Remember the famous film with the brutal Mel Gibson? In a post-apocalyptic world, people fight for water, fighting with incredible equipment and using homemade mechanics to survive. You can bet that most of this was powered by gasoline engines, since they are the only fully autonomous equipment. And in the real world, this tool is in the arsenal of almost every summer resident. If you have a chainsaw, you will not be lost in any situation. In this material, the editors of the online magazine HomeMyHome.ru have prepared for you a review of homemade chainsaws. With your own hands, using simple devices, you can make many useful devices for the household on the basis of “Druzhba” or “Ural”.

Don’t rush to get rid of the “old lady” chainsaw, you will still need it!

What can be made from a chainsaw

Homemade chainsaws belong to a very wide class of devices. This is a hand-held tool with a motor drive, such as:

- Bulgarian;

- motor drill;

- cultivator;

- snow blower;

- stationary machines and devices: sawmill;

- electric generator;

- motor pump;

- snowmobile;

And these are probably not all the possible homemade chainsaws.

Another way to create a homemade sawmill

You can use another method of making a sawmill. In terms of technology, this option will not differ much from the previous one. The tools and drawings will be identical as in the first version.

The drawing shows the main components. First of all, this is a chainsaw, its drive and a mechanism with which it will be possible to regulate the thickness of the resulting board. It is also worth noting the mechanism that allows you to move the cutting part of the structure, and a device for securely fixing the log.

The process of sawing a log on a sawmill is carried out by lowering or raising the base of the device, which is held on by four screws or welded to the plate with nuts with bent edges. A lock nut is placed on the top of the base and tightened once the sawmill is fully set up. The adjustment takes place to the desired thickness of the processed log.

The cutting part moves along the corners, which serve as guides along the frame. A gap of 50-55 cm is maintained between these elements. Two rollers are attached to each rack, the upper one rests on the guide angle, and the lower one will keep the sawmill from lifting. Instead of rollers, you can use 20 mm bearings.

The wood on this structure is secured using two combs, one of which moves with a screw, the second remains stationary. After installing the log, the first movable element is fixed in a stationary state with several screws. After installing the fixing device, you can start working on the sawmill.

Rework principle

The principle of alteration is very simple and combines the entire range of home-made devices and assemblies. A chainsaw is used as a drive. The unique qualities of the chainsaw motor, capable of operating at very large tilt angles, perhaps not upside down, allows this universal drive to be used in many designs. In the case of using a chainsaw as a drive for a homemade hand-held power tool, most of the parts of the original chainsaw are retained, and only the working part is changed.

Walk-behind tractor from a chainsaw

If, on the basis of a chainsaw, you make a stationary machine or vehicle with your own hands, the alteration becomes deeper. A gearbox, variator or belt drive is added to the design, the fuel tank is replaced with a more capacious one to ensure long-term operation without refueling.

Chain sharpeners

It doesn’t matter what kind of chainsaw you have, homemade or factory-made, in order for it to cut wood like clockwork, you need to regularly sharpen the chain. To do this, you can use various auxiliary devices.

For example, for the convenience of sharpening a chain, we recommend using a fairly easy-to-make device - a homemade stand with a clamp for fixing the bar.

This chainsaw clamp is U-shaped and the ends of the legs are pointed. This makes it possible to use the device even in hiking conditions, installing it in a place convenient for you.

We also recommend reading how to make your own chain sharpening device, which can be used both in the home workshop/garage and outdoors.

To make this homemade product, you will need a minimum of materials: strips of metal of different widths, nuts and threaded rods. You will need a standard tool: drill, angle grinder, welding.

Transport

Based on a chainsaw engine, you can make many homemade vehicles. It is important to remember that transport is a means of increased danger and the author and owner of the homemade product bears full responsibility for its safety.

Snowmobile

Structurally, a snowmobile is one of the most complex homemade products. The following components will need to be made:

- Support frame.

- Frame.

- Caterpillar.

- Front ski.

- Steering wheel with controls - gas and clutch handles.

- Suspension.

- Transmission.

