What can be made from a chainsaw Such popular tools as an electric drill and an angle grinder (grinder) have long passed into the category of “folk”. Not only because they are present in almost every workshop, but also because of their versatility - the scope of their application is truly impressive.

But there is another tool that can adequately compete with a drill and grinder - a chainsaw. Do you think you can only use it to cut firewood? But no!

Today, various DIY chainsaw crafts made by yourself are in widespread demand. The unit itself acts as a universal autonomous drive, and it can be used in various fields.

To make homemade chainsaws for the country house and garage, together with the tool, all kinds of homemade attachments, adapters and other devices are additionally used that allow you to fully realize the functionality of the gasoline drive.

Various homemade devices and mechanisms with a chainsaw engine can also be used in the field, which makes them especially attractive, especially for summer residents, fishermen and lovers of “wild” nature.

On our website you will find only the most useful and interesting homemade chainsaws that are easy to make yourself. True, in some situations you will additionally need the ability to work with welding, as well as access to a lathe.

Generator

A chainsaw with a 2-stroke engine with a power of 2-3 liters is suitable for production. With. Electric motors from old washing machines are often used as electric generators. The combination of these devices makes it possible to obtain an output voltage of 220 V. The power of such a gas generator is sufficient for lighting, powering electrical appliances and tools, and household appliances.

Order of operations:

- A bracket is made and the electric motor is attached to it. Install the resulting structure on the outer end of the chainsaw bar. At the same time they provide:

- perpendicularity of the electric motor axis to the plane of the tire;

- the location of the pulleys of both devices in the same plane.

- The output shafts of the engines are equipped with pulleys of suitable diameter.

- Put a belt drive on the pulleys.

- A device is made to regulate the speed of a chainsaw motor. A bolt is used, which is attached to the handle of the latter using a clamp. Tightening it leads to an increase in the number of revolutions, unscrewing it leads to a decrease.

- The external starting winding of the electric motor is supplied with 2 capacitors, which are designed for a voltage of 400-450 V and have a total capacity of 10 μF. Their connection is parallel.

rework principle

The basis of almost any homemade product is a chainsaw, using it as a universal drive that can be used for a huge number of different devices.

The area of their use is very wide: cutting stone and metal, pumping water, cleaning drilling, snow wells and holes, driving, moving various objects, swimming and even flying. Potential chainsaws realize their capabilities using a variety of attachments and accessories. The basis of any modification is the principle of a simple engine power take-off: the device necessary for the master is connected to the output shaft. The presence of a powerful motor, compact dimensions and relatively light weight of this tool, autonomy and the ability to work in extreme conditions make its capabilities truly limitless.

Of no small importance is the practical coupling design of the clutch, which protects the components and saws of the system from breakdowns and overload. A tool made from chainsaws is distinguished by its tightness, so it can be used in almost any position

to the table of contents?

Winch

The mechanism is designed for horizontal movement or lifting loads to a height. Does not depend on the availability of electricity, can be used outdoors, on hiking trips.

In order for it to have sufficient traction, you will need a Druzhba, Ural or other brand of chainsaw.

A prerequisite for this is that the engine power of a do-it-yourself chainsaw winch should not be less than 2.5 kW.

An important element of the device is the drum - it can be made independently or used from a hand winch. In addition, you will need:

- gearbox to reduce the speed of the chain saw;

- metal pipes or rolled profiles, levers, cam clamps, clamps.

The procedure for making a winch:

- A rigid frame is made from pipes. Welding is used.

- Attach the chainsaw motor to it. The gearbox is connected to it with clamps, and the drum is connected to the output shaft of the latter.

- Install a lever equipped with cam clamps connected to the drum shaft. This control element allows you to control the work process: when you move the lever in one direction, the drum rotates, and in the other, it stops.

- An anchor is made with which the winch will be secured in the soil or cling to any stationary object. Use pointed corners that are welded or hinged to the frame.

- A cable is wound onto a drum, the free end of which is equipped with a hook. It is used to capture and attach to a load that needs to be moved.

Transport

Based on a chainsaw engine, you can make many homemade vehicles. It is important to remember that transport is a means of increased danger and the author and owner of the homemade product bears full responsibility for its safety.

Snowmobile

Structurally, a snowmobile is one of the most complex homemade products. The following components will need to be made:

- Support frame.

- Frame.

