tool copes better than heads with a different profile. Therefore, tool sets with a Super Lock profile are often used by auto repair professionals.

Tool sets in a case with a Super Lock head profile are presented in our store here.

Unscrewing fasteners with broken edges

As a rule, this situation arises when dismantling old building structures located in an open place or when there is a defect in the fasteners. To remove the nut, it is important to choose the right tool and carry out the work correctly. Recommended methods:

- For large bolts that are in the public domain, you can use a chisel; you need to attach it along a tangent line to the head, and then apply several strong blows with a hammer. However, with this method there is a risk of surface damage. In addition, you can use a chisel to make a groove for a slotted screwdriver, and then carefully unscrew the bolt;

- If you have free access to the head, it is convenient to use a universal adjustable wrench. With it you can firmly clamp even a completely deformed head; for small nuts it is best to use a wrench with notches on the working surface - they allow you to achieve better adhesion to the fastener;

- If the edges are not very damaged, it is permissible to use a spanner. It should have 12 edges, so you can achieve closer contact with the metal alloy. The head should be selected a size smaller than the diameter of the bolt;

- Using a file or grinder, you can restore the edges of the fastener, which will allow you to safely use a regular hexagon of a smaller size. There is no need to cut out the entire head; it is enough to form two parallel edges.

If you have welding skills, then a bolt with a deformed surface can be restored. To do this, you need to cut off the head from another screw and then weld it onto the old element. This will allow you to use a regular wrench without any effort or additional tools.

How to unscrew a nut: 55 effective recommendations

How to unscrew the nut? We recommend effective approaches for complex situations and a variety of problems.

In this article we will tell you how to unscrew a stuck nut, a rusty nut, a nut with torn edges or a completely round one. Cases with non-standard nuts - plastic and large - are analyzed separately.

The material also describes the most suitable tool, incl. a special tool professionally used to work with fasteners.

The material is useful for those who intend to unscrew the fasteners of the engine crankshaft, hub, wheel, generator, exhaust manifold, variator and other components and assemblies of a car, motorcycle or other equipment.

The recommendations will also be useful for household use.

How to unscrew a nut

As a rule, nuts are unscrewed with hand tools - spanners or open-end wrenches, heads using a wrench or ratchet. However, problematic situations often occur.

How to unscrew a nut when the nut cannot be unscrewed with a regular tool using the usual application of force? In this situation, you should choose from the available tool the one that suits best:

- thin short open-end wrenches, especially with a too loose (broken) jaw, are the worst option, which is better to abandon immediately in a situation with unscrewing rusty stuck nuts (open-end wrenches will lead to torn edges and further difficulties);

- box wrenches with an extended handle are preferable to open-end wrenches, since they cover the perimeter of the nut more tightly;

- A 6-point socket wrench or socket is preferred over the 12-point version;

- Due to its simplicity and strength, a crank is preferable to a ratchet, because for the latter, the application of increased forces can lead to damage to the mechanism (this is especially true for ratchets with a large number of teeth, each of which is smaller and not so durable);

- an air impact wrench will do a better job than a hand tool;

- in combination with a long wrench or an air impact wrench, the best solution would be the Super Lock head, in which the force is applied not to the corners (edges), but to the planes, which eliminates the licking of the nut edges;

- A torque amplifier (multiplier) will help apply a force to a large stuck nut that is inaccessible using only the physical capabilities of a person.

Which way to unscrew the nut

In the vast majority of cases, the fastener has a right-hand thread direction: you need to unscrew the nut counterclockwise (we look at the nut from the side of the free threaded end of the bolt or stud through which you need to drive the nut).

Accordingly, unscrew the nut with a left-hand thread clockwise.

When deciding which way to unscrew the nut, just look carefully at the fasteners:

- on the side you can see the inclination of the threads at a small angle - unscrew the nut in the direction in which the thread “rises”;

- even if the threaded part is not visible, you can see the desired direction along the end of the nut at the point where the last turn of its internal thread exits.

How to unscrew a stuck nut

In order to unscrew a stuck nut, we recommend performing several preliminary preparatory operations:

- clean the fasteners from rust and dirt with a wire brush;

- tap the nut around with a hammer without damaging its edges and exposed threads.

When deciding how to unscrew a stuck nut, it is necessary to take into account several possible methods, based on the actual condition and availability of fasteners for the tool, the composition and parameters of the existing tool, and the feasibility of destroying the nut itself or the threaded part on which it is fixed.

The following options are available for unscrewing a stuck nut:

- apply heat to the nut (preferably until red and repeatedly);

- apply a penetrating compound (WD-40, liquid wrench or their analogues) into the contact gap between the nut and the thread of the bolt (stud), wait the time required for the product to work (from 20 minutes or more depending on the condition of the fastener and the activity of the product);

- increase the force impact on unscrewing by increasing the lever for applying forces through the use of an extended tool (or an extension attachment on a tool of normal length);

- use a special device - a torque amplifier (another name is a torque amplifier, torque multiplier);

- use a pipe wrench, holding the nut with it and applying force in the direction of unscrewing;

- clamp the nut in a rigidly fixed vice and unscrew it, rotating the entire part or assembly, if possible;

- clamp a small separate vice and try to unscrew the nut with it;

- use a pneumatic impact wrench;

- drill out the threaded rod on which the nut is stuck.

