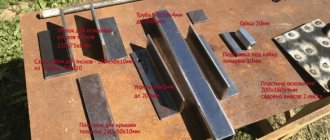

How to make an electromagnetic table from a microwave transformer - for plumbing and welding work

In this review, we want to share with you an interesting idea on how to make an electromagnetic table for welding and plumbing work with your own hands.

This idea (and its implementation) was shared by the author of the YouTube channel Gianni Pirola Fai Da Te.

The advantage of an electromagnetic table is that there is no need to use a vice, clamps or other devices for fixing metal workpieces.

On a homemade electromagnetic table you can both weld workpieces and process them: cut with a grinder, grind, etc.

- transformer from a microwave oven (microwave);

- power unit.

Making a surface grinding machine with your own hands

A surface grinding machine, which you can make yourself, is a very popular piece of equipment not only in manufacturing enterprises, but also in the home workshop.

Such a device is practically indispensable in situations where it is necessary to grind and adjust metal parts.

Of course, such work can be done manually, but this will take a lot of effort and time and will not allow achieving high precision processing.

Processing a workpiece on an industrial surface grinding machine

It makes sense to think about equipping your home workshop with a surface grinding machine if you often have to work on metal.

In this case, you can choose one of two options: buy serial equipment or make such a machine yourself.

The purchase of a serial machine is associated with serious financial costs, which is not always advisable for its use in a home workshop.

A homemade surface grinding machine will cost much less. Of course, the functionality of such equipment will be somewhat lower than that of serial equipment, but its capabilities will be quite sufficient to perform metal work at home.

DIY magnetic table

Tools for grinding flat surfaces

When grinding, parts can be secured directly to the machine table using clamping bars. However, such fastening is used in cases where the parts cannot be fixed to a magnetic plate or other devices.

Pattern vices (Fig. 10.9a) differ from conventional machine ones in manufacturing precision and the ability to turn. The fixed jaw of the vice is integral with the base 1. The body has grooves for the passage of the movable jaw 2, which is moved by a screw 3. The base of the body has threaded holes for attaching the vice to various devices. All vise planes are machined at an angle of 90°. The pressed-in cylindrical measuring pin 4 is used to measure inclined planes.

Article on the topic: DIY corner table

Rice. 10.9. Pattern vice (a) and electromagnetic plate (b)

Electromagnetic plates . The design of the electromagnetic plate (Fig. 10.9b) is based on the following principle. If a wire is wound around an iron core (Fig. 10.10a) and a direct current is passed through it, the core will be magnetized. If you now bring a steel object to one of the ends of the core, it will be strongly attracted to the core. After the current in the winding stops, the magnetic action of the core will also stop.

You can bend such a core in the form of a horseshoe (Fig. 10.10b) and also pass current through its winding. In this case, the magnet will be even stronger. By combining horseshoe-shaped magnets into a group, we get an electromagnetic plate.

Rice. 10.10. Diagram of the magnetic action of current (a) and a horseshoe magnet (b)

The magnet poles located on the top of the plate are carefully insulated from its body with non-magnetic alloys (babbitt, zinc), due to which the magnetic forces are not dissipated in the body of the plate, but are directed directly into the body of the part. Only magnetic metals (for example, steel, iron, cast iron) can be attracted to the electromagnetic plate.

Electromagnetic plates are used in various sizes, round and rectangular. Only direct current is suitable for powering them, so machines are installed with devices that convert alternating current into direct current.

Electromagnetic plates provide reliable and quick fastening of the parts to be ground. To maintain the functionality of the plate, it is necessary to protect it from shocks and shocks, and also to ensure that no coolant gets on the windings. Upon completion of work, you should immediately wipe the working surface of the stove dry.

Magnetic plates

In addition to electromagnetic plates, magnetic plates with permanent magnets are used on grinding machines. This type of stove does not require special generators and rectifiers with wiring and distribution devices. However, as a rule, the force of their attraction is weaker than the force of attraction of electromagnetic plates.

Article on the topic: Simple DIY milling table

The design of a rectangular magnetic plate and its operating principle are shown in Fig. 10.11. Its upper part is made of steel plates 1 with non-magnetic layers 2 between them (Fig. 10.11a). Strong permanent magnets 4 can be moved, closing them either to the iron plates or to the part being fixed. In Fig. 10.11b shows the position of the magnets when fastening parts 5, and in Fig. 10.11c – during their removal or installation. The magnets are switched using handle 3. The lower part of the plate 6 is fixed on the machine table.