- Caterpillar.

- Front ski.

- Steering wheel with controls - gas and clutch handles.

- Suspension.

- Transmission.

The supporting frame is welded from a square steel profile 20*20 or 20*30, it is necessary to provide a swing arm for the shock-absorbing rear suspension and install a motorcycle-type steering fork for the front. There are options with two skis - here the design of the front suspension will be more complicated - the steering wheel will not turn the axis of the ski, but pull the levers to control the steering linkage. This option is more difficult to manufacture, but guarantees better controllability and stability. For a snowmobile, a centrifugal clutch with a V-belt and chain is suitable. To increase the traction force, a gear is installed on the working shaft of the caterpillar, which is larger in diameter than the drive gear on the chainsaw shaft. For the caterpillar, you can take ready-made drawings from a light snowmobile with an engine of the same power as a chainsaw.

In order for a homemade product to confidently carry one or two people, the engine power must be at least five horsepower.

Snowmobile

A snowmobile is much simpler in design than a snowmobile; according to the principle of its operation, it resembles a small propeller-driven airplane moving on the ground. The load capacity, maneuverability and stability will be noticeably lower than that of a snowmobile with equal engine power. The advantage will be simplicity of design, greater reliability and greater speed in open spaces. The pusher type screw is installed in the protective casing of their mesh behind the driver's back and pushes the device forward. The device is controlled by turning the ski, the gas lever and the snow brake.

Homemade snowmobiles

In order to properly accelerate a homemade snowmobile or drive not only on the smooth ice of a frozen river, but through fields and small snowdrifts, you will need a chainsaw engine with a power of at least 10 horsepower.

Moped

A homemade summer vehicle with a chainsaw engine is unlikely to compete with industrial designs. Home craftsmen often assemble it as a test of their strength or as a training session before more serious designs. In addition to the chainsaw, you will need an old bicycle, or at least the main components from it, including bearings. Craftsmen weld the frame themselves from pipes or square profiles. It looks scary, but it is reliable. The drive is carried out to the rear axle by a bicycle chain.

The most advanced home craftsmen use a mountain bike with high-quality brakes and shock-absorbed suspension as a basis. A gearbox with a gear ratio of 1:15-1:20 and a variator are added to the chainsaw. With such a homemade product you can already travel quite comfortably at speeds of up to 30 km/h.

Homemade kart based on a chainsaw

What else can be made from a Ural or Druzhba saw? For example, a go-kart is a maximally simplified car model designed specifically for circuit racing. It is devoid of a body, shock absorbers, and sometimes even brakes - everything is done to make the design as light as possible to increase speed. The homemade kart frame is made from profiles or steel pipes. DIY wheels are often taken from industrial carts for transporting small loads. The drive is carried out to the rear axle by a bicycle chain, the steering linkage is taken from a minicar. To assemble the card you will need intermediate level metalworking and welding skills. It is better to take ready-made drawings as a basis and adhere to their basic parameters - although karting is considered a “children’s” sport, the speeds developed are quite adult, and you can seriously injure yourself.

Using a similar scheme, based on a chainsaw motor, craftsmen assemble the kart’s older brother, the buggy. This carriage has a reinforced suspension with large strokes and is designed for racing over rough terrain. The homemade center of gravity is located low to improve stability; the driver and passenger seats on top are protected by a powerful roll bar. The process of making a children's ATV will also be very similar.

Homemade scooter with a chainsaw motor

Despite the fact that this device looks like a children's toy, it can be a serious help to a postman or courier. Even though the scooter's maximum speed is low, 10-15 km/h, it has excellent maneuverability and incomparable efficiency. If the working day consists of many short trips from point to point, you couldn’t ask for a better option.

DIY scooter

Almost the entire structure of the chainsaw is preserved; you only need to remove the bar and the saw chain, replacing it with a bicycle chain that transmits torque to the rear wheel of the homemade scooter.

boat motor

Homemade boat motors first appeared in Southeast Asia after the Second World War. Poor fishermen and peasants built their own wooden boats, but they could not afford to buy a factory-made boat motor. Chainsaws were quite affordable. Without further ado, they put a bamboo stick on the saw shaft, secured it with a wooden cotter pin and, leaning it on a sawhorse with two oarlock pins, lowered it into the water from the stern at a slight angle. A screw cut out of wood was attached to the lower end of the pipe so that it was under water. The entire structure required only bamboo trunks and ropes, and it was assembled in a couple of hours. As the bamboo shaft and crossbar of the trestle wore out, they were replaced with new ones. Such a boat was steered by simply turning the pole behind the engine in the desired direction. The simplest version of a homemade boat motor will repeat the Indo-Chinese design, with the difference that instead of a pole, a steel pipe is taken, a screw from an old boat motor, and the goats are welded from a corner and equipped with a thrust bearing on a rotary support.

