Three-wheeled bike with a chainsaw engine

Dear visitors of the site “Visiting Samodelkin”, from the material presented by the author you will learn how you can independently make a three-wheeled mini-bike with an engine from a Ural chainsaw with a minimum of funds, so let’s go)

This three-wheeled mini-bike is the brainchild of one very good man and his name is Gainetdin Bulatov from the city of Pyt-Yakh, or simply Gennady. The author made the three-wheeler especially for his beloved grandchildren; Gennady has three of them)

The heart of the mini-bike is the engine from the Ural chainsaw; according to the author, it was lying abandoned in the garage because he uses modern saws. This engine is well suited for a mini-moped and has enough power to push a child around.

The frame is welded from a half-inch water pipe, the wheels are from a garden wheelbarrow, the axles are from the same, the small drive sprocket is from a D-6, the large driven sprocket is from a bicycle, the chain is also a bicycle chain. The throttle and brake cables are mounted on the bicycle handlebars. The rear axle is mounted through bearings at three points and is driven by transmitting torque from the engine through a chain drive from a small to a large sprocket.

The wings are also homemade and made of metal from an iron barrel. There is a small glove compartment under the seat where you can store and transport wrenches and a chainsaw starter.

So, let's look at what exactly the author needed to assemble a three-wheeled mini-bike?

Materials

1. engine from a Ural chainsaw 2. wheels from a garden wheelbarrow 3. bearings 3 pcs 4. sprocket from D-6 5. bicycle chain 6. half-inch pipe 7. cable 2 pcs 8. bicycle handlebar 9. rear axle for 2 wheels 10. paint 11. large bicycle sprocket 12. foam rubber 13. leatherette 14. plywood (for seat) 15. bolts, nuts, washers, engravers Tools

1. welding machine 2. grinder (angle grinder) 3. drill 4. set of wrenches 5. screwdriver 6. tape measure 7. spray gun 8. marker 9. hammer 10. angle Step-

by-step process of assembling a mini-bike with an engine from a Ural chainsaw with your own hands.

As mentioned above, Gainetdin created this mini-bike for his grandchildren in order to instill in them a love of motorcycles from a young age. A three-wheeled moped is very convenient in terms of stability, just like a bicycle in principle, and the child quickly gets used to riding such a bike. It’s clear that children love their grandfather very much for his invention and enjoy riding in the yard of the house (under the supervision of adults, of course)

To start the assembly, the author purchased 3 wheels from a garden wheelbarrow at a reasonable price.

Then I made the rear axle and prepared the bearings.

Next is fitting and test assembly.

In order to reduce the noise of the exhaust pipe, a muffler was additionally made from a pipe with 3 partitions inside, which helped reduce noise.

The seat is made of plywood and foam rubber trimmed with substitute leather, attached to the frame on hinges, and under it there is a trunk where you can put a tool and a starter.

Installed the gas tank and connected the gas line.

Torque is carried out by chain transmission.

The rear axle is attached to the frame via bearings at three points.

The gas and brake cables are routed to the steering wheel. The bike's fork is also homemade.

Asterisk from D-6.

This is such a cool bike

We also recommend watching a video of rides on a mini-bike

The creator of the three-wheeled mini-bike is Gainetdin Bulatov from the city of Pyt-Yakh.

As you can see, in order to make your children and grandchildren happy, you don’t have to buy expensive imported toys that he will play with, break and throw away, but such a bike will give happiness and joy to a little boy and respect among his peers and not only) Well done Gainetdin. Skillful fingers

That's all

Thank you all very much for your attention! Come visit often and don't miss out on new items in the world of homemade products! Source

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Do-it-yourself bicycle (moped, go-kart, scooter, ATV) with a chainsaw motor

Modern gardeners are increasingly experimenting with the gasoline-powered tools at their disposal. Mainly, a household chainsaw is used for this. Very often, its engine becomes the basis for the manufacture of simple but very useful homemade products for self-assembly. For example, from a suitable chainsaw motor you can make a bicycle, moped, go-kart, scooter and a host of other means of transportation.

Homemade mopeds made from chainsaws will be useful for moving over rough terrain. They are also often used for driving in urban areas, where a lot of traffic accumulates. The small dimensions of mopeds give them the opportunity to easily overcome traffic jams and pass small obstacles.

For assembly you will need:

- engine from a gasoline tool. The speed of the moped depends on its power. When choosing a motor, you need to start from the fact that an internal combustion engine with a power of 2 liters. With. enough for driving at a speed of no more than 40 km/h;

- tank for refueling the moped. It is best to choose metal tanks or containers made of hard multilayer plastic;

- gas lever and standard bicycle cable - they are needed to adjust the throttle position;

- switch and wiring - required for installation and connection of the standard motor ignition system for a moped;

- parts for making the bracket, nuts and bolts - needed to install the motor on the support frame;

- belts, chains and pulleys - they will make it possible to connect the drive wheel of the moped to the engine from the chainsaw.

