How to smoothly start a power tool from a regular outlet.

An ordinary socket, if modified a little, can extend the life of any of your tools - an angle grinder, a circular saw, a trimmer, etc.

All you need for this is a small soft start box costing about 200 rubles. For example, a brand like KRRQD12A.

It is well known that not every tool is equipped with such soft start circuits. They mainly come in expensive models from well-known brands Bosch, Hilti, and DeWalt. Moreover, both in the network line and in the battery one.

A power tool without such a device has a bunch of disadvantages:

- armature sparking on the commutator with armature lamellas burning out

- brushes burn out and wear out faster

- rotor and stator windings fail more often

- current surge into the general electrical network

- gears hitting each other and operating faster

- dangerous jerk when starting, tearing the tool out of your hands and increasing the risk of injury

When working with a miter saw with a PP, the blade will not stray from the prepared cutting point. Which is important for non-professional carpenters.

If at your dacha or in your house at the initial stage of construction there is no electricity yet and you use a generator, then sooner or later you will understand that without a soft start unit (soft start unit) with sharp initial currents, the generator will not last long. Therefore, such a thing can save not only the tool, but also emergency power supplies.

You can, of course, independently build a BPP into the inside of the same grinder or trimmer, but not everyone wants to disassemble the equipment and tinker with the insides.

Plus, opening a new case will void the warranty. Therefore, the best use for the KRRQD12A block is external connection.

This box is designed for a current of 12 Amps.

There is also a more powerful 20A model.

What is typical is that they have the same dimensions, but the difference in price is a couple of tens of rubles.

It would seem better to take it, but for a standard 16A socket the first option is more profitable. There will be no desire to connect a more powerful load and thereby burn all the contacts.

DIY craftsmen, of course, assemble similar circuits with their own hands, based on VTA 12-600 or other thyristors, capacitors, a dinistor and a couple of small resistors. You can find many examples of schemes on the Internet.

But for the average user of the instrument, it is much easier to buy all this in a ready-made compact case. You can order a similar block using the link here.

By the way, be careful, there are similar devices, but with three wires. For example XS-12/D3.

Or other models that look similar to KRRQD.

But they are assembled on a slightly different principle and need to be installed after the START button, in the instrument itself. Voltage should be applied to them only at the moment the grinder's start button is closed and immediately disappear after it is released.

The connection diagram for them is as follows:

The phase is supplied to contact “A”, zero to “C”. Next, the phase with the output control wire goes to the engine (this is exactly the third wire).

There is no such thing in a two-wire unit, since it is connected to an open circuit, and voltage (potential difference) is applied to it only at the moment of starting and operating the tool.

Another point is the so-called electric brake or brake winding on the crosscuts. It may not work with a 3-wire external soft starter, but it will work with a 2-wire model.

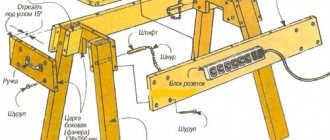

The most important requirement for such an outlet is its mobility. Therefore, you will need a carrier.

With its help, you can smoothly launch the tool anywhere - in the garage, at the dacha, during the construction of your house in different areas of the construction site.

The first step is to disassemble the carrier.

The main power wires in it can be either soldered or connected to screw terminals.

Depending on this, your additional outlet will also be connected. This should be an additional socket near the carrying case in order to be able to simultaneously connect the instrument in different modes.

By the way, if you mistakenly turn on an angle grinder or circular saw that has a factory built-in soft start into an outlet that is also equipped with such a soft starter, then surprisingly everything will work. The only thing is that there will be a delay in starting the saw or turning the disk for a couple of seconds, which is not very convenient to use and can be puzzling if you don’t get used to it.

Here are real tests of such a connection, carried out by one master from YouTube BaRmAgLoT777. His comment after such tests on a Dremel type engraver, a Bosch drill, a Makita router, and an Interskol circular saw:

Next, to assemble the socket, take a stranded copper wire with a cross-section of 2.5 mm2 and strip its ends.

Then you need to tin the contact pad on the carrier where this wire will be soldered.

Securely solder the cable cores to these pads.

Carefully lay out the wires and close the extension cord.

Take a square external socket for installation on the outer surface of the walls, and try on a soft starter unit in its housing. Since it has compact rectangular dimensions, it should fit there without any problems.

Mount and secure the socket body on the same platform as the extension cord.

It is installed on one of the wires.

Also for this BPP, there is no difference on which side to make the entrance and on which side to make the exit. The twists are soldered and insulated with heat shrink.

After that, all the insides of the socket are assembled into a housing and all that remains is to close the entire structure with a lid.

At this point, the entire reworking of the carrying case and the manufacture of the socket can be considered complete. It will take you no more than 15 minutes.

If you don’t want to assemble a bulky structure from a separate carrying case + an additional socket for it, this soft-start device can be assembled in one rubber socket of this shape.