The supporting frame is welded from a square steel profile 20*20 or 20*30, it is necessary to provide a swing arm for the shock-absorbing rear suspension and install a motorcycle-type steering fork for the front. There are options with two skis - here the design of the front suspension will be more complicated - the steering wheel will not turn the axis of the ski, but pull the levers to control the steering linkage. This option is more difficult to manufacture, but guarantees better controllability and stability. For a snowmobile, a centrifugal clutch with a V-belt and chain is suitable. To increase the traction force, a gear is installed on the working shaft of the caterpillar, which is larger in diameter than the drive gear on the chainsaw shaft. For the caterpillar, you can take ready-made drawings from a light snowmobile with an engine of the same power as a chainsaw.

In order for a homemade product to confidently carry one or two people, the engine power must be at least five horsepower.

Snowmobile

A snowmobile is much simpler in design than a snowmobile; according to the principle of its operation, it resembles a small propeller-driven airplane moving on the ground. The load capacity, maneuverability and stability will be noticeably lower than that of a snowmobile with equal engine power. The advantage will be simplicity of design, greater reliability and greater speed in open spaces. The pusher type screw is installed in the protective casing of their mesh behind the driver's back and pushes the device forward. The device is controlled by turning the ski, the gas lever and the snow brake.

Homemade snowmobiles

In order to properly accelerate a homemade snowmobile or drive not only on the smooth ice of a frozen river, but through fields and small snowdrifts, you will need a chainsaw engine with a power of at least 10 horsepower.

Moped

A homemade summer vehicle with a chainsaw engine is unlikely to compete with industrial designs. Home craftsmen often assemble it as a test of their strength or as a training session before more serious designs. In addition to the chainsaw, you will need an old bicycle, or at least the main components from it, including bearings. Craftsmen weld the frame themselves from pipes or square profiles. It looks scary, but it is reliable. The drive is carried out to the rear axle by a bicycle chain.

The most advanced home craftsmen use a mountain bike with high-quality brakes and shock-absorbed suspension as a basis. A gearbox with a gear ratio of 1:15-1:20 and a variator are added to the chainsaw. With such a homemade product you can already travel quite comfortably at speeds of up to 30 km/h.

Homemade kart based on a chainsaw

What else can be made from a Ural or Druzhba saw? For example, a go-kart is a maximally simplified car model designed specifically for circuit racing. It is devoid of a body, shock absorbers, and sometimes even brakes - everything is done to make the design as light as possible to increase speed. The homemade kart frame is made from profiles or steel pipes. DIY wheels are often taken from industrial carts for transporting small loads. The drive is carried out to the rear axle by a bicycle chain, the steering linkage is taken from a minicar. To assemble the card you will need intermediate level metalworking and welding skills. It is better to take ready-made drawings as a basis and adhere to their basic parameters - although karting is considered a “children’s” sport, the speeds developed are quite adult, and you can seriously injure yourself.

Using a similar scheme, based on a chainsaw motor, craftsmen assemble the kart’s older brother, the buggy. This carriage has a reinforced suspension with large strokes and is designed for racing over rough terrain. The homemade center of gravity is located low to improve stability; the driver and passenger seats on top are protected by a powerful roll bar. The process of making a children's ATV will also be very similar.

Homemade scooter with a chainsaw motor

Despite the fact that this device looks like a children's toy, it can be a serious help to a postman or courier. Even though the scooter's maximum speed is low, 10-15 km/h, it has excellent maneuverability and incomparable efficiency. If the working day consists of many short trips from point to point, you couldn’t ask for a better option.

DIY scooter

Almost the entire structure of the chainsaw is preserved; you only need to remove the bar and the saw chain, replacing it with a bicycle chain that transmits torque to the rear wheel of the homemade scooter.

boat motor

Homemade boat motors first appeared in Southeast Asia after the Second World War. Poor fishermen and peasants built their own wooden boats, but they could not afford to buy a factory-made boat motor. Chainsaws were quite affordable. Without further ado, they put a bamboo stick on the saw shaft, secured it with a wooden cotter pin and, leaning it on a sawhorse with two oarlock pins, lowered it into the water from the stern at a slight angle. A screw cut out of wood was attached to the lower end of the pipe so that it was under water. The entire structure required only bamboo trunks and ropes, and it was assembled in a couple of hours. As the bamboo shaft and crossbar of the trestle wore out, they were replaced with new ones. Such a boat was steered by simply turning the pole behind the engine in the desired direction. The simplest version of a homemade boat motor will repeat the Indo-Chinese design, with the difference that instead of a pole, a steel pipe is taken, a screw from an old boat motor, and the goats are welded from a corner and equipped with a thrust bearing on a rotary support.