Boat motor made from a chainsaw

A more advanced version uses a vertical propeller shaft and a sealed gearbox that changes the direction of rotation by 90 ⁰. A bearing with a device for lifting the propeller shaft and a control handle, to which the gas regulator is connected, are placed under the engine. The propeller is also selected from a boat motor. This option repeats the kinematic diagram of a factory-made outboard motor. It is capable of ensuring that a small boat travels at a modest speed over a considerable distance with enviable efficiency. It is important, however, to remember that not all saws are designed for long-term continuous operation, so you need to monitor the thermal conditions of the motor and periodically let it cool down.

Boer

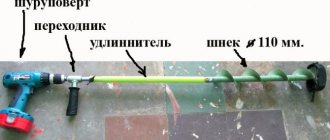

The device exists in 2 versions. Do-it-yourself chainsaw drills are made for the ground or for drilling ice. In the first case, the device facilitates the construction of deep holes for poles, fence supports, and other structures. In the second, he helps fishermen drill holes in winter. They differ in the drill used.

The design of a gas drill involves combining a finished drill and a chainsaw engine into one unit. To make a motor drill from a chainsaw, the latter must have a high-power motor - at least 2 liters. With. In addition, you will need:

- Gearbox. This is an important element of the device. It is necessary to reduce the speed of the saw motor, because when the drill rotates quickly, the engine power may not be enough, and it is difficult to work under such conditions.

- Bulgarian.

- Metal pipe.

- Drill.

- Welding machine.

Drill assembly sequence:

- Two rectangular frames are made from a metal pipe. The size of one is 45x35 cm, the second is 10x10 cm.

- The frames are connected to each other, placed parallel to one another at a distance of 30 cm. This is done with identical pieces of metal pipe, welding adjacent corners of the frames with them.

- Inside the resulting truncated pyramid, a gearbox is attached to the smaller frame.

- According to the drill assembly diagram, a motor is installed on top, connecting it to the gearbox with a short shaft (pre-made). The handle that regulates the fuel supply is placed on the upper large frame. It also houses an emergency engine shutdown system.

- Connect a drill using a piece of pipe to the output shaft of the gearbox. The parts are connected with dowels or studs.

Pros and cons of the solution

Various types of hand-held electric and gasoline tools are suitable for making grinders. The simplest and most convenient option is a device assembled on the basis of a saw with a chain. Advantages of homemade devices:

- Great power. If we compare a homemade nozzle with factory models, then its power is 2 times greater.

- Independence. The tool does not require electricity, so it can be used anywhere.

- Easy assembly. All the necessary tools and materials can be purchased at the store or searched on your farm.

- Affordable price. If you compare it with a ready-made tool, then you will need 2 times less money to assemble an angle grinder.

Despite all its advantages, the tool has a number of disadvantages. The air filters of the grinder become clogged with metal dust. Because of this, the engine gradually stalls and fails. A person can also get injured from using an angle grinder. Sometimes during operation the disks cannot withstand the load and burst. Under the influence of traction they fly apart. To protect yourself from injury, you need to choose discs up to 115 mm in diameter and use a protective cover.

Cultivator

The device simplifies the processing of vegetable gardens and beds. If they are of a small area, a DIY chainsaw cultivator has an advantage over branded products - it will save money on the purchase.

Making a homemade cultivator from a chainsaw starts with a frame. It is made in the form of a cube using 32x32 corners. An engine is attached to the transverse upper corners, which must have a power of at least 4 liters. With. Below it, a fuel tank is installed on brackets. The front vertical struts are equipped with supports for the intermediate shaft, which are attached to the longitudinal corners.

This placement of components and elements allows you to obtain the center of gravity of the walk-behind tractor above the supporting surface of the wheel. If it is necessary to adjust it, use a metal weight, which is placed in the front part of the frame.