It is called a portable socket with a protective cover - RBp13-1-0m.

The KRRQD12A block fits perfectly inside and does not interfere with anything.

By connecting a long KG cable with a plug to it, you will get a ready-made socket with a power supply unit, which additionally plays the role of an extension cord.

With such a dust-proof, waterproof socket, you can safely work outdoors without fear of rain, snow and extraneous splashes of water.

In both cases, you will get a compact mobile soft starter through which you can connect any tool with a motor up to 2.5 kW.

Of course, a tool without such a PP can and will survive for many years if the manufacturer initially included an increased safety margin in it. An example is Soviet drills.

Many of them were inherited in working condition. But today not every manufacturer has such an approach to tools. Quite the contrary, they save on all components, reducing the cost of production.

And the logic here is simple - the sooner it burns, the sooner they will come for a new one. A resource of 5-10 years is considered a good period for some. For others, this is not acceptable.

The master must work with the tool in such a way that he only has to periodically change the brushes and lubricant and do not forget to clean it. With the above socket this could very well become a reality for you.

Choosing a scheme

There are many soft start schemes, we will try to choose something suitable and most affordable for us.

On discrete elements

The regulator, the diagram of which is presented below, is assembled on a symmetrical thyristor (triac) KU208G and allows for smooth start-up of power tools with a power of up to 2 kW.

Triac soft start circuit

Immediately after applying voltage to the circuit (toggle switch SA1), capacitor C1 is discharged, triac VS1 is closed and motor M does not rotate. Next, the capacitor is gradually charged through the diode VD1 and resistor R2, the triac begins to open, but with a long delay from the beginning of the half-wave of the mains voltage. A small initial voltage is applied to the motor and it starts at minimum speed.

As the capacitor charges, the opening delay of the triac decreases, the voltage on the motor increases, and therefore the speed increases. As soon as the capacitor is fully charged, the symmetrical thyristor will open at the beginning of each half-wave, supplying full mains voltage to the motor, and the latter will reach full speed.

The soft start time can be adjusted by selecting the capacitance of capacitor C1. At the indicated ratings (500 µF), the instrument will return to operating mode approximately 2-3 seconds after switching on.

On a microcircuit and triac

This circuit is assembled on the domestic universal microcircuit KR1182PM1. With its help, you can build both a soft starter and a voltage regulator. In the diagram below, the microcircuit is turned on in soft start mode.

Soft start circuit on IC KR1182PM1

Since the microcircuit has a relatively low output power - up to 150 W - it is equipped with a powerful output switch, which is a symmetrical thyristor TS122-20-10, which can withstand current up to 20 A. The time it takes for the engine to reach operating mode depends on the capacitance of capacitor C1. Such a circuit can operate without a radiator at a load power of up to 1 kW.

Integral regulator

The circuit based on discrete elements is quite simple and does not contain scarce elements, but it is too bulky and will have to be placed in a separate case, especially if the power tool is powerful and a radiator is required. In this regard, it is much more convenient to use ready-made integrated soft start units. The most convenient option for us is KRRQD20A.

Soft starter KRRQD20A

The compact integrated soft start unit (SPU) is designed for current up to 20 A and is capable of switching power up to 4 kW. The module has 2 outputs and is connected to a break in one of the power wires of the tool motor. If you equip an extension cord with it (for some reason many people call it a carrier), then the power tool connected through it will start smoothly when you press the power button.

Connection diagram of the KRRQD20A module to the extension cord

The photo clearly shows that the module is designed for installation on a radiator, but if the power of the power tool does not exceed 1 kW, then a radiator is not required.

Soft starter XS-12/D3

The connection diagram is printed directly on the body of the device and it is obvious that it can only be used by installing it after the switch in the power tool itself. This is also a good option, but, firstly, the extension cord is a more universal solution (you can connect any tool or even a lamp), and, secondly, by disassembling the tool, we lose warranty service.

Smooth start of an angle grinder with your own hands

Angle grinder (grinder) MAKITA GA4530 without soft start. Photo 220Volt

When buying a cheap angle grinder, it will probably not have a soft start option . During startup, especially with a powerful angle grinder, you can feel all the “delights” of the jerk that the grinder produces when turned on. If you have a soft starter, the power tool will begin to do its job in a comfortable environment for the user . Undoubtedly, an angle grinder with this option costs more. However, it is possible to install a soft starter on the angle grinder yourself. This will solve the issues of saving money and will facilitate further operation - a device made by yourself is easier to repair if it fails.

Device

In grinders without a soft start, the windings of the commutator motor are immediately supplied with a 220 V mains voltage , and to bring it into working condition an increased starting current is required. The soft starter ensures a gradual increase in voltage and, accordingly, the current during startup also does not increase abruptly.