Boat motor made from a chainsaw

A more advanced version uses a vertical propeller shaft and a sealed gearbox that changes the direction of rotation by 90 ⁰. A bearing with a device for lifting the propeller shaft and a control handle, to which the gas regulator is connected, are placed under the engine. The propeller is also selected from a boat motor. This option repeats the kinematic diagram of a factory-made outboard motor. It is capable of ensuring that a small boat travels at a modest speed over a considerable distance with enviable efficiency. It is important, however, to remember that not all saws are designed for long-term continuous operation, so you need to monitor the thermal conditions of the motor and periodically let it cool down.

Goats for cutting firewood with chain saws

But still, when we are dealing with large volumes of firewood, torturing ourselves by manually sawing logs is a wasteful activity in terms of time and physical costs. Gasoline and electric chainsaws speed up the process tenfold and reduce physical labor.

But traditional sawhorses are not suitable for working with them, due to the high risk of injury and tool breakage when clamping the saw bar in a cut. Of course, you can only saw logs that exceed the dimensions of the log, but you will not achieve rational cutting of the logs. Therefore, other devices were invented to work with such saws, which, by tradition, retained their old name, although they bear little resemblance to their grandfathers.

The simplest sawhorses for working with a chainsaw have a similar design.

Heavy stable base and a pair of horns for fixing the log. What else is needed? Sawing takes place outside the dimensions of the structure, and the log is held in it by the foot. Productivity is low, but such goats are quite functional.

For sawing thin logs, the most suitable, in our opinion, are sawhorses of a similar design:

Their only drawback is that the logs of the bottom row are not sawn, but for large volumes this design flaw will not be fundamental. And you choose the dimensions of such trestles depending on the length of the firebox of your stove, the length of the bar and the power of your saw. Their undoubted advantage is quick disassembly, which makes it possible to simplify and speed up the removal of lumber.

A similar design of a trestle, but with the ability to saw bundles of logs to the end, due to the presence of transverse supports that provide a gap between the woodpile and the base of the trestle, is shown in this video, but the lack of the ability to quickly disassemble to a certain extent neutralizes this advantage.

Although you can turn it over on the end side, however, with a little more effort.

For thicker logs, a similar design is suitable, but with them secured in a sawing container, which will prevent the logs from pinching the saw.

And the size of lumps obtained in such goats can be minimal.

Not the most successful, as it seems to us, but a quite workable version of the device for sawing not very thick logs is shown in this photo:

The most valuable thing in such a trestle design is the stop template, which allows you to maintain the ideal height of the chocks, which is extremely important for small-sized stoves

Chainsaw for aircraft

Having conquered land and water, the inventors turned their gaze to the sky. The media is full of reports that another inventor has taken off from the ground on a homemade gyroplane or a homemade backpack helicopter with a chainsaw engine. In Australia, there is even a prize for a pilot who manages to fly one mile. However, aerodynamic calculations showed that the engine power is clearly insufficient to lift a 100 kg load off the ground and achieve confident, controlled flight. Four 5 horsepower motors operating synchronously can theoretically cope with this task. The question is synchronization and configuration of the control system.

With the development of quadcopters, there was a chance to adapt their control system to a homemade helicopter.

boat motor

The saw set is removed from the chain saw engine and the drive sprocket is removed. The clutch is remade by grinding out a smaller cup and replacing the tension spring, which makes it possible to reduce the mass of the unit and reduce the adhesion force. The motor shaft and gearbox are connected through a coupling.

For installation use a channel:

- in the top shelf the necessary holes are made for mounting the engine with the gearbox;

- The lower shelf is equipped with a hole, a tube is welded into it coaxially with the output shaft of the gearbox.

A shaft is passed through the tube, which transmits rotation to the propeller, and is connected to the output shaft of the gearbox. A fastening and rotating unit is attached to it, which is used to install the motor on the transom of the boat, raising and lowering the propeller into the water.