For manual control, crossbars are installed using pipes with a diameter of 30 mm. Rubber-coated rollers are used for the wheels of a chainsaw motor cultivator, and a chain drive is used to rotate the intermediate shaft. To do this, sprockets are installed on it and the engine output shaft. Their size is selected according to the required gear ratio.

snow blower

If in the previous design you replace the shaft with plowshares or harrow spokes with an auger mechanism, add a casing, an intake device and a pipe for throwing out snow, the cultivator will turn out to be quite a decent snow blower. Many home craftsmen design their homemade products with replaceable attachments for different seasons. Motor from a Shtil saw with a power of 3-5 hp. It will cope quite well with cultivating the garden in spring and autumn, and with removing loose snow from a summer cottage in winter. The most important unit is the screw mechanism.

Homemade snow blower

If you are not a professional designer, then it is better to download ready-made drawings from the Internet. The auger blades are made of thick rubber, for example, from a conveyor belt. The intake device is made of galvanized steel. A plastic sewer pipe is suitable for the snow disposal pipe.

Compressor

The craft consists of using an air blower from some device and using a chainsaw motor as its drive. If it is from an air conditioner, then you can make a device for quickly inflating the wheels of a car.

The procedure for making a compressor from a chainsaw:

- Make a mounting plate from sheet metal. On one side, 2 holes are drilled through which it is attached to the chainsaw instead of a tire. On the other hand, a compressor is placed.

- A coupling and pulley are installed on the supercharger drive shaft.

- Place the second pulley on the output shaft of the saw motor.

- A belt is placed on the pulleys to transmit rotation.

- The inlet pipe of the supercharger is equipped with an automobile oil filter with oil residues. Air through it is sucked in with oil particles, which reduces overheating of the compressor during operation.

To start the device, turn on the chainsaw motor. When it picks up speed, the coupling is activated and the supercharger starts working. A hose is connected to its outlet pipe, through which the car’s wheels are inflated.

Power station

For a mobile power plant with a power of up to 5 kW, there is a time-tested solution: a homemade generator based on a motor from a Druzhba or Ural saw. They are actively used on expeditions and in remote logging operations. The device includes a steel frame welded from a corner, on which an engine, a generator and a waterproof electrical distribution box with sockets for connecting electrical equipment or an extension cord are mounted. Through the gearbox, torque is transmitted to the generator shaft.

For low-speed generators, there is an option for a homemade power station with a belt drive. This design is smaller in size.

Mower

Most often, a do-it-yourself lawn mower from a chainsaw is a rotary type. It looks like a small cart on which all the units and parts are mounted. It is made welded using metal pipes or strips. Wheels are installed below, the size of which should allow the device to move without difficulty on any surface.

There are options for DIY chainsaw mowers, equipped with 2, 3 or 4 wheels. The 2-wheeled chainsaw lawn mower has better maneuverability, which is why it has become more widespread. It contains a special casing that prevents the operating unit from coming into contact with the ground.

To make a lawn mower, first remove the steering wheel and tire from the chainsaw. The motor is positioned on the frame so that the shaft is at the bottom. The cart is equipped with handles made from pipes. The chainsaw wheel is attached to them, and the cable that controls the carburetor throttle is extended.

Next, a unit is made from a chainsaw for the mower, with which the grass is cut:

- First, a piece of pipe 80 cm long and 50 mm in diameter is welded to the motor sprocket.

- Inside it there is another pipe, which is 8 mm smaller in diameter than the first.

- The pipes are connected to each other with M6 bolts. The tubular design allows you to adjust the cutting height of the grass.

- A metal disk 4 mm thick and 18 cm in diameter is welded at the end of a wide pipe.

- Knives-blades made from an old hacksaw are attached to the disk. Their width is 3 cm, length - 12. The connection is made loosely with M6 bolts, which helps protect the blades from breaking when encountering stones.

Types of sawmills

The most widespread today are the following three types of devices for sawing logs with a chainsaw with your own hands, which differ in their design:

- Tire.

- Tape.

- Disc sawmill.

https://youtube.com/watch?v=XR_TrDiAqQU

Disk installations

The relatively simple design of disc installations makes them easy for most homeowners. Due to their ease of assembly and versatility, these types of woodworking machines are most widespread and are found everywhere. The basis of this design will be a circular saw, which is mounted on the spindle of an electric motor. Additionally, a strong base is made, above or below which a shaft with a saw and an electric motor are fixed.