This starting mode can be achieved using a special electronic circuit . Its main component is a semiconductor chip , which controls another, more powerful semiconductor device, a triac, which supplies power to the electric drive of the angle grinder. The thyristors of the microcircuit operate with a delay in the supply voltage until the circuit capacitor is fully charged. The principle of operation of the microcircuit is successfully combined with ensuring a smooth start of angle grinders.

Microcircuits k1182, LM358

The most famous microcircuit for the K1182 soft starter. This microcircuit was created back in Soviet times and now it is not so easy to find. There are other more affordable chips, for example, LM358. Many modern angle grinders use the LM358 chip in the factory version of the device.

Principle of operation

The main disadvantage of asynchronous electric motors is that the moment of force on the shaft is proportional to the square of the voltage applied to the electric motor.

This creates strong jerks during startup and at the moment of stopping operation, which also increases the values of the induction current. Soft starters can be mechanical and electrical, as well as combined, combining the positive features of both devices.

Mechanical soft starters operate on the principle of counteracting a sharp increase in electric motor speed by influencing its rotor mechanically using brake pads, various clutches, counterweights, magnetic locks and other mechanisms. Such mechanisms have not been used often lately, since there are more advanced electrical control devices.

Electric soft starters gradually increase the current or voltage from the reference level to the maximum, which allows you to smoothly increase the speed of the electric motor and reduce loads and starting currents. Most often, electrical soft starters are controlled electronically using computer systems or electronic devices, which allows you to change starting parameters and control dynamic characteristics. Soft starters allow you to change the operating modes of the electric motor depending on the applied load and allow you to realize one or another relationship between the shaft rotation speed and voltage.

The operating principle of electrical devices is based on two methods:

- The method of limiting the current in the rotor winding is implemented using coils connected in a star configuration;

- A method of limiting voltage and current in the stator (using thyristors, triacs or a rheostat).

Operating principle

The soft start device in a factory-made angle grinder is located inside the angle grinder body and is connected by contacts to the power button and the stator windings of the electric drive. It takes a certain time for the angle grinder to reach its nominal mode, and the electromagnetic field created by the uniformly increasing current and voltage through the stator windings causes the armature of the angle grinder drive to smoothly gain speed.

For grinders where the manufacturer does not provide such a device, usually in very rare cases it is possible to hide it under the body of the grinder. Most often it is performed in the form of a separate block, arranged in a break in the power cable circuit. However, this does not change the principle of operation.

Variable speed operation

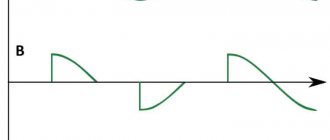

The AC mains voltage (Fig. 5) is rectified using a passive diode bridge.

This means that the diodes fire when the line voltage is greater than the voltage across the capacitor section. The resulting waveform has two pulses during each half-cycle, one for each diode conduction window. The waveform shows some continuous current as conduction passes from one diode to the next. This is typical when it is used in the DC link of the drive and some load is present. Inverters use pulse wide modulation to create output signals. A triangle signal is generated at the carrier frequency from which the IGBT inverter will switch.

This waveform is compared to a sine waveform at the fundamental frequency that must be delivered to the motor. The result is the U waveform shown in the figure.

Disadvantages of angle grinders without soft start

Cordless angle grinder Metabo W 18 LTX 125 602174850 with soft start. Photo VseInstruments.ru

In addition to providing comfortable working conditions for the user, the angle grinder with soft start has a number of other advantages.

- The absence of a large starting current during the soft start of the angle grinder , which is several times higher than the nominal value of this parameter during operation, increases the reliability of the electrical part of the power tool. In this case, the winding wires do not experience overloads and do not crack, the commutator lamellas and brushes are not subject to wear from increased sparking, and processes that worsen the connection do not occur at the contact points.

- During a uniform increase in the speed to the nominal value, the angle grinder with a soft start does not experience increased dynamic loads that arise in its absence. An instantaneous acceleration of 6000 rpm or more does not leave its mark on the gear transmission and bearing units . They fail faster, so angle grinders without such a device are more often repaired.

Frequent malfunctions, causes

The grinder may not gain the speed required by the regulatory regime, work with spontaneous changes, with jerks, and in extreme cases, stop rotating altogether. If there is a speed control option, it may not respond to changes in the position of the operating mode indicator.

Some types of malfunctions and methods for eliminating them are discussed in the presented videos.

Not gaining momentum

The Makita model grinder, powered by batteries, did not reach operating speed in the next video. The first reason that comes to mind is that the batteries are discharged, but this has not been confirmed. When disassembling the tool, faulty brush holders were discovered. The ingress of foreign oily liquid into the brush-collector assembly caused destruction of the brushes and melting of the plastic structure of the brush holders.

The author replaced the defective one with a new brush mounting unit.