A gearbox is installed at the lower end of the tube, which receives rotation from the vertical shaft and transmits it to the horizontal one. A propeller is installed on the latter, which will move the boat.

snow blower

If in the previous design you replace the shaft with plowshares or harrow spokes with an auger mechanism, add a casing, an intake device and a pipe for throwing out snow, the cultivator will turn out to be quite a decent snow blower. Many home craftsmen design their homemade products with replaceable attachments for different seasons. Motor from a Shtil saw with a power of 3-5 hp. It will cope quite well with cultivating the garden in spring and autumn, and with removing loose snow from a summer cottage in winter. The most important unit is the screw mechanism.

Homemade snow blower

If you are not a professional designer, then it is better to download ready-made drawings from the Internet. The auger blades are made of thick rubber, for example, from a conveyor belt. The intake device is made of galvanized steel. A plastic sewer pipe is suitable for the snow disposal pipe.

Rules for working with metal

Working with metal

In order for the blade to be strong and elastic, during its manufacture it is necessary to follow the rules of working with metal. They are as follows:

- The workpieces must not have visible or hidden damage. Before making a knife, the workpieces must be inspected and tapped. A solid part sounds loud, but a defective part sounds dull.

- When designing the shape of the blade, angles must be avoided. In such places the steel can break. All transitions must be smooth, without kinks. The cuts of the butt, handle and fuse must be ground at right angles.

- When sawing and sharpening, do not overheat the steel. This leads to a decrease in its strength. An overheated blade becomes brittle or soft. During processing, the workpiece must be constantly cooled by completely immersing it in a bucket of cold water.

- When making a knife from a saw blade, you need to remember that this product has already gone through a hardening cycle. Factory saws are designed to work with the hardest alloys. If you do not overheat the canvas during the turning and finishing process, then you will not have to harden it.

The blade shank should not be made too thin. It is this part of the product that will bear the heaviest load.

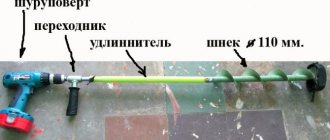

Motor drill

During the construction season, a motorized drill made from a chainsaw will do an excellent job of digging holes for posts or screwing in screw piles, and in winter it will delight ice fishing enthusiasts. The design of a homemade motor drill will require a speed reduction gearbox, since piles should be drilled and screwed at a speed of 30-60 revolutions per minute. It is better to take the auger from a ready-made motor drill made of good steel. An auger for a hand drill or a homemade one made of simple structural steel will not last long with active use.

Circular sawmill from an electric saw: detailed description and drawings

Before making a homemade sawmill from an electric saw, you need to decide on:

- the length of the materials that will be processed on this machine;

- volumes of workpieces;

- future homemade location.

Special attention should be paid to the choice of disc blade. Discs with a size of 400-500 mm, which are most often used in modern circular saws, are more than suitable for these purposes. And the problem with sawdust can be solved by using a disk with a minimum thickness.

The device of a grinder from a chainsaw

In reports about the work of rescuers, everyone saw how the building structures of destroyed houses or a crumpled car after an accident were cut with a hand-held device that produced beautiful sparks. A lightweight version of a professional device can be made by any home craftsman. In weight and dimensions it will significantly exceed the well-known electric angle grinder, or grinder. However, the homemade product is independent of power supply, and the engine power allows the use of cutting wheels with a diameter of 30 cm. Such a mobile device will allow you to cut and clean metal structures before welding or painting, treat the surface of wood and stone, and even cut concrete blocks along with reinforcement. The device will require welding a small frame on which the engine and the working shaft bearing will be mounted. The torque is transmitted to the working shaft pulley by a short belt, and at the other end of the shaft it is necessary to attach a mandrel for grinding wheels or a clamping device of sufficient diameter from an old grinder.

It is important to remember that when working with a homemade grinder, you must use personal protective equipment: goggles or a transparent shield, thick overalls, durable shoes and protective gloves.

How is it different from a jigsaw?

The main and most important difference between an electric hacksaw and a jigsaw is the different purposes of these tools. We can say that the electric hacksaw is designed to destroy, and its younger relative is designed to create.

Most often, an electric hacksaw is used to quickly cut material, mainly in straight lines. It can easily cope with structures of any shape and any material. Cardboard, wood, gypsum fiber, metal, concrete, glass, ceramics - this is just a small list of materials that can be cut using an electric hacksaw. This type of work is typical for dismantling and other relatively rough repair work.