Assembling a moped from a chainsaw should be done in the following order:

- First of all, you should calculate the transmission of force from the engine to the wheel. To do this, you will need to determine the required gear ratio for the moped. If it is too small, the internal combustion engine will not be able to transfer its force to the moped wheel. In the case of an extremely high gear ratio, the engine will operate at very high speeds, and the moped will move too slowly. There is a certain example, based on which you can determine the optimal gear ratio. If the power of the motor used is 1.8 liters. s., and its maximum speed is 12500 rpm, then the optimal gear ratio for the moped will be 1:26;

- The simplest method is to transfer force from the standard pulley to the moped wheel - directly from the engine. You can also equip the rear wheel with a pulley or sprocket, which must be connected to the motor with a chain or belt;

- Next you will need to equip the bike with a clutch. The easiest way is to use a standard centrifugal clutch from a chainsaw. In some cases, chainsaw owners connect a standard moped clutch to a bicycle ratchet. After this, the mopeds accelerate and move by inertia, which makes it possible to save fuel and engine oil;

- The next step is to install the gasoline tank. To make the device safe, the tank will need to be placed on the bicycle frame, connecting the tank to the engine using a fuel hose;

- Then you will need to install the ignition. To do this, the standard wire of the unit must be stretched from the motor to the handle of the bicycle. The latter must be equipped with a switch that will make it possible to turn off the internal combustion engine of a homemade moped.

To be able to control the motor, a homemade moped can be equipped with a gas handle. A part from a mountain bike is suitable for this. You need to remove the lock from the handle - this will give it the opportunity to move smoothly in any direction. After this, the stock cable will need to be connected to the factory throttle valve.

How to install a chainsaw engine on a bicycle?

After assembling the frame and organizing the transmission of torque, the moped will need to be equipped with an engine. To install it, it is best to prepare a separate metal platform, which will be welded to the support frame above the rear wheel. You will need to drill several holes in the platform to mount the power unit. This will allow the operator to unscrew the screws and remove the internal combustion engine from the moped for further installation on the chainsaw.

After installing the power unit, it will need to be connected to the transmission elements of the generated torque. To do this, you will need to connect a metal throttle valve and a standard fully functional clutch for the manufactured moped to the lever of the built-in ignition system. In this case, the tension force of the cables used must be calculated so that when starting, the engine instantly turns on and begins to spin the drive wheel.

What does it take to make a moped from a chainsaw and a bike?

For the most part, converting a bicycle into a moped with your own hands by attaching a chainsaw motor to it does not require any special skills of a mechanic or engineer. If you are new to this business, then numerous drawings of a moped made from a chainsaw, as well as educational video reviews, will help you. Also, not every man has everything he needs in his garage to make a motorbike from a chainsaw with his own hands. Therefore, before assembly, it is recommended to study the list of necessary parts, fasteners and spare parts and buy the missing elements.

In specialty stores you can find entire kits that include a ready-to-install engine, fasteners and other parts that are necessary to transform a bicycle into a moped. This kit will greatly facilitate the process of assembling a motorcycle, since there is no need to select an engine, suitable power, fasteners, battery, transmission belt, cable, etc.

Speaking of tools, you will really need all the popular types of auto mechanic kit components: screwdrivers, pliers, wrenches, wire cutters, etc.

Assembly instructions and drawings of a homemade moped

Firstly, we will first look at the simplest and most affordable option for how to make a moped from a chainsaw from the photo above. When assembling, the question often arises of how to install a chainsaw motor on a bicycle.

It is important that it is securely attached and does not move while riding. For this type of homemade motorcycle, you need to secure the following parts with clamps in certain places:

- the battery is installed on the top tube;

- the chainsaw bicycle motor itself is mounted at the intersection of the lower front and seat tubes;

- fuel tank - near the engine.

The next step in the conversion is to create and install the pulleys on the bike. They are needed so that engine operation provokes rotation of the rear wheel. Typically, pulleys use external barrier wheels, which are about the size of CDs.

When selecting wheels, take into account the strength and reliability of both the material itself and the fasteners. To install the pulleys, the front wheel is attached to the motor shaft, and the second pulley is attached to the rear wheel hub.

Next you need to put the belt on the pulleys. Sometimes men use a chain instead of a belt. In this case, the pulleys are replaced with a chain, and the principle of its installation is no different.

All that's left to do is connect the engine. First, the motor is connected to the battery, and then the ignition is assembled. To do this, you need to install the brake lever on the steering wheel and connect it with a cable to the engine.

If we talk about a more complex option, then as a result you will get a homemade vehicle that is most similar to a real motorcycle. The main differences from the previous design are a more reliable and durable frame, wider wheels that can be removed from an old moped, the presence of shock absorption and the installation of an engine from a chainsaw.

The most convenient place for the engine will be a separate platform welded at the bottom of the frame. You can also place a fuel tank there. An exhaust pipe is also attached to the engine. As for the battery, owners of homemade mopeds recommend placing it closer to the steering wheel. The next step will also be the transmission and connecting the engine. You can watch all the nuances of how to properly make a motorcycle from a chainsaw with your own hands in the video.