A durable and reliable frame for a disk unit can be made of metal or wooden parts that are welded or fastened together with nails and screws. The work table can be made of sheet metal; you just need to ensure the ideal geometry of the structure, which allows you to guarantee the highest possible quality of wood cutting.

The use of disc saws allows you to make slats of various sizes, produce timber, veneer, and cut boards to the required length and width. Thanks to the high rotation speed of the saw, it is possible to ensure that logs are cut with smooth, high-quality edges and cuts.

Band sawmill

Belt-type installations combine simplicity of design and excellent performance. Accordingly, they are popular not only in everyday life, but are also widely used in sawmills and enterprises that produce lumber. The advantages of this type of equipment include its high productivity, as well as the ability to cut large logs weighing more than 300 kilograms.

To make a band sawmill you will need the following:

- Pulleys.

- Channel.

- Metal corners.

- Pipes with different diameters and sizes.

- Metal structures for the production of sleepers.

The production of such a sawmill begins with the construction of a frame, which has the shape of the letter P and is made of a corner or channel with dimensions of 50 by 100 millimeters. The standard dimensions of the frame are a length of 8 meters and a height of at least 15 centimeters. To increase the strength of the base, the channels are additionally tightened with pipes and angles, which will allow the base to withstand the maximum possible load.

Next, they begin to build the mobile cart. For this, a steel plate is used, the thickness of which is 40 millimeters. An electric motor will be responsible for driving the trolley, the power of which should be 10-12 kW.

A saw is attached to the trolley with a chain drive, which is fixed to the electric motor shaft through a pulley. A handle-steering wheel is welded to the side of the movable cart, which will be responsible for moving the mobile structure along a fixed base.

https://youtube.com/watch?v=MVx1lq1COng

Tire sawmills

Tire sawmills or logosols differ in their design from other similar devices. Using this manual technique, you can longitudinally saw logs, producing high-quality slats and veneer. Thanks to its compact dimensions, logosol can be installed both outdoors and inside a small workshop or wooden shed. At such a sawmill it will be possible not only to cut logs, but also to produce small-sized workpieces with a non-standard shape.

Having a high-quality sawmill diagram in hand and choosing the correct length of the chainsaw blade, you can independently create a machine that will provide high-quality sawing of logs. It will be possible to decide how to make a sawmill with your own hands, saving on the purchase of components for equipment.

Circular

There are two sawmill options. They differ in the vertical or horizontal arrangement of the working tool.

The device with a vertical chainsaw position contains:

- A guide made from a section of channel or rectangular profile pipe. Its length should be greater than the size of the logs being processed.

- Sled. For production, use 2 pieces (40 cm each) of a 50x50 corner. They are welded at the ends of the upper shelves perpendicularly to 2 metal strips 3 mm thick. The distance between the inner surfaces of the vertical shelves of the corners must correspond to the size of the channel or pipe.

Then:

- In the middle of each corner, identical vertical plates with coaxial holes are welded on top.

- A steel rod is inserted into them, welded perpendicular to the chainsaw bar. Pipe sections are placed on the rod on both sides of one of the vertical corners. The latter are fixed with M8 bolts through the corresponding threaded holes. They serve to set the thickness of the resulting boards.

To operate the circular:

- A guide is placed on top of the log and secured to it with self-tapping screws that have countersunk heads.

- Installed on the slide guide.

- Turn on the chainsaw engine and move it along with the sled along the log.

Video reviews

Below is a video review demonstrating the chainsaw attachment

Alexander Mikhailovich:

Getting two tools in one is a great idea. A friend who is well versed in repairing such equipment helped me implement it. We used all the necessary parts from the angle grinder and got a multifunctional device. It works great, but I realized that it is better to install a small 115 mm disk, the work will be more efficient.

Advantages: not expensive, multifunctional device.

Disadvantages: Must be used with caution as this is a homemade device

Car

You can make different types of cars from chainsaws. One of them is a kart buggy, which is distinguished by the presence of a suspension in its design. It makes driving the car more comfortable off-road.

The process of creating such a homemade machine is complex. This is especially true for the frame, which is welded from metal or profile pipes according to pre-drawn drawings. Then they are engaged in the manufacture of suspension and steering parts.