Rice. 10.11. Magnetic plate:

a – general view; b – position of the magnets when securing the part; c - the same when installing and removing the part

Segmented grinding wheels for grinding flat surfaces

Surface grinding with solid grinding wheels of large diameter is economically unprofitable due to large waste, increased heat generation and the possibility of breakage during transportation. In addition, if a crack appears or partial destruction of the wheel, it is necessary to replace it entirely and lose a significant amount of usable abrasive material. These inconveniences are eliminated when using wheels made from inserted abrasive segments (Fig. 10.12). If one or more of them breaks, such segments can be easily replaced with new ones.

The insert segments are used until they are almost completely worn out. By releasing 1 clamp, you can remove 2 segments at once. As they wear, the height of the segments decreases, so spacers are placed under them.

Rice. 10.12. Segment grinding

DIY magnetic plate - Metals, equipment, instructions

Magnetic plates for grinding machines are a special class of metalworking equipment that is designed to hold steel workpieces on the working surface under the influence of electromagnetic attraction forces.

It would seem, why use such a sophisticated design when you can use traditional cams as a clamp, which reliably clamp the workpiece and provide maximum rigidity during processing? In fact, electromagnetic fixation using magnetic plates for grinding machines has a number of advantages, which we will discuss below.

The key advantage is the ability to operate the equipment in multi-threaded mode. The master can simultaneously fix several workpieces on one installation, thereby increasing the productivity of his work by an order of magnitude. In addition, the magnetic plate for the grinding machine can ensure extreme precision in machining the workpiece.

This is due to the fact that during the grinding process the metal part heats up and, accordingly, expands. In this case, the workpiece clamped in a vice is deformed, while the workpiece mounted on the electromagnetic plane expands freely on the working surface.

It is worth remembering that the plate is not capable of providing as much force as the locking cams. In addition, if an emergency interruption of the power supply occurs, the workpiece will fall off the working surface. That is why the scope of application of magnetic plates for grinding machines excludes work that requires high cutting forces.

Another disadvantage of such installations is the phenomenon of residual magnetism inherent in steel workpieces that were processed in this way. Fortunately, you can cope with the problem using a demagnetizer, which in most cases allows you to close your eyes to the above-described drawback.

Design and operating principle

The housing, the most important part of the design of the magnetic plate for the grinding machine, is made of mild steel. Its bottom has special pole protrusions. The working surface of the plate is covered with a special cover, sections of which are located above the poles and separated by special non-magnetic layers. Direct current is passed through the coils.

In this case, the outer surface of the table acts as one pole, and the remaining part of the surface represents the opposite pole. A metal part that covers the non-magnetic layer at any point on the slab closes the magnetic flux and is fixed on the surface.

The force of attraction is an important parameter to consider when working with a magnetic holding surface. It largely depends on the dimensions of the fixed structure and the material from which it is made.

In addition, the force of attraction is influenced by the number of parts attached to the installation, as well as the design of the plate itself. Where the master placed the workpiece also affects this parameter.

The force of attraction is measured in N/cm2. The optimal parameter value is from 20 to 130 N/cm2.

Every craftsman should remember that the magnetic plate for a grinding machine heats up during operation. Frequent changes in the temperature of the structure can lead to the formation of condensation inside.

Engineers involved in the design of such units carefully consider a system for protecting the coils from unwanted exposure to liquid.

Bitumen, which is factory-poured into the internal cavity of the electromagnetic table, allows you to cope with this kind of task.

The magnetic block is an important part of the design. This movable element is moved by the operation of an eccentric top. The magnetic plate functions only when switched on. It will delight the craftsman with its operational capabilities and ensure the most even placement of the product on the working surface, which will immediately affect the accuracy of the final result.

Results

A magnetic plate for a grinding machine is capable of reliable fixation of the workpiece, which affects the quality of the task.

It is interesting that the technical parameters and operational capabilities of this design do not change over time and as the service life of the equipment increases.

This, in part, provokes increased interest in electromagnetic cookers from potential buyers.