A jigsaw is more suitable for more precise work with flat surfaces and it is more advisable to use it in cases where shaped cutting is required.

Another major difference is the shape of the instruments, which determines their capabilities. The elongated body of the electric hacksaw and the rather long blade allow you to make cuts in the most inaccessible places, where it is simply impossible to get to with a wide electric jigsaw.

Thanks to its design and flexible blade, a reciprocating electric saw can cut down protruding elements flush with the wall, which a fairly wide jigsaw cannot boast of. An electric hacksaw can be used to cut “in weight” without any problems; for an electric jigsaw, a flat surface is required to ensure that the working area rests firmly on the material, in order to avoid breakage of the tool.

Thus, when you need to decide which tool you need: a reciprocating saw or a jigsaw, first of all you should clearly define the intended tasks.

An electric hacksaw is less demanding in terms of operating conditions and can work in the most extreme conditions. Even beginners can easily master it. The tool is capable of making fairly even cuts, but, nevertheless, is more suitable for rough work.

A jigsaw in the hands of a master becomes an unsurpassed tool for cutting out shaped elements, but it requires more skill and has limitations in its capabilities.

Winch

A homemade winch will be an excellent help in construction and lifting loads to a height, dragging a cut tree, rescuing a car stuck in a puddle, or pulling a boat out of the water. The thrust of such a homemade winch depends on the engine power and the gear ratio, and can reach one and a half tons. For specific applications, the unit is equipped with additional components: blocks, pulleys, hooks, sling belts and anchors for attachment to the ground or to a tree. To make a winch from a chainsaw with your own hands, you will need to weld a strong frame on which to place the engine, gearbox and drum with a stopper. The frame is provided with holes and lugs for various methods of attaching the device to the ground, a wooden or concrete foundation, or to a tree trunk. The drum can be taken from an old winch, or you can make it yourself according to the drawings.

Gasoline winch

You should follow the safety rules when carrying out lifting and rigging work:

- Cables, hooks and slinging accessories must be strong and periodically tested to tensile strength.

- The stopper must securely fix the drum and prevent spontaneous unwinding of the cable under load.

- When lifting heavy loads, the winch must be secured to a permanent or temporary foundation, the weight of which must be five times the maximum weight of the load being lifted.

- It is strictly forbidden to stand under the load and in the area of its possible scattering when falling, as well as to the side of a tensioned cable when moving objects horizontally.

Why do they resort to a homemade option?

Often, homemade versions of tools or improvement of existing ones are done out of a desire to save money. Using improvised means and parts left over from equipment or machinery that has fallen into disrepair, craftsmen skillfully make various devices, such as, for example, a chain saw from an angle grinder.

The second reason can be considered the desire to have a multifunctional tool that will help facilitate numerous tasks on the farm. The undeniable advantage of such a homemade device is the space saving. After all, an additional attachment takes up much less space in a shed or garage than a full-fledged device.

For remodeling, you can use absolutely any brand of grinder

The only point worth paying attention to is that the factory attachments may only fit a limited number of models, so when purchasing, be sure to check whether your angle grinder is suitable for the selected attachment

Power station

For a mobile power plant with a power of up to 5 kW, there is a time-tested solution: a homemade generator based on a motor from a Druzhba or Ural saw. They are actively used on expeditions and in remote logging operations. The device includes a steel frame welded from a corner, on which an engine, a generator and a waterproof electrical distribution box with sockets for connecting electrical equipment or an extension cord are mounted. Through the gearbox, torque is transmitted to the generator shaft.

For low-speed generators, there is an option for a homemade power station with a belt drive. This design is smaller in size.

Our hands are not for boredom

The Druzhba chainsaw is optimally used as an engine and drive for the following devices:

- generator;

- water pump;

- sawmills;

- circulars;

- Bulgarians.

The simplest belt drive from a chainsaw to a car generator will provide electric light to a country house or cottage. Using the same method, you can connect it to a centrifugal pump to pump water out of the basement.

By adding a worm gear to the chainsaw, you can easily construct a simple winch.

Using a chainsaw, you can easily construct something like a band sawmill , where instead of a band, a carriage with a saw attached to it will move. This design will allow you to dissolve the tree trunk onto the timber yourself. Theoretically, it is possible to saw boards, but due to the wide cut there will be large losses.