Buggy manufacturing operations include:

- suspension assembly;

- installation of the steering wheel, rods and launcher;

- wheel fastening;

- brake placement;

- installation of the driver's seat;

- mounting on the engine frame.

You can transfer rotation from the motor to the wheels using a chain or belt. In the first option, sprockets are installed, in the second - pulleys. To reduce noise, the engine is equipped with a muffler.

What else can you do

There are many options for possible homemade products. It all depends on the imagination and skills of the craftsman. In addition to what is described, you can make from a chainsaw:

- a generator that will provide electricity to a cottage far from communications, a comfortable outdoor recreation;

- a grinder capable of cutting metal, stone, concrete, and polishing surfaces;

- a winch that makes life easier for motorists who like to drive off-road;

- cultivator for processing the garden, harvesting.

The list includes motorized drills for making holes in the ground for poles and planting trees. Its winter variety is an ice drill for winter fishing.

Source

Scooter

For improvement, a scooter that has inflatable wheels and a hand brake is better suited. The first allows it to move over uneven surfaces, the second provides high braking ability.

Perform work in the following sequence:

- The chain and bar are removed from the chainsaw.

- Unscrew the centrifugal clutch from the crankshaft.

- Bicycle sprockets are attached to the output shaft of the engine and the axle of the rear wheel of the scooter.

- Place the motor at the back of the scooter platform. They are connected to each other with bolts. Both sprockets must be in the same plane.

- Put a bicycle chain on the sprockets, adjust it, removing excess links.

- Attach the accelerator to one of the handles of the scooter. Connect it to wires that turn the motor on/off. Instead of an accelerator, you can install a small pedal.

Let's cut everything around or grinder on a chainsaw

The cutting disc is used in a large size, this is taken taking into account the maximum speed that the chainsaw can produce.

List of materials:

- plywood; - wood screws; — bolts with nuts; - thin sheet metal; - Sheet steel; - a piece of leather or thick rope; — square steel pipe; - cutting wheel.

List of tools:

- rivet gun; — drill and drilling machine; - jigsaw; - lathe; - wrenches, pliers, clutch release wrench, spark plug wrench; — belt grinder; - Bulgarian; — semi-automatic welding machine or inverter; - wood glue; - pencil, ruler, tape measure, paper.

Homemade manufacturing process:

Step one. Preparing the grinder

First of all, remove the tire from the angle grinder, then you will need to remove the clutch along with the sprocket. This task can be quite difficult, since often the clutch is tightly stuck to the shaft and cannot be unscrewed without a service center. To try to unscrew the clutch, you will need a special wrench, it is similar to the one used to unscrew the nut on an angle grinder. Remove the top cover from the angle grinder and remove the spark plug.

Stick as much rope or a piece of leather into the candle hole as you can pull out. This will allow you to block the piston and try to unscrew the clutch. If it works, great!

Step two.

Thrust sleeve Step three.

Making the drive pulley Step four.

Cut out the fastener Step five.

Making a driven pulley Step six. How is the cutting disc attached?

Step seven.

Bearing platform Step eight.

Protective casing Delivery of new homemade products by mail Receive a selection of new homemade products by mail. No spam, only useful ideas!

*By filling out the form you agree to the processing of personal data

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Helicopter

This type of homemade product is considered complex and therefore has not been implemented to date. She is in the dreams of enthusiasts, in invented stories. One of them claims that back in the USSR, a prisoner who understood mechanics made a helicopter with a chainsaw engine and was able to escape from the colony.

Making a homemade helicopter requires, unlike a snowmobile, outboard motor, bicycle, grinder and even a snow blower, more complex engineering calculations. They also show that one, even powerful, engine is not capable of lifting such an aircraft into the air. At least 4 motors are required, moreover, forced and working in concert at the highest possible speed. But it is difficult to implement this with chainsaw engines in practice.

Features of creating homemade products from a Ural chainsaw

Such saws are more suitable for powerful units - a sawmill, for example. However, despite the high power, it is clearly not worth installing a Ural engine on a bicycle to improve driving performance. The fact is that the increased power is compensated by strong vibration, which can lead to the chain falling off while driving. And this is fraught with trouble.

“Ural 2 electron” - this can still be found on the shelves of Russian stores today

Helpful information! The undoubted advantage of the Ural is that the new device can be found on store shelves today. This means that for newer models there will be no problems with service and spare parts. The main thing is that your hands are in place.