As an additional advantage of the magnetic plate, it is worth noting that it does not require additional maintenance. If you follow the basic operating rules, it can last for decades without losing its functionality.

If you are looking for ways to increase productivity at your grinding machine, it’s time to think about purchasing an electromagnetic unit. Unlike standard jaws, this design allows you to process multiple parts at once with extreme precision and efficiency. All this is confirmed by the practice of tens of thousands of masters.

How to make a simple electromagnet - step-by-step instructions with diagrams

Such a device is convenient because its operation is easy to control using electric current - changing the poles, changing the force of attraction. In some matters it becomes truly indispensable, and is often used as a constructive element of various homemade products. It’s not difficult to make a simple electromagnet with your own hands, especially since almost everything you need can be found in every home.

What you will need

- Any suitable sample made of iron (it is highly magnetic). This will be the core of the electromagnet.

- The wire is copper, always with insulation to prevent direct contact of the two metals. For a homemade electric magnet, the recommended cross-section is 0.5 (but not more than 1.0).

- DC source - battery, battery, power supply.

Additionally:

- Connecting wires for connecting an electromagnet.

- Soldering iron or electrical tape to secure contacts.

Device and principle of operation.

3.1. The plate consists of three main parts: movable and fixed magnetic blocks and a housing. Magnetic blocks are assembled from steel plates, between which ceramic permanent magnets are located. The free space between the steel plates is filled with non-magnetic material.

Rice. Magnetic plate device

3.2. When switched on, poles 2 of the power unit lie on non-magnetic elements 5 of housing 1, directing the entire magnetic flux of magnets 3 through adapter 4 and parts 6. when switched off, poles 2 are located under non-magnetic spacers of the adapter. As a result, the magnetic flux has a new direction.

Article on the topic: DIY furniture facade

3.3. The movable magnetic block is located inside the housing and can be moved using an eccentric wolf to the right or left by turning the handle 180˚. In the off position, magnetic circuits with different polarities are combined; there is no non-magnetic flux on the working surface.

Compared to electromagnetic plates and hydraulic or pneumatic devices, they have the following advantages:

- do not require connection to an energy source;

- allow you to achieve higher precision when processing workpieces;

- provide absolute reliability of fastening;

- maintain the main technical parameters during the entire service life at the original level;

- do not require periodic repairs and maintenance

DIY magnetic water heater: list of materials and detailed assembly instructions

August 23, 2019

A magnetic water heater is a safe and environmentally friendly device that operates using Foucault eddy currents. Anyone can make a unit.

What it is

A magnetic heater is a simple and environmentally friendly device that, using Foucault eddy currents created by an electromagnetic field, warms up the coolant. Such a device is used for heating water, cooking food or even heating residential premises.

You can design various models of magnetic heaters using permanent magnets, but for home use, a vortex induction device (VIN) is best suited.

Operating principle of the heating unit:

- Through the converter, high-frequency current enters a cylinder made of copper wire, which acts as an inductor.

- An electromagnetic field is formed around the wire, creating eddy currents.

- Inside the inductor there is a heat exchanger, which heats up due to the incoming Foucault currents.

- Following the heat exchanger, the coolant also heats up.

Heater designs may vary slightly depending on the purpose of use, but the general operating principle is similar. Owners of private homes may also be interested in interesting ways to use solar energy to heat water.

Why is it profitable to make a device with your own hands?

You can immediately highlight the main advantages of heaters operating due to electromagnetic forces:

- high efficiency. The efficiency of the device can reach 99%, that is, electricity is converted into thermal energy without loss;

- long service life. Due to the simplicity of the design, the magnetic unit can operate without breakdowns for decades;

- safety. Gas equipment much more often provokes emergencies, fires, etc.;

- environmental friendliness. People who care about the environment and are interested in alternative energy sources will be pleased by the absence of hazardous emissions and combustion products. To use the unit, you do not need to install hoods or chimneys;

- ease of use. The device does not require special maintenance. The field appearing between electrically charged particles not only produces a heating effect, but also creates vibrations that prevent scale formation on the heat exchanger;

- no noise. The unit operates very quietly, so it will not cause discomfort;

- small size. Compact dimensions allow the device to be used in any type of room.

The main disadvantage is the high price. However, there is a way out: making a magnetic water heater with your own hands is not at all difficult.