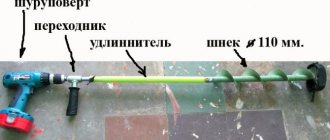

Motorized scooter made from a lawn mower

If you like to make something in the garage, or make a unique type of transport, this instruction is just for you. Here you will learn how you can equip your scooter with a gasoline engine. The author decided to use an unnecessary motor from a trimmer as a power unit. Similarly, you can install an engine from a chainsaw, lawn mower, and so on.

Materials and tools for homemade work: - an old scooter (can be made from scratch); — engine from a lawn mower; — bicycle wheels (will be used for spare parts); - bicycle chain; — metal pipes (found in an unnecessary chair); — cable for throttle control; — welding; - Bulgarian; - paint - wrenches, screwdrivers and more.

The process of making a gas scooter:

Step one. Freewheel device

A special feature of this homemade product is that the rear wheel is connected to the engine through a bicycle hub. This means that having gained a certain speed and releasing the gas, you can roll by inertia. But this is very convenient, because it allows you to significantly save fuel and also prevent engine overheating.

In other similar options, the torque is transmitted directly to the tire, which is not very professional.

As for installing the carriage, you will have to tinker. You may need to make some spacers, bushings, etc. to connect everything together.

Step two. Installing the sprocket on the engine

Petrol mowers come in different varieties; the author needed one that was equipped with a centrifugal clutch. Otherwise, if it is not there, it will be very difficult to use the scooter, because when you start the engine it will immediately drive away. And so the engine will idle without problems, and will only begin to move when the crankshaft speed increases.

From the scythe engine you need to cut off a piece of the shaft that goes to the knife, that is, the area behind the clutch. As a result, a shaft will remain, to which the sprocket is welded. The star needs to be well centered. Most likely, you will have to select or make a bushing.

Step three. Frame diagram

The author first made the frame wooden in order to decide on the creation of a metal one. The problem was that the new rear wheel mounts did not fit the old frame.

As a result, it was necessary to make a different rear fork. It must hold not only the wheel, but also the engine. A chair came to the rescue as materials, in other words, steel pipes are needed. Well, then the pipes are cut exactly according to the diagram and welded thoroughly. It is necessary to make a mount under the engine; for such purposes you will need a piece of strong steel plate. You need to cut a hole in the center for the clutch, and also drill four mounting holes for mounting the motor. Well, this sheet is welded to the rear fork.

Step four. Assembly

Now everything can be put together.

Step five. Painting

At this stage, the author paints the frame. If the original board has become bad or is not there at all, then it can be made from a sheet of plywood and then painted. The size is selected depending on your needs.

How to make a scooter from a chainsaw?

To independently manufacture a scooter based on a utility saw, the designer will need to prepare 3-mm steel plates, as well as metal pipes and corners. The engine of a gas powered tool must be fully operational and serviced. Assembly order:

- First you need to make a supporting frame. Profile pipes and a steel plate pre-treated against rust are well suited for its assembly. Scooter wheels from a pre-disassembled chainsaw can be taken from an old garden cart;

- To transmit the torque generated by the power unit, you will need a chain and a sprocket. To install the second part of the chain, you need to machine a small metal tensioner;

- The driver of the scooter will pour the fuel mixture into a remote tank, which must be installed a few centimeters above the engine;

- The homemade brake system will be of the disc type. To assemble it, parts from an old moped are suitable.

Making a go-kart from a chainsaw

To assemble a go-kart from a chainsaw, you will need to prepare a number of elements.

These include:

- 2 pairs of small rubberized wheels - can be taken from old baby strollers;

- steering unit - a bicycle design is suitable for assembly;

- frame – welded from metal directly during the manufacture of the karting;

- control and braking systems - mechanisms from a mountain bike are suitable.

Making a kart from a household chainsaw is inexpensive.

The assembly procedure for this vehicle is as follows:

- First of all, you need to weld a strong frame. It must be resistant to road irregularities and engine vibration. Pipes and metal corners are suitable for its manufacture. They should not be too heavy so as not to increase the weight of the machine;

- After this, you should assemble the suspension. It is best if the mechanism is of the torsion bar type - it performs well when driving on uneven roads;

- Then you will need to assemble the steering assembly. To do this, you need to take the handlebars from an unnecessary bicycle and secure it to the front of the frame;

- Next you need to install the steering mechanism and rods;

- After this, you should attach the wheels and install the brake mechanism. The kart will also need to be equipped with a handbrake, which will make it possible to quickly take sharp turns;

- At the end, all that remains is to install the driver's seat and secure the engine. Between the engine and the frame you will need to first lay a thick layer of rubber, which will dampen vibrations from the crankshaft of the internal combustion engine.

To ensure the transmission of torque from the motor to the drive wheels, it is best to use a belt or chain. To do this, pulleys or sprockets should be installed on the drive wheels. In order to reduce noise during operation, the card must be equipped with a muffler. To do this, you can take a ready-made standard muffler from a chainsaw, or weld a new element.

What details are needed?