Important: graphite dust from damaged brushes should be carefully removed from the stator and rotor, the surface of the commutator should be cleaned with emery cloth and preferably polished

Does not develop speed and smokes

The stability of the rotation speed of the spindle working shaft largely depends on the presence of malfunctions in the components of the electrical part of the angle grinder. In the next video, the stator winding burned out, resulting in smoke and the grinder stopped rotating. Stator failure can be easily determined visually: broken wires, burnt insulation.

The author had a used, but fully functional stator in stock, so he eliminated the defect by replacing the failed one.

It's getting warm

Poor contact in the connections of the electrical part of the angle grinders leads to strong heating of the body, the formation of increased spark strength due to deviations from the nominal values of the electrical parameters. In the next video, the contacts on the brush holders burned out. Perhaps this happened due to a violation of the location of the brushes, which led to a large formation of graphite dust and the creation of additional resistance on the commutator unit. The author suggested a more reliable connection of contacts and corrected the location of the guides for the brushes.

Loses speed under load

In the next video, the grinder spontaneously changed speed during operation, and from time to time there were jerks. At the same time, there was no option for adjusting the speed on the angle grinder. One such jerk caused the cutting disc to break. After which it was decided to find and fix the problem. Diagnostics of the electrical part when testing with a multimeter revealed that the power (start) button was faulty.

Since such buttons are usually not suitable for repair (when disassembling it, a completely defective contact was discovered), the author found a replacement. Functionally, the new button duplicated the old one, but was slightly different in size. The author successfully chose a new location for it and the grinder restored its functionality.

How to make a starter unit for a power tool

There are quite a lot of options for independently equipping an angle grinder with a soft start device. Some of them are presented in the author's videos.

Starter unit based on LM358 chip

In the following video, the author shares his experience of independently manufacturing a soft-starter board according to a diagram taken from the Internet, based on the LM358 chip . The author made the housing for the board from a shampoo box, which speaks of the rich imagination of amateur craftsmen. The author did not just blindly copy the circuit from the Internet, but modified it by replacing the characteristics of some of its elements : transistors, diodes, resistors. The radiator for cooling semiconductor devices is taken from a tape recorder. In order to be able to place the soft start unit inside the body of the angle grinder, and not as in the case of the proposed option, a smaller board was developed.

Technology of work on the manufacture of the starting unit

The author of the following video describes in detail the work methods, components used and auxiliary technological materials for the manufacture of a soft starter. the k1182 microcircuit is taken as the basic element . The technology is not designed for use as the basis of a printed circuit board; the author calls such an assembly “surround mounting” technology. In this type of work, in addition to soldering, individual elements are fastened using fasteners, for example, this is how a triac is attached to a heat sink. The ready-made launcher is not universal for all angle grinders. On two angle grinders taken separately by the author, they reached the operating mode in significantly different periods of time.

One of the layout options for a homemade launch unit

As the initial option, the author of the following video chose a well-known assembly with the LM358 chip . Since the assembled starting unit did not fit inside the body of the angle grinder, the author “packed” only a triac with a radiator inside, due to good cooling conditions from the angle grinder’s fan wheel. The rest of the block, together with the microcircuit, was secured to the body of the angle grinder.

Using an iron as an additional load to reduce the speed of an angle grinder

This method does not specifically relate to the topic of soft start of an angle grinder. However, to understand the principle of operation of an electronic device, a dimmer , which is used to adjust the power (or number of revolutions) of an angle grinder, is quite acceptable. In the next video, the iron takes a certain power from the angle grinder, thereby reducing its speed.

The typical starter circuit diagram should be modified for each individual power tool

The author of the following video tells how he equipped his household grinder with a soft start device to increase its service life.

How to install a standard dimmer in an angle grinder to adjust speed

In the next video, the author modified the power button (made it spring-loaded) in order to use the capabilities of a purchased dimmer to adjust the speed of the angle grinder. After turning on the angle grinder, moving the button sets the required speed mode. The dimmer fixes this mode and when turned on again, it is set.

Download

If the topic interests you more deeply, I recommend that you read the literature provided on the Download page.

Here is one of the books listed there: • Lomonosov, V.Yu.; Polivanov, K.M.; Mikhailov, O.P. Electrical engineering. / Lomonosov, V.Yu.; Polivanov, K.M.; Mikhailov, O.P. Electrical engineering. One of the best books on the basics of electrical engineering. The presentation begins with the very basics: it explains what voltage, current and resistance are, provides instructions for calculating the simplest electrical circuits, talks about the relationship and interdependence of electrical and magnetic phenomena. It explains what alternating current is and how an alternating current generator works. It describes what a capacitor is and what an inductor is, what their role is in alternating current circuits. It is explained what three-phase current is, how three-phase current generators are designed and how its transmission is organized. A separate chapter is devoted to semiconductor devices: it talks about semiconductor diodes, transistors and thyristors; on the use of semiconductor devices for rectifying alternating current and as semiconductor switches. The achievements of microelectronics are briefly described. The last third of the book is entirely devoted to electrical machines, units and equipment: chapter 10 deals with direct current machines (generators and motors); Chapter 11 is devoted to transformers; AC machines (single-phase and three-phase, synchronous and asynchronous) are described in detail in Chapter 12; switches, electromagnets and relays are described in Chapter 13; Chapter 14 deals with electrical diagramming. The last, chapter 15, is devoted to measurements in electrical engineering. This book is an excellent way to learn the basics of electrical engineering, to understand the fundamental principles of the operation of electrical machines and units., zip, 13.87 MB, downloaded: 836 times./