Necessary materials

To make a structure at home, you should prepare in advance:

- a piece of plastic pipe;

- circular pump for water;

- thyristors for creating an inverter - a device that converts direct current into alternating current;

- 2 types of wire: copper and any stainless metal;

- pliers and wire cutters;

- adapters and ball valve.

This kit will help you make a simple magnetic vortex heater for household needs.

Step-by-step instruction

The assembly process can be divided into several main stages, each of which is devoted to the preparation of a specific element: the heating part, the inductor and the inverter. The connection completes the assembly process.

Next, we will dwell in detail on each stage:

- Secure the pipe hole on one side with a metal mesh.

- Using wire cutters, cut the stainless steel wire into many pieces and fill the pipe with them. Important: there should be no voids left inside.

- Cover the second pipe hole with mesh in the same way as the first.

- Wrap the pipe with copper wire. Recommended number of turns: from 90 to 120. Anything less is pointless.

- According to the electrical diagram presented below, a thyristor inverter is constructed, which converts electricity into high frequency current.

The final stage is connecting the magnetic eddy current water heater to the heating system using adapters and ball water taps.

Everything, a self-assembled device can be immediately used at home.

The test results of a unit assembled according to this scheme showed: if it is used as a flow-through heater, then in the first stages, with a power of 1500 W, the water will heat up from 15 to 27 °C in 15-20 seconds.

When interpreting the results, you need to take into account that the temperature depends on the pressure of the stream from the tap. In this test the flow was weak.

Assembling a magnetic heater yourself is the right solution for those who want to save on heating water. Thanks to its high efficiency, the device will be a worthy competitor to water heating elements.

How do surface grinding machines work?

The vast majority of parts made of metal undergo a technological operation such as grinding. To perform this with high efficiency and accuracy, surface grinding machines are used.

A rather difficult to manufacture banding machine with excellent functionality

Surface grinding machines of serial models can process both flat and profile parts. The surface processing accuracy that can be achieved using such devices is 0.16 microns. Of course, it is almost impossible to achieve such a result when processing on machines made by yourself. However, even the accuracy that homemade machines allow to obtain is quite sufficient for many metal products.

The load-bearing structural element of the machines of this group (as well as any other equipment) is the bed. Its dimensions directly determine what size parts can be processed on the machine. The most common material for manufacturing beds of surface grinding equipment is cast iron, since this metal, due to its characteristics, perfectly dampens vibrations, which is especially important for devices of this type.

Work table and controls of the 3G71M grinding machine

The structural element of surface grinding machines on which the workpiece is fixed is a work table having a round or rectangular shape. Its dimensions can vary significantly depending on the specific model of surface grinding equipment. The workpieces can be fixed on such a work table due to its magnetized surface or using special clamping elements. During processing, the work table makes reciprocating and circular movements.

Article on the topic: DIY furniture from old tires

In mass-produced surface grinding machines, the work tables are driven by a hydraulic system. In self-assembled equipment, mechanical transmissions are used for this.

Grinding a steel workpiece fixed on the working surface of the machine using a magnetic field

Important elements of the design of surface grinding equipment, which ensure the accuracy and smooth movement of the work table, are guides. In addition to high precision manufacturing, the guides must have exceptional strength, since in the process of almost constant movements of the desktop they are subject to active wear.

To achieve high processing accuracy, the guides must ensure accurate, smooth (without jerking) movement of the worktable with minimal friction of the contacting elements. That is why high-strength steel is used for the manufacture of these structural elements, which is hardened after the guides are made from it.

Option for manufacturing guides using angles and bearings

The working tool of a surface grinding machine, which can be a grinding wheel or an abrasive belt, is mounted on the spindle of the headstock. Rotation of the working tool, for which the main electric motor is responsible, can be transmitted through a gearbox or belt drive.

For do-it-yourself surface grinding machines, you can choose a simpler option: select the diameter of the grinding wheel so that it can be mounted directly on the electric motor shaft. This will eliminate the need to use a gear or belt drive.

How to make a simple electromagnet - step-by-step instructions with diagrams

Such a device is convenient because its operation is easy to control using electric current - changing the poles, changing the force of attraction. In some matters it becomes truly indispensable, and is often used as a constructive element of various homemade products. It’s not difficult to make a simple electromagnet with your own hands, especially since almost everything you need can be found in every home.