In order to assemble the motorbike structure you will need the following materials:

- chainsaw motor

- bicycle wheels 2 pcs.

- tank, headlight, seat from a motorcycle or other suitable unit

- spray paint cans 4 pcs. and masking tape

- metal pipe 16-20 mm.

- cable

- chain

- cycling stars

- front and rear bicycle forks

- axis

- hose

- plastic bottle

- IV

- steering wheel

- throttle handle

It should be noted that on the modern market there are ready-made kits that include all the necessary parts for making homemade products. But the question here is price. If you want to save money and use unnecessary parts lying around in the barn, you will have to try on your own.

How to make a moped from a bicycle and a chainsaw?

To assemble homemade mopeds from a chainsaw, manufacturers will need:

- wheels, a fully assembled brake system, shock absorbers and an exhaust pipe - this must be removed from the old moped;

- a welded frame from an old, unused bicycle;

- drill, grinder, welding machine and other equipment.

The algorithm for further work on assembling the moped should be as follows:

- If the designer could not find a ready-made frame from an old bicycle, then you need to make it yourself. To do this, you need to weld metal pipes together to form a triangle. To the finished frame for the moped, you will need to additionally weld 2 more pipes, which will give the structure rigidity and stability. Next, you need to attach a soft seat and steering wheel to the frame;

- At the next stage, the designer must organize the transfer of the force created by the engine from the chainsaw to the moped’s organs of movement. To do this, you must first remove the front sprocket and pedals from the finished bicycle frame. After this, sprockets will need to be installed on the shaft of the engine used and the side of the rear wheel of the moped;

- Then the rear wheel must be installed on the support frame and the two sprockets connected using a chain.

To ensure stable transmission of continuous force from the motor to the installed drive wheel on a moped from a chainsaw, it is necessary to mount a gearbox pre-filled with new transmission oil.

Do-it-yourself ATV from a chainsaw - how to make it from improvised means?

The main advantage of a homemade ATV is the lightness and simplicity of the device. To assemble it, you do not need to buy expensive mechanisms, because it can be made from existing equipment.

The procedure for making an ATV from a chainsaw is as follows:

- First you need to assemble the support frame. To do this, the steel beams will need to be connected to each other using spot welding. After carefully checking the parts, they can be finally welded to each other;

- After this, you need to install the motor from the chainsaw in the designated place. It can be mounted in the front or rear of the ATV. The main thing is to securely fasten the motor to the platform;

- Next, you should install the transmission and drive mechanism on the rear wheels. The finished drive can be taken from an old motorcycle. The mechanisms used must be securely fastened to the frame to avoid play;

- Then you need to install the steering, which can be taken from an old motorcycle;

- At the end you will need to install a seat from a car and 4 wheels from a ZAZ-968 or Oka.

The homemade ATV will need to be tested. To do this, you first need to ride it over rough terrain with few obstacles. If the car works normally, then you can go on a trip on severe off-road conditions.

Chainsaw vehicles – what are the pros and cons?

When independently assembling 2- or 4-wheeled vehicles based on a household chainsaw, the manufacturer receives several quite important advantages:

- Manufacturing the unit makes it possible to save money. Of course, during assembly you will have to spend money on individual parts or entire working units. Nevertheless, these expenses are incomparable with the purchase of branded equipment;

- assembling vehicles with your own hands will allow you to obtain a reliable and fairly passable unit that does not require frequent special maintenance or complex repairs;

- When manufacturing vehicles, the designer can create any of the selected modifications: go-kart, ATV, moped or scooter from a chainsaw.

The only drawback is the need to have skills in operating an angle grinder, drill, welding machine and other types of garage equipment. Otherwise, you won’t be able to assemble a moped or other type of equipment.

What does it take to make a moped from a chainsaw and a bike?

For the most part, converting a bicycle into a moped with your own hands by attaching a chainsaw motor to it does not require any special skills of a mechanic or engineer. If you are new to this business, then numerous drawings of a moped made from a chainsaw, as well as educational video reviews, will help you. Also, not every man has everything he needs in his garage to make a motorbike from a chainsaw with his own hands. Therefore, before assembly, it is recommended to study the list of necessary parts, fasteners and spare parts and buy the missing elements.

Moped

In specialty stores you can find entire kits that include a ready-to-install engine, fasteners and other parts that are necessary to transform a bicycle into a moped. This kit will greatly facilitate the process of assembling a motorcycle, since there is no need to select an engine, suitable power, fasteners, battery, transmission belt, cable, etc.

Assembly instructions and drawings of a homemade moped

Firstly, we will first look at the simplest and most affordable option for how to make a moped from a chainsaw from the photo above. When assembling, the question often arises of how to install a chainsaw motor on a bicycle.

It is important that it is securely attached and does not move while riding. For this type of homemade motorcycle, you need to secure the following parts with clamps in certain places:

- the battery is installed on the top tube;

- the chainsaw bicycle motor itself is mounted at the intersection of the lower front and seat tubes;

- fuel tank - near the engine.