How to unscrew a broken nut

Damage to the edges (their breakdown) causes serious difficulties. There are several main solutions in this case:

- use a Super Lock head (acts on planes, not on edges);

- hold the torn nut in a pipe wrench (in a vice, clamp, pliers, etc.) and unscrew it;

- hammer a suitable larger nut on top of the nut with licked edges, the inner diameter of which allows it to be tightly seated; for additional fixation, drill a recess in the area of contact of the nuts, inserting a metal rod there (a piece of a drill and a piece of nail) as a key to prevent rotation) and unscrew the fastener using a tool that matches the size of the nut of larger diameter with working edges;

- put on a nut of larger diameter, weld both nuts together using a semi-automatic welding machine (covering the thread of the stud or bolt with a tube with a suitable wall thickness), unscrew the large nut together with the welded small one.

How to unscrew a round nut

For round nuts, when the edges are cut and smoothed completely by previous unsuccessful attempts, or the nut was made in this form initially, several approaches can also be applied:

- fit a standard hex nut of larger diameter into tension on it and drill a hole and a key that prevents rotation at the line of their contact and unscrew it using the large nut;

- if the side surface is of sufficient height, use a special tool - a pin driver;

- put a square washer of large thickness (comparable to the height of the nut) on the round nut, cut on one side and with the internal diameter of the washer exactly corresponding to the outer diameter of the round nut, clamp the nut with a pipe wrench or a vice, giving in to compression, the nut in the cut will select a gap until it tightly covers the surface round nut, unscrew the fastener.

Unscrew the broken bolts and nuts

“Licked” edges on bolt heads or nuts are not that uncommon. Excessive forces that we apply when tightening and then when unscrewing often lead to the fact that the boundary between the edges of the bolt is erased. If the bolt does not unscrew, ordinary wrenches are powerless in this case - they simply turn, and the fasteners remain in place.

Torn or licked edges on a nut or bolt prevent it from being unscrewed

There are several ways to unscrew shear bolts and nuts:

- Using a gas adjustable wrench. Due to the ribbed jaws, adjustable degree of “tightening” and a fairly large lever, an adjustable wrench helps in most cases. This tool is not uncommon, so the first thing to do if you need to unscrew fasteners with licked threads is to try this method.

A gas (pipe) wrench is the best tool for loosening nuts

How to use the extractor

If there is a plastic or rubber gasket under the bolt, remove it and try one of the suggested methods again. If you can’t unscrew a bolt with torn edges using all these methods, there is only one thing left: cut off/saw off the head and drill out the pin.

Option seven, final

In that unfortunate case, when you have no luck and none of the above methods helped, and a damaged nut or bolt with broken edges has not budged, despite all the titanic efforts, there is only one way out. But these, alas, are extreme measures. So, the torn nut needs to be cut into pieces using a chisel and a hammer (by hitting the chisel placed in the right place with a hammer several times), and only then begin to disassemble the entire connection. True, after this you will have to replace not only the damaged nut, but also the bolt (if it was still intact). But the problem will be solved.

Sooner or later, any owner is faced with a situation where a nut, bolt or self-tapping screw does not want to be unscrewed. There are several reasons for this: low-quality metal, violation of technology (overheated screws), rust, time, too much effort applied when tightening the connection. However, it is possible to unscrew a bolt with torn edges, a licked nut, or a rusty connection. In this article we will talk about how to do this.

Rusted nut

Another problem that is familiar to car enthusiasts (and not only) is a rusted nut and/or thread. In this case, you should not make heroic efforts to unscrew the fasteners. Your edges will simply “stick together” and another problem will be added to the boiling thread. If after a couple of attempts you can’t unscrew it, try the following methods one by one:

- Tap the bolt with a wrench. There is a chance that the rust will crack and the nut will be unscrewed.

- Fill the connection with kerosene and wait. It will eat away the rust, after which it will be easier to unscrew the rusted nut. But during this operation you cannot smoke, turn on welding, or be near an open flame.

Not the most elegant, but effective solution

Removers for broken nuts

You can also fight rust with lubricant. Try filling the joint with fluid universal lubricant (available in WD40 cans). After waiting a couple of hours, we try to work with the key. If it doesn’t work, we try other methods one by one.

Self-tapping screws with stripped splines (asterisk)

If overheated screws are unscrewed/twisted a couple of times, their edges lose their sharpness, the screwdriver turns, but the screw itself remains in place. If it “sits” in wood, plaster, chipboard or other similar, not too hard materials, you can put a thin elastic band (for example, for hair) under the screwdriver. Due to the elastic force, a tighter fit is achieved to the remaining edges, which helps to move the self-tapping screw from its place. Other methods are more “traumatic”:

- Cut grooves inside the “licked” funnel using a flat-head screwdriver and unscrew. This method is quite dangerous: if the walls of the “funnel” are too thin, there is a chance that the screw head will simply crumble from the effort. All that remains is a screw that cannot be unscrewed.

It’s already difficult to unscrew such a self-tapping screw

Unscrew the self-tapping screw with torn edges (cross)

The remains of a bolt or stud without a head can be unscrewed as follows: cut a left-hand thread in the remaining body, drip “moment” glue, screw in the left-hand tap, and leave for an hour. Apply some oil to the main thread and leave for an hour. When the glue sets, unscrew it. If the remains of a self-tapping screw are stuck in the wood, it is easier to seal this hole and install another fastener nearby.