Another manual on motors:• Starting and protecting AC motors / Starting and protecting AC motors. Starting and braking systems for AC motors. Protection devices and fault analysis of AC motors. Guide to selecting protection devices. Manual from Schneider Electric, pdf, 1.17 MB, downloaded: 581 times./

How to connect, installation

For users of grinders who do not have electrical installation skills, you can purchase a separately sold soft start unit. You just need to install it correctly. There are two options for placing the starting device - inside the body of the angle grinder and, if not possible, outside.

In the next video, the author placed one of the purchased blocks inside it with the help of a slight modification of the angle grinder body. The two wires of the starting unit are connected according to the following diagram: one wire to the switch contact, the other to the stator winding of the electric drive.

In another video, the author also managed to place the purchased block inside the grinder. However, he chose a different connection scheme - to break the network. In this case, it is not important to consider where to connect the “zero” and where the “phase”.

Star connection and its advantages

Reversible motor circuit 380 to 220 Volts

Each of the three working windings of the electric motor has two terminals - the beginning and the end, respectively. The ends of all three windings are connected to one common point, the so-called neutral.

If there is a neutral wire in the circuit, the circuit is called 4-wire, otherwise, it will be considered 3-wire.

The beginning of the terminals is connected to the corresponding phases of the supply network. The applied voltage on such phases is 380 V, less often 660 V.

The main advantages of using the star scheme:

- Stable and long-term non-stop operation of the engine;

- Increased reliability and durability by reducing equipment power;

- Maximum smooth start-up of the electric drive;

- Possibility of exposure to short-term overload;

- During operation, the equipment housing does not overheat.

There is equipment with internal connection of the ends of the windings. Only three pins will be output to the block of such equipment, which does not allow the use of other connection methods. Electrical equipment made in this form does not require competent specialists for its connection.

Connecting a three-phase motor to a single-phase network using a star circuit

How to check

At home, before assembling an angle grinder with a soft starter, it’s a good idea to check it for an open circuit. The following video tests a three-pin device. Usually there is a connection diagram . There are two network wires here, one goes to the electric drive. If you assemble a circuit with an indicator light and include a starter in it, then you can determine the break in it by the indicator light coming on/not coming on .

General information

The stator of an electric motor is an inductance coil; therefore, there are resistances with an active and reactive component.

When electric current flows through radioelements that have resistance with an active component, losses occur due to the conversion of part of the power into thermal energy. For example, a resistor and the stator windings of an electric motor have a resistance with an active component. Calculating active resistance is not difficult, since the phases of the current (I) and voltage (U) coincide. Using Ohm's law for a section of a circuit, you can calculate the active resistance: R = U/I. It depends on the material, cross-sectional area, length and its temperature.

If the current passes through a reactive type of element (with capacitive and inductive characteristics), then, in this case, a reactive R appears. An inductor that has practically no active resistance (the calculations do not take into account the R of its windings). This type of R is created due to the Electromotive Force (EMF) of self-induction, which is directly proportional to the inductance and frequency I passing through its turns: Xl = wL, where w is the angular frequency of the alternating current (w = 2*Pi*f, and f - network current frequency) and L - inductance (L = n * n / Rm, n - number of turns and Rm - magnetic resistance).

When the electric motor is turned on, the starting current is 7 times greater than the rated current (the current consumed during operation of the tool) and the stator windings heat up. If the stator coil is old, then an interturn short circuit may occur, which will lead to failure of the power tool. To do this, you need to use a soft starter for a power tool.

One of the methods for reducing the inrush current (Ip) is to switch windings. To implement it, 2 types of relays (time and load) and the presence of three contactors are required.

Starting an electric motor with windings connected in a star type is possible only with 2 contactors not simultaneously closed.

After a certain time interval, which is set by a time relay, one of the contactors is turned off and another one, not previously used, is turned on. Thanks to this alternation of switching on the windings, the inrush current decreases. This method has a significant drawback, since when two contactors are simultaneously closed, a short-circuit current occurs. However, when using this method, the windings continue to heat up. Another way to reduce the starting current is to control the frequency of starting the electric motor. The principle of this approach is the frequency change of the supply U. The main element of this type of soft starter is a frequency converter, consisting of the following elements:

- Rectifier.

- Intermediate chain.

- Inverter.

- Electronic control circuit.