The next step in the conversion is to create and install the pulleys on the bike. They are needed so that engine operation provokes rotation of the rear wheel. Typically, pulleys use external barrier wheels, which are about the size of CDs.

DIY moped

When selecting wheels, take into account the strength and reliability of both the material itself and the fasteners. To install the pulleys, the front wheel is attached to the motor shaft, and the second pulley is attached to the rear wheel hub.

Next you need to put the belt on the pulleys. Sometimes men use a chain instead of a belt. In this case, the pulleys are replaced with a chain, and the principle of its installation is no different.

If we talk about a more complex option, then as a result you will get a homemade vehicle that is most similar to a real motorcycle. The main differences from the previous design are a more reliable and durable frame, wider wheels that can be removed from an old moped, the presence of shock absorption and the installation of an engine from a chainsaw.

The most convenient place for the engine will be a separate platform welded at the bottom of the frame. You can also place a fuel tank there. An exhaust pipe is also attached to the engine. As for the battery, owners of homemade mopeds recommend placing it closer to the steering wheel. The next step will also be the transmission and connecting the engine. You can watch all the nuances of how to properly make a motorcycle from a chainsaw with your own hands in the video.

Which saw is suitable to use?

The most optimal gasoline saws for remodeling are “Druzhba”, “Ural”, “Shtil” and similar models with a large power reserve

It is this parameter that you should pay attention to when converting a bicycle into a moped. Some German chainsaws with high power lend themselves very well to conversion

The device should be selected with a power of at least 2 hp. and engine volume no more than 50 cm3. Bicycle motors from such units are the most durable.

In order to make a motorbike, it is not necessary to have a special technical education, but it is desirable to understand diagrams and drawings, as well as have skills in repairing garden equipment. Skills in working with a welding machine will not be superfluous.

Motorcycle made from chainsaws

This Dolmette chainsaw bike was built a while ago, but I've never seen any build information. What a wonderful design!

The combined power of 24 engines from DOLMAR chainsaws is transmitted to a five-speed Harley Davidson transmission using a set of twelve timing belts. For use in the Dolmette, the motors were tuned and tuned to provide 5.2 kW (7.1 metric hp) power at 10,000 rpm. The maximum torque is 5.5 newtons per meter at 7,750 rpm. When all 24 engines are put together, the result is a 24-cylinder unit with a total displacement of 1.9 liters, a power output of 125 kW (170 metric hp) and a torque at the centrifugal clutches of 130 newton per meter. The twelve motors are mounted in two rows of six on each side of the drive belt housing. Each motor is held in place by threaded rods, which are typically used to secure the bar to the power head of the chainsaw. The individual motors are held together in sets of three via double-sided drive belts, creating eight modules. The individual motors are not rigidly connected - instead they transmit torque through a centrifugal clutch, which is a standard part of every chainsaw.

Scooter

For improvement, a scooter that has inflatable wheels and a hand brake is better suited. The first allows it to move over uneven surfaces, the second provides high braking ability.

Perform work in the following sequence:

- The chain and bar are removed from the chainsaw.

- Unscrew the centrifugal clutch from the crankshaft.

- Bicycle sprockets are attached to the output shaft of the engine and the axle of the rear wheel of the scooter.

- Place the motor at the back of the scooter platform. They are connected to each other with bolts. Both sprockets must be in the same plane.

- Put a bicycle chain on the sprockets, adjust it, removing excess links.

- Attach the accelerator to one of the handles of the scooter. Connect it to wires that turn the motor on/off. Instead of an accelerator, you can install a small pedal.

How to make a scooter that runs on gasoline

Using a regular old scooter and a chainsaw engine, you can build your own gasoline-powered vehicle.

What you will need:

- Chainsaw engine (in a metal or plastic case)

- Chain

- Various bolts, nuts and washers

- Manual accelerator from a mountain bike

- Switch

- Electric drill

- Chain link removal tool (to ensure good bike chain tension)

- Optional: welding equipment

- Make sure you have a handbrake!

1. Find a scooter with a hand brake and inflatable wheels. Scooters with hand brakes have better stopping power. Inflatable wheels allow the vehicle to better overcome uneven terrain. You can also assemble the scooter frame (welding will be required).

2. Prepare the chainsaw engine by removing the bar and chain. Leave the remaining parts untouched. Keeping the motor in the housing will make it easier to attach to the scooter platform.

3. Unscrew the centrifugal clutch from the crankshaft. The power from the motor will be transmitted through sprockets and a bicycle chain. The obvious problem is the fact that you will not be able to stop the running engine with the scooter stationary, and you will also have to lift the rear wheel off the ground to start it. You can also keep the clutch and use a chain that fits the sprocket on the clutch flange. If your chainsaw has a two-stroke engine (you will have to add oil to gasoline), then keep the centrifugal clutch. Rolling down a slope without a clutch will eventually cause the engine to burn out, as the engine will be forced to run without the lubrication of the mixture of gasoline and oil.

4. Bolt the remaining sprockets to the rear axle of the scooter. This may be easier said than done - choose your scooter carefully, understanding that you may need to modify the rear wheel mount and also install sprockets on it.