What you will need

- Any suitable sample made of iron (it is highly magnetic). This will be the core of the electromagnet.

- The wire is copper, always with insulation to prevent direct contact of the two metals. For a homemade electric magnet, the recommended cross-section is 0.5 (but not more than 1.0).

- DC source - battery, battery, power supply.

Additionally:

- Connecting wires for connecting an electromagnet.

- Soldering iron or electrical tape to secure contacts.

This is a general recommendation since the electromagnet is made for a specific purpose. Based on this, the components of the circuit are selected.

And if it is done at home, then there cannot be any standard - whatever is at hand will do.

For example, in relation to the first point, a nail, a lock shackle, or a piece of iron rod are often used as a core - the choice of options is huge.

Winding

The copper wire is carefully wound onto the core, turn by turn. With such scrupulousness, the efficiency of the electromagnet will be the maximum possible.

After the first “pass” along the iron sample, the wire is laid in a second layer, sometimes a third. It depends on how much power the device requires.

But the direction of winding must remain unchanged, otherwise the magnetic field will become “unbalanced”, and the electromagnet will hardly be able to attract anything to itself.

To understand the meaning of the ongoing processes, it is enough to remember the physics lessons from the high school course - moving electrons, the EMF they create, the direction of its rotation.

After winding is completed, the wire is cut so that the leads can be conveniently connected to the power source. If it's a battery, then directly. When using a power supply, battery or other device, you will need connecting wires.

What to consider

There are certain difficulties with the number of layers.

- As turns increase, reactance increases. This means that the current strength will begin to decrease, and the attraction will become weaker.

- On the other hand, increasing the current rating will cause the winding to heat up.

The operating principle of the electromagnet is described in detail in the following video:

Connection

- Cleaning the copper terminals. The wire is initially coated with several layers of varnish (depending on the brand), and it is known to be an insulator.

- Soldering copper and connecting wires. Although this is not essential, you can twist it by insulating it with a PVC pipe or adhesive tape.

- Fixing the second ends of the wires on the clamps. For example, the “crocodile” type. Such removable contacts will allow you to easily change the poles of the electromagnet, if necessary during its use.

Useful tips

- To make a powerful electromagnet, home craftsmen often use a coil from an MP (magnetic starter), relays, or contactors. They are available for both 220 and 380 V.

It is not difficult to select an iron core based on its internal cross-section. For ease of control, you need to include a rheostat (variable resistance) in the circuit. Accordingly, such an electric magnet is already connected to the outlet.

The force of attraction is regulated by changing the R chain.

- You can increase the power of an electromagnet by increasing the cross-section of the core. But only up to certain limits. And here you have to experiment.

- Before making an electric magnet, you need to make sure that the selected iron sample is suitable for this. The check is quite simple. Take a regular magnet; There are a lot of things in the house on such “suction cups”. If it attracts the part selected for the core, it can be used. If the result is negative or “weak,” it is better to look for another sample.

Making an electromagnet is quite simple. Everything else depends on the patience and ingenuity of the master. You may have to experiment to get what you need - with the supply voltage, wire cross-section, and so on. Any homemade product requires not only a creative approach, but also time. If you do not regret it, then an excellent result is guaranteed.

Magnetic levitation at home

In the 90s of the 20th century, the Levitron toy, based on the influence of a magnetic field, became very popular.

This is a levitating top hovering in the air. A similar toy can be assembled at home to understand the essence of magnetic levitation. How to make Levitron - we will present detailed instructions.

List of materials:

- wooden board;

- a simple pencil;

- insulating tape;

- washers made of plastic or brass;

- cardboard;

- 13 neodymium disk magnets brand N52, size 12*3 mm;

- wide ring magnet with an outer diameter of 20, an inner diameter of 10 mm, brand N42.

Article on the topic: DIY country style chandelier

Description of the assembly process step by step:

- Making a layout. Initially, the top was assembled on two ceramic ring magnets. In our design we will use standard neodymium magnets. First, let's print out a diagram of the marking holes for installing magnets. Before starting work, check the conformity of the dimensions in the printed diagram and those indicated in the source code. If everything matches, then cut out the layout.

- Preparing the foundation. Attach a paper diagram to the board and mark according to it. Please note that the thickness of the wooden blank must be 6mm or more.