The rectifier is made of powerful diodes or thyristors , acting as a converter U of the network supply into a direct pulsating current. The intermediate circuit smoothes out the pulsating direct current at the output of the rectifier, which is collected on large capacitors. An inverter is necessary to directly convert the signal at the output of the intermediate circuit into a signal of the amplitude and frequency of the variable component. An electronic control circuit is needed to generate the signals necessary to control the rectifier or inverter.

Choosing a Miter Saw

It is impossible to imagine the woodworking industry without the use of special tools. One popular tool is a miter saw. Already from the name it becomes clear that its main purpose is to process the ends of workpieces, that is, to cut wood crosswise. This differs from a circular saw, which is used for longitudinal cuts.

READ How to Properly Sharpen a Stihl Chainsaw with a File

Understanding how to choose a miter saw is not a very difficult matter, but only if you understand the basic concepts and characteristics. Either way, a consultant will help you, but the process will go faster if you know what questions to ask. Further in the article we will look at the design of miter saws, their technical characteristics, additional functions and consumables.

Protective cover

The protective cover serves to protect the operator during operation. Even when the saw is turned on, a special casing covers the blade. As the workpiece is immersed, the casing moves away, revealing the disk.

Asynchronous motor

Among all types of motors, asynchronous is considered the most economical. It is reliable and makes little noise. Asynchronous motors are reliable because they have a minimum number of rubbing elements. This allows them to heat up little and not wear out for a long time - the only part that is subject to wear is the bearings.

Among the disadvantages is the high weight-to-power ratio. An asynchronous motor with a power of about 2 kW will weigh about 20 kg. This imposes some restrictions on its use, since using an overly heavy tool is not very convenient. In addition, when operating on electricity at industrial frequency, the engine will not be able to develop a rotor speed above 2850 rpm.

Laser guide

The presence of a laser allows you to see the trajectory along which the cut will take place

This is important when cutting at an angle, as you will spend less time preparing for work

Operating principle

During the start-up of a commutator-type electric motor, a significant short-term increase in current consumption occurs, which causes premature failure of the power tool and requires it to be repaired. Electrical parts wear out (current exceeds 7 times) and mechanical parts (sharp start). To organize a “soft” start, soft start devices (hereinafter referred to as soft starters) should be used. These devices must meet the basic requirements:

- Smooth increase in load.

- Possibility of starting the engine at certain time intervals.

- Providing protection against linear surges of U, phase loss (for a 3-phase electric motor) and various interference of the electrical component.

- Significantly increased service life.

The most widely used are triac soft starters, the operating principle of which is smooth regulation of U by adjusting the opening angle of the triac junction. The triac must be connected directly to the motor windings and this allows you to reduce the starting current from 2 to 5 times (depending on the triac and control circuit). The main disadvantages of triac soft starters are the following:

- Complex schemes.

- Overheating of windings during prolonged startup.

- Problems with starting the engine (leads to significant heating of the stator windings).

The circuits become more complicated when using powerful engines, however, with light loads and idle speed, simple circuits can be used.

Soft starters with regulators without feedback (1 or 3 phases) have become widespread. In models of this type, it becomes possible to pre-set the start time and U value before starting the engine. However, in this case it is impossible to regulate the amount of torque under load. With this model, a special device is used to reduce the starting current, protect against phase loss and imbalance, as well as against overloads. Factory models have a function for monitoring the condition of the electric motor.

The simplest single-phase control circuits are executed on a single triac and are used for instruments with a power of up to 12 kW. There are more complex circuits that allow you to adjust the power parameters of an engine with a power of up to 260 kW. When choosing a factory-made soft starter, it is necessary to take into account the following parameters: power, possible operating modes, equality of permissible currents and the number of starts in a certain period of time.

Characteristics of the soft starter

The main criteria for choosing a soft starter are the current limit range, the degree of protection of the housing, the permissible number of starts per unit of time, rated current and voltage, permissible motor power, and the possibility of parallel connection of a shunt electrical device. The choice of device is carried out according to standard methods.

When choosing a soft starter, it is also necessary to take into account the presence of the following functions:

- Trigger as a function of current or voltage. Soft starters with this function are used when the power of the supply network is limited. Such soft starters allow you to regulate the current and avoid overheating of cables, tripping of protection, and stopping of generators that are sensitive to sudden fluctuations in the current consumed by the load. For process equipment where fast starting with increased torque is unacceptable, a soft starter with starting as a function of voltage is used. Such devices smoothly increase the voltage in the windings of electrical machines. For more precise adjustment, a soft starter with current and voltage feedback is used.

- Number of phases. To start electric motors, soft starters are used with adjustment of electrical parameters in one, two and three phases. Devices of the first two types are used to drive equipment with infrequent start-up, since an asymmetrical load at the time of start-up negatively affects the operation of the electric machine.