5. Place the motor on the back of the scooter platform to make sure the stars are in line.

6. Drill holes in the platform and motor housing of the chainsaw so that they can be bolted together. Note that the body is usually made of plastic, so you will need to be extremely careful about where you are going to attach the bolts and the size of washers you use (to prevent them from going through the plastic)

7. Pull the bicycle chain onto the sprockets. Remove the required number of links to keep the chain tight.

8. Attach the hand accelerator to one of the handles.

9. Connect the electric hand accelerator to the on and off wires on the motor from the chainsaw. This allows the scooter operator to control the power supplied to the motor.

The motor provides enough torque to the gears. If the gear slips and does not turn with the axle, the gear may need to be welded. This will provide maximum power and ensure that the transmission will not spin again.

If problems arise when installing a manual accelerator, a small pedal can be used as an option.

You can protect yourself from injury by adding chain guards, open sprocket guards, and protective covering to prevent hands, clothing, and other objects from getting caught in the drive mechanism. Be careful when using the scooter. It is capable of accelerating to high speeds, which can be dangerous. Try to drive only on relatively smooth roads. Potholes can lead to unpleasant consequences.

Chainsaw moped

At first glance, a moped and a saw are absolutely incompatible things that cannot interact in any way. But this is wrong, and numerous craftsmen have proven that making a moped from a chainsaw is quite possible. But there is little to be done; this unit also drives and transports its owner. The speed, of course, is not very fast, but it’s still better than walking. You can use a bicycle as the basis for the design or do everything completely yourself. The bike motor amazes with its endurance, but this is what everyone expects from time-tested saws.

The older generation is familiar with self-propelled structures in the form of a bicycle with a motor. It is difficult to classify this equipment as mopeds, but they no longer fall into the category of bicycles. A kind of “middle link”. A significant advantage of such a unit is low fuel consumption and the ability to drive without a license. You can’t ride it on public roads, but you can drive along rural streets and alleys.

The frame has undergone changes, which have been extended to accommodate bicycle or other wheels, depending on what is available. A fuel tank is also attached, a motorcycle seat is installed, and a headlight is attached for driving in the evening. A water system has been developed to cool the bicycle motor. This was done to prevent the engine from overheating quickly and losing power.

Assembly principle

The first thing that attention is paid to is the design of the frame, which is made of pipe and on which the power unit will subsequently be placed. Then the tank, headlight and wheels are installed

If you are using old parts, you must first clean them of rust. This is especially true for seams. After the initial stage is completed, the frame is covered with several layers of paint. Be sure to dry each layer thoroughly to avoid corrosion. As a recommendation, it is best to use spray paint to avoid smudges. You can paint not only the frame, but also the wheels, after sealing the rims with masking tape.

Moped from chainsaw Druzhba-4

After all the parts are dry, you can begin installing the chainsaw engine. Make sure that the motor is well installed and secured. Without a cooling system, such a bicycle motor will overheat after 30 minutes of operation, so it is advisable to make a water cooling system. The homemade device looks like this. 2 flexible tubes are connected to the plastic bottle. One is attached in the upper part for air intake, the other in the lower part and through it, using a drip system, water flows to the engine cylinder head. The result is simple homemade drip irrigation and effective cooling.

As an additional comfort for the driver, you can install fenders, since clods of dirt and water can get on the engine. The resulting unit is capable of speeds of up to 60 km/h.

Below is an approximate drawing that can be used to convert a bicycle into a moped.

This is interesting: Characteristics of the TOP 2 popular models of Motor Sich 270 and 475 chainsaws

Assembly principle

The first thing that attention is paid to is the design of the frame, which is made of pipe and on which the power unit will subsequently be placed. Then the tank, headlight and wheels are installed

If you are using old parts, you must first clean them of rust. This is especially true for seams. After the initial stage is completed, the frame is covered with several layers of paint. Be sure to dry each layer thoroughly to avoid corrosion. As a recommendation, it is best to use spray paint to avoid smudges. You can paint not only the frame, but also the wheels, after sealing the rims with masking tape.

After all the parts are dry, you can begin installing the chainsaw engine. Make sure that the motor is well installed and secured. Without a cooling system, such a bicycle motor will overheat after 30 minutes of operation, so it is advisable to make a water cooling system. The homemade device looks like this. 2 flexible tubes are connected to the plastic bottle. One is attached in the upper part for air intake, the other in the lower part and through it, using a drip system, water flows to the engine cylinder head. The result is simple homemade drip irrigation and effective cooling.

As an additional comfort for the driver, you can install fenders, since clods of dirt and water can get on the engine. The resulting unit is capable of speeds of up to 60 km/h.

Below is an approximate drawing that can be used to convert a bicycle into a moped.

Assembly principle

The first thing that attention is paid to is the design of the frame, which is made of pipe and on which the power unit will subsequently be placed. Then the tank, headlight and wheels are installed

If you are using old parts, you must first clean them of rust. This is especially true for seams. After the initial stage is completed, the frame is covered with several layers of paint. Be sure to dry each layer thoroughly to avoid corrosion. As a recommendation, it is best to use spray paint to avoid smudges. You can paint not only the frame, but also the wheels, after sealing the rims with masking tape.