- Transfer of all circuit blocks to the base. Glue the paper carrier to the resulting base. Using a Forstner drill (d=12mm), punch the center of the circles. This will ensure further drilling accuracy.

- We drill holes. Using a Forstner drill (d=12mm), we make holes in the workpiece so that the bottom of the hole extends 3 mm into the top of the block. The magnets should be positioned as close to the top as possible.

- Installation of magnets. When the holes are ready, you have double-checked their dimensions, install the magnets with one pole facing up, for example the south one. To determine the polarity, you can use the marked D68PC-RB magnet. Place the block on a steel plate to make it easier for the magnets to move to the bottom of the holes. Let's take N52 magnets and place them in the holes, one at a time, as deep as possible. If you need to push the magnet through, you can use a wooden dowel.

- How to make a top. Take a pencil 40 mm long with a pointed end. We wrap electrical tape around it to increase the diameter to fit the central part of the ring magnet. Insert the pencil into the magnet so that the south pole is at the bottom, like the pointy part of the pencil. To add weight to the top, use plastic or brass washers: put several on top. To ensure proper operation, it is necessary to determine the acceptable number of washers using the selection method.

- Let's start the system. Cut cardboard or plastic for the platform. Place it on a magnetic base. On the platform, the top begins to spin and gradually rises with the platform until it falls into the magnetic field well.

Article on the topic: DIY laminate table

If everything is done correctly, the top will freeze. Debugging the mechanism may take a long time.

Tips for adjusting the top:

- Try to ensure the base is balanced. Use pieces of cardboard or paper to raise the sides of the base and level it. If it deviates from the center to some side, lift it by placing pieces of paper under it.

- Apply three-point leveling.

- Consider the weight of the top: the device assumes the presence of a magnetic pit - the strength of the magnet in the center is weaker than near the edge. To keep the magnet in the center, you should add weight (when the top flies out) or decrease it (if the top does not rise from the platform).

- Another significant indicator is the height of the platform: a low platform does not allow the top to spin sufficiently. Therefore, you need to place paper or cardboard under it.

- If you have a 3D printer at hand, you can print a toy on it.

Thus, it is possible to make Levitron with your own hands at home. Based on the presented materials, you can design various souvenirs and interior items that can please you and your friends. In addition, you can show all kinds of tricks with magnets and levitation to children.

Do-it-yourself induction heating: simple, warm and economical

Did you know that with the help of the simplest induction hob you can fully heat a room of more than 30 m²? If not, then you should read this article and find out how to make simple induction heating at home.

A little theory

Anyone can make this device

Many people know that induction cookers exist, but not many know about the principle of their operation.

And this is very simple - a special coil of the plate generates magnetic fields of a certain frequency, which, when exposed to metal, excite electric vortices in it.

The latter, in turn, heat it up due to the resistance of the metal. This is how kitchen utensils: pots and pans are heated. The main condition in this process is a metal with magnetic properties -

for example, stainless steel, cast iron and iron, but aluminum and other non-ferrous metals will not heat up.

Induction stove heater

Induction cooker

Knowing this principle, you can build a full-fledged heater in a couple of hours, which will be not only effective, but also economical.

Using it you can save about 50% of electricity when compared with a similar heater operating on heating elements.

What is needed for making

Induction heater option

To make it you will need:

- Induction hob 1.2 kW

The cheapest tile will do,

without built-in cooking programs. The cost is about 1.2 thousand rubles.

- Corrugated steel hose about 2 meters long

Sold in construction stores, in the plumbing department.

The cost is about 500 rubles.

- Two hose connection fittings

- Aluminum radiator

The number of sections is selected according to the heated area.

Approximate calculation: 1 kW per 10 m².

- A piece of copper tube, about 20 cm

Making a heating boiler

It is imperative to loop the spiral, otherwise it will not heat up

1

A heating boiler is a container where the coolant will be heated, i.e. water.

To make it, we form a spiral from a corrugated metal hose, as shown in Fig. 2. This will require about 1 meter. The spiral must be formed in such a way that the remaining ends of the hose are enough to connect to the aluminum radiator.

2

The resulting spiral needs to be looped,

those. connect the end of the spiral to its center using a copper piece of tube (see Fig. 2). This is necessary so that the induction cooker recognizes the boiler and heats it.

You can make a cauldron of a different shape.