- Availability of a bypass contactor. At the end of the transition process, it is advisable to turn off the current supply through the soft starter to prevent overheating of the triacs. This is achieved by connecting a contactor in parallel to the circuit, which closes the power contacts after the electric motor accelerates. There are soft starter models that do not provide for parallel connection of contactors, however, for a powerful motor it is better to choose a device with a shunt switching device.

- Protection functions. Many soft starters have built-in protection against overheating of the device itself, changes in the frequency of the supply voltage, a decrease in the output current, as well as load shutdown functions when the acceleration time is exceeded, phase failure, or uneven load. In some models it is also possible to connect a heating sensor for the electric motor windings. To protect a drive with a soft starter from short circuits, fuses or circuit breakers are required.

- Speed control functions. There are soft starters where the possibility of reducing the rotation speed of the electric motor is implemented. However, soft starters do not replace a frequency converter. Speed adjustment is carried out in steps. When operating for a long time at a reduced speed, the soft starter overheats greatly. The soft starter does not ensure long-term operation of the engine at reduced speed. Such modes are used when adjusting and setting up production equipment.

- Braking mode. For drives of inertial equipment, you should select a soft starter with a braking function. In this mode, voltage is applied to the electric motor windings, causing the electric machine to brake. Such devices are used for lifts, conveyors, traction fans.

- Monitoring the status of the bypass contactor. When the power contacts of the bypass contactor are not closed, upon reaching the rated speed of the electric motor rotor, the soft starter switches off the drive.

- Start with maximum torque. Soft starters with this function supply the rated mains voltage to the windings. After a sharp starting push, the voltage is limited. Further acceleration of the electric machine is carried out in a smooth mode. A soft starter with this function is used for equipment drives that are switched on under significant load.

Application in an angle grinder

When starting an angle grinder (angle grinder), high dynamic loads appear on the tool parts.

Expensive models are equipped with soft starters, but not ordinary varieties, for example, angle grinders. An inertial jerk can tear an angle grinder out of your hands, and this poses a threat to life and health. In addition, when starting the electric motor of the tool, an overload of current occurs and, as a result, wear of the brushes and significant heating of the stator windings, wear out of the gearbox and possible destruction of the cutting disk, which can crack at any time and cause harm to health, and maybe even life. The tool needs to be secured and for this you should make an angle grinder with speed control and soft start with your own hands.

Double-sided cut

Quite often, when attaching a sheet to a profile in difficult places, it is necessary to perform a double-sided cut. This method is used when designing window openings, door openings, and, if necessary, bypassing beams and other complex structures. What is the best way to cut drywall in this case? First you need to make a hole of a rectangular or square shape. You can cut it using such a simple tool as a hacksaw or a sharp knife. The cutting process is not difficult:

- First you need to mark the sheet with a simple pencil and ruler;

- on one side the sheet must be cut using a hacksaw, and on the other using a knife;

- Now the drywall is cracking and being cut off on one side.

Afterwards, you need to carefully process the edge using a roughing plane to get smooth edges. When the sheet is cut, you can fix it in the required place using self-tapping screws. After installation, joints and seams are puttied and pre-glued with a special mesh.

Homemade options

There are many schemes for modernizing power tools using soft starters. Among all varieties, devices based on triacs are widely used. A triac is a semiconductor element that allows you to smoothly regulate power parameters. There are simple and complex circuits that differ in design options, as well as in the supported power of the connected power tool. The design includes internal ones, which allow them to be built inside the case, and external ones, manufactured in the form of a separate module, which acts as a speed limiter and starting current when starting the angle grinder directly.

The simplest scheme

A soft starter with speed control on a thyristor KU 202 is widely used due to its very simple design (diagram 1). Connecting it does not require any special skills. Radio elements for it are very easy to obtain. This regulator model consists of a diode bridge, a variable resistor (acts as a U regulator) and a thyristor tuning circuit (supplying U to the control output with a nominal value of 6.3 volts) from a domestic manufacturer.

Scheme 1. Electrical diagram of the indoor unit with speed control and soft start (electrical circuit diagram)

Due to the size and number of parts, this type of regulator can be built into the body of a power tool.

In addition, the variable resistor knob should be removed and the speed controller itself can be modified by integrating a button in front of the diode bridge. The basic principle of operation is to regulate the speed of the electric motor of the tool by limiting the power in manual mode. This circuit allows you to use power tools with a power of up to 1.5 kW. To increase this indicator, it is necessary to replace the thyristor with a more powerful one (information about this can be found on the Internet or in a reference book). In addition, you need to take into account the fact that the thyristor control circuit will differ from the original one. KU 202 is an excellent thyristor, but its significant drawback is its configuration (selection of parts for the control circuit). To implement a soft start in automatic mode, scheme 2 is used (soft starter on a microcircuit).