After all the parts are dry, you can begin installing the chainsaw engine. Make sure that the motor is well installed and secured. Without a cooling system, such a bicycle motor will overheat after 30 minutes of operation, so it is advisable to make a water cooling system. The homemade device looks like this. 2 flexible tubes are connected to the plastic bottle. One is attached in the upper part for air intake, the other in the lower part and through it, using a drip system, water flows to the engine cylinder head. The result is simple homemade drip irrigation and effective cooling.

As an additional comfort for the driver, you can install fenders, since clods of dirt and water can get on the engine. The resulting unit is capable of speeds of up to 60 km/h.

Below is an approximate drawing that can be used to convert a bicycle into a moped.

Car

You can make different types of cars from chainsaws. One of them is a kart buggy, which is distinguished by the presence of a suspension in its design. It makes driving the car more comfortable off-road.

The process of creating such a homemade machine is complex. This is especially true for the frame, which is welded from metal or profile pipes according to pre-drawn drawings. Then they are engaged in the manufacture of suspension and steering parts.

Buggy manufacturing operations include:

- suspension assembly;

- installation of the steering wheel, rods and launcher;

- wheel fastening;

- brake placement;

- installation of the driver's seat;

- mounting on the engine frame.

You can transfer rotation from the motor to the wheels using a chain or belt. In the first option, sprockets are installed, in the second - pulleys. To reduce noise, the engine is equipped with a muffler.

Motorized winch made from a chainsaw

Many owners living in the private sector have an old chainsaw in stock, usually a “Druzhba” or “Ural”. However, they sometimes use a saw when preparing firewood. Folk experts found another use for it, coming up with the idea of making it into a motorized winch with a set of rope-traction tools. From now on, it has become easier to plow the ground for planting vegetables, hill up, dig, and plow the land.

The traction device with a saw weighs approximately 40 kilograms, so it will be quite easy to master the new tool on the site. The implements used in processing are equipped with wheels, and therefore the device can be rolled across a field or piece of land with ease and ease.

The plow is able to stay in the furrow on its own, without requiring the use of physical force by the plowman. So, thanks to the tool, the plowed strip has a depth of 20 centimeters.

Pay attention to the manual: how to sharpen a chainsaw chain correctly.

When planting potatoes in ridges at the end of plowing, the plow is replaced by a hiller, equipped with the same wheel drive. Thus, the motorized winch can cut even ridges. As soon as the time for hilling comes, the winch will quickly float across the site, leaving behind only loosened rows.

As soon as the opportunity arises to dig up potatoes, we enrich the device with a redeemer, attach it to a winch, and then work through each row of land.

You can also use a chainsaw to make a sawing tool like a huge grinder. It is worth noting that the idea of creating such a tool is quite popular.

Bulgarian

A portable power station from a chainsaw engine is quite possible when you have the time and desire.

Power station

A rubber boat can easily be equipped with a motor if you have an unnecessary chainsaw. This will be a real joy for a true fisherman.

As you might guess, adapting an old chainsaw for other purposes is quite possible. The main thing is ingenuity and desire.

Do-it-yourself motor scooter from a chainsaw

An equally famous homemade product that the domestic “Kulibins” learned to make. To recreate it we will need:

- a scooter designed to support the weight of the person who will operate it. It is desirable that it initially have a manual braking system. The pneumatic wheelbase of the scooter must be durable;

- a chainsaw from which the engine is removed - medium and high-power models are suitable.

The process of assembling a scooter looks simplified compared to previous homemade products:

- First, remove the motor base and secure it to the back of the scooter frame. Make sure that the motor and wheel sprockets match;

- we attach a manual accelerator with ignition of the chain saw - this way the operator can control the moving process;

- If necessary, the scooter is equipped with a brake pedal, but in most cases, the lever for manual control of the scooter is enough for its full operation.

- testing a scooter made from a chainsaw - if it is working properly, the new motorized device is ready and can be used.

Motor scooter made from a chainsaw - assembly procedure

A scooter is another means of transportation that you can make from a chainsaw with your own hands. It is distinguished by its modest dimensions and light weight, but can only be used for driving on a flat road.

The scooter is assembled in the following order:

- First you need to make a frame. To do this, you need to take profile pipes, paint them, and connect them together using solid welding;

- The front and rear wheels should be attached to the frame. They can be taken from an old baby stroller;

- Next, you need to secure the engine from the chainsaw to the rear of the support frame. The torque from the motor to the rear drive wheel will be transmitted by the gearbox, which will need to be turned in the opposite direction;

- A chainsaw scooter must be equipped with an ignition system. A high-voltage coil from any VAZ model, as well as an uninterruptible power supply battery, are suitable for this;

- Then you need to install a sprocket and chain, which can be taken from an old bicycle;

- Next you need to install the fuel tank. It can be attached to the frame and connected to the engine using a fuel hose.