For example, as shown in the photo below.

This variation is also looped, connected using tin

Connecting the boiler to the radiator

Top - supply, bottom - return, - gravity system

Using fittings, we connect both ends to the radiator .

Up-down decoupling scheme, one-way.

Connecting to the tile and checking functionality

Checking performance at full power

1

Now we fill the system with coolant. Unscrew the top nut of the radiator and fill it with water. We leave a little empty space, which is needed for the expansion of water.

2

Place the spiral boiler on the induction hob. And we check the functionality of the system. If everything is done correctly, the radiator will heat up to 60 degrees within 5 minutes.

More compact position

3

To prevent the tile from taking up space, it can be attached to the wall, i.e. vertically.

Control and monitoring devices

Parallel toggle switch

1

In order to organize automatic control of induction heating without extra costs, you need to turn on the stove mechanically. To do this, we disassemble the plate, and on the board we find the power terminals and solder a parallel toggle switch to them. This is necessary so that the stove starts working immediately when connected to the mains.

2

Now you can connect various adjustment sensors. For example, a temperature sensor.

temperature sensor

3

You can also set the heating to turn on by timer. An ordinary mechanical timer will cope with this task - a minimum value of 15 minutes.

Budget on timer

User manual

The magnetic plate should be re-opened and the equipment passport should be examined.

- Place it on the machine table.

- Check that the mounting is correct and start working.

- A workpiece made of ferromagnetic material must be placed on the working surface in the required position and the lever must be rotated 180 degrees. Check the reliability of the fastening.

- Start processing the workpiece.

- Metal shavings generated during operation can be removed with a brush after turning the handle 180 degrees. Then, after cleaning the surface, you need to fix the workpiece again using the handle.

- Upon completion of work, turn the handle and remove the workpiece.

Magnetic table for a milling machine: design and characteristics, operating principle

If your work depends on working on a milling machine, then increasing the number of products should be a priority for you. A magnetic plate will be a good tool for increasing productivity.

A magnetic plate for a milling machine will allow you to process more than one part at once, unlike standard jaws. And processing will be carried out with utmost precision and efficiency. Let's take a closer look at all the features of this device.

What is a magnetic plate?

Magnetic plates are a special type of equipment for milling machines, which is needed for processing metal elements, which is necessary for fixing metal elements on the working surface of the machine under the influence of electromagnetic attraction.

Before their appearance, cams were actively used to hold workpieces, which ensured maximum retention during operation. But still, magnetic plates have a number of more outstanding advantages compared to cams:

- there is an alternative to processing several workpieces at once;

- the maximum precision of the impact is ensured, which is associated with the phenomenon of heating the metal part. It expands, but does not deform like a part in clamps;

- provide high reliability of fastening;

- maintain basic performance characteristics at the original level for the entire period of use;

- do not require annual (or more often) technical inspection and repair activities.

But these devices also have disadvantages:

- not used in work that requires high cutting force;

- residual magnetism of workpieces made of steel, but a demagnetizer will help cope with this feature.

Reference! Demagnetizer (demagnetizer) - is necessary to deprive the attractive forces of a tool or workpiece so that metal shavings do not stick to it.

Magnetic plates are most often used on grinding, milling and lathes for processing metal-containing products.

Important!

Magnetic plates are very rarely included in the basic equipment of the machine, so they must be purchased and installed separately, taking into account the necessary parameters of the product.

Design Features

The main structural elements of a magnetic plate for a milling machine are:

- The body of the device is made from soft steel. Its base has special oppositely charged protrusions.

- A special lid that covers the work surface. The cover is one pole, and the remaining surface is the opposite pole.

- Coils - designed to pass direct current.

- A magnetic block is a movable element that moves due to the work of an eccentric top.

Specifications

Technical conditions for the production of magnetic plates are regulated by GOST 16528-87 . It describes all the characteristics of stoves with different types of control.

The main parameters affecting the operation of magnetic plates are:

- Overall dimensions – minimum starting from 10x25 cm and maximum up to 32x100 cm. The final dimensions of the workpiece depend on this value. Also, the significant size of the plate increases the load on the machine’s work table.

- Magnetic force - acts constantly and when not in working position it is prevented by blocks of non-magnetic material. The range of action of this value is 50–120 N/cm².