Soft start on a chip

The best option for manufacturing a soft starter is a soft starter circuit with one triac and a microcircuit that controls the smooth opening of a pn type transition. The device is powered from a 220 V network and is easy to assemble yourself. A very simple and universal soft start circuit for an electric motor also allows you to regulate the speed (diagram 2). The triac can be replaced with the same one or with characteristics exceeding the original ones, according to the reference book of semiconductor-type radioelements.

Scheme 2. Scheme for soft start of a power tool

The device is implemented on the basis of the KR118PM1 microcircuit and a triac. Due to the versatility of the device, it can be used for any tool. It does not require configuration and is installed into the power cable.

When the electric motor starts, U is supplied to KR118PM1 and the charge of capacitor C2 gradually increases. The thyristor opens gradually with a delay depending on the capacitance of the control capacitor C2. With a capacitance of C2 = 47 μF, there is a delay at startup of about 2 seconds. It depends directly proportionally to the capacitance of the capacitor (with a larger capacitance, the startup time increases). When the angle grinder is turned off, capacitor C2 is discharged using resistor R2, the resistance of which is 68 k, and the discharge time is about 4 seconds.

To regulate the speed, you need to replace R1 with a variable resistor. When changing the parameter of the variable resistor, the power of the electric motor changes. R2 changes the amount of current flowing through the triac input. The triac needs cooling and, therefore, a fan can be built into the module housing.

The main function of capacitors C1 and C3 is to protect and control the chip. The triac should be selected based on the following characteristics: direct U should be 400..500 V and direct current should be at least 25 A. With such ratings of radio elements, it is possible to connect a tool with a power from 2 kW to 5 kW to the soft starter.

Thus, to start electric motors of various tools, it is necessary to use factory-made or home-made soft starters. Soft starters are used to increase the service life of the tool. When starting the engine, there is a sharp increase in current consumption by 7 times. Because of this, the stator windings may burn out and the mechanical part may wear out. Soft starters can significantly reduce the starting current. When making a soft starter yourself, you need to follow safety rules when working with electricity.

Modification for grinders interskol with a 15 A triac

Soft start for a device with 15 A triacs is considered universal and is often found in low-power types. The difference between the devices is their low conductivity. The circuit (device) for such a start involves the use of transceivers of a certain type, which operate at a frequency of forty Hz. Many species use comparators. Such parts are supplied with filters. The rated voltage of starters starts from 200 V.

Starters for angle grinders with a 20 A triac

Devices with 20 A triacs are suitable for professional grinders. Many types use special resistors. First of all, they can operate at high frequencies. The maximum temperature of the starters is fifty-five degrees. Most devices have a well-protected case. The classic scheme involves the use of 3 contactors with a capacity of thirty pF or more. Craftsmen believe that the devices stand out for their conductivity.

- The lowest frequency for starters is about thirty-five Hz. They can operate in a DC network. The model is connected via adapters. Such devices are perfect for two hundred W motors. Filters are very often installed with triodes. Their sensitivity indicator is 300 mV and no more.

- Quite often you can find special comparators with a protection system. If you look at foreign models, they have an integrated converter that comes with insulators. Current conductivity is produced at around five microns. With a resistance of forty ohms, the model can maintain high speeds for a long time.

Models for angle grinder 600 W

- For 600 W instruments, use starters with contact triacs; they have an overload of no more than ten A. Also remember that there are many devices with plates. They are good for their security and will not be afraid of rising temperatures. The minimum frequency for 600 W devices is 30 Hz. In this case, the resistance will depend on the supplied triode. If it is used linear type, then the above parameter will not exceed 50 Ohms.

- If we talk about duplex triodes, then the resistance at high speeds can reach up to 80 Ohms. Very rarely, models may have stabilizers that operate from comparators. In most cases, they are attached directly to the modules. Some types are created with wired transistors. Their lowest frequency starts from five Hz. They are afraid of overload, but can maintain huge speeds at 220 volts.

Devices for grinders at 800 volts

800 W devices can operate with low frequency starters. Triacs are often used at fifteen A. If you look at the diagram of the models, you should notice that they use special transistors whose current carrying capacity starts from 45 microns. Capacitors are used with or without filters, and the capacitance of the parts is no more than three pF. It is also worth knowing that starters may differ in sensitivity. Lever with speed control and soft start. Angle grinder Makita GA5030. The Makita grinder with speed control is one of the most popular models. The range of rotation adjustment will depend entirely on the maximum diameter of the nozzle.

Remember that there is a high probability of breakdown of the electric motor and breakdown of the device after not a soft start, but a sharp, jerky start. Therefore, it is better to make a limiter, fulfilling the restrictions can directly protect the engine. The device should also have a commutator motor, not an asynchronous one, so that everything can be safely turned off. The block is needed to supply power to the switching relays.

Well, and most importantly, the start button must be installed correctly, and even better, look at the electrical diagram before creating your own device. It is better to carry out repairs of models kr1182pm1, xs, 12, d3 carefully, because such devices are expensive.