The finished scooter from a chainsaw can be equipped with disc brakes. The battery will make it possible to install a headlight and a sound signal on the homemade product.

What engines are suitable for assembly?

To answer this question, you need to select in advance the type of equipment that the manufacturer wants to assemble.

There may be several options:

- scooter is a small-sized homemade product. The heaviest part is the niche for the user’s feet. The remaining elements can be made of light steel or aluminum. Power units with a capacity of about 3 - 4.5 liters are best suited for assembling a scooter based on a chainsaw. With.;

- Karting is a small device designed for high-speed movement on a flat asphalt or concrete surface. The estimated engine power for assembling a go-kart should be approximately 4 - 5 hp. With.;

- A moped is a medium-sized vehicle based on a strong, stable frame. For the manufacture of a moped, motors from chainsaws with a power of 5 - 6 liters are suitable. With.;

- An ATV is a relatively large vehicle that is assembled from fairly strong and heavy parts. To assemble an ATV, a chainsaw with a rated power of at least 6 liters is suitable. With.

Regardless of the equipment that the manufacturer wants to obtain, the homemade engine must be in fully working order. It is best to clean or completely replace all filters in its design in advance, as well as make carburetor and ignition adjustments.

How to install a chainsaw engine on a bicycle?

At the final stage, the chainsaw moped will need to be equipped with a motor. To do this, you need to make room in the rear of the frame, immediately behind the driver's seat. To make engine installation faster, you will need to remove the bike fender.

Most often, this scheme is used: first, the prepared drive shaft is installed, after which a tire is used instead of the driven shaft. This drive is distinguished by its efficiency and simplicity. To make it you do not need to use a large number of elements. When moving a homemade moped, the friction shaft used will transmit force from the motor. To prevent losses in internal combustion engine power, the diameter of the standard shaft must be at least 2.5 cm.

To mount the motor behind the seat, you will need to weld a metal stand. The engine itself should be located as low as possible so that the moped is more stable when moving. You can securely secure the engine to the stand using any available method - welding, clamps or bolts.

Useful tips

For proper assembly of a moped with your own hands, reliable service, for remodeling and designing other equipment, listen to the advice:

- Before assembling the motorbike, make sure that the main part - the bicycle - is in optimal technical condition. Modernization will increase the load on all its parts.

- Check the condition of the gasoline tank carefully. Fuel should not spill out, as this may cause a fire.

- In addition to engine power, don't forget about volume and weight. The volume should not exceed 50 cm³, weight - no more than 6 kg.

- When installing the belt, make sure that the part is held firmly on the wheels, otherwise the accuracy of the impulse transmission from the motor to the wheel will decrease.

- Using a chainsaw motor, you can independently design other equipment: a go-kart or a tricycle. You will have to make an effort: weld a strong metal frame, prepare a working gearbox.

- With a strong frame, gearbox, driver's seat, wheels with a diameter of at least 35 cm and a saw engine, try to construct an ATV.

Don't throw away spare parts from old equipment. You can breathe a second life into them and create a convenient means of transportation.

How to make a scooter from a chainsaw and an angle grinder gearbox

In this review, the author shows how to make a scooter from a chainsaw engine and an angle grinder gearbox. It will also be necessary to prepare profile pipes and spare parts from the old bicycle.

First of all, the master cuts the profile pipes to size. You will need 2 long pieces and four short ones.

It is necessary to weld the base of the scooter from pieces of profile pipe. To do this, the author connects two long sections using short ones welded perpendicularly.

Then you will need to weld a frame with a fork from an old bicycle to the base. We clean the welds using a grinder and a flap wheel.

Helicopter

This type of homemade product is considered complex and therefore has not been implemented to date. She is in the dreams of enthusiasts, in invented stories. One of them claims that back in the USSR, a prisoner who understood mechanics made a helicopter with a chainsaw engine and was able to escape from the colony.

Making a homemade helicopter requires, unlike a snowmobile, outboard motor, bicycle, grinder and even a snow blower, more complex engineering calculations. They also show that one, even powerful, engine is not capable of lifting such an aircraft into the air. At least 4 motors are required, moreover, forced and working in concert at the highest possible speed. But it is difficult to implement this with chainsaw engines in practice.

Compressor

The craft consists of using an air blower from some device and using a chainsaw motor as its drive. If it is from an air conditioner, then you can make a device for quickly inflating the wheels of a car.

The procedure for making a compressor from a chainsaw:

- Make a mounting plate from sheet metal. On one side, 2 holes are drilled through which it is attached to the chainsaw instead of a tire. On the other hand, a compressor is placed.

- A coupling and pulley are installed on the supercharger drive shaft.

- Place the second pulley on the output shaft of the saw motor.

- A belt is placed on the pulleys to transmit rotation.

- The inlet pipe of the supercharger is equipped with an automobile oil filter with oil residues. Air through it is sucked in with oil particles, which reduces overheating of the compressor during operation.

To start the device, turn on the chainsaw motor. When it picks up speed, the coupling is activated and the supercharger starts working. A hose is connected to its outlet pipe, through which the car’s wheels are inflated.