- The distance between magnetic poles or coils. The smallest size available for the part being manufactured depends on it.

Operating principle of a magnetic table

The principle of operation of the stove is quite simple and understandable. A magnetic field is formed on its working surface, which fixes metal workpieces. Thanks to this function, it becomes possible to process not only the outer part of the materials, but also the side areas.

If necessary, simultaneous processing of several parts is available. Thanks to its magnetic properties, you can install additional tools on the work surface that will be useful in your work.

User manual

The magnetic plate should be re-opened and the equipment passport should be examined.

- Place it on the machine table.

- Check that the mounting is correct and start working.

- A workpiece made of ferromagnetic material must be placed on the working surface in the required position and the lever must be rotated 180 degrees. Check the reliability of the fastening.

- Start processing the workpiece.

- Metal shavings generated during operation can be removed with a brush after turning the handle 180 degrees. Then, after cleaning the surface, you need to fix the workpiece again using the handle.

- Upon completion of work, turn the handle and remove the workpiece.

Important!

The impact of a shock load on a workpiece fixed on a magnetic plate is unacceptable, since this leads to a decrease in the magnetization of individual elements and, accordingly, to a decrease in the attractive forces of the plate as a whole.

Expert advice and price

The best-selling models of magnetic plates are:

- MP 400x125 sinus 2S7208-0003. Its advantage is the reliable clamping of workpieces using the magnetic currents of permanent magnets, which guarantees a constant clamping force throughout the entire operation. The price of such a device is from 50 thousand rubles.

- MP 250x100 (7208-0001) – slightly cheaper than the previous model, sold from 19 thousand rubles.

- MP flat X91 300x680 (66120-6) – makes it possible to process parts with a minimum thickness of 8 mm/7 mm. Its cost is from 170 thousand rubles.

It provides reliable fixation of the workpiece, which affects the quality of the work. Another good thing about this device is that the technical parameters and possibilities for using such a design remain the same over time. This quality arouses buyers’ interest in electromagnetic cookers.

Purpose

The effectiveness of this simulator has long been proven by experts. Such tables are intended for the treatment of various diseases of the musculoskeletal system .

Article on the topic: DIY makeup table

Inversion tables are effective for the following diseases and pathologies:

- moderate postural disorders (initial stage scoliosis);

- chronic spasms in the muscles of the back or neck;

- as a prevention of varicose veins on the legs;

- for training people who lead a sedentary lifestyle;

- chronic stress as relaxation;

- to strengthen the back muscles.

Keep in mind that you shouldn’t expect any special miracles from using an inversion table .

Although it is used for the treatment and prevention of various pathologies, as a separate treatment method, it has little effect. Since the simulator treats existing diseases and does not in any way affect the cause of their formation.

Therefore, exercises on an inversion table must be combined with other treatment methods, for example, lifestyle changes.

You can buy a finished product in a store, or you can make it yourself. If you have little experience in manufacturing and assembling furniture items, you can resort to the second option.

Making a tabletop with lighting from New Year's garland

There is an easier way to make your own table with an infinity effect. In this case, instead of an LED strip, a regular New Year's garland is used. First, a square or rectangular frame is made from bars, then the number of light bulbs on the garland is counted.

After this, marks are placed on the frame in the places where the light bulbs will be located. It is recommended to place them at a distance of about 2 cm from each other. At the next stage of work, holes for light bulbs are drilled in the frame of the future table.

Then light bulbs are inserted into these holes and secured there. Then you need to glue the frame onto the mirror with your own hands, and glue glass with a mirror film on top of the frame.

What is the difference between a homemade and factory vacuum table?

Working equipment created independently allows you to adapt the device to the needs of a specific production process. Do-it-yourself vacuum tables allow you to take into account all the nuances of processing parts related to their size, as well as include all functions - from milling to molding work. A vacuum table for a CNC machine, assembled independently, saves the user money and simplifies further maintenance of the device.

Article on the topic: Do-it-yourself table and bench in a cemetery

Vacuum tables can significantly improve the efficiency of the production process and improve the quality of manufactured products. This is achieved by creating the powerful clamping force needed to achieve consistent quality. If the CNC machine does not come with a ready-made table, you can make it yourself. This is a simple process, and diagrams and drawings of devices can be found freely available on the Internet.

- November 15, 2020

- 1218